- 5 -

INSTRUMENT START-UP:

Switch on the instrument and wait for about 5 minutes until all the components will reach a steady

temperature. Verify that the displayed weight is positive and that it increases if one subjects the

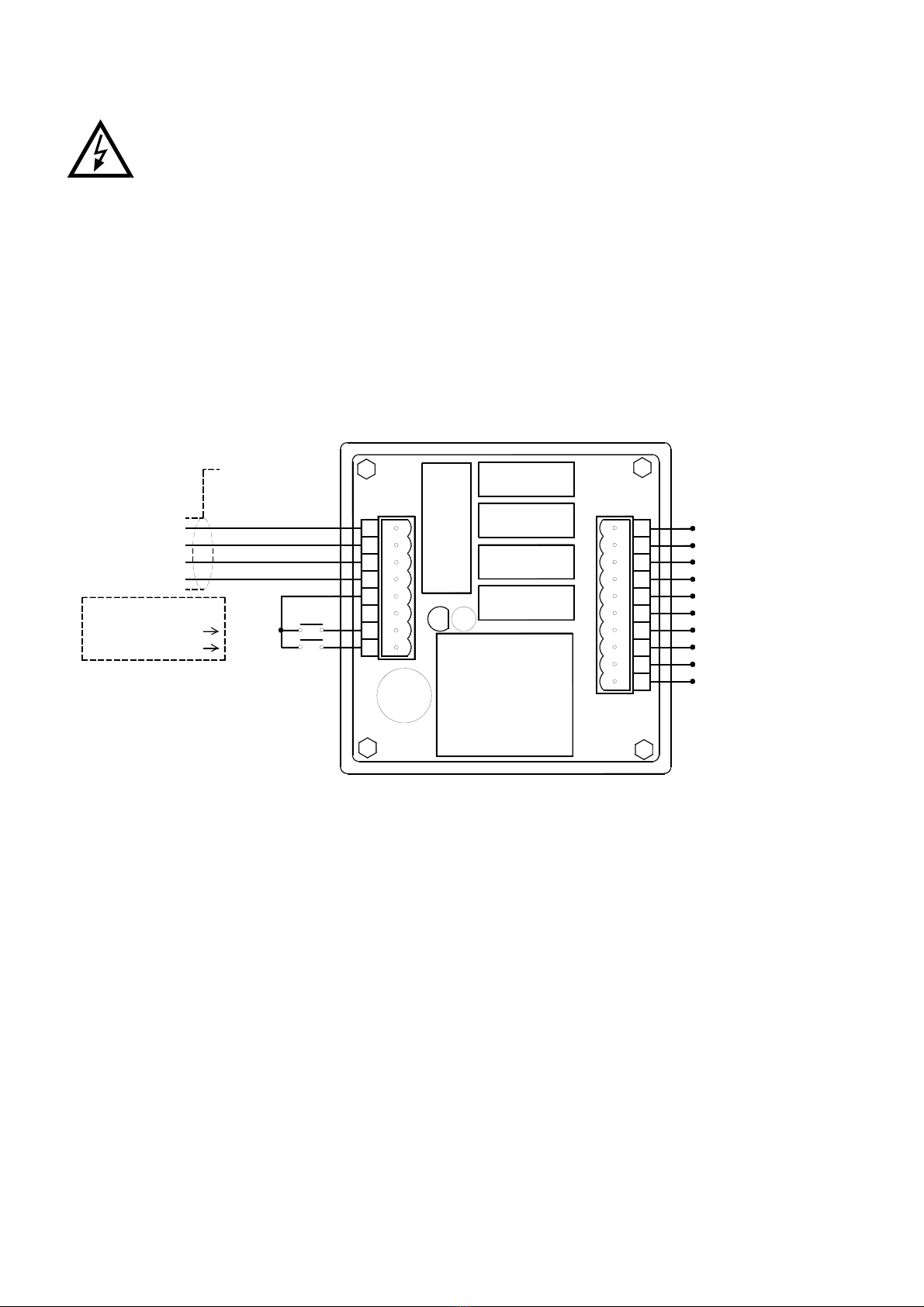

container to a force weight. In case a negative value is displayed check the load cells connections

and their correct installation ( direction of charge ). Check also that the container is correctly

installed ( tubes position, links, etc.).

If the “JOL.4” message appears, select the desired operating mode, see page 1.

THEORETICAL INSTRUMENT CALIBRATION:

Switch off the instrument, then turn on by keeping pressed the MENU key, the “C.0.S.c.”, message

appears, press ENTER and the following will appear:

“dECP” , set the number of decimals (max. 3 decimals) using the and keys. Confirm

with ENTER , the following will appear:

“CELL” , set 10% of the system’s full scale by using the and keys (for example with 3

load cells of 100 kg ; full scale = 100 x 3 = 300.0 kg ; 10% of 300.0 kg = 30.0 kg).

Confirm with ENTER , the following will appear:

“nU-U” , set the load cell sensitivity expressed in mV/V (normally 2,000) using the and

keys. Confirm with ENTER , the following will appear:

“rISO” , set the system resolution by using the and keys: x 1, 2, 3, 4, 5 . Confirm with

ENTER , the following will appear:

“unit”, set the unit of measure using the and keys: 0 = kg; 1 = t.

Confirm with ENTER , the following will appear:

“tArE” , set the tare value, if you knows it, by using the and keys. Confirm with ENTER

and “C.0.S.c.” message appears again.

Press MENU to exit.

TARE ZERO-SETTING:

Make sure that the container is empty and press the key, the "tArE " message will be displayed,

keeping pressed press the ENTER key at the same time and the tare will be set to zero.

By pressing , after 1 second, the tare value appears.

It is also possible to set the tare to the zero by using the ZERO-SETTING EXTERNAL

CONTACT (ONLY FOR “4SEt” OPERATING ); in this case the LED of DOSA key will start

blinking.

WARNING: TURNING OFF THE INSTRUMENT, THE DIVISIONS SET TO ZERO BY

EXTERNAL CONTACT WILL BE LOST.