STT Emtec SCRmarine Instruction sheet

Document

STT SCRmarine

Installation Guideline

Date

2019-05-15

Page

1

Issue: 1.8

STT Emtec AB (pbl)

Box 46, Njurundavägen 16A

SE-862 02 NJURUNDA

SWEDEN

Tel: +46 (0)60

-

64 10 40

Fax: +46 (0)60 64 10 45

e-mail: info@sttemtec.com

Internet: www.sttemtec.com

Head office:

Njurunda

Org.nr: 55 62 05 – 2927

VAT ID: SE556205292701

ISO-cetrifikat nr: 15627

Installation Guideline

This guideline describes the recommended installation procedure and maintenance for the STT SCRmarine system

Latest version available at www.sttemtec.com

Document

STT SCRmarine

Installation Guideline

Date

2019-05-15

Page

2

Issue: 1.8

STT Emtec AB (pbl)

Box 46, Njurundavägen 16A

SE-862 02 NJURUNDA

SWEDEN

Tel: +46 (0)60

-

64 10 40

Fax: +46 (0)60 64 10 45

e-mail: info@sttemtec.com

Internet: www.sttemtec.com

Head office:

Njurunda

Org.nr: 55 62 05 – 2927

VAT ID: SE556205292701

ISO-cetrifikat nr: 15627

Table of content

1. Purpose

1.1. SCR technology

1.2. System overview

1.3. Components overview

1.4. System requirements

1.5. Commissioning requirements

2. Exhaust components installation

2.1. Flanges and gaskets

2.2. Thermal expansion

2.3. Insulation

2.4. Exhaust mixer and SCR chamber (SCR assembly)

2.4.1. Function

2.4.2. Installation

2.4.3. Maintenance

2.5. POC (Particle Oxidation Catalyst)

2.5.1. Function

2.5.2. Installation

2.5.3. Maintenance

3. DEF dosing components installation

3.1. General

3.2. Components placement

3.3. DEF supply lines

3.3.1. Function

3.3.2. Installation

3.3.3. Maintenance

3.4. DEF service tank

3.4.1. Function

3.4.2. Installation

3.4.3. Maintenance

3.4.4. Bulk tank

3.4.5. Tank heating

3.5. FR unit

3.5.1. Function

3.5.2. Installation

3.5.3. Maintenance

3.5.4. Adjusting the air pressure

3.5.5. Air compressor considerations

3.6. DEF supply pump

3.6.1. Function

3.6.2. Installation

3.6.3. Maintenance

3.7. DEF dosing unit

3.7.1. Function

3.7.2. Installation

3.7.3. Maintenance

3.7.4. Replacing the DEF filter

3.7.5. Replacing the DEF dosing unit

Document

STT SCRmarine

Installation Guideline

Date

2019-05-15

Page

3

Issue: 1.8

STT Emtec AB (pbl)

Box 46, Njurundavägen 16A

SE-862 02 NJURUNDA

SWEDEN

Tel: +46 (0)60

-

64 10 40

Fax: +46 (0)60 64 10 45

e-mail: info@sttemtec.com

Internet: www.sttemtec.com

Head office:

Njurunda

Org.nr: 55 62 05 – 2927

VAT ID: SE556205292701

ISO-cetrifikat nr: 15627

3.8. Injection nozzle

3.8.1. Function

3.8.2. Installation

3.8.3. Maintenance

3.8.4. Replacing the injection nozzle

4. Electrical components installation

4.1. Control cabinet

4.1.1. Function

4.1.2. Installation

4.1.3. Maintenance

4.2. NOx concentration sensor

4.2.1. Function

4.2.2. Installation

4.3. Exhaust temperature sensors

4.3.1. Function

4.3.2. Installation

4.4. Exhaust backpressure sensor

4.4.1. Function

4.4.2. Installation

4.4.3. Sensor relocation

4.5. Cables

4.5.1. Cable restrictions

4.5.2. Wire connection

4.5.3. Component layout

4.5.4. CAN databus

4.5.5. CAN termination

4.5.6. Activation relay input

4.5.7. Alarm relay output

4.5.8. Fuses and system disable

4.5.9. Cable shield

4.5.10.Power consumption

4.5.11.Discrete engine sensors

5. System operation

5.1. Routine operation

5.2. Enabling and disabling DEF dosing

5.3. Troubleshooting

5.4. Monitoring system

5.4.1. Control system operating states

5.4.2. LCD diagnose operation

5.4.3. Diagnose menus

5.4.4. Runtime data

5.4.5. Actuator test

5.4.6. Diagnostic trouble codes

5.4.7. “Normal” trouble codes

5.5. External diagnose options

5.5.1. Slave display panel

5.5.2. PC diagnose software

Document

STT SCRmarine

Installation Guideline

Date

2019-05-15

Page

4

Issue: 1.8

STT Emtec AB (pbl)

Box 46, Njurundavägen 16A

SE-862 02 NJURUNDA

SWEDEN

Tel: +46 (0)60

-

64 10 40

Fax: +46 (0)60 64 10 45

e-mail: info@sttemtec.com

Internet: www.sttemtec.com

Head office:

Njurunda

Org.nr: 55 62 05 – 2927

VAT ID: SE556205292701

ISO-cetrifikat nr: 15627

Appendix 01 Technical specifications

Appendix 02 Commissioning prerequisites

Appendix 03 Maintenance

Appendix 04 Engine CAN bus access points

Appendix 05 Post-installation inspection

Appendix 06 LCD diagnostics chart

Appendix 07 System process chart

Appendix 08 AdBlue®safety manual

Appendix 09 Sensors datasheet

Appendix 10 Electrical reference drawings

Appendix 11 Mechanical reference drawings

Appendix 12 Installing discrete engine sensors

Appendix 13 PC diagnose manual (EmtecDiag)

Appendix 14 Retrieving diagnose data

Document

STT SCRmarine

Installation Guideline

Date

2019-05-15

Page

5

Issue: 1.8

STT Emtec AB (pbl)

Box 46, Njurundavägen 16A

SE-862 02 NJURUNDA

SWEDEN

Tel: +46 (0)60

-

64 10 40

Fax: +46 (0)60 64 10 45

e-mail: info@sttemtec.com

Internet: www.sttemtec.com

Head office:

Njurunda

Org.nr: 55 62 05 – 2927

VAT ID: SE556205292701

ISO-cetrifikat nr: 15627

1 Purpose

The purpose of this document is to give sufficient information on how to install and

operate the key components of the SCRmarine system. The installation guideline also

describes the post adjustments and inspection processes and gives general information

on service and maintenance.

The first section gives an overview of the system and presents key points to enable

commissioning.

1.1 The SCR technology

NOx, nitrogen oxides, produced during the combustion process in diesel engines is a

contributing factor to air pollution. In an SCR system (Selective Catalytic Reduction) the

injected urea reacts over the catalyst with the harmful NOx gases in the exhaust and

converts it to water and nitrogen.

4NH3 + 4NO + O2→ 4N2+ 6H2O

Urea is a clear, non-toxic chemical. It is in normal conditions safe to handle and is not

harmful to the environment. To be able to inject the urea into the exhaust, a mixture of

urea diluted in distilled water, called Diesel Exhaust Fluid (DEF) is used. Another

technical name is Aqueous Urea Solution (AUS). Urea can cause corrosion to metal

parts; therefore the handling equipment must be designed to withstand urea. This applies

to tanks, pumps, lines, etc.

In this document the common names DEF and urea are used instead of trade

names.

It is important to only use DEF in accordance to the ISO 22241 or ISO

18611 standards.

Note! The fuel quality for the SCR system must fulfill EN 590.

Note! If a POC is used in combination with SCR or as a stand alone unit,

the fuel quality must fulfill EN 590.

For other fuel qualities please contact Stt Emtec AB for consultation.

Document

STT SCRmarine

Installation Guideline

Date

2019-05-15

Page

6

Issue: 1.8

STT Emtec AB (pbl)

Box 46, Njurundavägen 16A

SE-862 02 NJURUNDA

SWEDEN

Tel: +46 (0)60

-

64 10 40

Fax: +46 (0)60 64 10 45

e-mail: info@sttemtec.com

Internet: www.sttemtec.com

Head office:

Njurunda

Org.nr: 55 62 05 – 2927

VAT ID: SE556205292701

ISO-cetrifikat nr: 15627

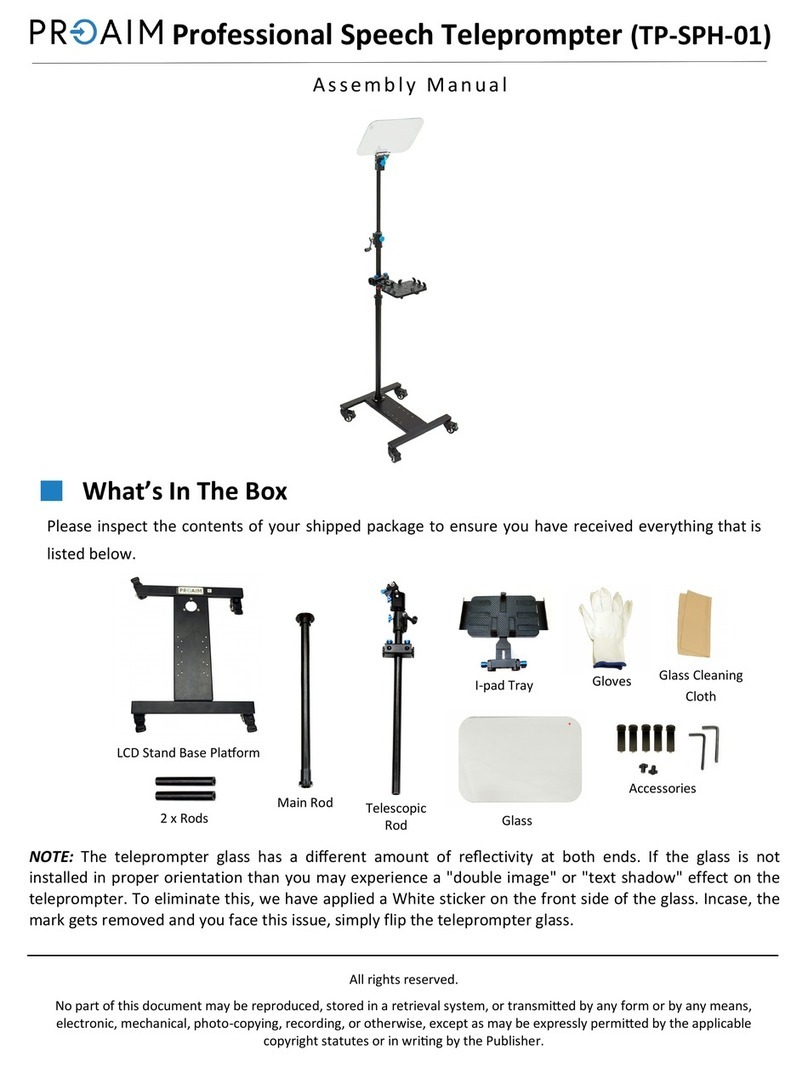

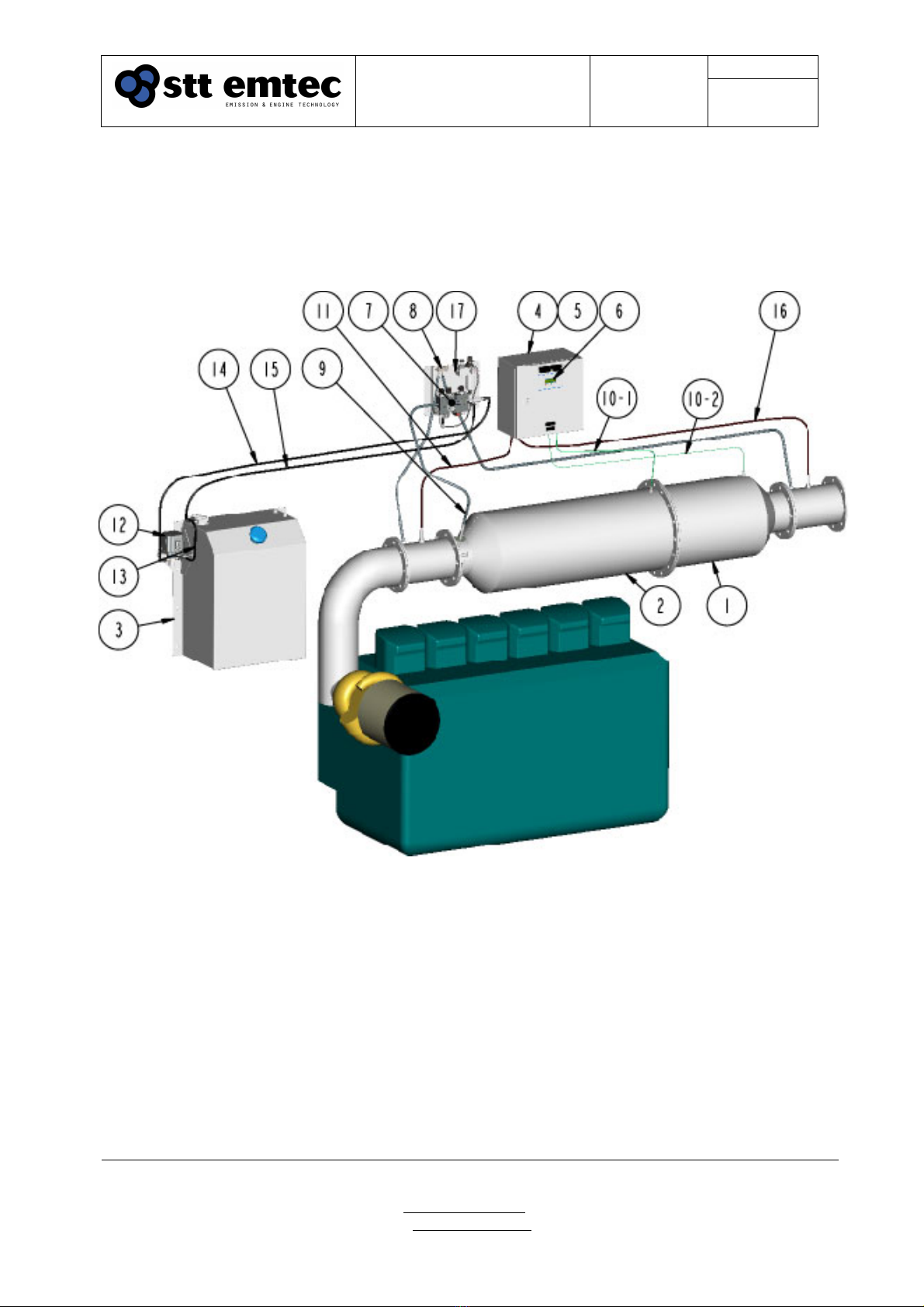

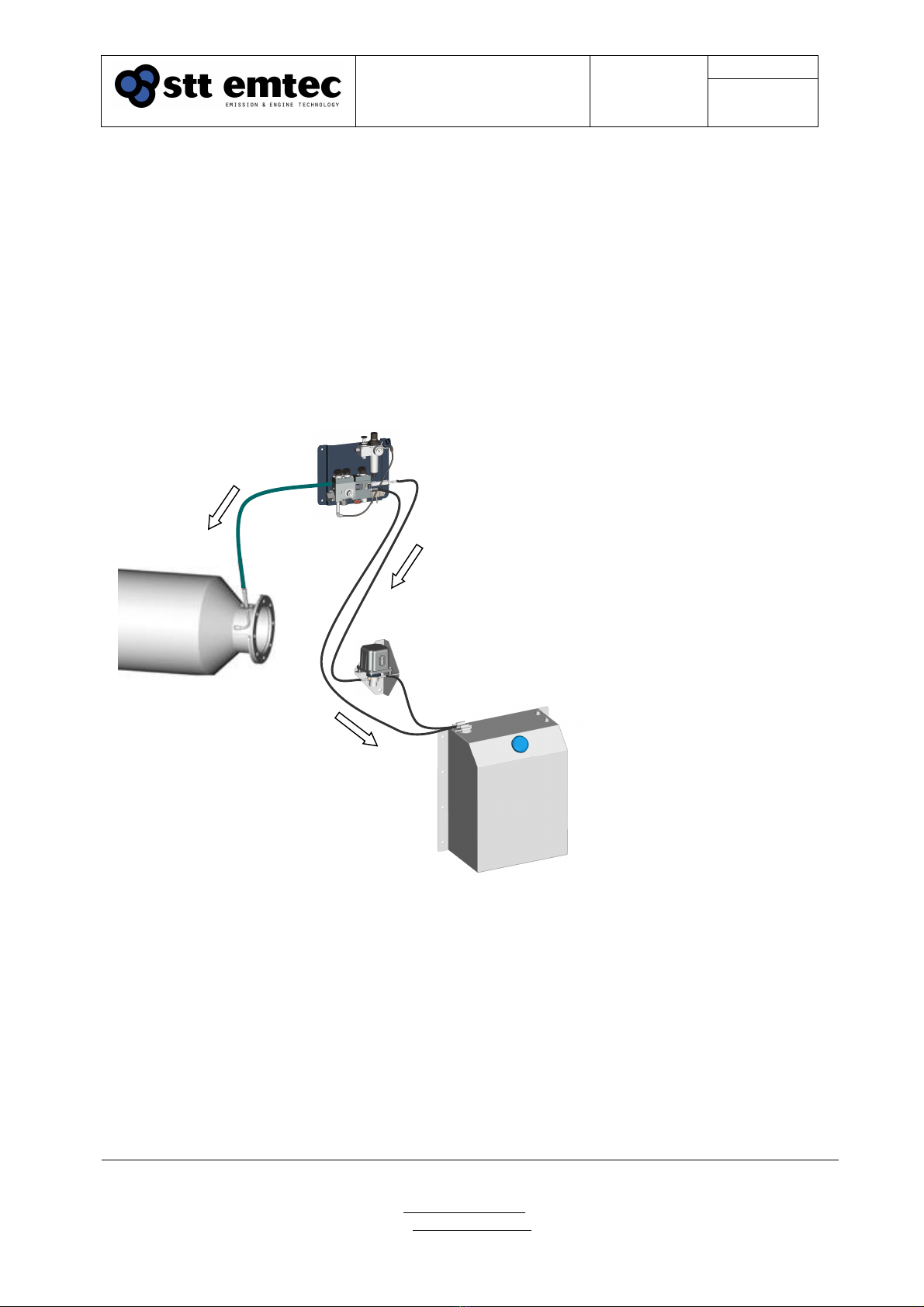

1.2 System overview

The schematic diagram in Figure 1 shows the layout of the SCRmarine system. It is a

fully automated after-treatment NOx reduction system with simple calibration and low

maintenance requirements.

Figure 1.

SCR marine system, arrangement and layout

1. SCR chamber, 2. Exhaust mixer, 3. DEF service tank, 4. Control cabinet, 5. Electronic Control Unit (ECU),

6. Diagnostic display, 7. DEF Dosing Unit (DDU)), 8. Exhaust pressure sensor, 9. Injection Nozzle,

10-1. SCR temperature sensor 1, 10-2. SCR temperature sensor 2, 11. NOx Sensor 1, 12. DEF supply pump,

13. DEF line; from service tank to supply pump, 14. DEF line; from supply pump to DDU,

15. DEF line; from DDU to service tank. 16. NOx sensor 2 (option), 17. FR unit (compressed air supply)

Document

STT SCRmarine

Installation Guideline

Date

2019-05-15

Page

7

Issue: 1.8

STT Emtec AB (pbl)

Box 46, Njurundavägen 16A

SE-862 02 NJURUNDA

SWEDEN

Tel: +46 (0)60

-

64 10 40

Fax: +46 (0)60 64 10 45

e-mail: info@sttemtec.com

Internet: www.sttemtec.com

Head office:

Njurunda

Org.nr: 55 62 05 – 2927

VAT ID: SE556205292701

ISO-cetrifikat nr: 15627

1.3 Components overview

The following are the key components of the SCRmarine system. Some parts are

optional, such as the POC (Particle Oxidation Catalyst). Appearance and contents can

vary between specific systems.

Figure 2.

SCR marine system, key components

DEF Service Tank

DEF Supply Pump

DEF Dosing Unit

FR Unit

Exhaust Mixer / SCR Chamber

Control Cabinet

Sensor Kit

Cable Kit

Injection Nozzle

Particle Oxidation Catalyst

(option)

Hose kit

Document

STT SCRmarine

Installation Guideline

Date

2019-05-15

Page

8

Issue: 1.8

STT Emtec AB (pbl)

Box 46, Njurundavägen 16A

SE-862 02 NJURUNDA

SWEDEN

Tel: +46 (0)60

-

64 10 40

Fax: +46 (0)60 64 10 45

e-mail: info@sttemtec.com

Internet: www.sttemtec.com

Head office:

Njurunda

Org.nr: 55 62 05 – 2927

VAT ID: SE556205292701

ISO-cetrifikat nr: 15627

1.4 System requirements

The SCRmarine is an automatic NOx reduction system. It is based upon a NOx sensor

measuring the actual emissions from the engine and therefore requires little or no

calibration during commissioning. An SCR catalyst assembly, and optionally a POC

(Particulate Oxidation Catalyst), is installed in the exhaust line as close to the engine as

possible to preserve exhaust temperature. Besides from the sensors relating to the SCR

assembly the SCRmarine requires the following from the vessel installation:

Power supply

24VDC or 230 VAC @ 150W nominal power

Power supply shall always be active to the control system

Compressed air supply

40 l/min FAD nominal while the engine is running

Min supply pressure 5 bar

An air tank of at least 50 l if air supply depends on engine running

Access to engine runtime data

The following signals need to available in runtime:

oEngine speed

oEngine load

oEngine boost air pressure

oEngine boost air temperature

oEngine running (ON/OFF) signal

The runtime signals can be obtained from the engines CAN (J1919) databus or

using discrete sensors

DEF

The reaction fluid for the SCR catalyst must always be available in the service

tank

As a rule of thumb the DEF consumption is ~ 5% of engine fuel consumption

1.5 Commissioning requirements

A checklist to enable system commissioning and to make sure that no vital details have

been overlooked is available in Appendix 02 - Commissioning prerequisites

In order to complete system commissioning an installation report must be completed and

returned to STT Emtec AB. The report document can be found in Appendix 05 – Post

installation check-up

Document

STT SCRmarine

Installation Guideline

Date

2019-05-15

Page

9

Issue: 1.8

STT Emtec AB (pbl)

Box 46, Njurundavägen 16A

SE-862 02 NJURUNDA

SWEDEN

Tel: +46 (0)60

-

64 10 40

Fax: +46 (0)60 64 10 45

e-mail: info@sttemtec.com

Internet: www.sttemtec.com

Head office:

Njurunda

Org.nr: 55 62 05 – 2927

VAT ID: SE556205292701

ISO-cetrifikat nr: 15627

2 Exhaust components installation

This section provides general and specific information on installing the mechanical

components in the exhaust system.

The exhaust system is stressed both by high temperature variations and vibrations. It is

therefore important to observe both the application notes in this document as well as

applying regulation according to the vessel requirements to ensure trouble free operation

of the SCRmarine system.

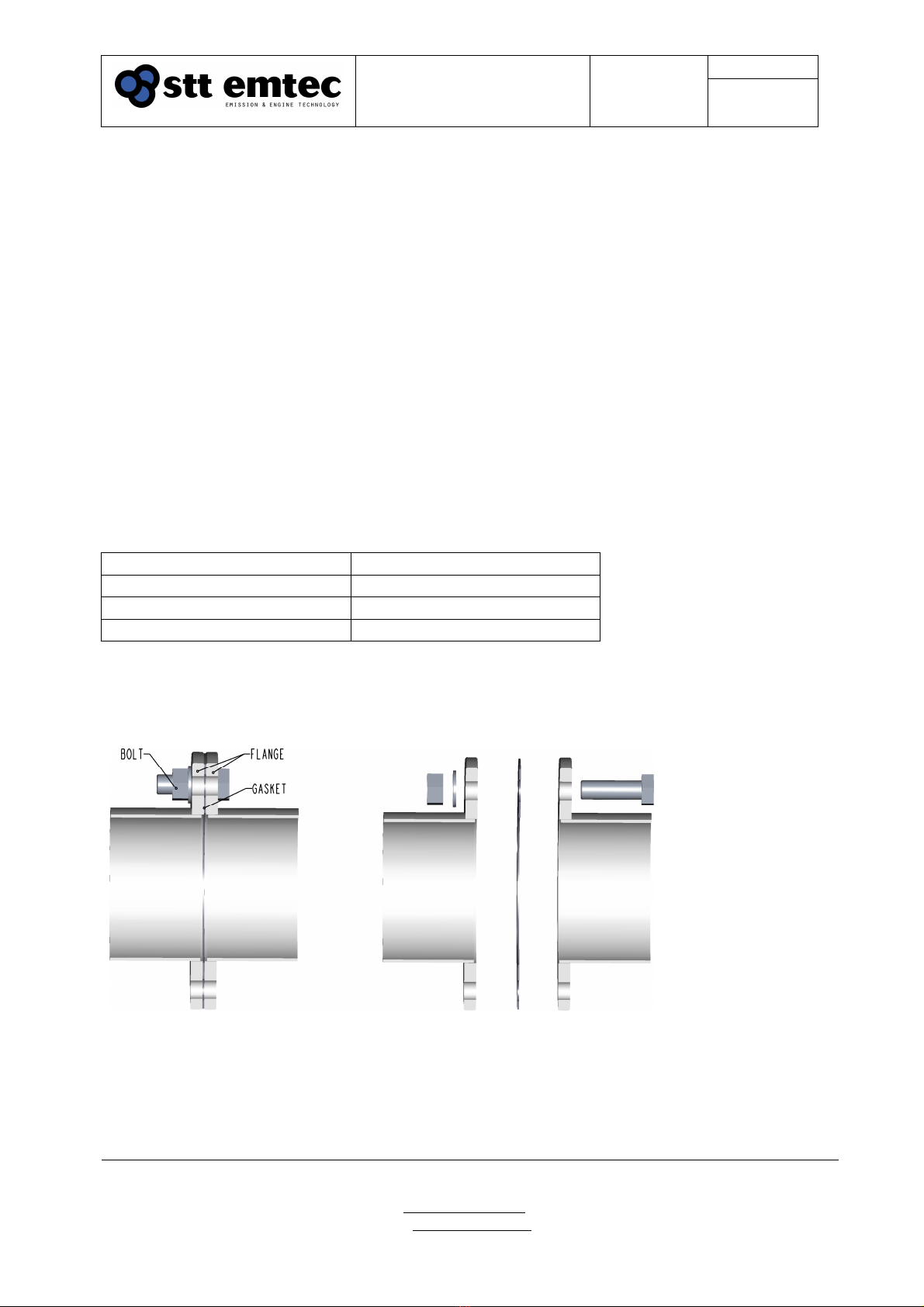

2.1 Flanges and gaskets

The canning of the exhaust components is produced of stainless steel with flanges on the

in- and outlet ports. The shape of the flanges can differ due to regulations and/or

customer demands. Please observe the type of flanges in the BOM for your SCRmarine

installation kit.

Table 1 Flange dimensions

Flange

Gasket part no

DN125 108665

DN150 109104

DN200 108893

Flanges are welded on the pipe ends. The flange pairs are mounted together with a

1.5mm stainless steel reinforced graphite gasket. For attachment, 8 - 16 pcs of zinc

plated screws (or stainless) M16x60 8.8 with nuts and washers are used.

Figure 3.

Flange pair, installed and exploded view

Document

STT SCRmarine

Installation Guideline

Date

2019-05-15

Page

10

Issue: 1.8

STT Emtec AB (pbl)

Box 46, Njurundavägen 16A

SE-862 02 NJURUNDA

SWEDEN

Tel: +46 (0)60

-

64 10 40

Fax: +46 (0)60 64 10 45

e-mail: info@sttemtec.com

Internet: www.sttemtec.com

Head office:

Njurunda

Org.nr: 55 62 05 – 2927

VAT ID: SE556205292701

ISO-cetrifikat nr: 15627

2.2 Thermal expansion

Relative movements and heat extension must always be considered when routing and

installing exhaust pipes. Use gastight flexible parts and compensators when necessary.

In general a heat expansion of 1-2 mm /meter piping for every 100°C can be used as a

rule of thumb.

2.3 Insulation

All exhaust components and the pipes leading from the engine need insulation. The

purpose of the insulation is to retain required operating exhaust temperature for the SCR

catalyst or POC at low load conditions and cold ambient temperatures. It is also

necessary to keep the surface temperature of the pipes and SCR mixer at a level where

condense is avoided. Insulation is also required to ensure the engine crew safety and

protection of the surrounding areas.

It is important to leave space for the insulation at the installation. In a typical installation

the insulation is minimum 50 mm thick. Additional insulation may be required according

to regulations and/or customer demands.

Document

STT SCRmarine

Installation Guideline

Date

2019-05-15

Page

11

Issue: 1.8

STT Emtec AB (pbl)

Box 46, Njurundavägen 16A

SE-862 02 NJURUNDA

SWEDEN

Tel: +46 (0)60

-

64 10 40

Fax: +46 (0)60 64 10 45

e-mail: info@sttemtec.com

Internet: www.sttemtec.com

Head office:

Njurunda

Org.nr: 55 62 05 – 2927

VAT ID: SE556205292701

ISO-cetrifikat nr: 15627

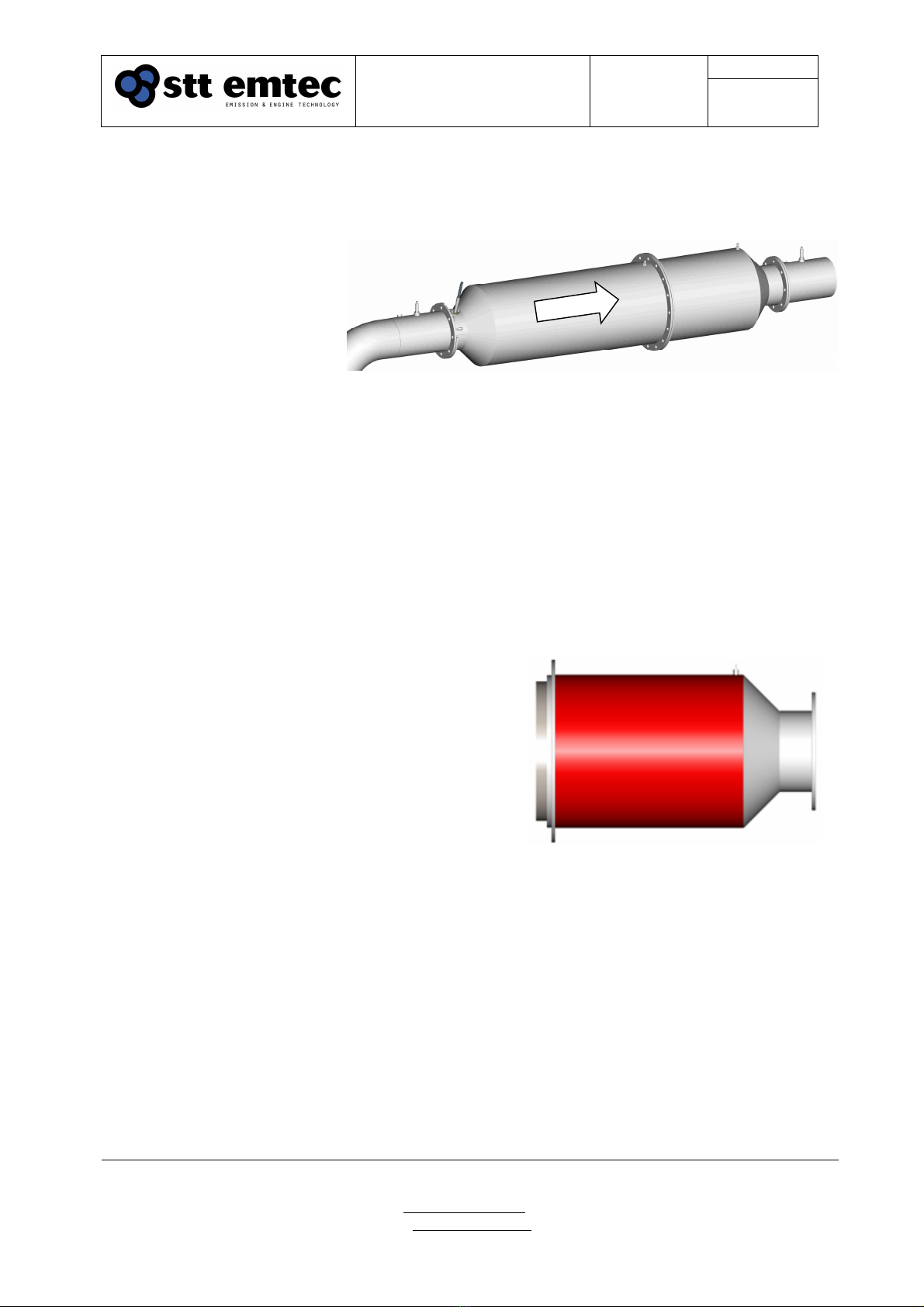

2.4 Exhaust mixer and SCR chamber (SCR assembly)

2.4.1 Function

In the SCR catalyst

chamber a chemical

reaction that converts NOx

and DEF into Nitrogen and

Water takes place. The

first part of the SCR

assembly is the exhaust

mixer which ensures that

the injected mixture of

DEF and air gets

thoroughly and

homogenously atomized before entering the catalyst chamber. The catalyst is only active

in temperatures above 220°C and it is therefore important that the whole SCR assembly,

and the pipes leading to it, are well insulated to preserve as much of the exhaust

temperature as possible, especially in low load and low ambient temperature conditions.

2.4.2 Installation

The SCR assembly can be installed in either vertical or horizontal position. The exhaust

mixer shall face the engine. The flange pairs are mounted with a 1.5mm stainless steel

reinforced graphite gasket, see section Flanges. It is important to leave space for the

insulation at the installation, see section

Insulation. Additional brackets to support the

catalyst assembly are required due to the weight

of the catalyst. The design of the support may be

depending on the surroundings and support of

other parts. STT Emtec recommends the use of

metal resilient elements type Vibratec® or

similar.

Welding is not allowed on the catalyst chamber

in the red area marked in figure 5. The catalyst

contains sliding parts for heat elongation

handling which can be damaged by welding.

2.4.3 Maintenance

The SCR is designed not to trap soot and therefore virtually maintenance free. It is

recommended to regularly check flanges for tightness and to verify the NOx converting

function of the catalyst. NOx conversion verification must be performed by trained

personnel only; please contact STT Emtec for more information. See also Appendix 03 –

Maintenance for further information

Exhaust

mixer

SCR

chamber

Exhaust flow

direction

Figure 4.

SCR assembly

Figure 5.

SCR chamber. The red area shows where

welding is not allowed.

Document

STT SCRmarine

Installation Guideline

Date

2019-05-15

Page

12

Issue: 1.8

STT Emtec AB (pbl)

Box 46, Njurundavägen 16A

SE-862 02 NJURUNDA

SWEDEN

Tel: +46 (0)60

-

64 10 40

Fax: +46 (0)60 64 10 45

e-mail: info@sttemtec.com

Internet: www.sttemtec.com

Head office:

Njurunda

Org.nr: 55 62 05 – 2927

VAT ID: SE556205292701

ISO-cetrifikat nr: 15627

2.5 POC (Particle Oxidation Catalyst)

2.5.1 Function

The POC is designed to trap soot and works with a

combination of wall-flow and partial flow to guarantee

trouble free engine operation without active

regenerations. The separated particles are reduced by

a continuous reaction with NO2.

The POC is an option and may not be included in all

SCRmarine systems.

2.5.2 Installation

The POC can be installed in either horizontal or vertical

position but must be installed as close as possible to

the turbocharger outlet. The POC shall be installed upstream of the Exhaust mixer and

SCR chamber. The POC and the exhaust pipe leading to it must be insulated in order to

preserve as much exhaust temperature as possible from the engine, but also to ensure

the engine crew safety and protection of the surrounding areas since the POC is typically

installed in the engine room.

The flange pairs are mounted with a 1.5mm stainless steel reinforced graphite gasket,

see section Flanges. It is important to leave space for the insulation at the installation,

see section Insulation.

Additional brackets to support the POC assembly may be needed depending on the

surroundings and support of other parts. STT Emtec recommends the use of metal

resilient elements type Vibratec® or similar. Additional insulation may be used according

to regulations and/or customer demands. It is important to leave space for the insulation

at the installation. In a typical installation the insulation is minimum 50 mm thick. Observe

the exhaust flow direction arrow on the POC.

Note! The flow direction arrow must be pointing

with the exhaust flow.

2.5.3 Maintenance

The POC is maintenance free but it is recommended to check for exhaust leaks at the

same time as the rest of the exhaust system, see Appendix 03 - Maintenance

Figure

6

.

(Picture from Emitec)

Exploded view of the POC

Figure 7.

Flow direction arrow on the POC

Document

STT SCRmarine

Installation Guideline

Date

2019-05-15

Page

13

Issue: 1.8

STT Emtec AB (pbl)

Box 46, Njurundavägen 16A

SE-862 02 NJURUNDA

SWEDEN

Tel: +46 (0)60

-

64 10 40

Fax: +46 (0)60 64 10 45

e-mail: info@sttemtec.com

Internet: www.sttemtec.com

Head office:

Njurunda

Org.nr: 55 62 05 – 2927

VAT ID: SE556205292701

ISO-cetrifikat nr: 15627

3 DEF dosing components installation

This section provides information on installing and maintaining the DEF dosing

components of the SCRmarine.

3.1 General

The dosing components are designed to carry liquid DEF from the service tank to the

exhaust stream. When dehydrated the DEF solution will form salt deposits from its Urea

content. This salt is prone to block the supply lines and the dosing components. The

following guidelines are intended to ensure that the system can evacuate DEF thoroughly

when injection is not required, i.e. when the engine is stopped, in order to avoid forming

deposits.

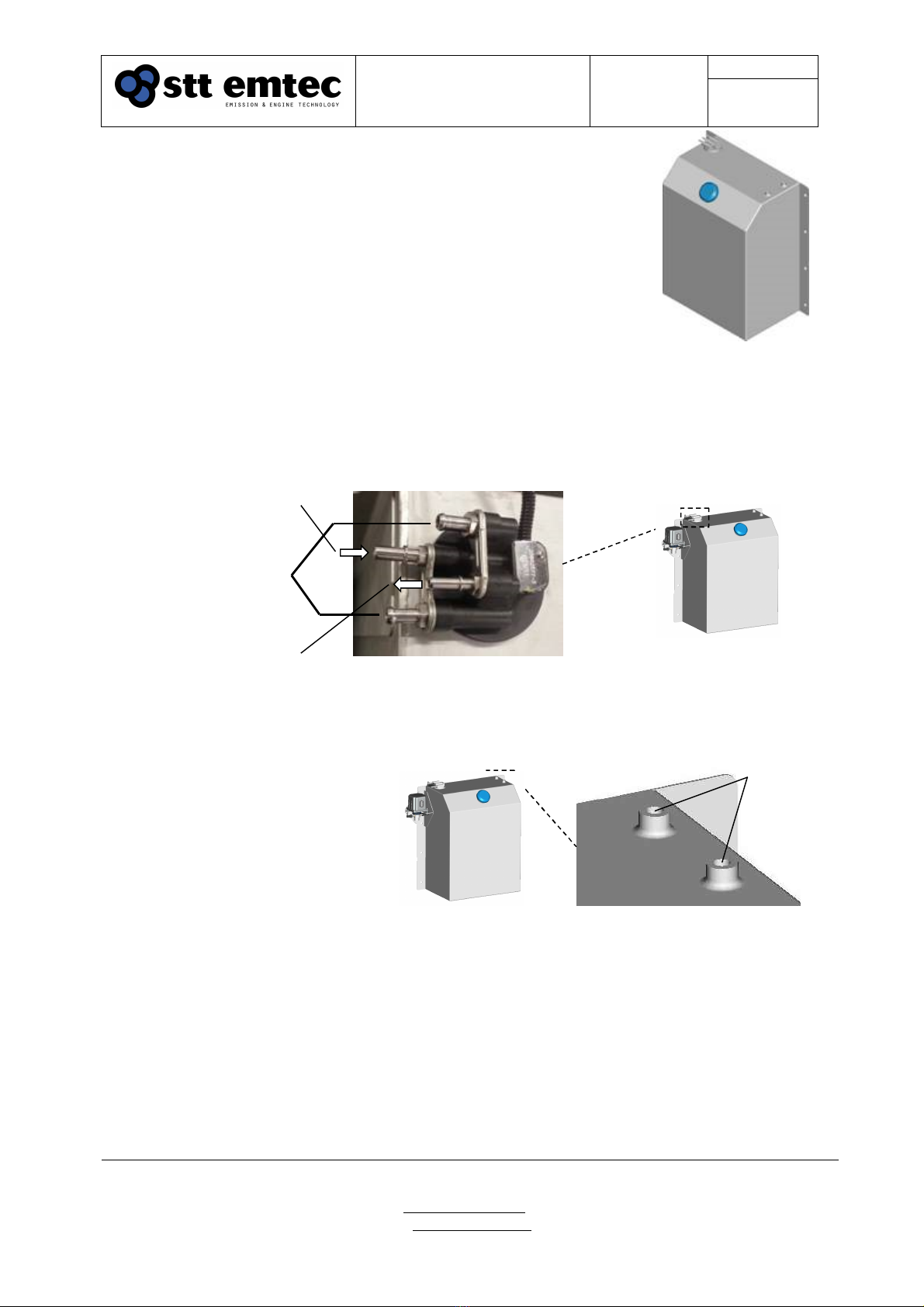

3.2 Components placement

When positioning the injection components it is important to consider their relative

positions in altitude. It is also important to maintain a constant slope of the pipes or hoses

carrying DEF and to avoid any air pockets.

These rules serve to accomplish a good evacuation of DEF from the injection

components

DDU above

mixer

DDU above

DEF supply

pump

DEF supply pump

above DEF

service tank (or

mounted on tank)

Figure 8.

Relative positioning of

injection components

Document

STT SCRmarine

Installation Guideline

Date

2019-05-15

Page

14

Issue: 1.8

STT Emtec AB (pbl)

Box 46, Njurundavägen 16A

SE-862 02 NJURUNDA

SWEDEN

Tel: +46 (0)60

-

64 10 40

Fax: +46 (0)60 64 10 45

e-mail: info@sttemtec.com

Internet: www.sttemtec.com

Head office:

Njurunda

Org.nr: 55 62 05 – 2927

VAT ID: SE556205292701

ISO-cetrifikat nr: 15627

3.3 DEF supply lines

3.3.1 Function

The DEF lines (Service tank - - Supply pump, Supply pump - - Dosing unit, Dosing unit - -

service tank) carry the DEF from the tank to the DEF dosing unit. The lines supplies in

the kit are made of polyamide (PA) or reinforced rubber with SAE quick lock fittings

matching those of the service tank, supply pump and DEF dosing unit. Other materials

requested must be supplied by installer and/or yard.

3.3.2 Installation

The DEF lines can be made either of stainless steel tubes, steel braided teflon hoses,

reinforced rubber hoses suitable for DEF or polyamide (PA) hoses. Depending on the

application, the connectors can be of compressed type (cone sealing) or SAE quick lock

type with O-ring sealing.

All DEF lines, suction- as well as pressure lines, have to be routed as straight as possible

to prevent air pockets which may have a negative impact on post injection drainage and

lead to freezing and other blockage. The inner diameter of hoses or pipes must be

minimum 4 mm and they must withstand a pressure of 20 bar.

Due to the volatility of the DEF; when using other lines than the supplies PA hoses, make

sure that all fittings are tight. Stainless steel compression fittings are very difficult to get

tight when carrying DEF.

Note! DEF is very volatile and will slip thru the slightest gap! Make sure all

connections are tight!

3.3.3 Maintenance

There supplied PA hoses are maintenance free.

Fittings are allocated according to the following table:

Table 2 DEF fittings

From

To

Fitting

DEF service tank DEF supply pump SAE 3/8”

DEF supply pump DEF dosing unit SAE 3/8”

DEF dosing unit DEF service tank SAE 5/16”

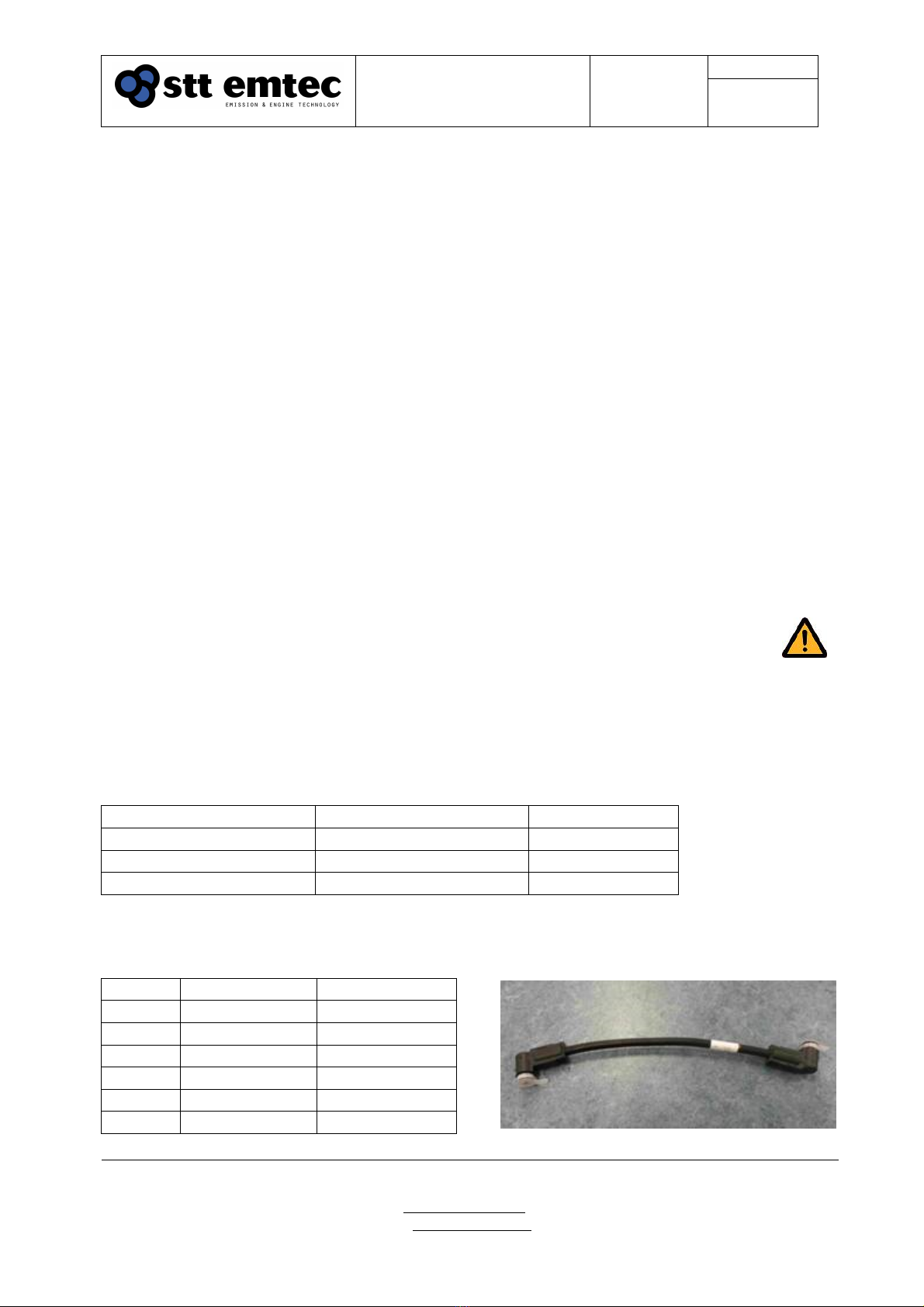

PA hoses with prefabricated fittings are available in the following lengths:

Table 3 DEF PA hoses part no

Length

SAE 3/8”

SAE 5/

16”

0.4 108744 108745

2 107462 107463

3 107997 107994

4 107998 107995

5 107999 107996

7 108344 108345

Figure

9

.

PA hose, 0.4m

Document

STT SCRmarine

Installation Guideline

Date

2019-05-15

Page

15

Issue: 1.8

STT Emtec AB (pbl)

Box 46, Njurundavägen 16A

SE-862 02 NJURUNDA

SWEDEN

Tel: +46 (0)60

-

64 10 40

Fax: +46 (0)60 64 10 45

e-mail: info@sttemtec.com

Internet: www.sttemtec.com

Head office:

Njurunda

Org.nr: 55 62 05 – 2927

VAT ID: SE556205292701

ISO-cetrifikat nr: 15627

3.4 DEF service tank

3.4.1 Function

The service tank provides the DEF dosing unit with AdBlue®.

The liquid is pumped from the tank by using the DEF supply

pump normally mounted on the side of the tank. A built-in level

sensor is used by the control system to indicate refill on the

system display. The service tank has a filling cap for manual

filling and the cap is ventilated.

3.4.2 Installation

The DEF service tank can be mounted on additional brackets and has to be attached

firmly. The service tank connects to the DEF supply pump (suction line) and to the DEF

dosing unit (pressure line) thru nipples at the tank top.

3.4.3 Bulk tank

The tank also has two spare

bosses (M12x1.5) to the right at

the top of the tank suitable for

automatic refill from a bulk tank.

One of the connections should

be used to vent the service tank

to atmosphere during filling. If a

bulk DEF tank is located in the

vessel and the service tank is

permanently connected by a line

or hose, there must be a mechanical shut-off valve before the service tank. This is in

order to prevent hydraulic lock of the engine, in case of a DEF pump breakdown.

The bulk tank and service tank refill system is not within STT Emtecs scope of supply.

An automated service tank refill system should implement a high level alarm.

The recommended material selection for a bulk tank is chromium nickel or chromium

nickel molybdenum steel. Note that no forms of copper alloy are allowed.

SAE 3/8” DEF return line

from DEF dosing unit

SAE 3/8” DEF suction line

to DEF supply pump

Figure

11

.

Nipples for DEF and coolant water circulation

Engine coolant water

circulation for cold

environment operation

Figure 10.

DEF service tank.

Figure 12.

Bosses for automatic filling

Bosses for

automatic

service tank

filling

Document

STT SCRmarine

Installation Guideline

Date

2019-05-15

Page

16

Issue: 1.8

STT Emtec AB (pbl)

Box 46, Njurundavägen 16A

SE-862 02 NJURUNDA

SWEDEN

Tel: +46 (0)60

-

64 10 40

Fax: +46 (0)60 64 10 45

e-mail: info@sttemtec.com

Internet: www.sttemtec.com

Head office:

Njurunda

Org.nr: 55 62 05 – 2927

VAT ID: SE556205292701

ISO-cetrifikat nr: 15627

3.4.4 Tank heating

If tank heating is required in a cold environment an autonomous temperature control

circuit must be implemented. Circulating high temperatures, such as 80+°C engine

coolant, water thru the tank will degrade the DEF solution.

The tank heating system is not within STT Emtecs scope of supply.

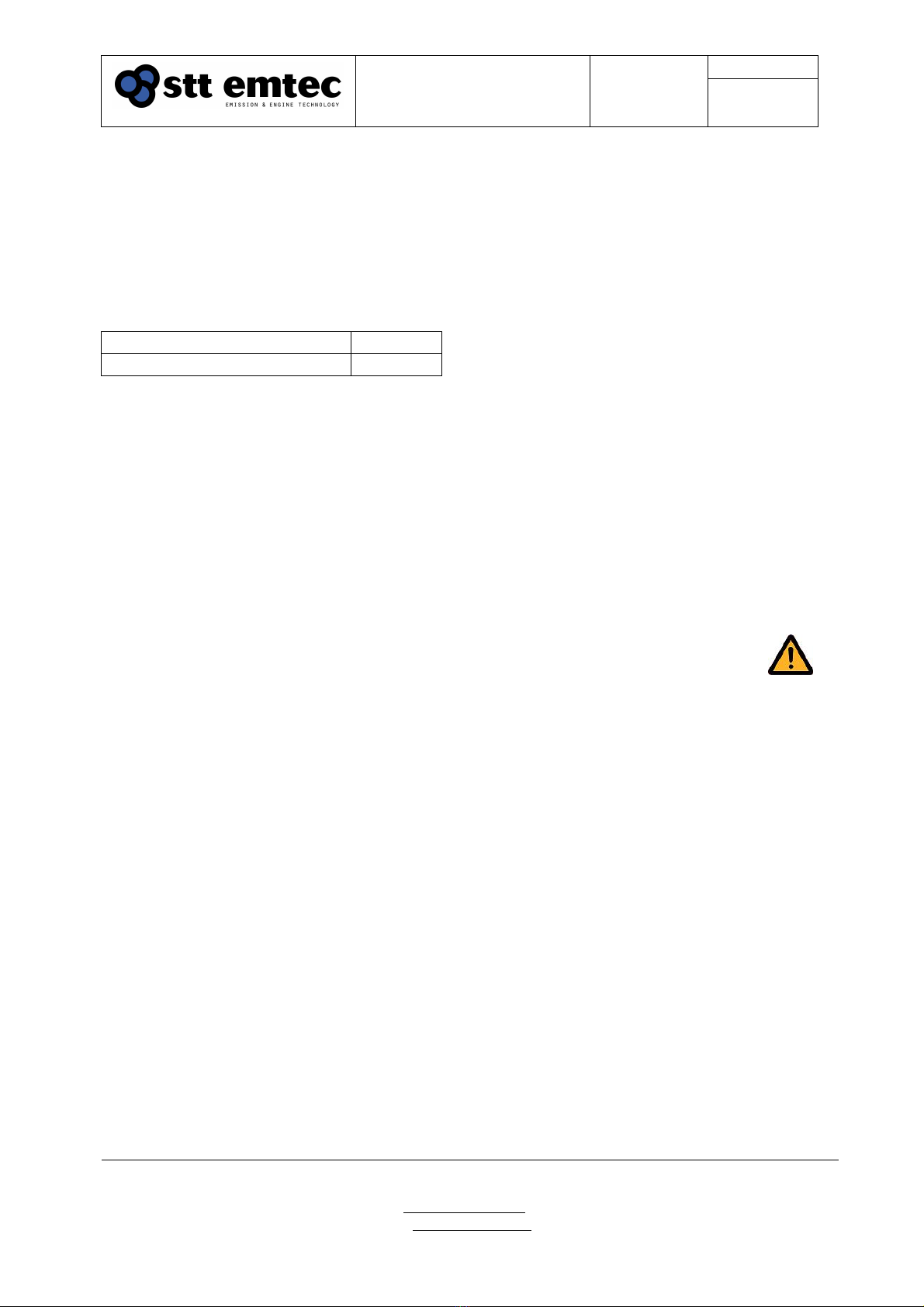

Table 4 DEF service tank part no

Detail

Part no

DEF service tank 100L 107598

The 100 liter tank is sufficient for at least 70 hours of normal operation on a 300 kW

engine. Different tank sizes are available upon request.

3.4.5 Maintenance

The mesh filter under the filling cap should be observed during filling.

The mesh filter in the bottom of the tank (fitted on the armature) should be checked, and

cleaned if necessary,

Note! Prevent DEF from getting in contact with the air line or its

connections. Any air equipment that has been polluted with DEF has to

be replaced. DEF liquid or crystals in the air inlet can cause blockage

and damage to the DEF dosing unit!

Document

STT SCRmarine

Installation Guideline

Date

2019-05-15

Page

17

Issue: 1.8

STT Emtec AB (pbl)

Box 46, Njurundavägen 16A

SE-862 02 NJURUNDA

SWEDEN

Tel: +46 (0)60

-

64 10 40

Fax: +46 (0)60 64 10 45

e-mail: info@sttemtec.com

Internet: www.sttemtec.com

Head office:

Njurunda

Org.nr: 55 62 05 – 2927

VAT ID: SE556205292701

ISO-cetrifikat nr: 15627

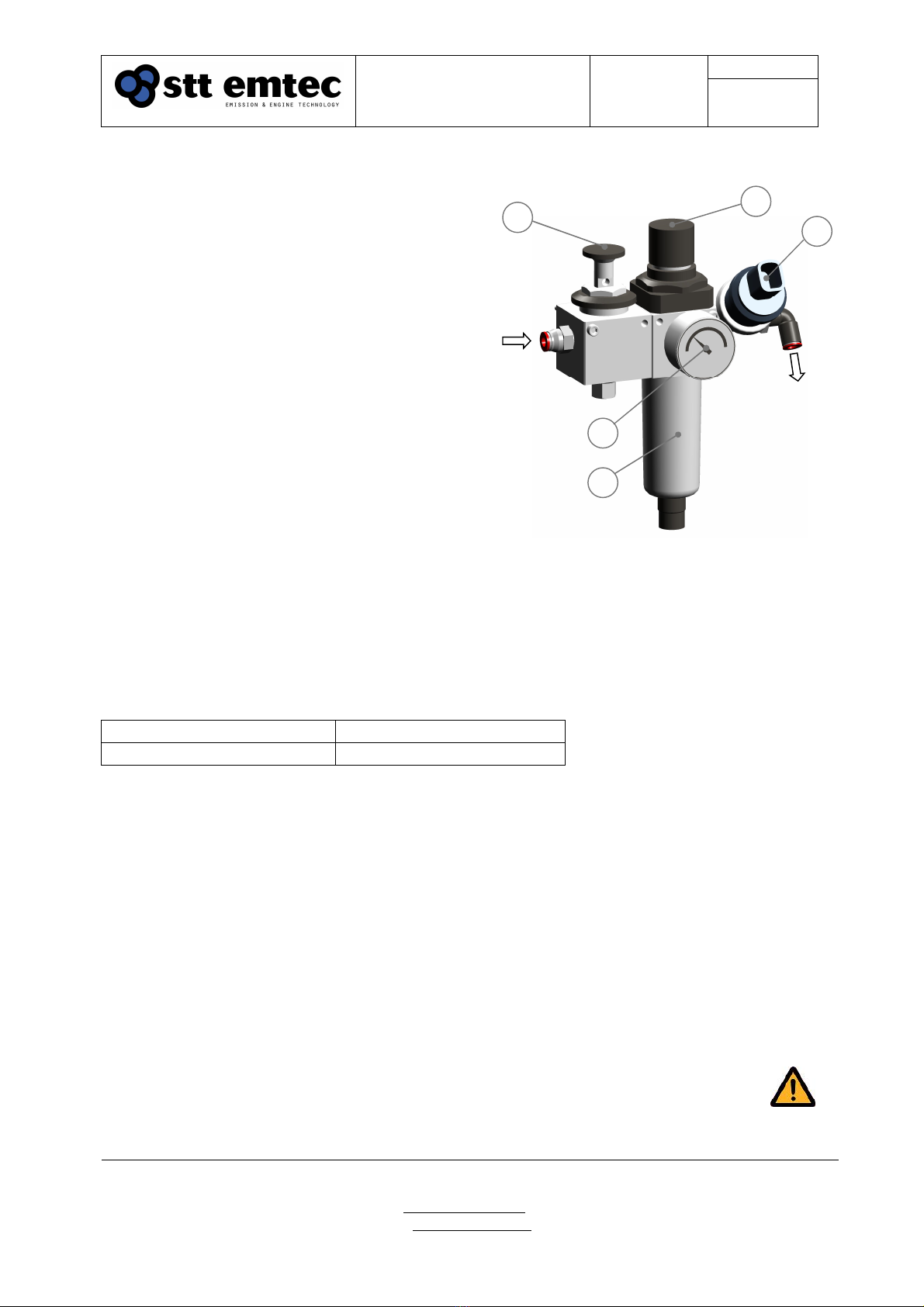

1

2

3

5

4

Air inlet from

external

compressor

Air outlet to

DEF dosing

unit

Figure 13. FR unit

1. Shut-off valve, 2. Pressure regulator, 3. Pressure switch,

4. Pressure gauge, 5. Condensate trap

3.5 FR unit

3.5.1 Function

The FR unit consists out of a

shut-off switch, a pressure

regulator with gauge, an

electronic pressure switch and a

condensate trap. The purpose of

the unit is to supply regulated air

pressure of 4.5 bar to the DEF

dosing unit. The pressure switch

fitted on the air outlet side is used

by the control system to indicate

air supply failure. The shut-off

switch on the FR unit should

always be open unless for safety

or maintenance purposes. If the

air supply needs to be shut off

always first shutdown the DDS by

releasing the Disabling switch

(right side fuse) in the control

cabinet and then wait for the

system display to read System OFF.

See section 5.2 Enabling and disabling.

Table 5 FR unit, part no

Detail

Part no

FR unit assembly 109105

3.5.2 Installation

The FR unit is connected to the vessel air pressure or an additional air compressor and

to the DEF dosing unit. Connections are typically made using Ø6mm PA hose but other

materials, such as stainless steel, may be required due to regulations.

The FR unit is normally located on the same mounting bracket as the DEF dosing unit

but may be relocated for space reasons. The unit comes assembled with Ø6 mm pneu-fit

quick release fittings on both inlet and outlet ports. The thread of the fittings is G1/4”

internal.

3.5.3 Maintenance

Check the condensate trap

Note! Do not attempt to disable the DDS by shutting off the air supply!

Blockage or damage to the injection components may occur!

See section Operating procedures – System shutdown.

Document

STT SCRmarine

Installation Guideline

Date

2019-05-15

Page

18

Issue: 1.8

STT Emtec AB (pbl)

Box 46, Njurundavägen 16A

SE-862 02 NJURUNDA

SWEDEN

Tel: +46 (0)60

-

64 10 40

Fax: +46 (0)60 64 10 45

e-mail: info@sttemtec.com

Internet: www.sttemtec.com

Head office:

Njurunda

Org.nr: 55 62 05 – 2927

VAT ID: SE556205292701

ISO-cetrifikat nr: 15627

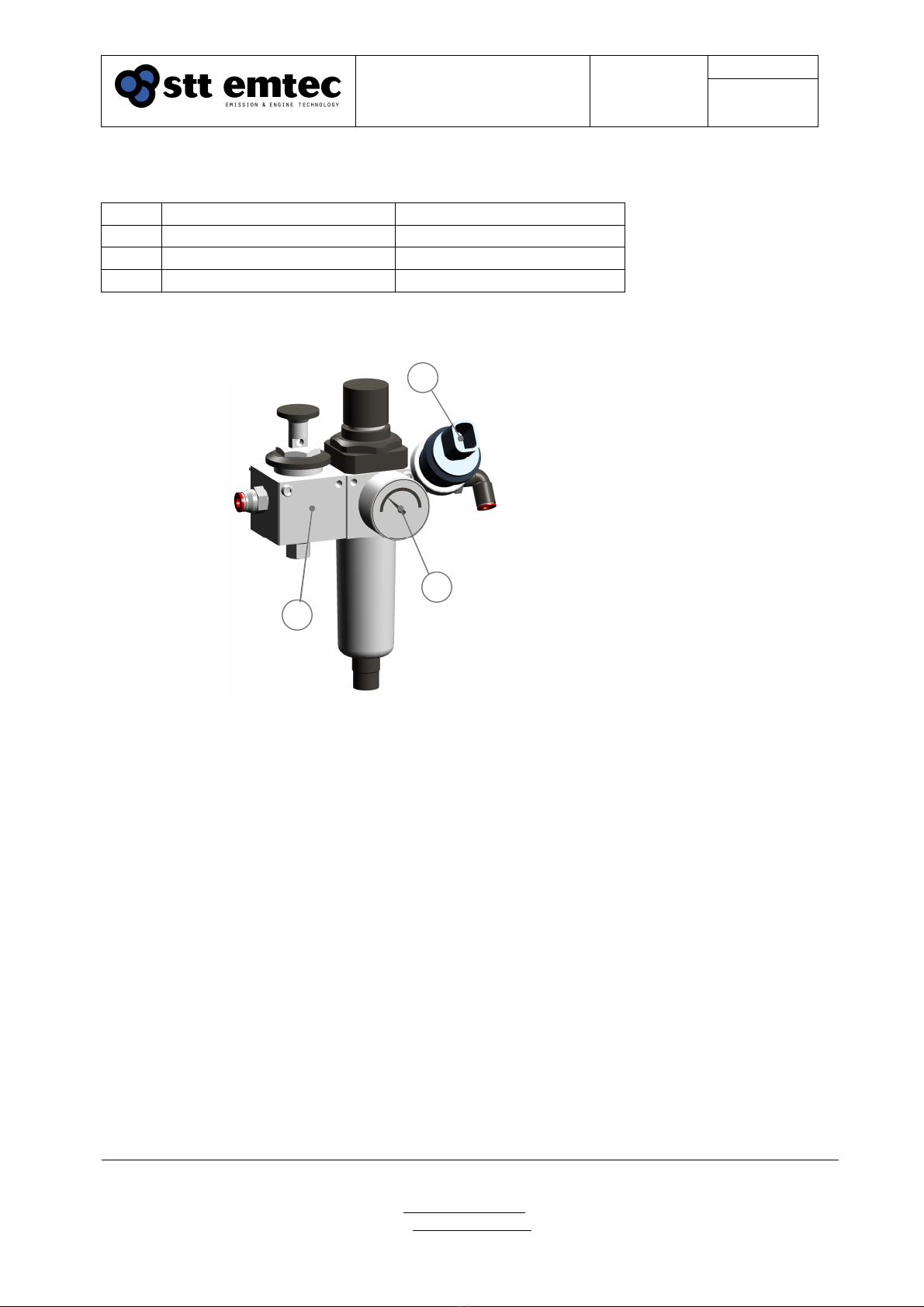

1

3

4

Figure 14.

FR unit

Spare parts

Table 6 FR unit, spare parts

Pos

Detail

Part no

1 Air regulator 107357

2 Gauge/manometer 108859

3 Pressure switch 108984

Document

STT SCRmarine

Installation Guideline

Date

2019-05-15

Page

19

Issue: 1.8

STT Emtec AB (pbl)

Box 46, Njurundavägen 16A

SE-862 02 NJURUNDA

SWEDEN

Tel: +46 (0)60

-

64 10 40

Fax: +46 (0)60 64 10 45

e-mail: info@sttemtec.com

Internet: www.sttemtec.com

Head office:

Njurunda

Org.nr: 55 62 05 – 2927

VAT ID: SE556205292701

ISO-cetrifikat nr: 15627

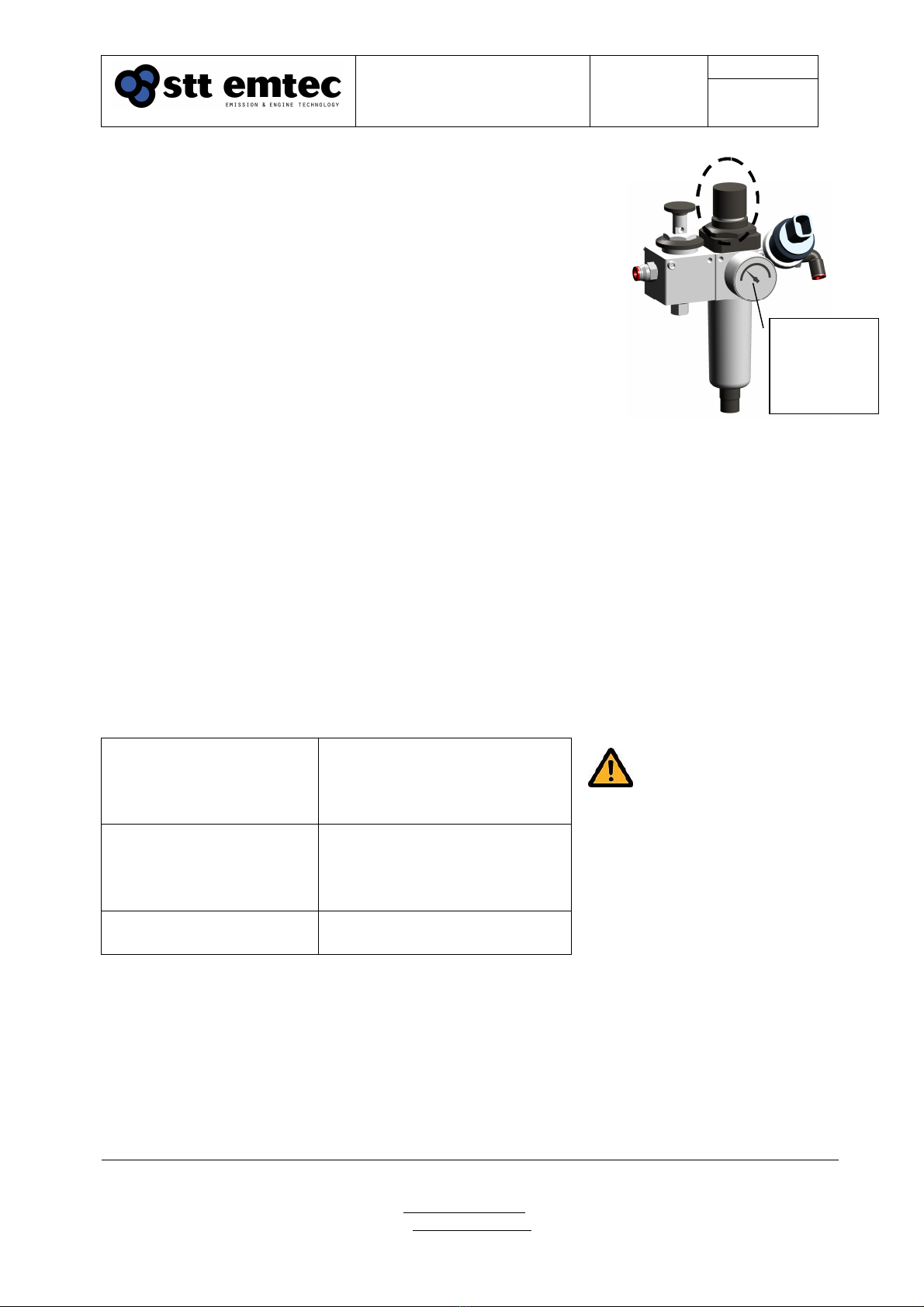

3.5.4 Adjusting the air pressure

The air pressure regulator is located on the right hand side

of the FR-unit. Max allowed inlet pressure is 16 bar and has

to be adjusted to 4.5±0.2 bar. Use the manometer on the

FR-unit when adjusting the air pressure.

Use the Diagnostic display, see section 5.4, to verify the

main air pressure;

1. Stop the engine

2. Go to the Actuator test page (Main page ↓ Key down)

3. Step to the AIR test (→Key right)

4. Activate the Atomization air valve (↓ Key down)

5. ‘Nozzle prs’ shall read 1600±200 mbar when correct

air pressure is adjusted

Note: The ‘Nozzle prs’ indicates the backpressure in the

injection nozzle resulting from the air flow thru the DEF dosing unit. This pressure level

should not be confused with the gauge reading of the pressure on the FR unit!

3.5.5 Air compressor considerations

Compressed air should be provided from the vessel air supply with installed oil separator.

If the compressed air supply includes an air dryer, then if possible, take the air supply to

the urea pump before the air dryer. If a compressed air system is not available a

separate air compressor has to be installed. Table 7 below contains STT Emtec’s

recommendations for the air compressor.

Table 7: Compressor data recommendations

Air consumption 40 l/min FAD

80 l/min peak (at flush)

Regulated pressure 4,5±0,2

Bar (gauge pressure)

Recommended

compressor capacity 290 l/min FAD

8-10 bar capacity

Screw compressors are

recommended

Tank volume Min 90 l to reduce the

compressor load time

When using a compressor driven by the engine, either by direct (e.g. belt-) drive or when

the engine supplies electrical power to the compressor, the same capacity requirements

as above regarding the compressor are recommended. However when the engine stops

so does the compressor and in this case the tank volume must be sufficient to handle

post-operation component cleaning.

Minimum tank volume depends on the pressure according to the following calculation:

Tank volume= 180/(pressure-4.5) liters (pressure expressed in bar)

Adjust to:

4.5 bar

gauge

Figure 15

FR unit

Note!

Piston type

compressors are

typically not designed for

continuous operation and

power capacity and tank size

must be selected with this in

mind.

Document

STT SCRmarine

Installation Guideline

Date

2019-05-15

Page

20

Issue: 1.8

STT Emtec AB (pbl)

Box 46, Njurundavägen 16A

SE-862 02 NJURUNDA

SWEDEN

Tel: +46 (0)60

-

64 10 40

Fax: +46 (0)60 64 10 45

e-mail: info@sttemtec.com

Internet: www.sttemtec.com

Head office:

Njurunda

Org.nr: 55 62 05 – 2927

VAT ID: SE556205292701

ISO-cetrifikat nr: 15627

3.6 DEF supply pump

3.6.1 Function

The DEF supply pump delivers pressurized DEF liquid to the

DEF dosing unit. Liquid that is not metered by the DDU is

returned to the service tank. The supply pump is speed- and

direction controlled by the ECU in the control cabinet. During

post injection the pump is reversed to assist in the evacuation

of the injection lines.

3.6.2 Installation

The preferred mounting position of the DEF supply pump is on

the left side of the DEF service tank near the tank fittings. The

pump bracket is designed to match the mounting holes of the

service tank. Should this location not be suitable the DEF supply

pump can be positioned within 0.2 metres below (equals max

DEF filling level) to 1.0 metres above the service tank top, see

figures 17-19. The low position restriction is to prevent drainage

of the tank and the high position limit is to ensure priming of the

supply pump under all conditions, Maximum length of the suction

line from the service tank to the supply pump is 2 metres.

The supply pump connects to the service tank and to the dosing

unit according to Figure 16.

3.6.3 Maintenance

The DEF supply pump is maintenance free

Table 8 DEF supply pump, part no

Detail

Part no

DEF supply pump 108918

Figure 17

Default (and lowest) DEF supply

pump mounting position

Figure 19

Mounting the DEF supply pump

below default position is not ok!

DEF pressure

line to dosing

unit

DEF suction

line from

service tank

Figure 16

DEF supply pump interface

Figure 18

Max elevation of DEF

supply pump

Max 1.0 m

above tank

top

Other manuals for SCRmarine

1

Table of contents

Popular Service Equipment manuals by other brands

Sealey

Sealey AK462DX.V2 quick start guide

Motorvac

Motorvac CARBONCLEAN MCS 245 Operator's manual

Chicago Pneumatic

Chicago Pneumatic CP87700 Operator's manual

Tektino

Tektino RCC-9A Maintenance manual

Selecta

Selecta DIESELPAK 300 instruction manual

Schumacher Electric

Schumacher Electric DSR PROSERIES DSR136 owner's manual