3

Turn off the power switch for safety and disconnect the power plug when moving the machine.

Do not install on the place where direct sunlight or light of fluorescent lamp strikes.

Cover the machine with cloth for rubber of rollers not to deteriorate when you are not in using.

Raise the top roller always when you do not do lamination.

Wipe the rollers by cloth with neutral detergent when glue of the film is attached to them.

(Do not clean with benzene, paint thinner, and a scrubbing brush.)

Be sure to take care not to be caught up your necktie, necklace, and hair

during operation of the machine or insertion of film.

Do not block vent hole. There is a risk of fire or failure if you block it.

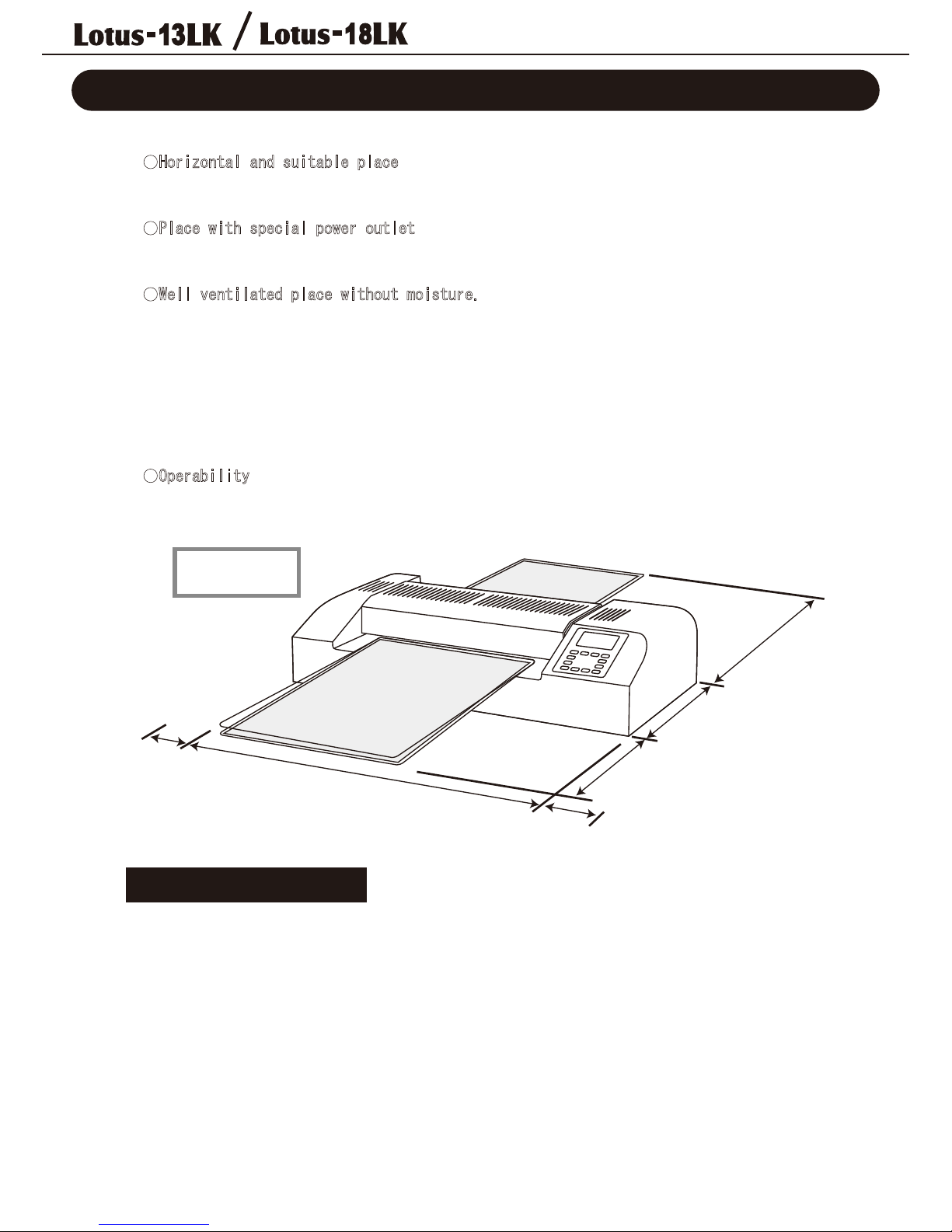

Do not put in the place of air conditioning wind directly striking.

Do not put the machine on an unstable location (inclined place, wobbly place, and place

where mechanical vibration is easily transmitted) to prevent from risk of injury when it falls.

Do not step on the machine or place heavy object on the machine.

Do not set up or storage in the reach of small children.

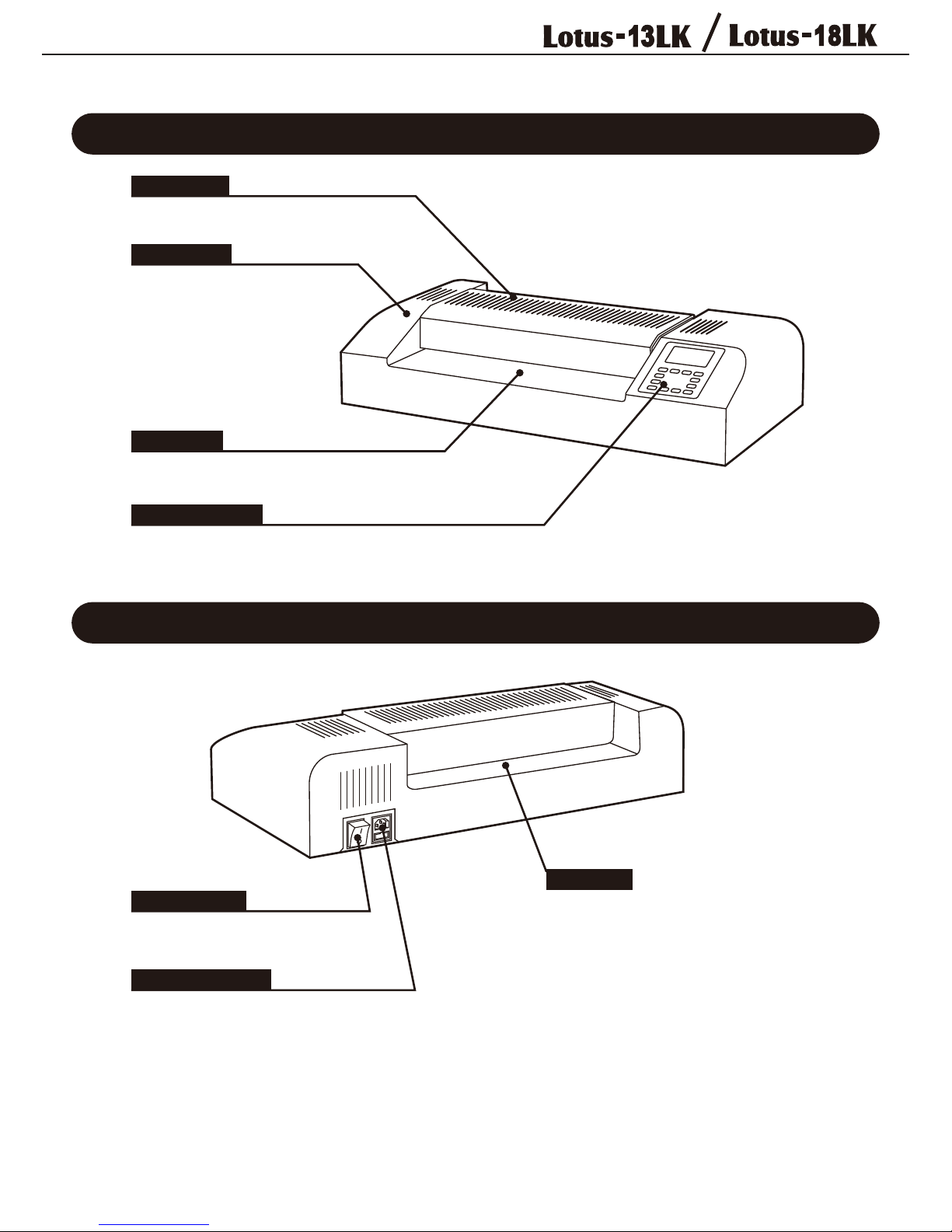

Be sure to have ground connection before you plug in the power plug.

Be sure to disconnect the power plug when you disconnect the ground connection.

Do not connect or disconnect the power plug with wet hands.

When not in use for a long period of time, please unplug the power cord from the power outlet.

Caution

Do not use the machine in abnormal condition with smoke or strange smell or sound.

When it becomes such a state by any chance, turn off the power switch immediately,

disconnect the power plug, please contact us or dealer. Do not repair by yourself.

Do not disassemble or modify the machine.

Do not bring fire or high temperature objects close.

Do not put metal, flammable substances, or liquid into the machine.

Do not install in hot and humid place, poor ventilated place, or place where flammable,toxic, or

explosive gas occurs. Do not install in place where much dust exists or on the top of flammable

objects.In case you install against a wall, place with a gap of 50 cm or more from the wall.

Unplug power plug from the outlet periodically, clean the base of the electrodes and between

the electrodes. Do not insert plug with dust attached.

When you connect or disconnect the power plug, please hold the plug part.If you bend or twist

or pull code forcefully, inside of cable is damaged and this may cause electric shock, fire or

malfunction.If by any chance, the power cord is damaged, please contact to us or our dealers.

Please insert the plug completely up to the base of the electrode portion.

Do not modify power code. Do not use damaged power code. Do not overloaded.

Do not place heavy objects on the power code. Do not place the cable near heating equipments.

Use attached power code. Use indicated power source only.

Warning

Cautions of handling