(T9)ENTERkey:Pressing thiskeywhen aLEDcorresponding toan operation islitbutnot

flashing will permitmodifying the timesand the fluidquantities.Upon completion of

modification, press the keyagaintoconfirmthe datum

(T10)STARTkey: Pressing thiskeywill start the operation indicated bythe lighted LED

(T11)STOPkey: Pressing thiskeywill stop the operation indicated bythe flashing LED.

(T12)TEMPERATUREkey:Pressing thiskeythe displaywill showthe bottletemperaturein

Celsiusdegree and Fahrenheit degree.

(T13)Display:According tothe operation selected,displays the timeorrefrigerantquantity

values.

STATUSAND ALARMPANEL

See fig10:

(C1)HEATERON:Lightstoindicatethatthe electricalresistanceofthe machine isheating

the bottletomaintainfluidpressurebetween 5.5and 8,5bar. The resistancedoesnot operate

during the RECOVERYphaseof operation

(C2)HIGHPRESSURE:Lightsand emitsan acousticsignalwhen the pressureofthe fluidin

the circuit catchup 17.5bar. The RECOVERYoperation isautomaticallyinterrupted.

(C3)FULL BOTTLE:Lightsand emitsan acousticsignalwhen the bottleisfull tomorethan

80%capacity(that is, 10 kg). The Recoveryoperation isautomaticallyinterrupted.

(C4)EMPTYBOTTLE:Lightsand emitsan acousticsignalwhen the quantityofrefrigerant

fluidcontained inthe bottleislow(2kg).inordertoavoidthe emission ofnon-condensable

gases.Fill the bottleaccording tothe proceduredescribed inthe ROUTINEMAINTENANCE

section.

PRELIMINARYOPERATIONS

Checkthatswitch(j) issettoposition 0.Checkthatall the machine tapsare closed.Connect the

machine tothe electrical supplyand switchon.Checkthatthe vacuumpumpoil level indicator shows at

least one-halffull.Ifthe level islower,add oil asexplained in the MAINTENANCEsection.Checkthatin

the top-up oil container (e) there are atleast 100 cc ofthe oil recommended bythe manufacturer ofthe

vehicle A/Csystem. Checkthe level ofthe oil in container (m)(<200 cc).Checkon the machine display

thatthere are atleast 3kgofrefrigerantin the bottle.Should thisnotbe the case,fill the machine bottle

froman external bottle ofappropriaterefrigerantfollowing the procedure described in the ROUTINE

MAINTENANCEsection.

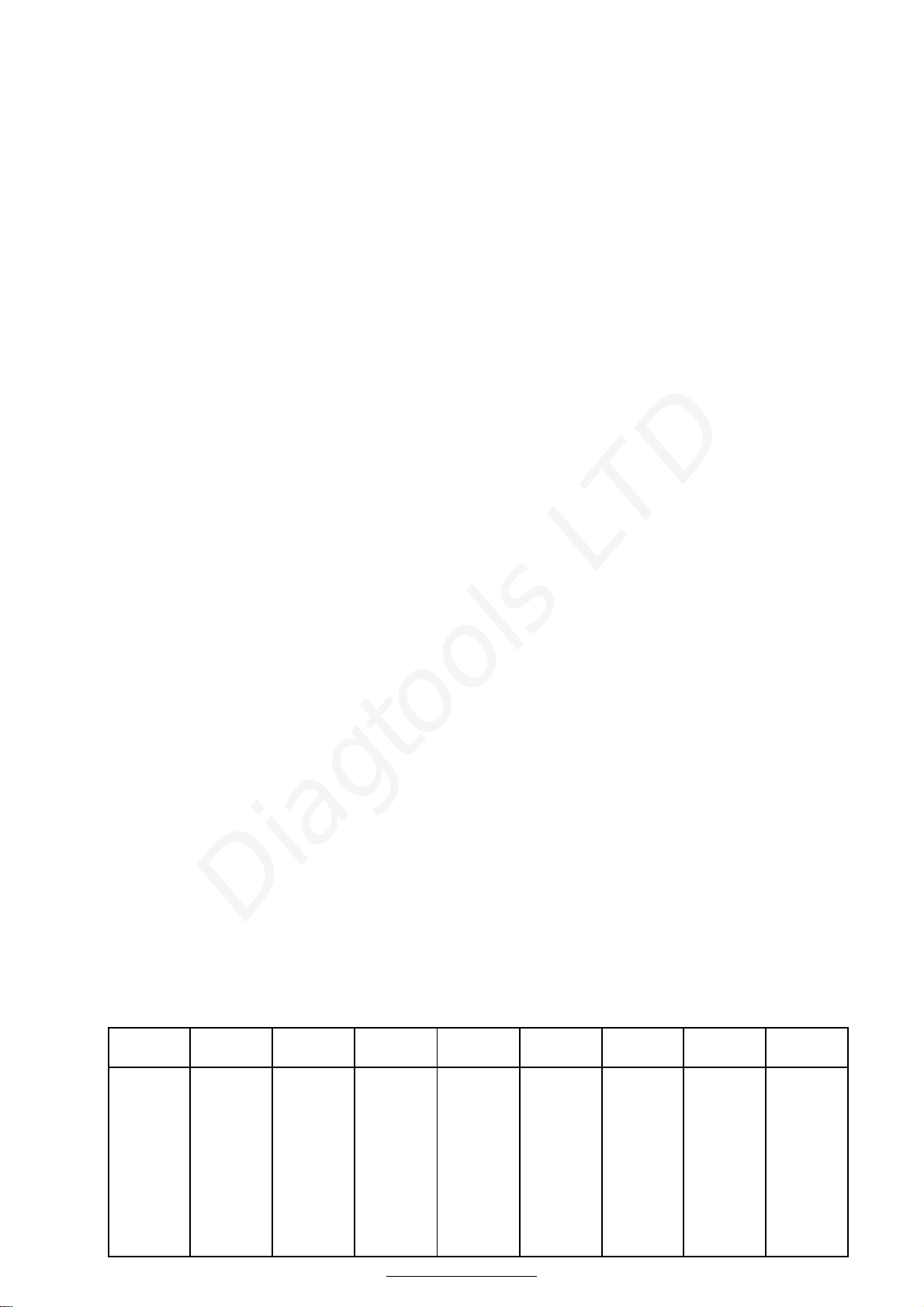

PURGENONCONDENSABLEGAS

Beforeeveryservice,check ifthereisairintothe bottle;press the temperaturebottlekey(ref

.12 fig.9)and read the temperatureof the bottle. Comparethe bottlepressurewiththe one into

the table;ifthe bottlepressureifhigherofthe pressureread on the table,pull the ring ofthe

securityvalveand bring back the bottlepressuretothe tablevalues.Example:Bottle

temperature=20 °C, the bottlepressuremust bring back at 5,2bar.

T

(°C) P

(bar)

T

(°C) P

(bar)

T

(°C) P

(bar)

T

(°C) P

(bar)

T

(°C) P

(bar)

T

(°C) P

(bar)

T

(°C) P

(bar)

T

(°C) P

(bar)

T

(°C) P

(bar)

10 3,6 15 4,4 20 5,2 25 6,1 30 7,2 35 8,3 40 9,6 45 11 50 12,6

10,5

3,7 15,5

4,4 20,5

5,3 25,5

6,2 30,5

7,3 35,5

8,4 40,5

9,7 45,5

11,2

50,5

12,8

11 3,8 16 4,5 21 5,4 26 6,3 31 7,4 36 8,6 41 9,9 46 11,3

51 12,9

11,5

3,8 16,5

4,6 21,5

5,5 26,5

6,4 31,5

7,5 36,5

8,7 41,5

10 46,5

11,5

51,5

13,1

12 3,9 17 4,7 22 5,6 27 6,5 32 7,6 37 8,8 42 10,2

47 11,6

52 13,3

12,5

4 17,5

4,8 22,5

5,6 27,5

6,6 32,5

7,7 37,5

8,9 42,5

10,3

47,5

11,8

52,5

13,4

13 4,1 18 4,9 23 5,7 28 6,7 33 7,8 38 9,1 43 10,4

48 12 53 13,6

13,5

4,1 18,5

4,9 23,5

5,8 28,5

6,8 33,5

8 38,5

9,2 43,5

10,6

48,5

12,1

53,5

13,8

14 4,2 19 5 24 5,9 29 6,9 34 8,1 39 9,3 44 10,7

49 12,3

54 14

14,5

4,3 19,5

5,1 24,5

6 29,5

7,1 34,5

8,2 39,5

9,5 44,5

10,9

49,5

12,4

54,5

14,2

www.diagtoools.lv

DiagtoolsLTD