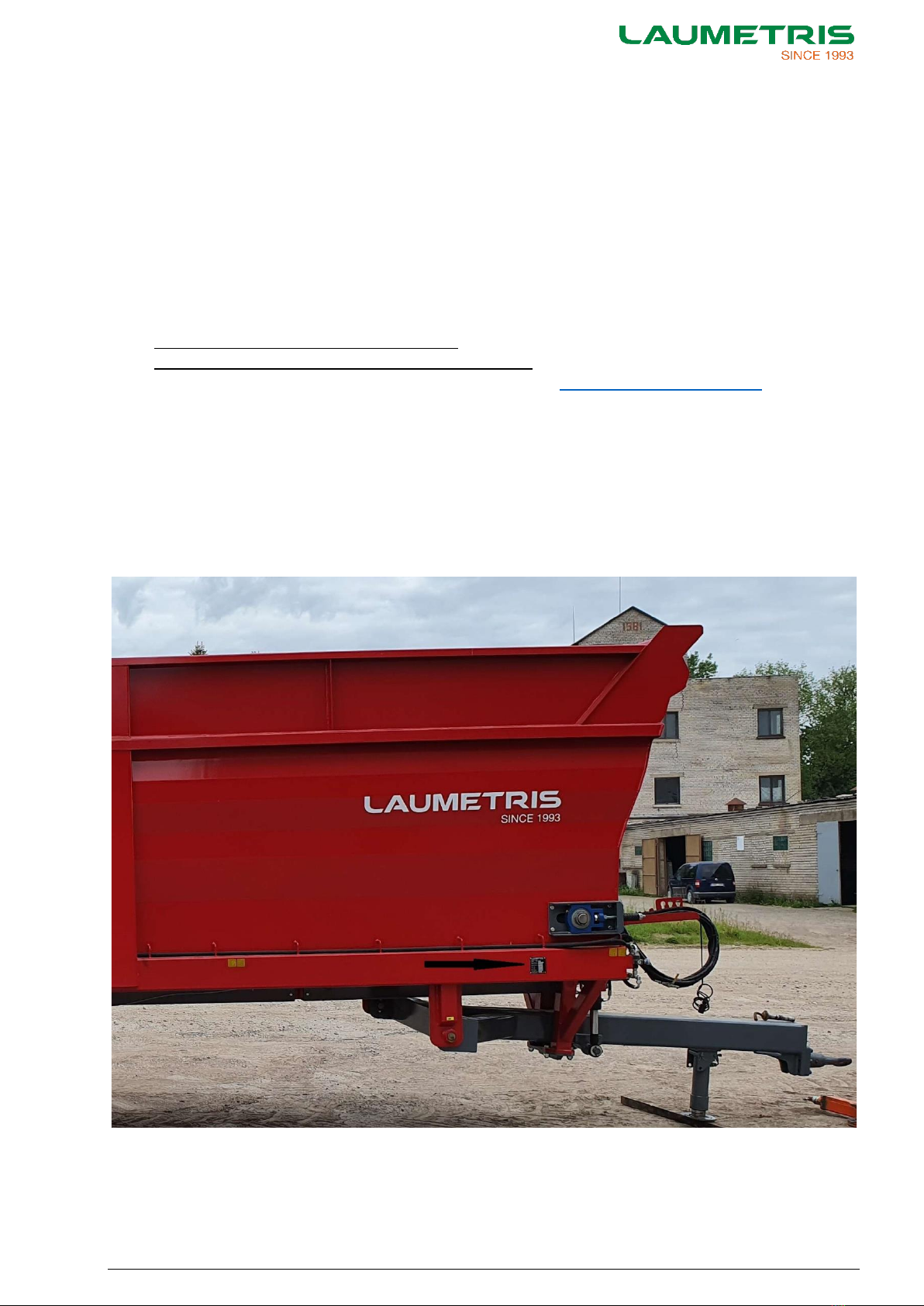

USER MANUAL Manure spreader MKL 5

Table of Contents

Declaration of conformity........................................................................................................................7

1. INTRODUCTION....................................................................................................................................8

1.1 Identification..................................................................................................................................8

1.2 Purpose ........................................................................................................................................10

1.3 Scope of supply ............................................................................................................................10

1.4 Transportation .............................................................................................................................10

1.4.1 Manure spreaders transportation on a trailer......................................................................10

1.4.2 Requirements prior to use ....................................................................................................11

2. GENERAL REQUIREMENTS FOR WORK SAFETY..................................................................................11

2.1 Symbols and definitions...............................................................................................................11

2.2 Obligatory provision of information ............................................................................................12

2.3 General requirements for work safety and use...........................................................................12

2.3.1 General requirements for work safety..................................................................................12

2.3.2 Wheels...................................................................................................................................13

2.3.3 Hydraulic and pneumatic systems ........................................................................................13

2.3.4 Periodical servicing................................................................................................................13

2.3.5 Driving on public roads. ........................................................................................................14

2.4 Signs and notices..........................................................................................................................14

3. TECHNICAL SPECIFICATIONS ..............................................................................................................18

4. DESIGN AND OPERATING PRINCIPLE..................................................................................................18

4.1 Frame ...........................................................................................................................................20

4.2 Chassis..........................................................................................................................................20

4.3 Body .............................................................................................................................................20

4.4 Variable-height support foot........................................................................................................20

4.5 Hydraulic tailgate lifting mechanism............................................................................................21

4.6 Warning light signalling................................................................................................................21

4.7 Brake system................................................................................................................................22

5. Storage ...............................................................................................................................................23

6. INFORMATION FOR THE USER ...........................................................................................................23

6.1 Preparation of the manure spreader for work ............................................................................23

6.2 Loading of a manure spreader.....................................................................................................24

6.3 Spreading manure........................................................................................................................24

6.4 Detaching the manure spreader off the tractor ..........................................................................25

7. ACTIONS DURING SERVICING.............................................................................................................27

7.1 Chassis..........................................................................................................................................27

7.1.1 Maintenance of wheels.........................................................................................................27

7.1.2 Maintenance of axles............................................................................................................29