2

WINTER OPERATION SNOW PLOW GUIDE

SYSTEM OVERVIEW: WHAT IT DOES & HOW IT WORKS

THE SYSTEM

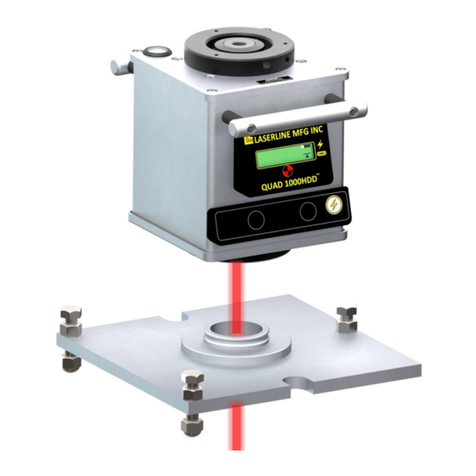

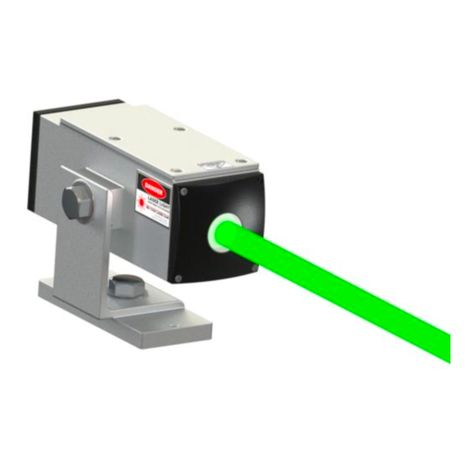

The GL3000PMC-E Guidance Laser uses an “ultra-

bright” green laser to establish wing plow trailing edge

location before you get there.

The laser spot impacts on the road/snow surface ahead

of the truck and shows the driver where the wing plow

trailing edge will be. The laser reference spot is on the

road and in the driver’s normal field of view.

The GL3000PMC-E is electronically designed for cold

weather operation. This laser is coupled to a special

heat source for the exit window to reduce or eliminate

ice build-up on the front of the laser output lens. The

GL3000PMC-E also has a unique pneumatic snow re-

moval system incorporated with the laser housing that

automatically fires a blast of air at the front of the laser

lens every 5 seconds. This removes snow build-up from

the laser output lens.

The laser housing is weatherproof, and hermetically

sealed and dry nitrogen charged for operation in virtu-

ally any weather condition.

THE PRODUCT

The GL3000PMC-E is a versatile all weather product

that can also be used for guiding highway paint stripers,

asphalt distributors, pavement profilers, or virtually any

other vehicle or equipment requiring line control. Use it

in the winter and summer for all your guidance needs.

Main Housing: Weatherproof, containing optic plate

mounting platform, micro processor electronics, laser,

laser mounting assembly, laser driver board, automatic

cooling and heating system, front window is automati-

cally heated to reduce or eliminate icing.

Pneumatic Air Blast Module: Removes snow build up

from laser exit window with automatic air blast every

5 seconds.

Control Panel In Cab: Allows the operator to turn the

laser on and off as well as the deicing and automatic air

blast functions.

20 Feet (6.09 Meters) of Interconnect Cable: With wa-

terproof mil spec in-line connector mounted between

the laser main housing and the control panel mounted

in the cab.

5 Feet (1.52 Meters) of 12V DC Cable: Running from

control box for connection to vehicle’s 12V DC power.

20 Feet (6.09 Meters) of 1/4-Inch Pneumatic Hose Line:

Complete with connectors for tying into vehicle’s sec-

ondary air source.

THE ADVANTAGES

•Cuts damage caused by plow strikes by 80 to 100%.

• Less strain on the driver.

• Reduces equipment down time.

• It’s much safer.

• It will save you money.

GL3000PMC-E Guidance Laser Laser spot showing future path of trailing edge GL3000PMC-E laser shown

US Patent No. 7,966,753

The systems work directly off the 12 volt side of the

truck, and will operate from

tive or negative ground.