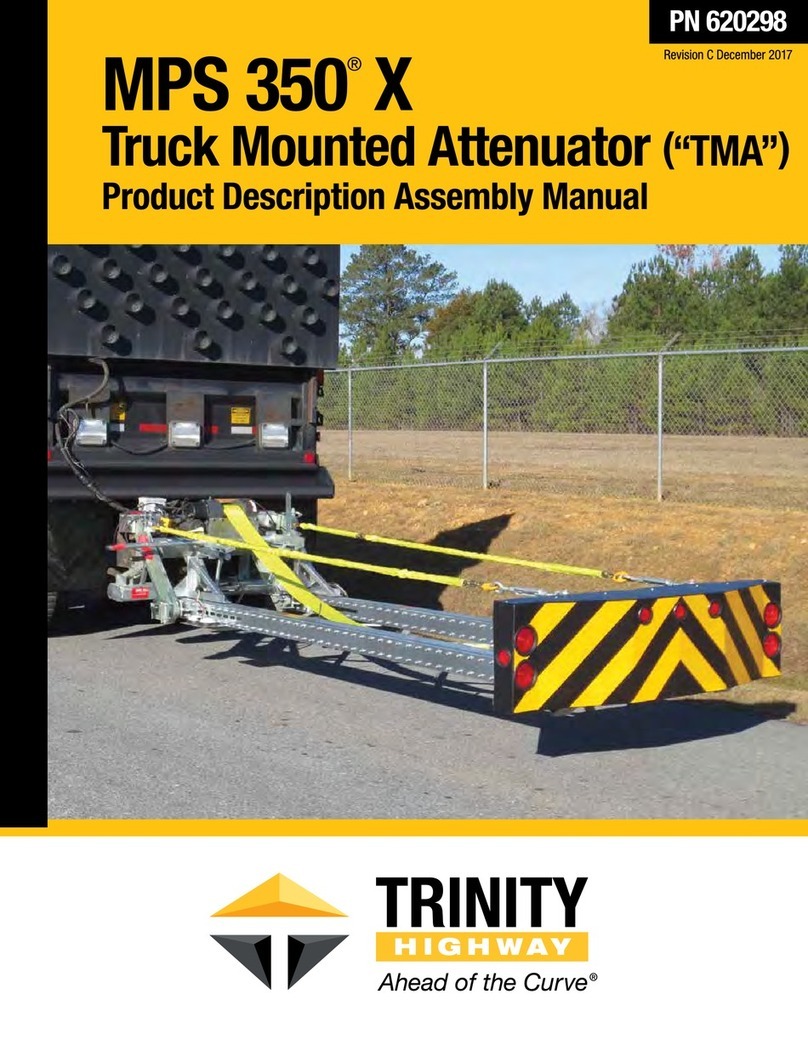

TrinityHighway.com 2 Revision A August 2020

Table of Contents

Customer Service Contacts..........................................................................................................3

Important Introductory Notes ........................................................................................................3

Safety Symbols.............................................................................................................................4

Safety Rules for Assembly............................................................................................................4

Limitations and Warnings..............................................................................................................5

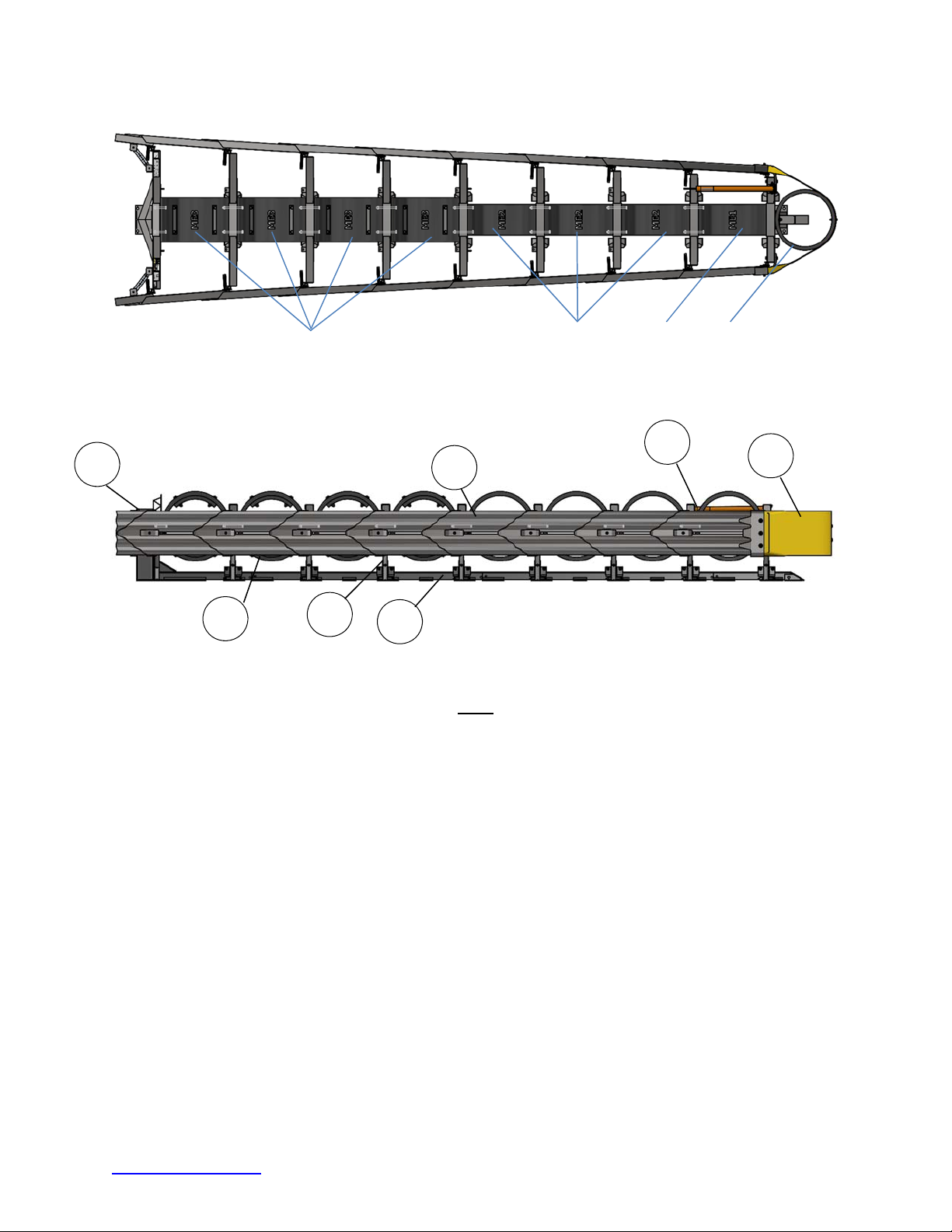

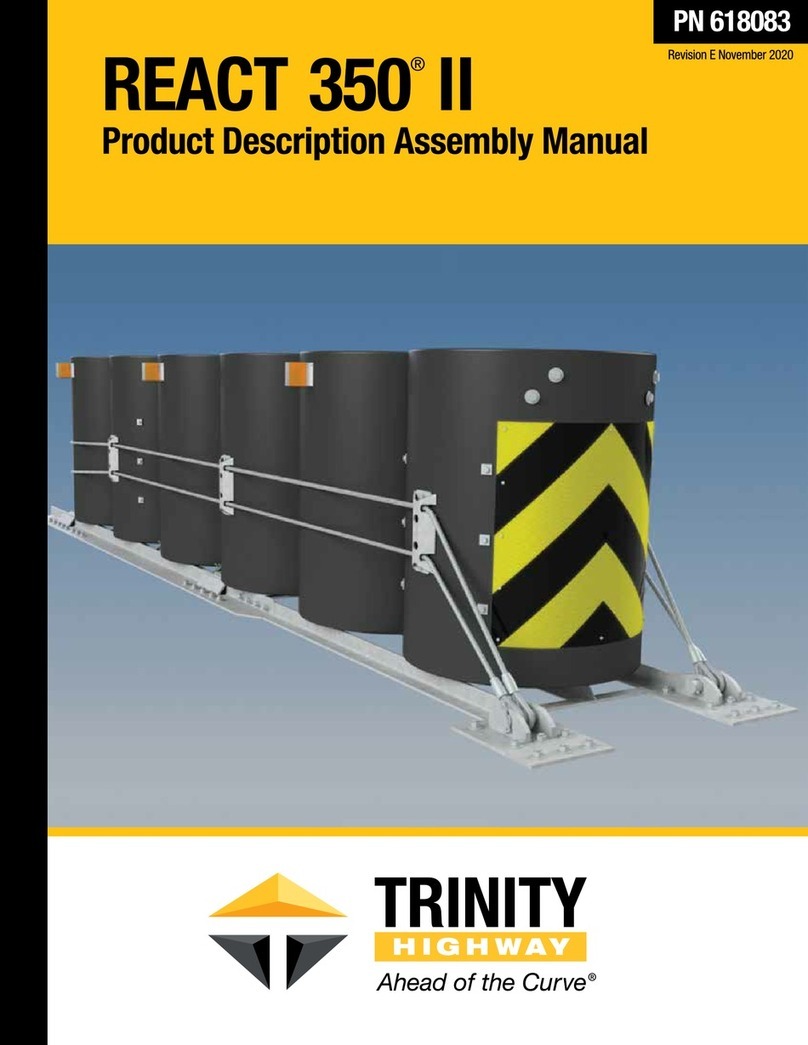

System Overview..........................................................................................................................6

Inspect Shipping......................................................................................................................6

System Components...............................................................................................................7

Select Transition ...................................................................................................................11

Recommend Tools......................................................................................................................12

Site Preparation/Foundation.......................................................................................................14

Foundation/Anchoring...........................................................................................................15

Trinity Highway Approved Adhesive Anchoring System.............................................................16

Vertical Anchors....................................................................................................................16

Steel Rebar Anchor Assembly Cautions...............................................................................17

Horizontal Anchors................................................................................................................18

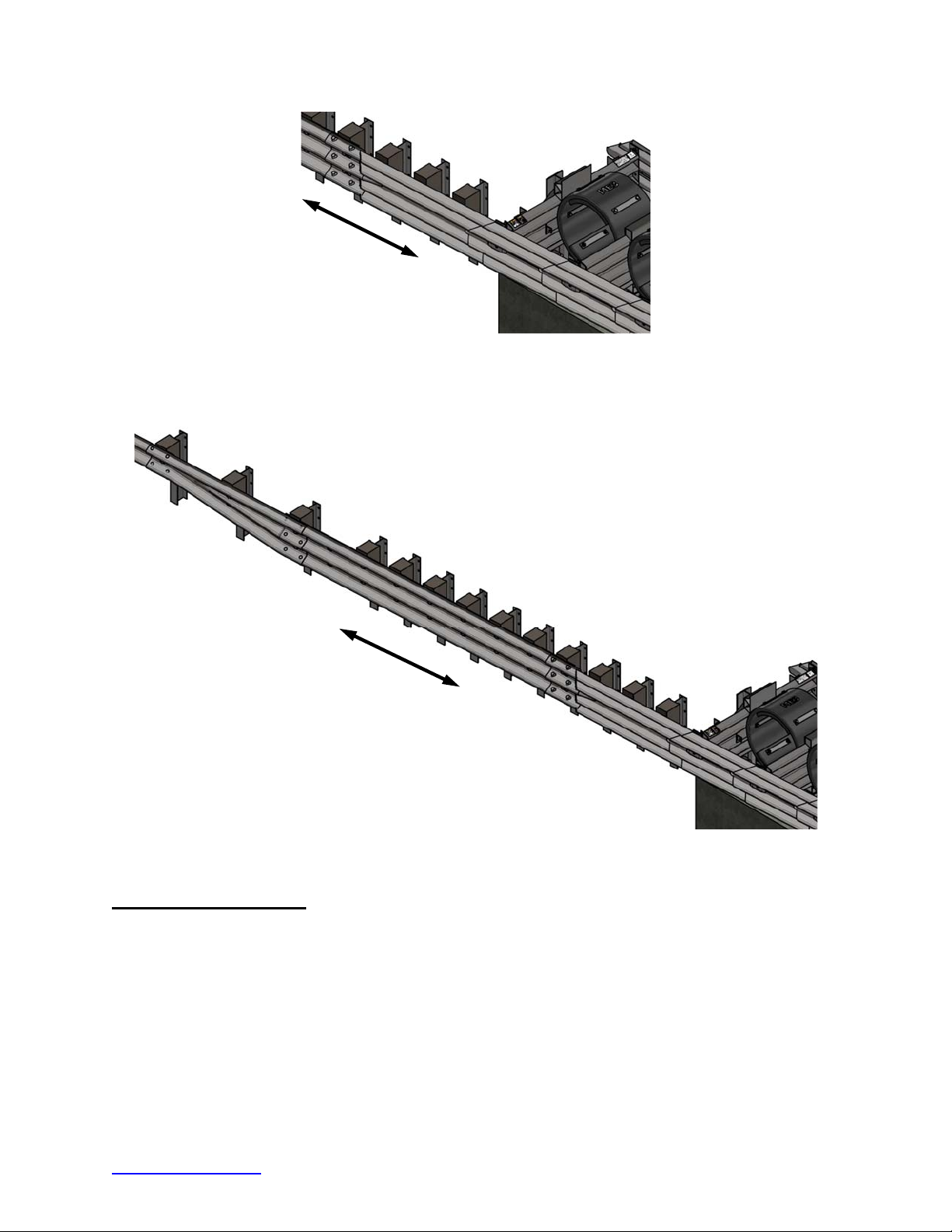

System Assembly .......................................................................................................................21

QuadGuard®Elite M10 Wide Final Inspection Checklist.............................................................37

Maintenance and Repair.............................................................................................................38

Visual Drive-By Inspection....................................................................................................38

Walk-Up Inspection...............................................................................................................38

Maintenance Flow Chart.............................................................................................................40

Post-Impact Instructions........................................................................................................41

Parts Ordering Procedure and Drawings....................................................................................44

QuadGuard®Elite M10 Wide QGEMTSCVR8-U69...........................................................46

Backup Assembly, Tension Strut627528...........................................................................47

Bay 1 Diaphragm Assembly627506.................................................................................48

Standard Diaphragm Assembly627506............................................................................49

Fender Panel Assembly608240 ........................................................................................50

Cylinder Attachment618879.............................................................................................51

Nose Assembly627505.....................................................................................................52

Hit Indicator610237...........................................................................................................53

Monorail Assembly625637...............................................................................................54

TS Concrete Pad618686...................................................................................................55

TS Concrete Pad 8” w/Rebar618686 ................................................................................56

TS Concrete Pad 8” wo/Rebar618686 ..............................................................................57

31” W-Beam TransitionQFEMTSCVR-TWLR....................................................................58

Thrie-Beam TransitionQFEMTSCVR-TTLR......................................................................59

4” Safety Shape TransitionQFEMTSCVR-T4LR ..............................................................60

4” Safety Shape Flared TransitionQFEMTSCVR-T4LRF..................................................61

6” Single Slope TransitionQFEMTSCVR-T6LR................................................................62

6” Single Slope Flared TransitionQFEMTSCVR-T6LRF ...................................................63

End Shoe TransitionQFEMTSCVR-ESLR........................................................................64