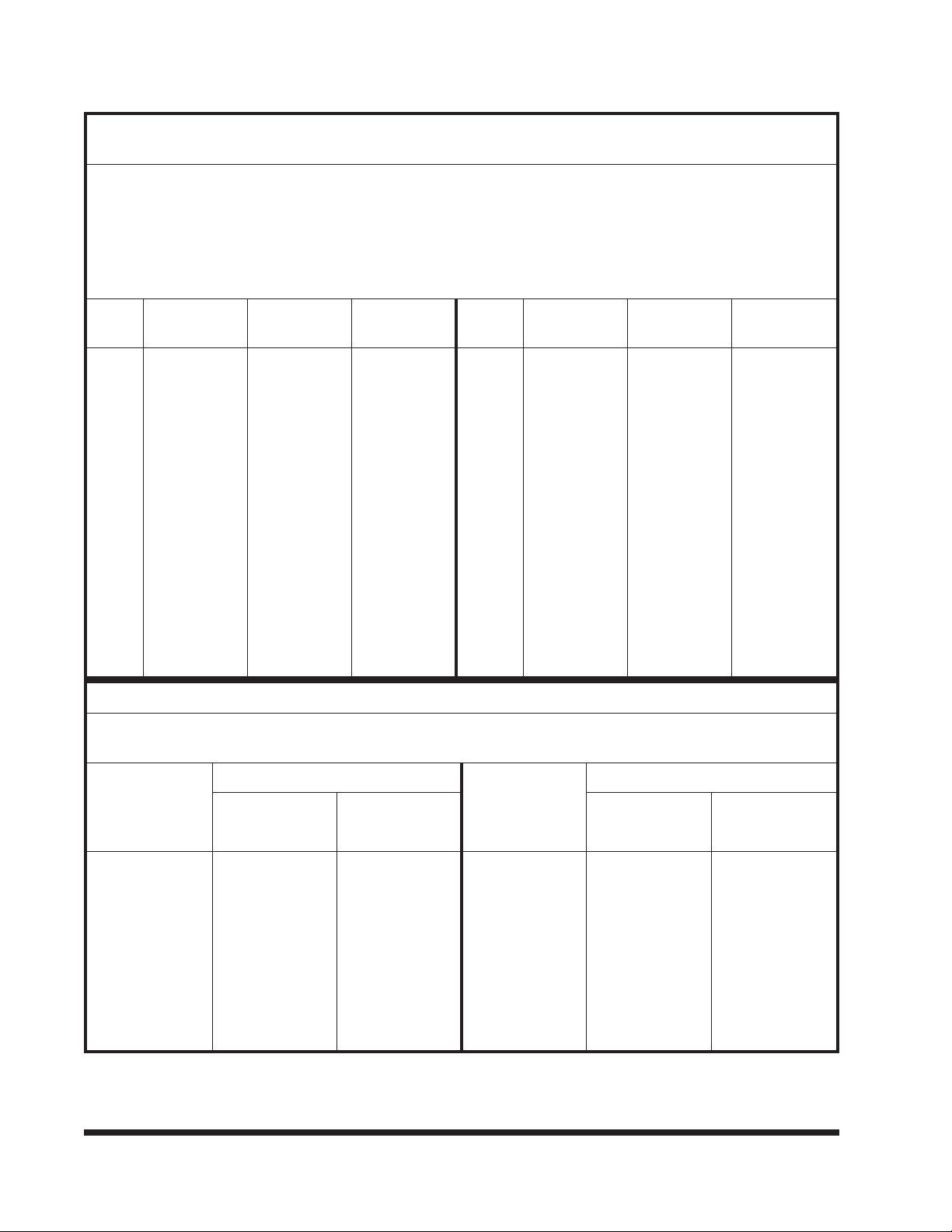

2STANDARD SPECIFICATIONS

MACHINE TYPE ROLLING

WIDTH

TRANSPORT

WIDTH

ROLLER

QTY. PER

MACHINE

DRAWBAR

HP

APPROXIMATE

WEIGHT (Lbs.)

Machine w/ 17” Smooth Rollers

Front and Rear

10’-1” 10’-7” 56 50 4,048

12’-2” 12’-10” 68 60 5,000

13’-2” 13’-10” 72 65 5,300

14’-2” 14’-10” 78 70 5,535

15’-3” 15’-11” 84 75 5,790

18’-2” 18’-7” 100 90 7,170

Machine w/ 19” Smooth Rollers

Front and Rear

10’-1” 10’-7” 56 50 4,475

12’-2” 12’-10” 68 60 5,530

13’-2” 13’-10” 72 65 5,862

14’-2” 14’-10” 78 70 6,144

15’-3” 15’-11” 84 75 6,445

18’-2” 18’-7” 100 90 7,570

Machine w/ 17” Crowfoot

Rollers Front and 17” Smooth

Rollers Rear

10’-1” 10’-7” 19C/28S 50 3,824

12’-2” 12’-10” 22C/34S 60 4,758

13’-2” 13’-10” 24C/36S 65 5,093

14’-2” 14’-10” 25C/39S 70 5,267

15’-3” 15’-11” 28C/42S 75 5,550

18’-2” 18’-7” 35C/50S 90 6,970

Machine w/ 17” Crowfoot

Rollers Front and Rear

10’-1” 10’-7” 38 50 3,613

12’-2” 12’-10” 44 60 4,433

13’-2” 13’-10” 48 65 4,782

14’-2” 14’-10” 50 70 4,900

15’-3” 15’-11” 56 75 5,203

18’-2” 18’-7” 70 90 6,638

Machine w/ 20” Crowfoot

Rollers Front and 19” Smooth

Rollers Rear

10’-1” 10’-7” 19C/28S 50 4,256

12’-2” 12’-10” 22C/34S 60 5,295

13’-2” 13’-10” 24C/36S 65 5,662

14’-2” 14’-10” 25C/39S 70 5,883

15’-3” 15’-11” 28C/42S 75 6,210

18’-2” 18’-7” 35C/50S 90 7,270

Machine w/ 20” Crowfoot

Rollers Front and Rear

10’-1” 10’-7” 38 50 4,040

12’-2” 12’-10” 44 60 4,963

13’-2” 13’-10” 48 65 5,344

14’-2” 14’-10” 50 70 5,509

15’-3” 15’-11” 56 75 5,858

18’-2” 18’-7” 70 90 6,838

Options - Looped “C” Tines or Danish Vibrating Tines (with 2-1/2” shovels), Front Scraper Kit, Land Leveler Kit,

Weed Wiper Kit, Hydraulic Tooth Control, Rear Hitch

2-1