3

Lapierre Equipment | VISION EVAPORATOR | USER MANUAL | Version 03 - March 2023

5.2.1 Lighting up the combustion chamber ................................................. 14

5.2.2 Syrup production ................................................................... 16

5.2.3 Changing the syrup pan ............................................................. 16

5.3 Evaporator shutdown ..................................................................... 16

6. Equipment maintenance and cleaning ............................................................17

6.1 Recommended maintenance at the start of the season ........................................17

6.2 Recommended maintenance at the end of the season.........................................17

6.3 Annual replacement of parts, recommendation ...............................................17

6.4 Door cleaning and maintenance.............................................................18

6.5 Evaporator cleaning........................................................................18

7. Equipment specifications....................................................................... 19

8. Our warranty (Warranty certificate) ..............................................................21

9. Parts and consumables.........................................................................24

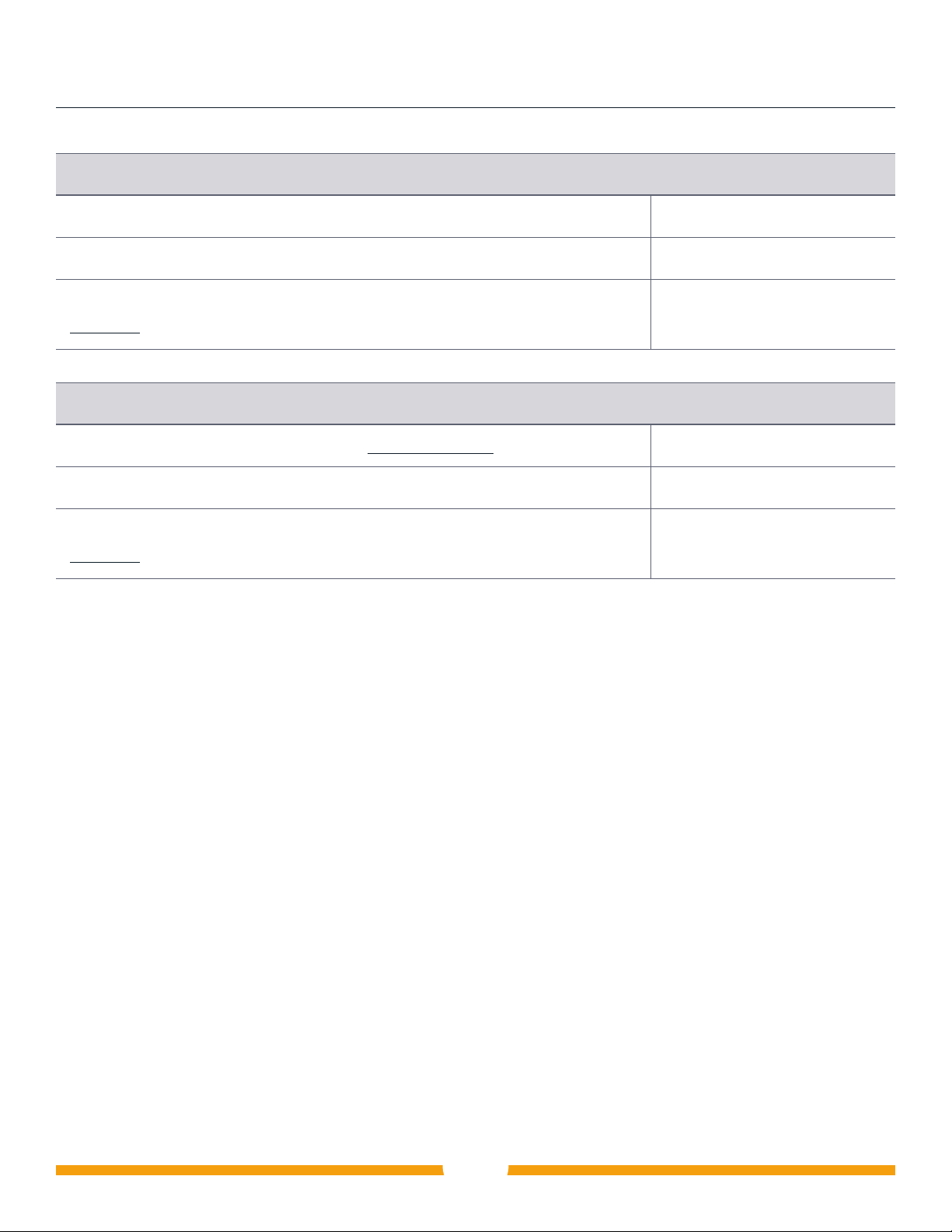

TABLE OF ILLUSTRATIONS

ILLUSTRATION 1 | Sections for levelling the 6-legged evaporator ................................. 10

ILLUSTRATION 2 | Typical illustration of a 4-legged VISION evaporator ............................20

ILLUSTRATION 3 | Typical illustration of a 6-legged VISION evaporator ............................20

TABLE OF TABLES

TABLE 1 | Evaporator, chimney and vent sizes by model ..........................................7

TABLE 2 | Grid for calculating the minimal height of the chimney ..................................8

TABLE 3 | Log sizing by model number ..........................................................15

TABLE OF APPENDICES

APPENDIX A | Installation instructions for insulating materials....................................25

APPENDIX B | Insulation material installation diagrams VISION 18 x 48 in..........................30

APPENDIX C | Insulation material installation diagrams VISION 18 x 60 in. . . . . . . . . . . . . . . . . . . . . . . . . . 35

APPENDIX D | Insulation material installation diagrams VISION 24 x 72 in .........................40

APPENDIX E | Insulation material installation diagrams VISION 24 x 96 in .........................45

APPENDIX F | Insulation material installation diagrams VISION 24 x 120 in. .........................51

APPENDIX G | Insulation material installation diagrams VISION 30 x 120 in. ........................57

APPENDIX H | Insulation material installation diagrams VISION 36 x 120 in. ........................64

APPENDIX I | Insulation material installation diagrams VISION 36 x 144 in. .........................71

APPENDIX J | Installing the single-wall chimney (non-listed) .....................................78

APPENDIX K | Installing the steam vents .......................................................80

APPENDIX L | Vision performance.............................................................82

TABLE OF WARNINGS

Important information about your VISION evaporator ..................................................1

Insurance: before installing your equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Protect children ...................................................................................13

Safety goggles and heat-resistant gloves and clothing ................................................13

People near the equipment .........................................................................13

Cleaning product residue on all components .........................................................18

Keep your purchase invoice.........................................................................21