April 8, 2011 HN FAQ Memo, Version 3.0 Page 2 of 108

Table of Contents

1Introduction.............................................................................................................................................. 4

1.1 Revision History .............................................................................................................................. 4

2Trouble shooting...................................................................................................................................... 6

2.1 HSM error messages:....................................................................................................................... 6

2.1.1 AI State = Wait ............................................................................................................................ 6

2.1.2 DosageLineOpenTimeout............................................................................................................ 6

2.1.3 DosageMissed.............................................................................................................................. 6

2.1.4 BD1Posttimeout........................................................................................................................... 6

2.1.5 BD5PostSampleTimeout.............................................................................................................. 7

2.1.6 BD5PresampleTimeout................................................................................................................ 7

2.1.7 BD3 Air........................................................................................................................................ 7

2.1.8 BD3PresampleTimeout................................................................................................................ 7

2.1.9 EL_AC_OFF_EXTERNAL_BUS............................................................................................... 7

2.1.10 Heart beat : AC ........................................................................................................................ 8

2.1.11 Heart beat : AI.......................................................................................................................... 8

2.1.12 Heart beat : SI .......................................................................................................................... 8

2.1.13 Heart beat : DSM ..................................................................................................................... 8

2.1.14 Heart beat: PC.......................................................................................................................... 8

2.1.15 Incubator 90% RH / or visible signs of liquid in the IM.......................................................... 8

2.1.16 Quarantine................................................................................................................................ 9

2.2 VMS and VMS sampler errors in HSM......................................................................................... 10

2.3 Trouble shooting on samplers........................................................................................................ 12

2.4 Using the “Sample all” function in the AC.................................................................................... 14

3Best Practices / How do I....................................................................................................................... 15

3.1 Sample Intake................................................................................................................................. 15

3.1.1 Activate Sample simulation in SI. (Parlour only and needs Vacuum)....................................... 15

3.1.2 How to simulate samples trough SI :......................................................................................... 17

3.1.3 How to manually test Safty/flush and Filter valve in SI (Needs Vacuum):............................... 18

3.1.4 Start Cleaning from SI menu : ................................................................................................... 19

3.1.5 Adjustment of Index on SI Multivalve. ..................................................................................... 20

3.1.6 Mounting the Tube for Milkpump in the Sample Intake. .......................................................... 23

3.1.7 Correct mounting of the Air detector assembly, BD1,BD5,BD3 and BD4............................... 27

3.2 Analyzer Instrument (AI)............................................................................................................... 36

3.2.1 Procedure for complete cleaning of milk transport system between SI and AI......................... 36

3.2.2 Measuring the water amounts during AI cleaning..................................................................... 45

3.2.3 Adjustment of dosage needle clean position.............................................................................. 48

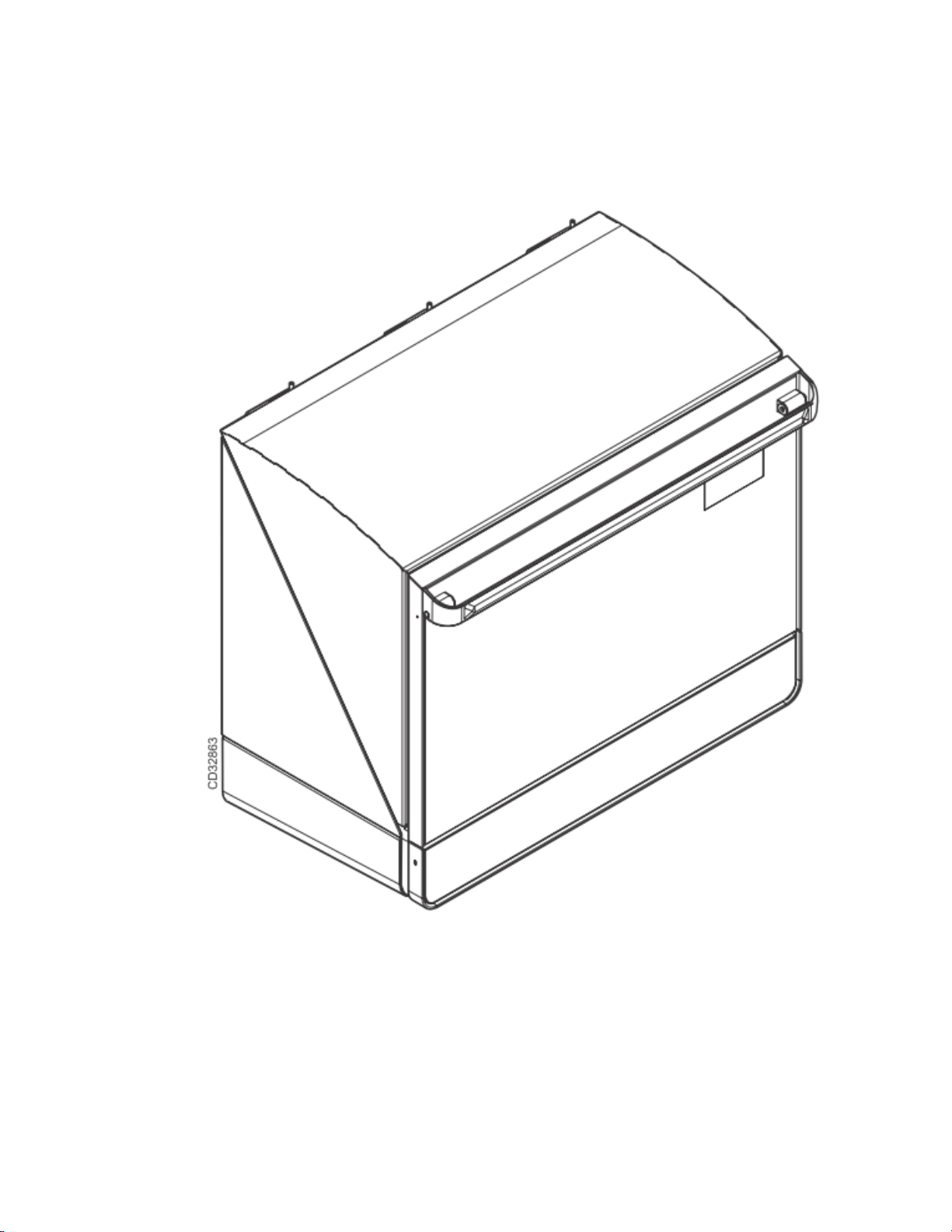

3.2.4 Howto –Close Hatch Manualy.................................................................................................. 52

3.2.5 Replacing Flow and Dosage module + 2 years AI service........................................................ 55

3.3 HN and Delaval C200 parlour cleaning......................................................................................... 58

3.3.1 Abbreviations............................................................................................................................. 58

3.3.2 Herd Navigator and C200 installation in the parlour................................................................. 58

3.3.3 C200 and HN cleaning sequence............................................................................................... 59

3.3.4 C200 parametre.......................................................................................................................... 60

3.3.5 AC and SC parameters............................................................................................................... 60

3.3.6 SI parameter............................................................................................................................... 61

3.3.7 C200 parameters from diff. HN Farms...................................................................................... 62