General safety messages are listed in this Safety Messages section. Specific safety messages appear as

appropriate in this manual where a potential hazard may occur if procedures or instructions are not

followed correctly and completely.

SAFETY SYMBOL

This is the international safety alert symbol. This symbol is used in combination with a signal word

and written message to warn you of a potential for bodily injury or death.

A signal word "DANGER", "WARNING", or "CAUTION" is used with the safety alert symbol.

DANGER: Imminent hazards, that if not avoided, will result in serious personal injury or death.

WARNING: Potential hazards or unsafe practices, that if not avoided, could result in serious

personal injury or death:

CAUTION: Potential hazards or unsafe practices, that if not avoided, could result in minor personal

injury, product damage, or property damage.

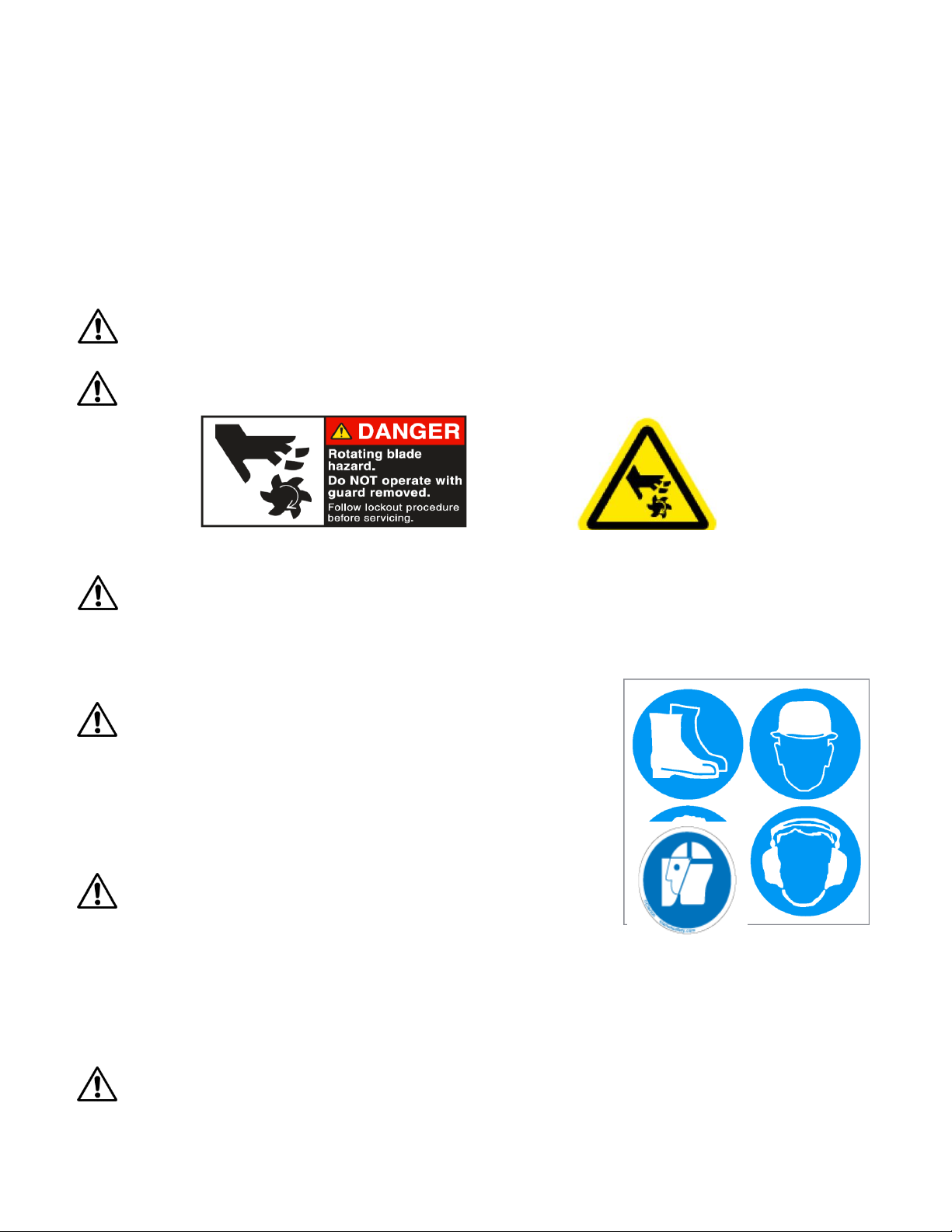

Safety decals with a signal word "DANGER", "WARNING", or "CAUTION" are affixed to the stump

grinder near specific hazards.

This machine shall always be used in accordance with this manual. Study it and ALL decals on the stump

grinder before operating the stump grinder.

ALWAYS make sure the engine

by means other than under its own

power.

Before using, always visually inspect to see that the tools are not worn or damaged. Replace worn or

damaged elements and bolts in sets to preserve balance.

Use extreme caution when reversing the machine towards you.

Do not change the engine