2

TABLE OF CONTENTS

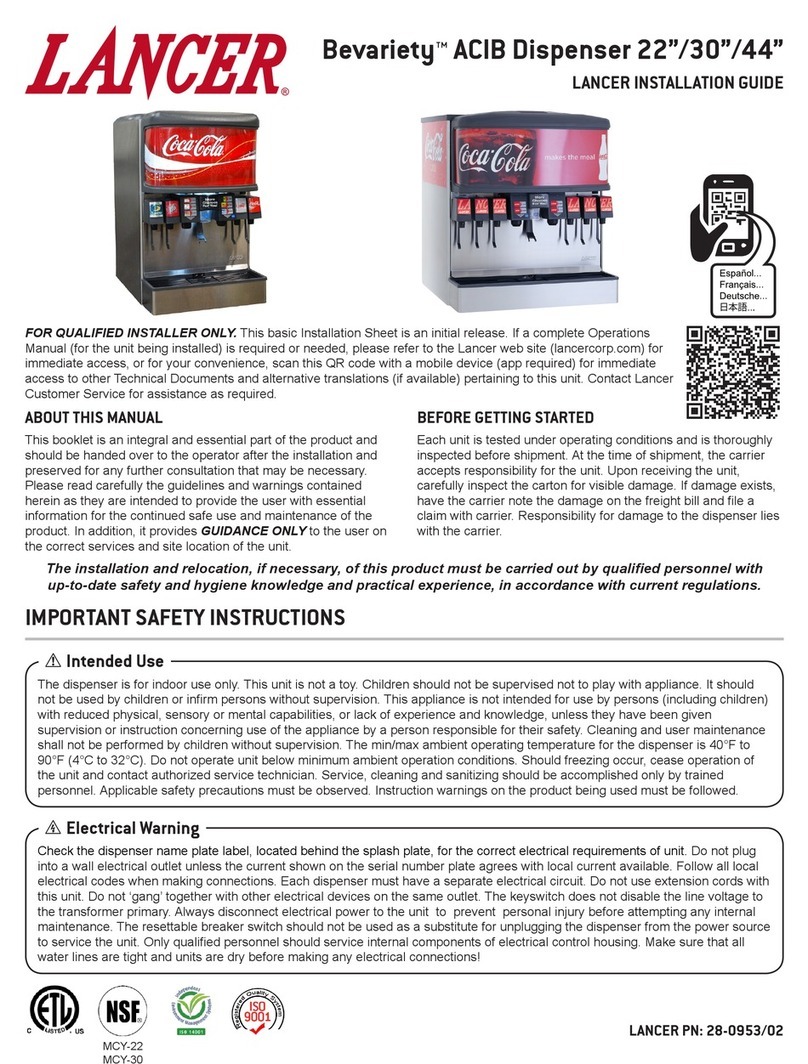

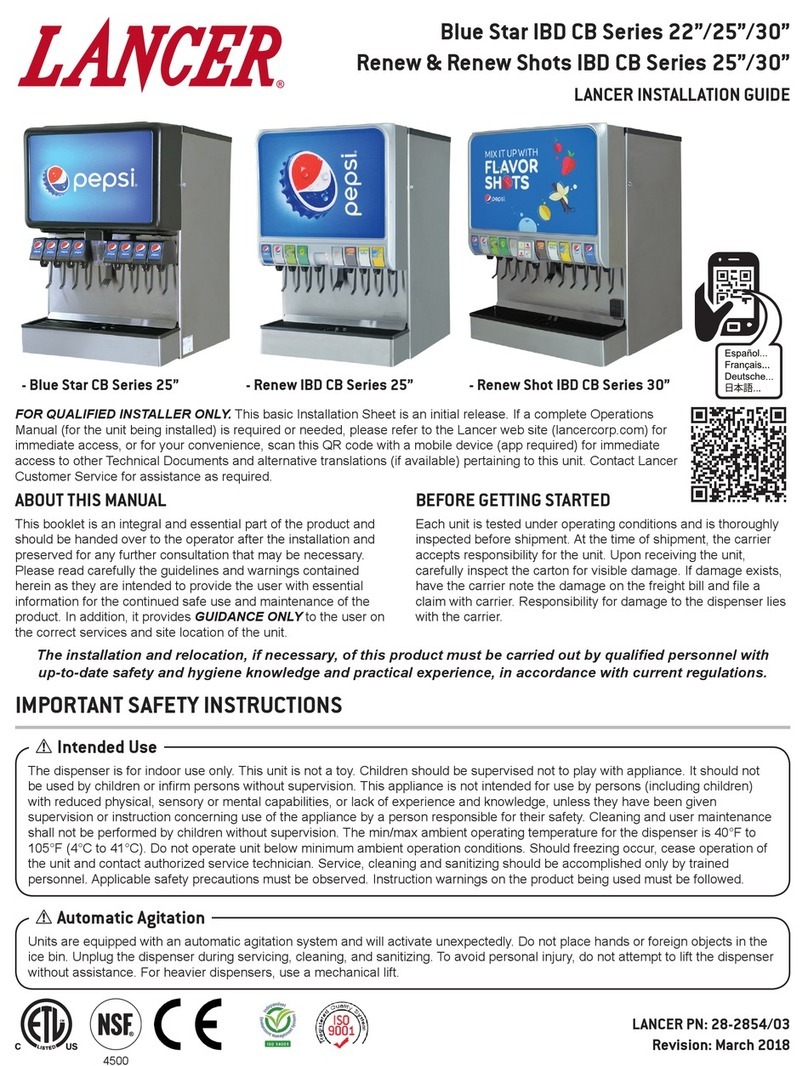

BEFORE GETTING STARTED

Each unit is tested under operating conditions and is thoroughly

inspected before shipment. At the time of shipment, the carrier

accepts responsibility for the unit. Upon receiving the unit, care-

fully inspect the carton for visible damage. If damage exists, have

the carrier note the damage on the freight bill and le a claim with

carrier. Responsibility for damage to the dispenser lies with the

carrier.

The installation and relocation, if necessary, of this product must be carried out by qualied personnel with

up-to-date safety and hygiene knowledge and practical experience, in accordance with current regulations.

Warning........................................................................................2

Basic Safety Rules.................................................................2

Installation.................................................................................4-5

Transport Instructions............................................................4

Unpacking..............................................................................4

Positioning..............................................................................5

ElectricalConnection..............................................................5

Use............................................................................................6-7

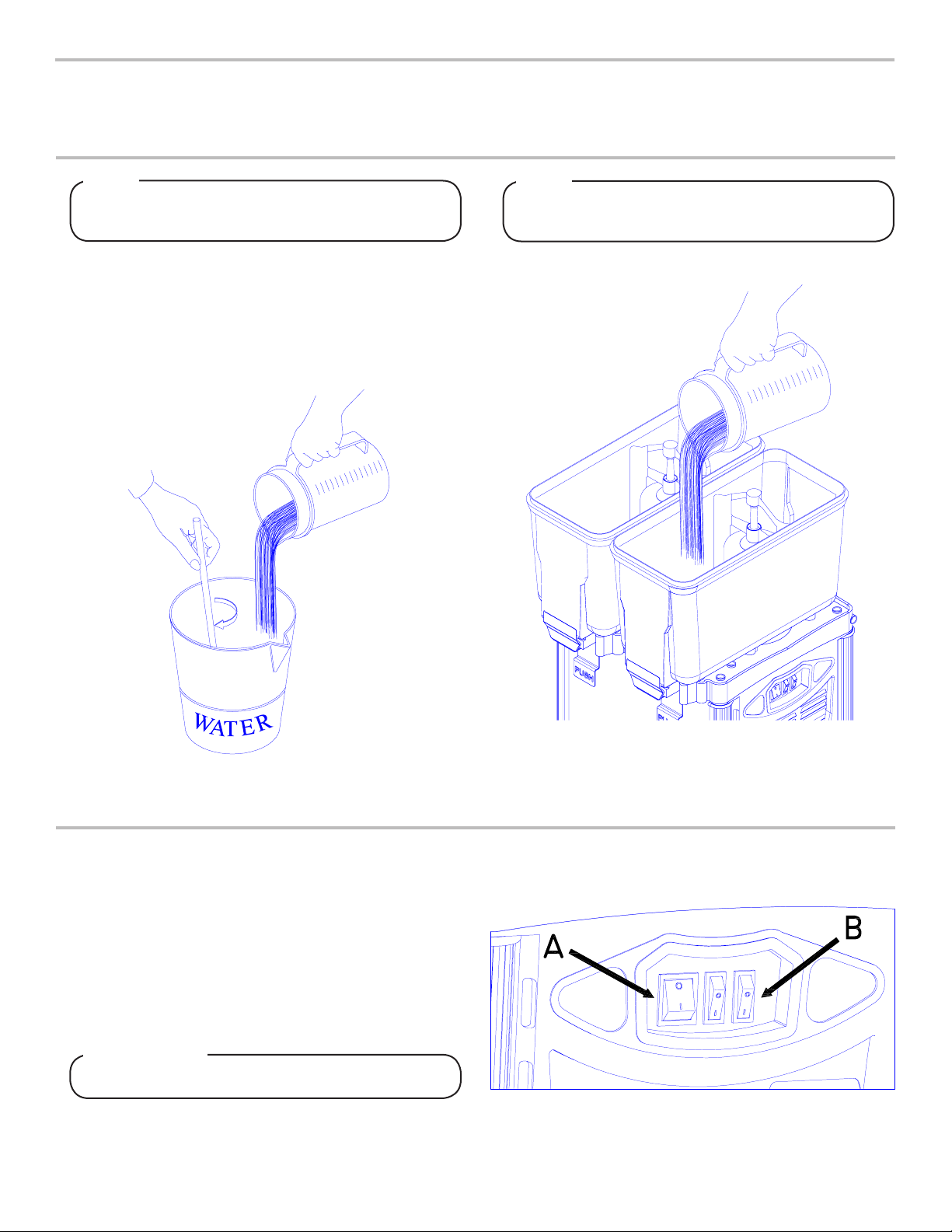

Dispenser Setup....................................................................6

Dispenser Function................................................................6

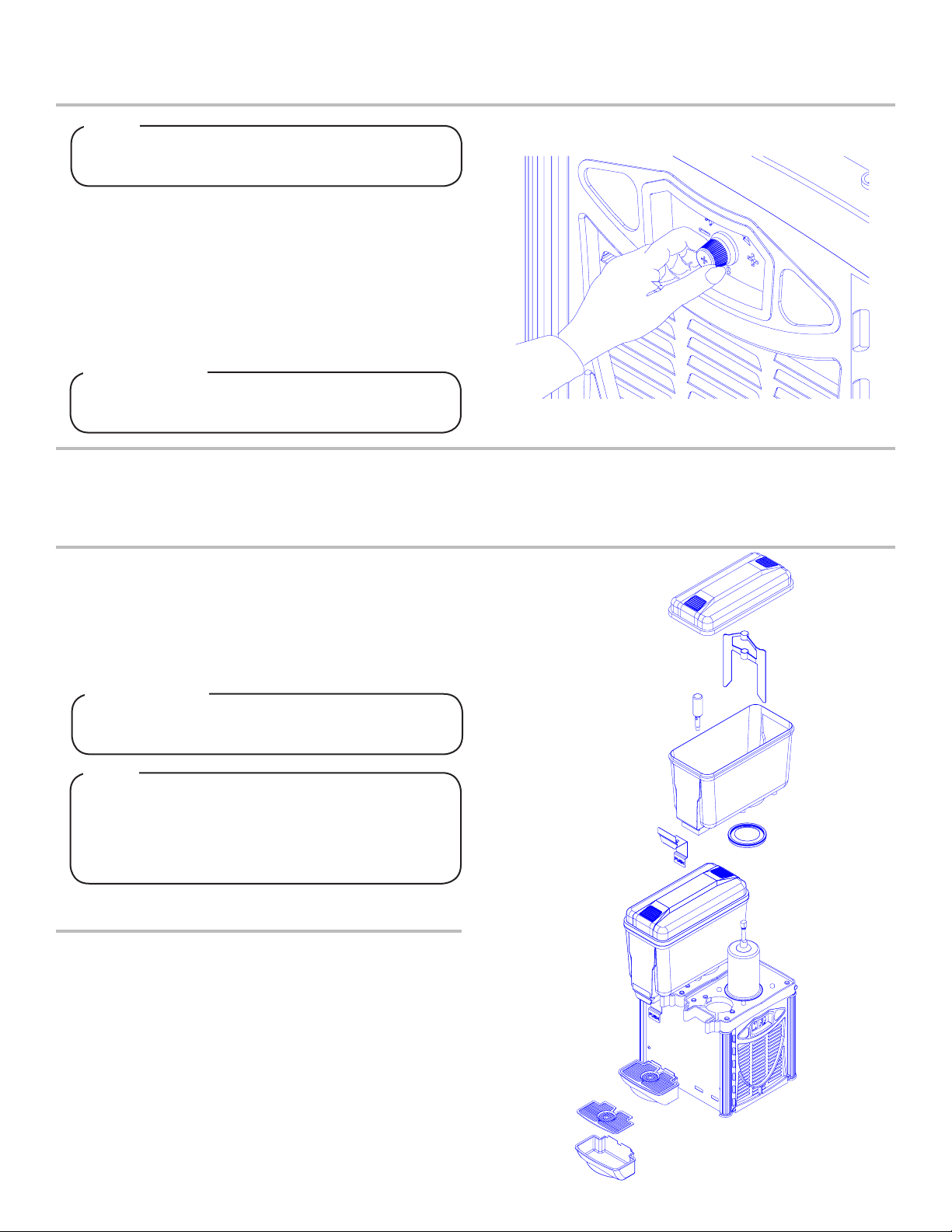

Beverage Temperature Regulator..........................................7

Cleaning and Sanitizing..........................................................7-8

Disassembling and Assembling.............................................7

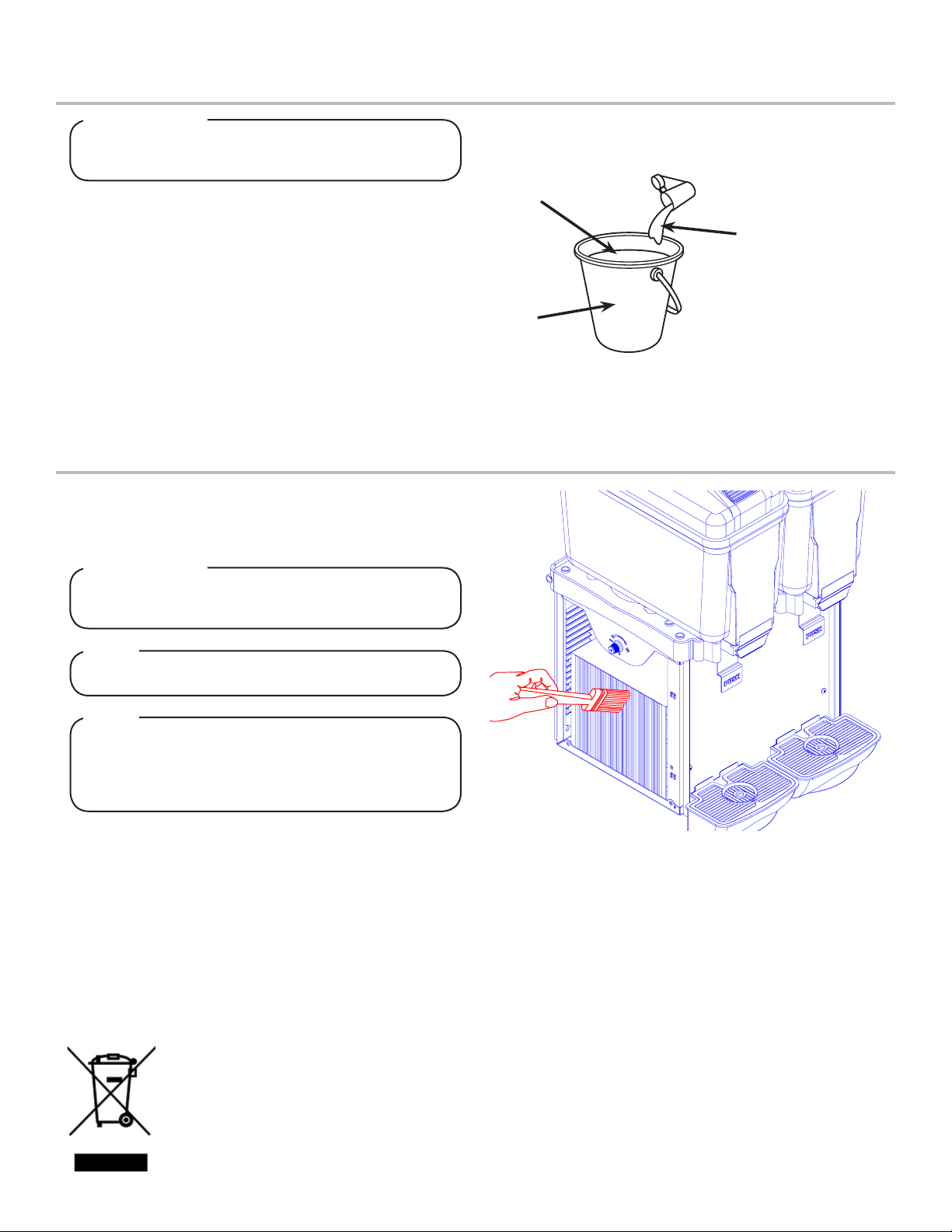

Cleaning.................................................................................8

Servicing................................................................................8

Troubleshooting..........................................................................9

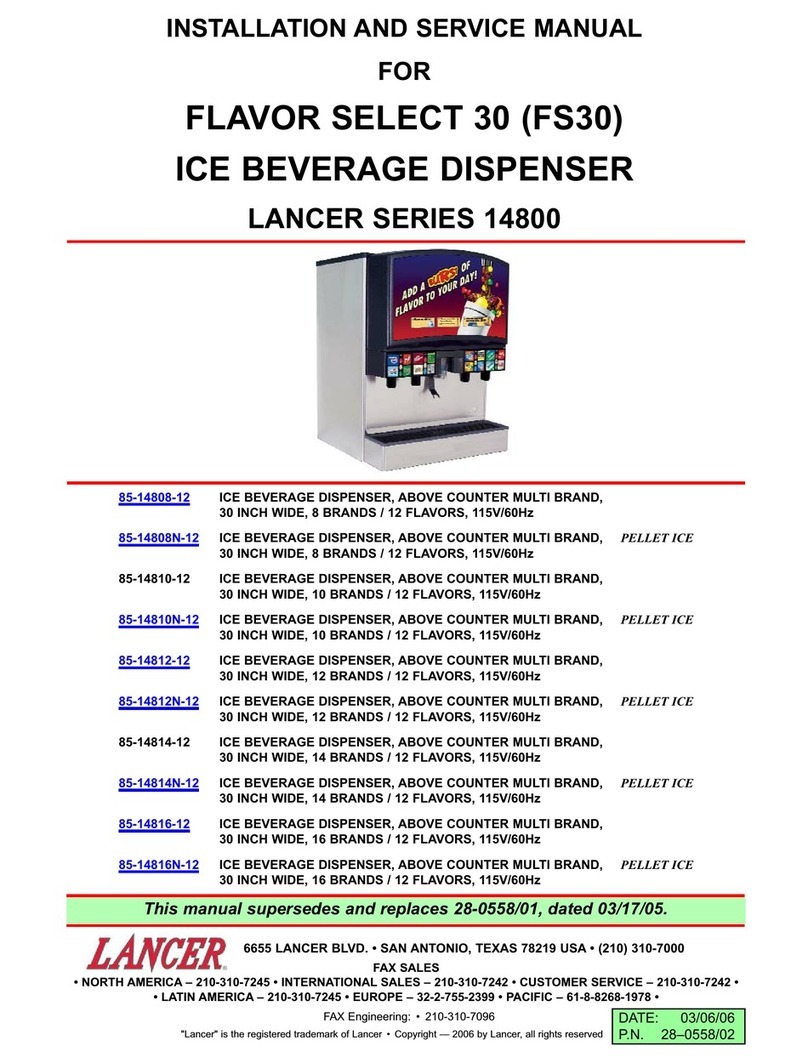

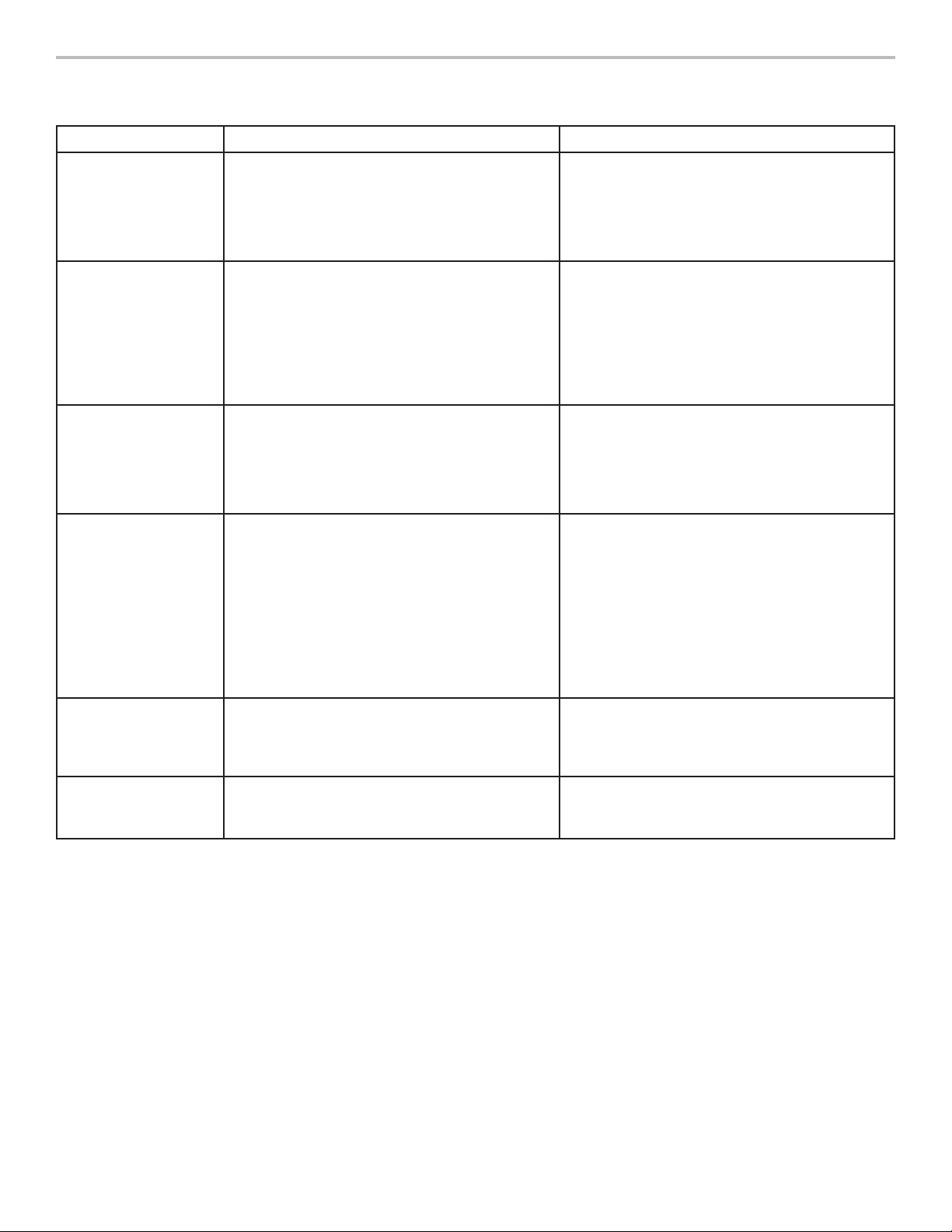

Illustrations and Part Listing...............................................10-12

Main Unit Assembly..............................................................10

Unit Specications................................................................11

WiringDiagram.....................................................................12

READ ALL SAFETY INSTRUCTIONS BEFORE USING THIS UNIT.

This manual contains important safety information and all applicable safety precautions must be observed. To reduce the

risk of re, electric shock, damage to the equipment or personal injury when using this unit all instuctions/warnings on the

product being used must be followed:

ABOUT THIS MANUAL

This booklet is an integral and essential part of the product.

Please carefully read the guidelines and warnings contained

herein as they are intended to provide the user with essential

information for the continued safe use and maintenance of the

product. In addition, it provides GUIDANCE ONLY to the user on

the correct services and site location of the unit.

Text following the Warning signal indicates a

hazardous situation, which if not avoided, will result

in death or serious injury. Be sure to read all Warning

statements before proceeding with the installation.

! WARNING

Text following the Caution signal indicates a

hazardous situation, which if not avoided, could result

in death or serious injury. Be sure to read the Caution

statements before proceeding with the installation

! CAUTION

Text following the Attention signal addresses a

situation that if not followed could potentially damage

the equipment. Be sure to read the Attention

statements before proceeding

! ATTENTION

Text following the Note signal provides you with

informationthatmayhelpyoumoreeectivelyperform

the installation procedures within this manual.

Disregarding information will not cause damage or

injury, however it may limit the performance of the

dispenser.

NOTE

WARNING

This instruction manual is an integral part of the machine and must be kept for any further consultation.

This machine is a cold drink dispenser.

This machine should be used only for the purpose for which it was designed. Any other use is inappropriate and therefore

dangerous.

The manufacturer will not be held responsible for any damage caused by improper use.

Before installing and operating on the machine read carefully this instruction manual.

The company reserves the right to modify the construction or appearance without notice.