TABLE OF CONTENTS

USER WARNINGS................................................................................................................. 1

RECOMMENDATIONS FOR CORRECT INSTALLATION OF WEIGHING INSTRUMENTS. 1

RECOMMENDATIONS FOR CORRECT INSTALLATION OF THE LOAD CELLS ............... 1

LOAD CELL INPUT TEST (QUICK ACCESS) .........................................................................4

LOAD CELL TESTING.............................................................................................................4

MAIN SPECIFICATIONS OF THE INSTRUMENT.................................................................. 5

BUFFER BATTERY..................................................................................................................5

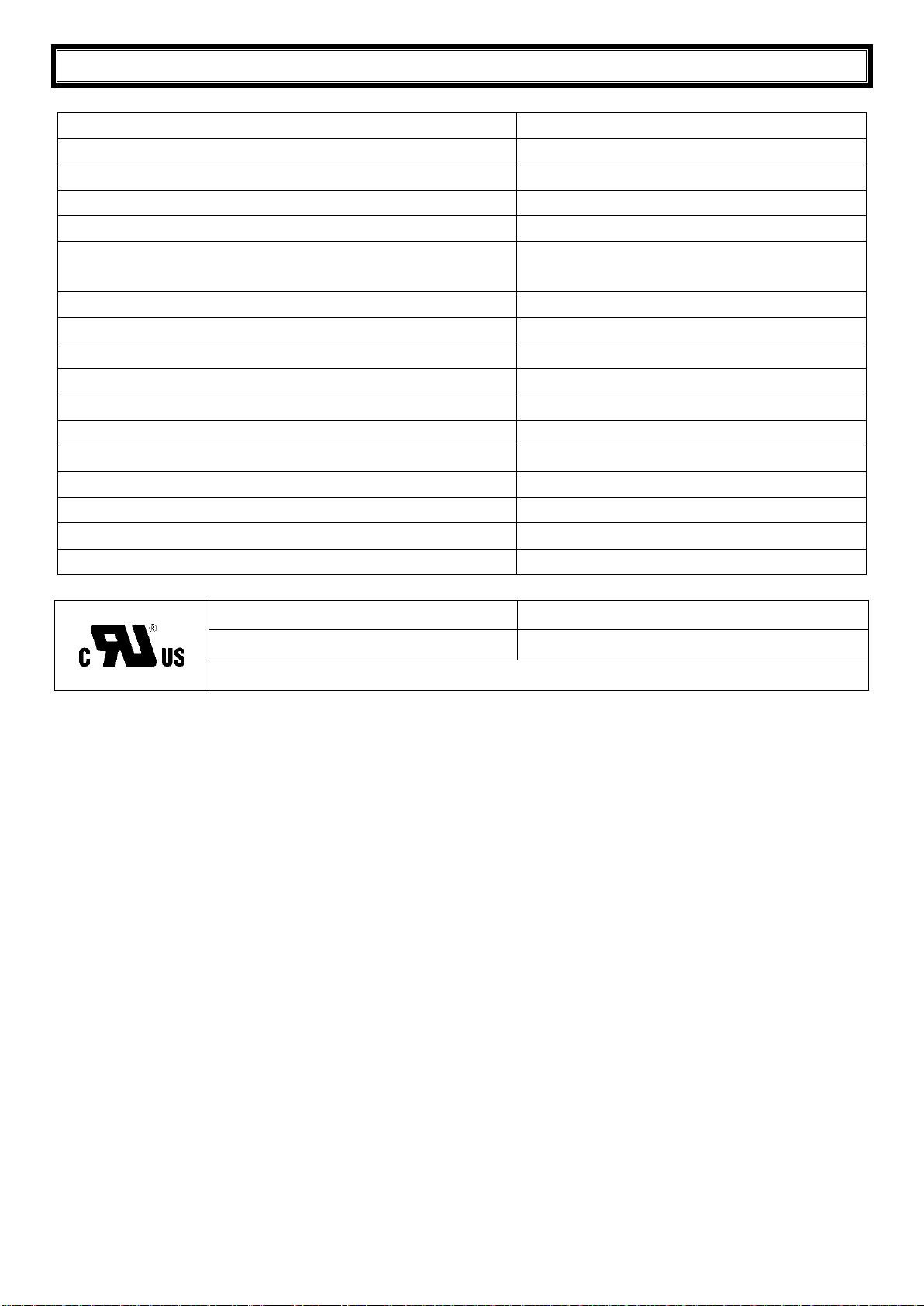

TECHNICAL SPECIFICATIONS ............................................................................................ 6

ELECTRICAL CONNECTIONS.............................................................................................. 7

BASIC INFORMATION............................................................................................................. 7

KEY CONNECTORS ........................................................................................................................ 7

KEYS AND LED FUNCTIONS ............................................................................................... 8

MENU MAP .......................................................................................................................... 10

SYSTEM PARAMETERS ....................................................................................................... 10

INSTRUMENT COMMISSIONING........................................................................................ 11

PROGRAMMING OF SYSTEM PARAMETERS .................................................................. 12

THEORETICAL CALIBRATION ............................................................................................. 12

MAXIMUM CAPACITY ................................................................................................................... 13

TARE WEIGHT ZERO SETTING.................................................................................................... 13

ZERO VALUE MANUAL ENTRY.................................................................................................... 13

REAL CALIBRATION (WITH SAMPLE WEIGHTS)............................................................... 14

FILTER ON THE WEIGHT...................................................................................................... 15

ANTI PEAK..................................................................................................................................... 15

ZERO PARAMETERS............................................................................................................ 16

RESETTABLE WEIGHT SETTING FOR SMALL WEIGHT CHANGES ......................................... 16

AUTOMATIC ZERO SETTING AT POWER-ON............................................................................. 16

ZERO TRACKING .......................................................................................................................... 16

SETTING UNITS OF MEASURE ............................................................................................ 17

NET FUNCTIONS................................................................................................................... 17

SEMI-AUTOMATIC TARE (NET/GROSS).............................................................................. 18

PRESET TARE (SUBTRACTIVE TARE DEVICE) ................................................................. 18

SEMI-AUTOMATIC ZERO (WEIGHT ZERO-SETTING FOR SMALL VARIATIONS) ............ 19

PEAK...................................................................................................................................... 19

SERIAL COMMUNICATION SETTING .................................................................................. 20

RS232 SERIAL COMMUNICATION ............................................................................................... 21

DIRECT CONNECTION BETWEEN RS485 AND RS232 WITHOUT CONVERTER...................... 21

TEST....................................................................................................................................... 22

BATTERY OPERATION......................................................................................................... 22

ENERGY SAVING .................................................................................................................. 23

DATE AND TIME SETTING.................................................................................................... 23

INFO MENU............................................................................................................................ 23