Lavo Solutions CLEANJET User manual

Rev. AA| 122020

1

CLEANJET

SPRAYER / FOAMER

2

TECHNICAL CHARACTERISTICS:

Water supply

connection Connection on left side with elbow

Inlet connection type Female ¾” GHT

Outlet connection type Male ¾” GHT

Chemical product

channel flow rate

Water supply of 8gal/min flow rate and 50psi: 2.5 gal/min

Rinse channel flow rate

Water supply of 8gal/min at 50psi: 3.4 gal/min

Maximum dimensions

H = 400mm (15.75”)

L = 330mm (13”)

D = 160mm (6.3”)

Working pressure Min 22 PSI (1.5 bar) Max 85 PSI (6 bar)

Optimum: 30 – 60 PSI (2 – 4 bar)

Temperature

Max 140°F (60°C)

PLEASE READ THE FOLLOWING WARNINGS BEFORE INSTALLING OR SERVICING THE CLEANING

STATION

Make sure that the water supply pressure is between 22 -85 PSI, in case of excessive pressure use a

pressure regulator to avoid breackage.

Make sure that the water supply temperature does notexceed 140° (60°C)

The ProTwin’s fittings have been tested with commonly used liquid detergents mixed with water.

Check that the detergent used is compatible with polypropylene.

Install the station near as possible to a water supply connection point.

Mount the CleanJet considering easy access for cleaning and routine maintenance.

WARNING: Disconnect water supply before servicing theCleanJet.

WARNING: THE MAXIMUM OPERATING PRESSURE is 6bar (85 PSI) and isintended asa maximum

static pressure applicable to thesystem. Care should betaken that the equipment cannot produce

scenarios of over pressurization, which could cause damage to the structure of the system. The use

of a pressure reducer isalways recommended and theinstallation of a tap onthewater outlet of the

system which can be closed when thesystem itself is not in use.

WARNING: Follow common safety procedures. Use adequate protection forthe eyes, face, hands,

and clothing.

We constantly work to improve our products and reserve the right to make changes at any time

without prior notice.

Failure to follow these safety precautions may cause personal injury or damage to the equipment.

Only use recommended accessories.

3

INSTALLATION

The CleanJet should be installed where it is easily connected to the water supply.

Before mounting, check that allvalves can be easily operated and exposed surfaces are accessible for cleaning

and routine maintenance.

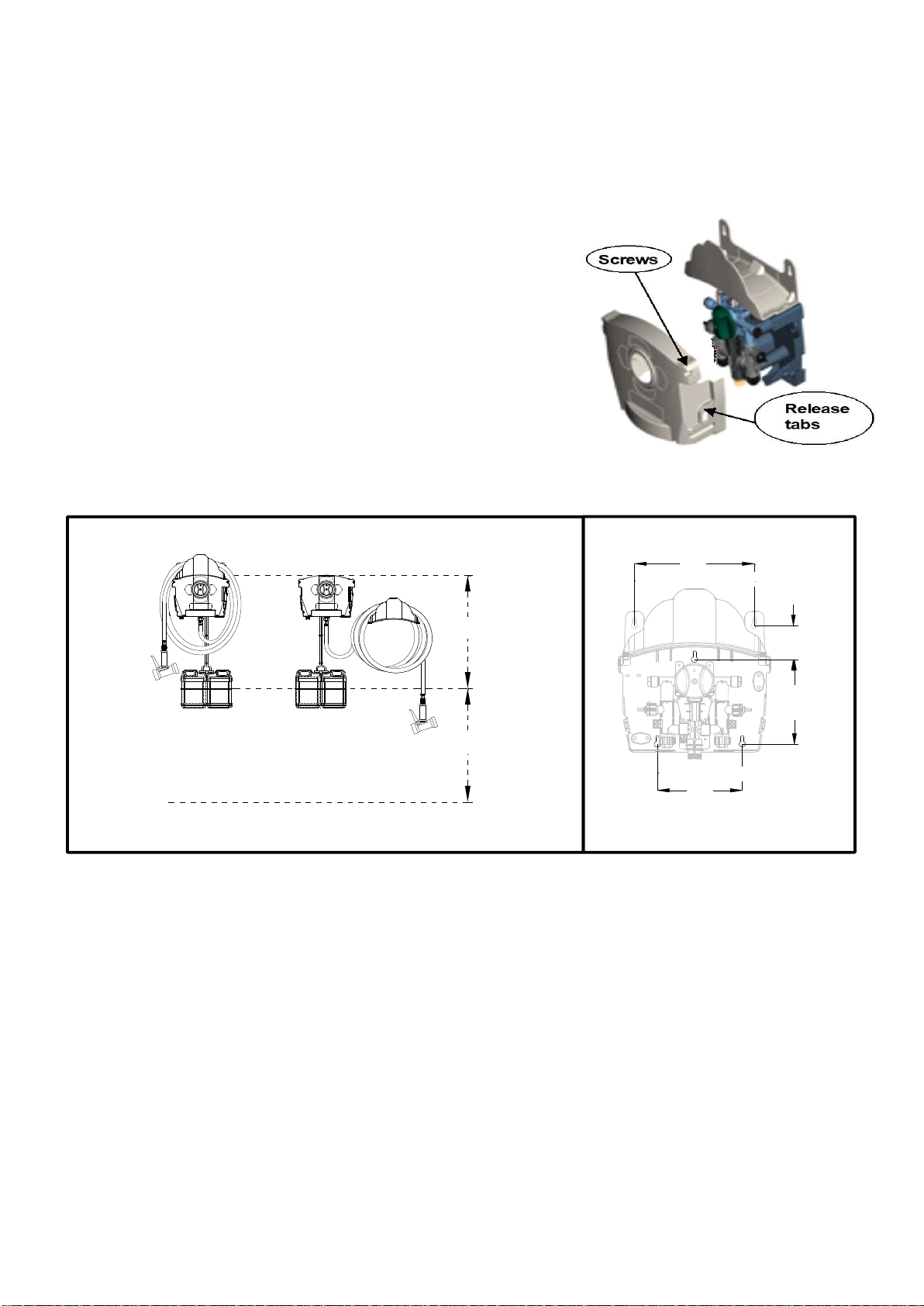

Positioning and drilling plans:

Remove the CleanJet from the box and remove the cover byremoving

the screws at the top and pressing the release tabs. You can now access

to the mounting holes (located on the rear panel). Mount the CleanJet on

the wall using the supplied anchors, screws and washers.

The versatility of the CleanJet allows the hose bracket to be installed as

an integrated part of the unit or mounted independently as pictured

below.

Figure 2 – Drilling plans and positioning

GROUND

700 mm (27,56’’)

700 mm (27,56’’)

248.9 mm

(9,

8’’)

177.8 mm

(7,

0’’)

198.1 mm

(7,8’’)

78.7 mm

(3,1’’)

PACKAGE CONTENTS:

1. CleanJet System

2. Suction hose 1.83m / 6ft(1 roll for eachproduct)

3. Hose bracket

4. Complete installation kit:

-Water inlet elbow fitting ¾” GHT

-Plastic hoseclamps (2 for each product)

-15 metering tips (1 bag for each product)

-4 ultra-lean tips (1 bag for each product)

-Foot valve (1 for each product)

-Ceramic weight (1for each product)

- Suction elbow (1 for each product)

-Wall anchors (3 pcs)

-Screws (3 pcs)

-Washers (3 pcs)

4

How to install:

Figure 3 –Installation

1. Disconnect the 90° water inlet from the station by rotating it 45°counterclockwise to unlock it.Then connect

the water inlet hose;

2. Reconnect the 90° inlet fitting back into the CleanJet,tilting by45°to its side, consecutively rotate 45°

clockwise to lock the connection;

3. Secure the hose to CleanJet through the clamp and the screw supplied as shown;

4. Drill the top ofthe product container using a 3/8 drill bit;

5. Slide the cap, ceramic weight onto the bootom of the supplied product pick up tube. Connect to the foot

valve as in figure above.

6. Connect the pick up tube to the CleanJet as follows:

a. Select the ' nozzle calibration produced according to the table to be inserted into the aspiration valve as

shown in the figure;

b. Insert the link at 90°;

c. For each product, place the aspiration tube into the fitting 90° and then fix it with plastic cable tie.

7. Attach the discharge hose to ¾ Male GHT fitting at the bottom of the CleanJet;

8. Attach the dosing gun.

5

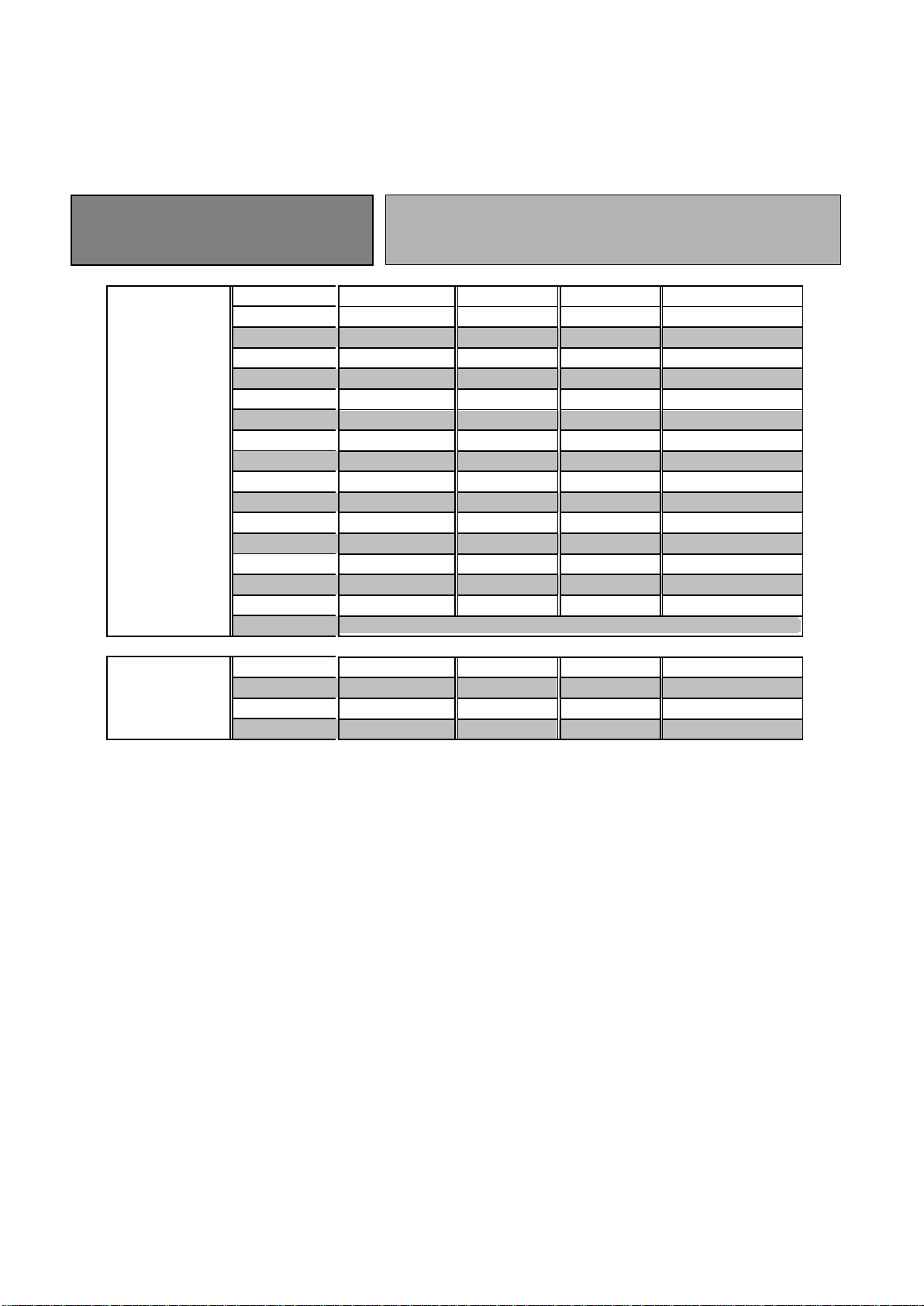

DILUTION RATIO CHART

The dilution ratio can be achieved by using one of the 19 supplied metering tips;

Metering tips have small openings of decreasing diameter and are distinguished by different colors.

Table 1 below shows the dilution ratio’s of the various colored tips assuming chemical viscosity of 1 cps (water thin)

(Water supply pressure and flow rates will vary so adjustments in the field may be necessary)

The dilution ratios refer to a static pressure of

50PSI with products

having a viscosity of 1 cps

Black Venturi

2.5 GPM

STANDARD

MEASUREMENT

TIP

Tip color: Oz/Gal gr/lt % Ratio

No tips 24.8 186 18.6 5:1

Grey 24.5 183 18,3 5:1

Black 24.4 183 18.2 5:1

Beige 20.9 156 15.6 6:1

Red 15.2 114 11.4 9:1

White 10.2 76 7.6 12:1

Blue 8.4 63 6.3 15:1

Tan 6.5 49 4.9 20:1

Green 4.4 33 3.3 32:1

Orange 4.0 27 2.7 36:1

Brown 2.6 19.6 2 50:1

Yellow 2.016.5 1.6 64:1

Acqua 1.8 13.4 1.3 70:1

Purple 1.0 6.6 0.6 128:1

Pink 0.503.4 0.3 256:1

Transparent No drill

ULTRAFINE TIP

Lime 0.40 2,6 0.26 320:1

Burgundy 0.35 2,8 0.28 365:1

Pumpkin 0.30 2,2 0.22 425:1

Copper 0.251,8 0.18 512:1

Table 1 – The dilution values given in this table are measured at a flow rate of 8 gpm and a supply

pressure of 50psi with a delivery hose of 15.24 m (50 ft).

The values in the table should be considered only as a reference, as they are dependent on many variables such

as water flow rate, pressure, chemical viscosity, temperature of the water etc.

To obtain a proper dilution it is recommended to perform the calibration as follows:

1. Fill a graduated container with the chemical product.

2. Using the Table 1, select and insert the metering tip closest to the desired dilution ratio for the product.

3. Insert the suction hose into the graduated container.

4. Select the product to be calibrated by turning the selector to the left or to the right.

5. Activate the spray gun and discharge into a container until the suction and delivery hoses are completely

full and free of air (check for air bubbles at the input and for a steady output stream).

6. Mark the level in the graduated container.

7. Turn on the spray gun to the maximum and discharge into a 1 liter or 1 gallon container (or other volumes

considering the proportion).

8. Turn off the spray gun when the container is completely filled.

9. Read the amount of product in the graduated container.

10. The difference of level between the point 8 and 5 indicates the amount of mixed product per gallon.

11. Repeat the calibration procedure for the other product.

A transparent metering tip is also provided without a pre-drilled opening.

This tip can be manually drilled to obtain a customized degree of dilution.

6

Operation

The CleanJet allows the dilution of chemical products with water without

using an electrical or other power source. The only energy required is the

pressure of the water passing through a venturi which aspirates a metered

chemical into the flow of water through the venturi.

When the installation is properly completed,follow these steps:

1. Turn on the water supply

2. Select the desired cleaning phase

-Selector facing up “OFF”

-Selector facing right “PRODUCT N° 1”

-Selector facing down “RINSE”

-Selector facing left “PRODUCT N° 2”

3. Activate the spray gun

4. Shut off the water supply when not in use

Accessories & Options:

The CleanJet Sprayer comes standard with Blue Trigger Sprayer (PN 410-0001) and 25 ft Black Hose (PN 410-0002).

Black Fan Foaming attachment (no air required) - PN 410-0007

Faoming Wand and Gauge System (air required) - PN 410-0008

AutoScubber Gun Attachment; 3/4" Hose Barb Fitting - PN 400-0048

25ft Hose; 3/4" FGHT x 3/4" MGHT - PN 410-0002 (not shown)

7

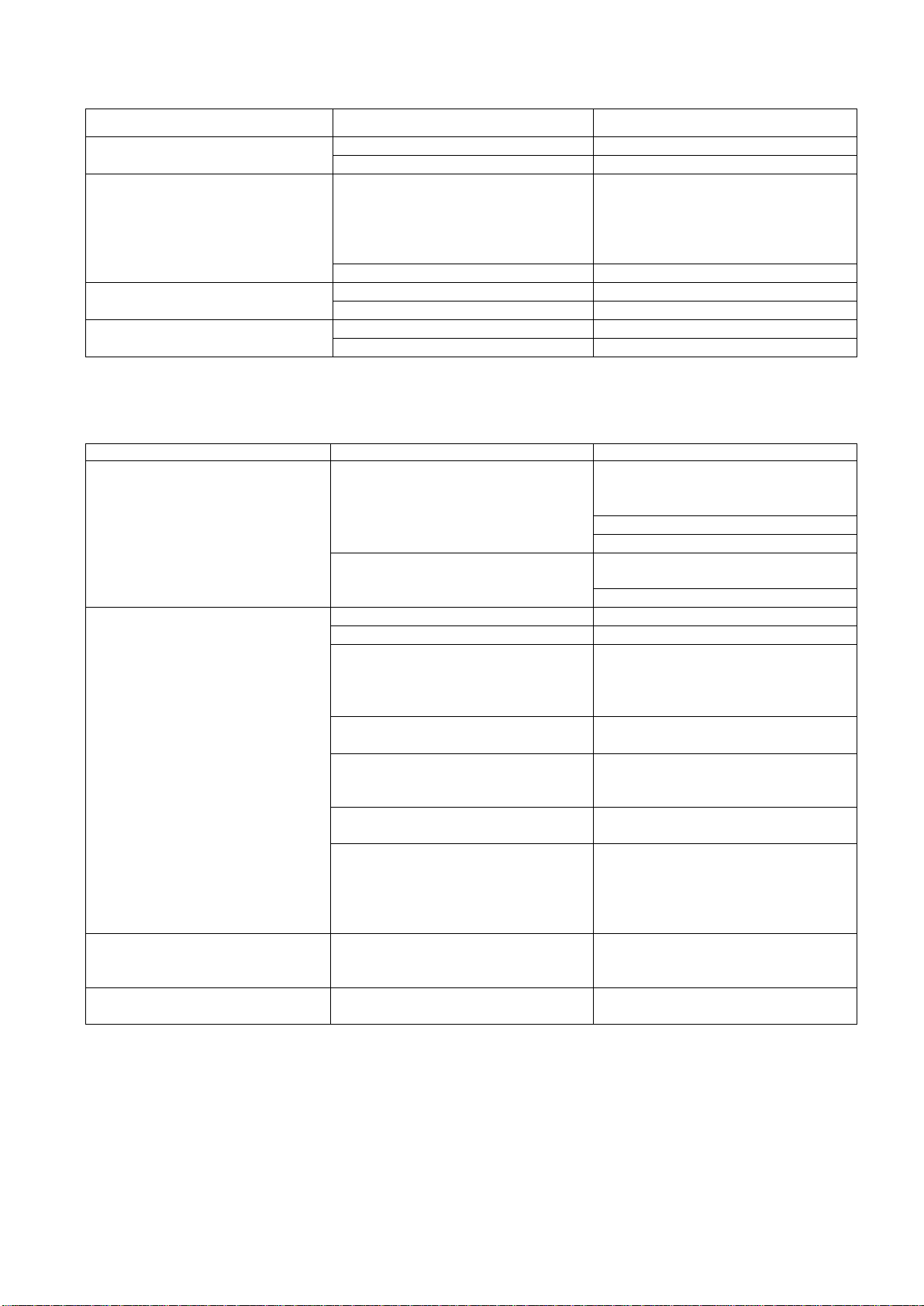

MAINTENANCE

ITEM CAUSE MAINTENANCE

Water supply filter

Limestone deposits on the screen

Replace

Debris or solids on the screen

Clean with water or replace

Venturi Limestone deposits

Clean or replace

(Warning: do not use tools to

remove the lime deposits because

you can affect the functioning of the

venturi; only use anti lime products)

Congealed product

Clean with water

Non-return valves

Worn

Replace

Congealed product

Clean if possible or Replace

Foot filters

Worn

Replace

Congealed product

Clean if possible orReplace

TROUBLESHOOTING GUIDE

PROBLEM

CAUSE

REMEDY

No flow

No water supply Open the water supply outside tap

Select product or rinse

Turn on the spray gun

Clogged hydraulic parts

Check the water supply filter (input

station)

Check the venturi

Product is not mixed or not dosed

correctly

The foot filter is clogged

Clean or replace the filter

The calibration nozzle is clogged

Clean or replace the nozzle

Insufficient water pressure

A minimum pressure of 22PSI is

required for correct operation; if the

pressure is not correct, contact a

plumber

The chemical product container is

empty

Refill or change the chemical

product container

The suction hose is not properly

connected to the elbow fitting

Check that the suction hose is

properly connected to the fitting, use

a clamp for a better grip

The suction hose is crimped

somewhere

Check that the suction hose is

properly positioned

Debris or Solids in the venturi

Clean with water or compressed air

(Warning: do not use tools to

remove the lime deposits because

you can affect the functioning of the

venturi; only use anti lime products)

Concentration too high The nozzle is not fully inserted or

Wrong metering tip

Check that the nozzle is securely

plugged into the non return valve or

select a smaller metering tip

The chemical product container

fills with water.

The non return valve is clogged or

worn

Clean or replace the non return

valve

Page | 27

Terms & Conditions

Company warrants its Goods to be free from material defects in material and workmanship for a period of one year ex-

cept: i. when Goods have been modified following delivery and/or subject to improper handling, storage, installation, op-

eration, or maintenance unless those modifications have been authorized in writing by Seller. ii. when an item is pur-

chased by Company as a component part of the Goods, except to the extent to which such item or items are covered by

the warranty, if any, of the original manufacturer. iii. when an item which is a component part of the product has been

furnished by Buyer. iv. no warranty of a component part shall extend beyond the warranty period of the device in which

such component part is incorporated. b. There is no implied warranty of merchantability or of fitness for particular pur-

pose and there are no warranties of any nature except as set forth in paragraph 3 herein. Any claim by Buyer made pur-

suant to Company’s warranty must be made in writing. Company shall have the right to inspect the Goods claimed to be

defective and shall have the right to determine the cause of such alleged defect. All Goods replaced or repaired by Com-

pany under its warranty shall be replaced or repaired F.O.B. Company’s facility. Buyer must notify Company, in writing,

within fifteen (15) days from receipt of Goods of any obvious defect in the product, or shortages, or Company shall have

no obligation to correct such defect. Company shall have the option of re-inspection at Buyer’s plant or its own before

allowing or disallowing Buyer’s claim. Defects that do not impair service shall not be a cause for rejection or recovery

under any warranty. Buyer assumes full responsibility for the use and application of the product. Buyer accepts Compa-

ny’s design and material selection and specifications in placing this order unless other specifications are agreed to in

writing by both parties prior to the manufacture of Goods by Company. Statements and data relating to Products on

Seller’s literature and website are not intended to define the performance of the product in actual usage or in com-

bination with other equipment or processes. These statements should not be used by Customer solely as an indication

of performance or suitability for specific applications or uses.

THE ABOVE WARRANTIES ARE THE SOLE AND EXCLUSIVE WARRANTIES MADE BY SELLER WITH RESPECT

TO ALL PRODUCTS AND SERVICES.

Components and spare parts such as O-rings, squeeze tubes, roller blocks and other plastic components are consid-

ered to be wear parts and are not warranted. Seller shall have no warranty or liability for product that was damaged dur-

ing shipment, product that is not being used in its recommended use, product that is not operated in accordance with the

operating manual and procedures, product that was not properly installed, product used in a manner that is inconsistent

with its designed purpose, product that is subject to a power surge or similar event, products that fail due to usage of a

non Lavo Solutions replacement or spare part or product that was not maintained in accordance with recommended

maintenance programs.

For full terms and conditions, please visit:

http://lavosolutions.com/LAVO-T&C-02-2018.pdf

Lavo Solutions, LLC

23192 Verdugo, Suite #D

Laguna Hills, CA 92653

O: 949-377-1250

W: www.lavosolutions.com

Table of contents

Other Lavo Solutions Paint Sprayer manuals

Popular Paint Sprayer manuals by other brands

C.A. Technologies

C.A. Technologies Tomahawk TG Product information

Graco

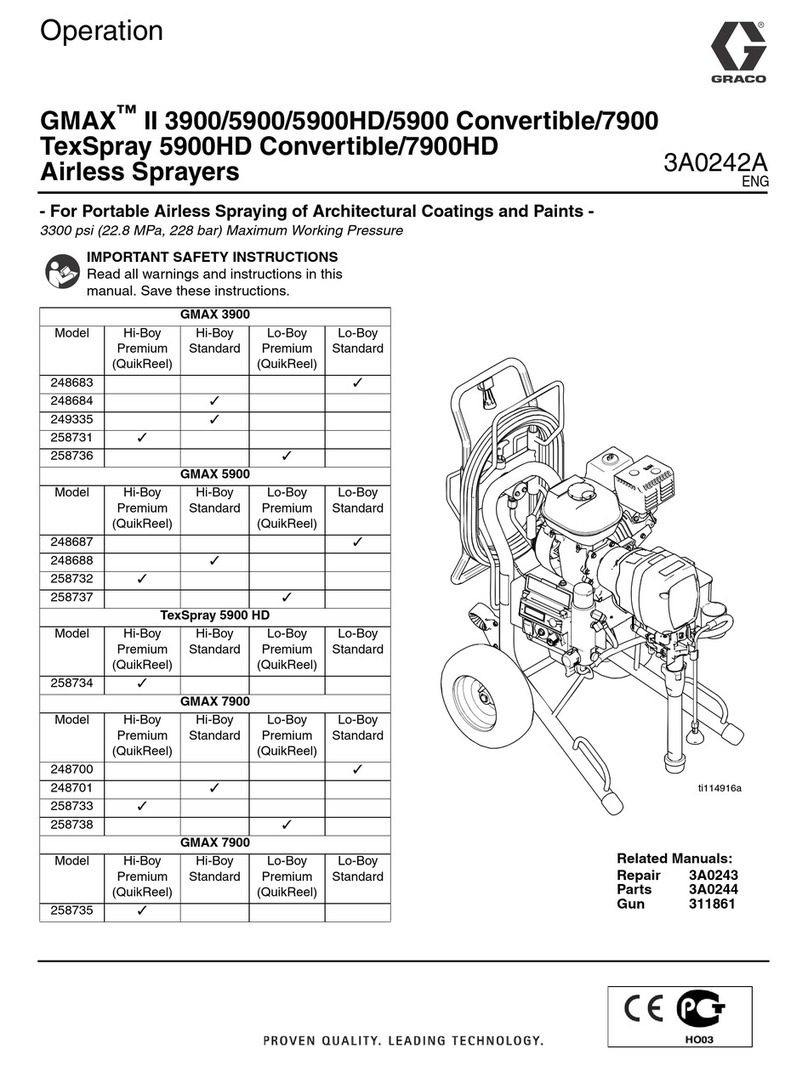

Graco GMAX 258731 Operation manual

IRONSIDE GARDEN

IRONSIDE GARDEN IGS 12P Recommendations for Use

Fimco

Fimco PRO Series owner's manual

Storch

Storch HVLP JustFinish Translation of the original instruction

WAGNER

WAGNER AG-19 owner's manual

BlueSpot

BlueSpot 07910 user manual

WAGNER

WAGNER ProjectPro 117 owner's manual

Graco

Graco 311736A Operation manual

Kobalt

Kobalt KSP 1024B-03 manual

Profi-AirBrush

Profi-AirBrush AB01117 operating instructions

Campbell Hausfeld

Campbell Hausfeld AL1860 - METAL Operating instructions and replacement parts list