Safety Circuit Integrity and ISO 13849-1 Safety Circuit Principles

Safety circuits involve the safety-related functions of a machine that minimize the level of risk of harm. These safety-

related functions can prevent initiation, or they can stop or remove a hazard. The failure of a safety-related function or its

associated safety circuit usually results in an increased risk of harm.

The integrity of a safety circuit depends on several factors, including fault tolerance, risk reduction, reliable and well-tried

components, well-tried safety principles, and other design considerations.

Depending on the level of risk associated with the machine or its operation, an appropriate level of safety circuit integrity

(performance) must be incorporated into its design. Standards that detail safety performance levels include ANSI B11.19

Performance Criteria for Safeguarding and ISO 13849-1 Safety-Related Parts of a Control System.

Safety Circuit Integrity Levels

Safety circuits in International and European standards have been segmented into Categories and Performance Levels,

depending on their ability to maintain their integrity in the event of a failure and the statistical likelihood of that failure.

ISO 13849-1 details safety circuit integrity by describing circuit architecture/structure (Categories) and the required

performance level (PL) of safety functions under foreseeable conditions.

In the United States, the typical level of safety circuit integrity has been called "Control Reliability". Control Reliability

typically incorporates redundant control and self-checking circuitry and has been loosely equated to ISO 13849-1 Category

3 or 4 and/or Performance Level “d” or “e” (see ANSI B11.19).

Perform a risk assessment to ensure appropriate application, interfacing/hookup, and risk reduction (see ANSI B11.0 or

ISO 12100). The risk assessment must be performed to determine the appropriate safety circuit integrity in order to

ensure that the expected risk reduction is achieved. This risk assessment must take into account all local regulations and

relevant standards, such as U.S. Control Reliability or European "C" level standards.

Fault Exclusion

An important concept within the requirements of ISO 13849-1 is the probability of the occurrence of a failure, which can

be reduced using a technique termed "fault exclusion." The rationale assumes that the possibility of certain well-defined

failure(s) can be reduced via design, installation, or technical improbability to a point where the resulting fault(s) can be,

for the most part, disregarded—that is, "excluded" in the evaluation.

Fault exclusion is a tool a designer can use during the development of the safety-related part of the control system and the

risk assessment process. Fault exclusion allows the designer to design out the possibility of various failures and justify it

through the risk assessment process to meet the requirements of ISO 13849-1/-2.

Safety Mat Requirements

WARNING: Risk Assesment

The level of safety circuit integrity can be greatly affected by the design and installation of the safety

devices and the means of interfacing of those devices. A risk assessment must be performed to

determine the appropriate level of safety circuit integrity to ensure the expected risk

reduction is achieved and all relevant regulations and standards are complied with.

The following are minimum requirements for the design, construction, and installation of four-wire safety mat sensor(s) to

be interfaced with the Safety Mat Monitoring Module. These requirements are a summary of standards ISO 13856-1 and

ANSI/B11.19. Review all relevant applicable regulations and standards and apply the Module and any sensors in full

compliance.

Design and Constructions

The safety mat system [Safety Module, sensor(s), and any additional devices] must have a response time that is fast

enough (less than 100 to 200 ms, depending on the relevant standard) to reduce the possibility of an individual stepping

lightly and quickly over the mat’s sensing surface, without being detected.

For a safety mat system, the minimum object sensitivity of the sensor must detect, at a minimum, a 30 kg (66 lb.) weight

on an 80 mm (3.125 in) diameter circular disk test piece, anywhere on the mat’s sensing surface, including at joints and

junctions. The effective sensing surface or area must be identifiable and can comprise one or more sensors. The safety

mat supplier should state this minimum weight and diameter as the minimum object sensitivity of the sensor.

User adjustments to actuating force and response time are not allowed (ISO 13856-1). The sensor should be

manufactured to prevent any reasonably foreseeable failures (for example, oxidation of the contact elements) which could

cause a loss in sensitivity.

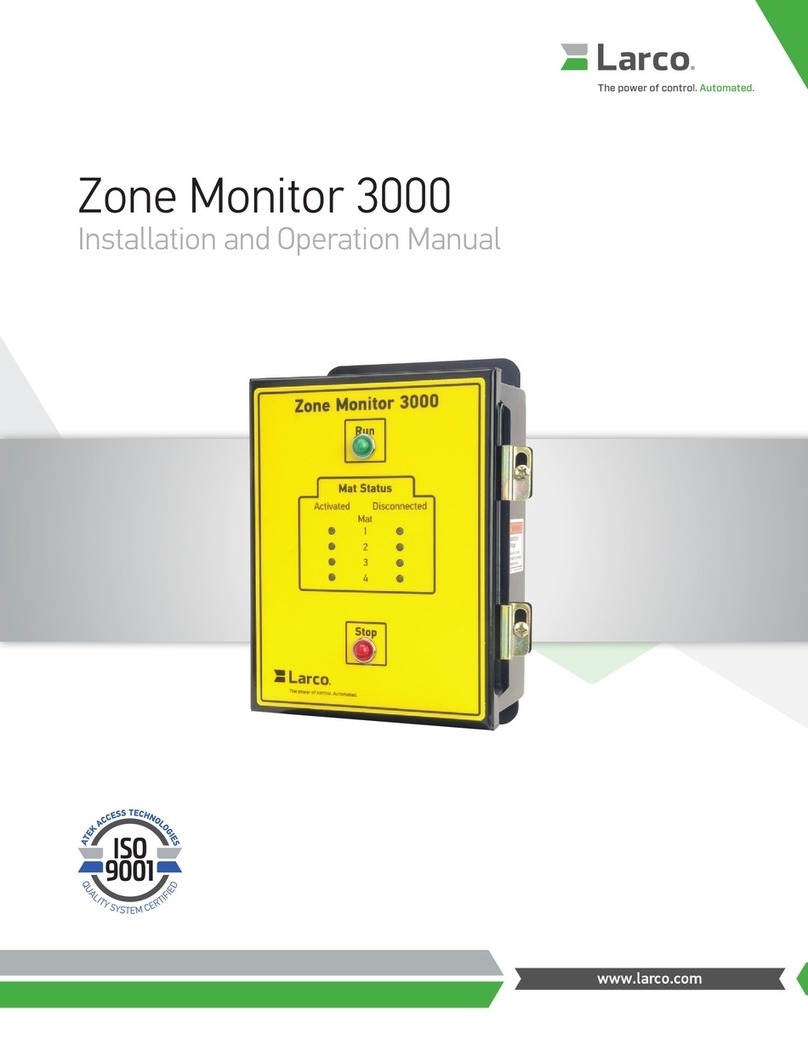

MAX1524 and MAX2324 Safety Mat Monitoring Modules

P/N 122366 Rev. B www.LARCO.com TEL: 800-523-6996 3