BlueSpot 07910 User manual

HVLP SPRAY GUN

(600ML)

User Manual

07910

01

Thank you for purchasing a BlueSpot product, you can find further information

on our range at www.BlueSpot.uk.com. Please ensure that you are using the

product correctly and that all guidance and cautions are followed in accordance

with the instructions. Please retain these instructions for future reference.

General Information

Please make sure that you read these instructions carefully to avoid injury when using the

HVLP spray gun. Follow all health and safety rules and regulations. If in doubt and available

please contact a more knowledgeable source.

DO NOT use if damaged.

• If the spray gun is damaged do not use as this may cause damage to property or injury.

• Maintain the spray gun in good and clean condition for best and safest performance.

• Keep the work area clean and uncluttered and ensure that there is adequate lighting.

• Maintain correct balance and footing. Ensure the floor is not slippery and wear

non-slip shoes.

• Keep children and unauthorised persons away from the work area.

• When the spray gun is not in use always ensure the air supply is turned off.

• ALWAYS make sure the spray gun is disconnected from the air supply before changing

accessories, servicing or performing any maintenance.

• BE AWARE the paint cup remains pressurised after the gun has been disconnected

from the airline. Depressurise the paint cup by gently opening, do not pull the trigger.

• BE AWARE paints and solvents may be harmful or fatal if swallowed or inhaled. Avoid

prolonged contact with solvents or paint on the skin as it will cause irritation. After any

contact, immediately wash the exposed area with hot, soapy water.

• BE AWARE that air hose fittings may get hot during use. Allow all the fittings to cool

down before you disconnect.

• ALWAYS dress appropriately – protective overalls, paint spraying gloves and boots are

recommended.

• ALWAYS wear the correct eye or face protection when operating the spray gun.

• ALWAYS wear approved respiratory protection.

• NEVER point the spray gun at yourself, at other persons or animals.

• DO NOT carry the spray gun by the air hose.

Safe use

• DO NOT operate the spray gun while tired or under the influence of alcohol, drugs or

medication.

• DO NOT allow untrained persons to operate the spray gun.

• DO NOT exceed the maximum air pressure.

• DO NOT get the spray gun wet or use in damp or wet locations or areas where there is

condensation.

• DO NOT spray near open flames, pilot lights, stoves, heaters, the air compressor or

another heat source. Most solvents and coatings are highly flammable, in particular

when sprayed. Keep a distance of at least 25 feet from the air compressor. If you can,

locate the air compressor in a separate room.

• NEVER use the spray gun to spray hazardous materials. This may result in serious

injury or death. Do not spray pesticide, acid, corrosive material, fertilizer or toxic

chemicals.

Standard Set Up

Pattern Width Covering

Air Pressure

Air Consumption

Pot Capacity

1.5mm

110-250mm

50 PSI (3.5 bar)

10CFM (283L/min

600ml

Please make sure that you read these instructions carefully to avoid injury when using the

HVLP spray gun. Follow all health and safety rules and regulations. If in doubt and available

please contact a more knowledgeable source.

DO NOT use if damaged.

• If the spray gun is damaged do not use as this may cause damage to property or injury.

• Maintain the spray gun in good and clean condition for best and safest performance.

• Keep the work area clean and uncluttered and ensure that there is adequate lighting.

• Maintain correct balance and footing. Ensure the floor is not slippery and wear

non-slip shoes.

• Keep children and unauthorised persons away from the work area.

• When the spray gun is not in use always ensure the air supply is turned off.

• ALWAYS make sure the spray gun is disconnected from the air supply before changing

accessories, servicing or performing any maintenance.

• BE AWARE the paint cup remains pressurised after the gun has been disconnected

from the airline. Depressurise the paint cup by gently opening, do not pull the trigger.

• BE AWARE paints and solvents may be harmful or fatal if swallowed or inhaled. Avoid

prolonged contact with solvents or paint on the skin as it will cause irritation. After any

contact, immediately wash the exposed area with hot, soapy water.

• BE AWARE that air hose fittings may get hot during use. Allow all the fittings to cool

down before you disconnect.

• ALWAYS dress appropriately – protective overalls, paint spraying gloves and boots are

recommended.

• ALWAYS wear the correct eye or face protection when operating the spray gun.

• ALWAYS wear approved respiratory protection.

• NEVER point the spray gun at yourself, at other persons or animals.

• DO NOT carry the spray gun by the air hose.

02

When the spray gun is not in use store it in a safe, dry area, away from children. Ensure you

have cleaned the spray gun correctly before storing away.

Safe use (continued)

Storage

The BlueSpot HVLP Spray Gun is ideal for painting substrates with minimal wastage. The

supplied nozzle (1.5mm) and operating pressure of 50psi (3.5bar) cover a pattern width of

110-250mm with reduced overspray.The cup capacity of 600ml is ideal for larger projects.

Air consumption is 10CFM (283L/min). 1/4" BSP inlet.

Introduction

Specification

• DO NOT operate the spray gun while tired or under the influence of alcohol, drugs or

medication.

• DO NOT allow untrained persons to operate the spray gun.

• DO NOT exceed the maximum air pressure.

• DO NOT get the spray gun wet or use in damp or wet locations or areas where there is

condensation.

• DO NOT spray near open flames, pilot lights, stoves, heaters, the air compressor or

another heat source. Most solvents and coatings are highly flammable, in particular

when sprayed. Keep a distance of at least 25 feet from the air compressor. If you can,

locate the air compressor in a separate room.

• NEVER use the spray gun to spray hazardous materials. This may result in serious

injury or death. Do not spray pesticide, acid, corrosive material, fertilizer or toxic

chemicals.

03

Parts Diagram

Before use

1. Air Nozzle

2. Retaining Ring

3. Trigger

4. Adjustment Knob

5. Adjustment Screw

6. Adjustment Valve

7. Cup

8. Air Inlet 1

2

6

3

5

7

4

8

Before using the spray gun check for damage. If the spray gun is damaged do not use as this will

affect the performance and could cause damage to property or injury. Check for the following –

• Loose screws

• Misalignment or binding of moving parts

• A clogged nozzle or fluid tip

• Damaged air supply hose

• Cracked or broken parts

• Check the cleanliness of the spray gun

• Anything else that could affect safe operation

Air Supply Connection / Adjustment

1. Before connecting the spray gun to the air supply always ensure that the spray gun air

valve is in the ‘off’ position.

2. You will require an air pressure of 50 PSI.

ALWAYS ensure when using the spray gun that the air supply is clean and does not exceed

50PSI. Using unclean air and air pressure that is too high will result in the product life being

shortened for the spray gun due to excessive wear. This may result in the spray gun becoming

dangerous and causing damage to property and/or injury.

retaining

ring

air nozzle Horizontal Fan Vertical Fan

04

Work Area Set Up

1. Keep the work area clean and uncluttered and ensure that there is adequate lighting.

2. Ensure there are no children or pets within the work area that could cause distraction

or injury.

3. Make sure the air hose route can reach the work area without creating a tripping

hazard. Ensure the air hose is long enough to allow free movement whilst working.

4. Before you begin spraying, mask nearby objects that are not being sprayed.

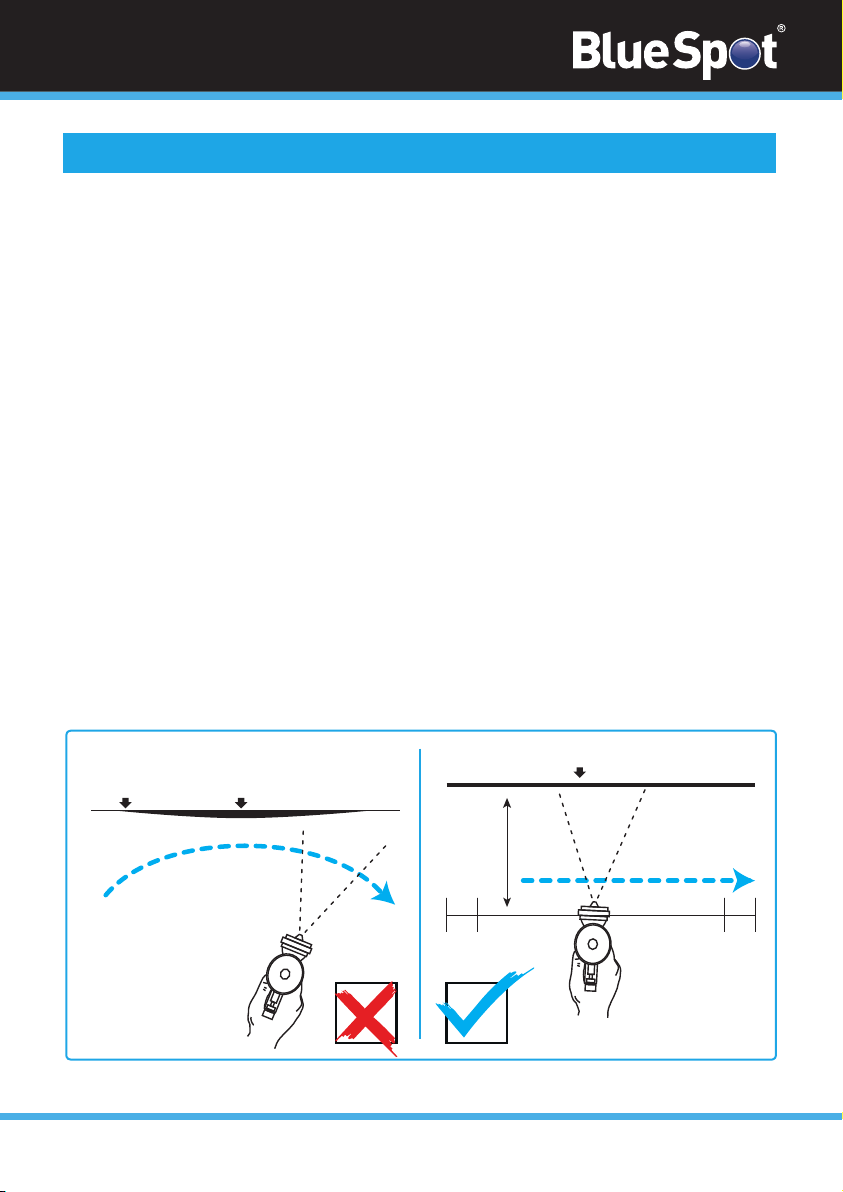

Fan Direction

To change the direction of the fan from horizontal to vertical, loosen the retaining ring (2)

and turn the air nozzle 90°.

NOTE - Test the consistency by spraying onto a piece of scrap material.

As the width of spray is increased more material must pass through the spray gun to obtain

the same coverage on the increased area.

1. Thread the cup to the top of the spray gun and tighten until the cup is securely in place.

2. Follow the paint manufacturer’s directions for prepping the paint and mix thoroughly.

3. Unscrew the lid on the cup. Fill the cup with the paint ¾ full. Secure the lid back onto

the cup and tighten.

4. Start the air compressor and set the regulator to the needed pressure. NEVER exceed

the maximum air pressure.

5. Use the adjustment valve (6) to adjust the pressure according to the paint

concentration.

6. Use the adjustment knob (4) to adjust the atomization length.

7. Use the adjustment screw (5) for adjusting the amount of paint liquid.

8. Turn the air nozzle (1) to achieve either a horizontal or vertical fan spray.

9. Lock the nozzle in place with the retaining ring (2).

Spray Gun Set Up

fig.1

05

Spraying Technique

1. Hold the spray gun perpendicular to the surface being sprayed and move it parallel to it.

2. Use two hands, one to steady the cup and the other to operate the spray gun.

3. Aim the nozzle at the piece of material that you would like to spray.

DO NOT stop when spraying. If you need to stop for more than 5 minutes, turn off the air

supply, disconnect the cup from the spray gun, and thoroughly rinse the cup and spray gun

with clean water.

4. Pull the trigger slowly and move the spray gun parallel to the workpiece you are

spraying. Keep a distance between the spray gun and the material to about 6” to 9”,

depending on the flow adjustment and the paint (refer to figure 1).

5. To avoid paint building up in the spray gun, start the stroke before squeezing the trigger.

6. To obtain a uniformed finish each stroke must overlap the preceding stroke.

7. When you have finished, release the trigger before finishing the stroke.

DO NOT stop moving the spray gun while spraying.

ALWAYS allow are hose fittings to cool down completely before dismantling the spray gun.

8. Release the trigger, disconnect from the air supply, and safely discharge any residual air

pressure.

9. Clean the spray gun immediately after every use, in between coats and when it is not

being used for 5 minutes or longer.

Coating will

be light at

this point

Coating should be even and wet

when spraying

Coating will

be heavy at

this point

150 -

250mm 6 - 10”

INCORRECT CORRECT

Travel of gun

Start

Stroke

End of

Stroke

Pull

Trigger

Release

Trigger

06

Cleaning

ALWAYS make sure that the spray gun is cleaned immediately after every use. Delayed or

inadequate cleaning of the spray gun will cause blockages and affect the performance of the

product in the future.

ALWAYS disconnect the spray gun from the air supply before attempting to clean or

perform maintenance.

ALWAYS follow the paint manufacture’s recommendations for cleaning, solvent and

disposal.

Cleaning the spray gun cup

1. Make sure any solvent used is recommended by the paint manufacturer.

2. Remove the cup, as well as any tubes.

3. Scrape the paint out of the cup carefully. Dispose of this excess paint properly.

4. Clean the cup with the solvent.

5. Allow to dry.

Cleaning the spray gun

1. Immerse the front end of the spray gun only in solvent.The solvent should just cover the

fluid connection. DO NOT immerse the entire spray gun in solvent. This can cause the

lubricants on the rubber seals to dissolve. The dirty solvent may also clog narrow

passages in the spray gun.

2. To wash off any paint that has accumulated on the spray gun use a bristle brush and

solvent.

3. Flush the spray gun through with clean thinners.

4. With a dampened solvent rag wipe the outside of the spray gun.

5. Allow to dry.

Air nozzle, fluid nozzle and needle assembly

1. To clean the nozzles soak them in solvent to dissolve any dried material then blow them

clean with air. Carefully handle all nozzles and do not make any alterations to the gun.

2. If you need to probe the holes in the nozzles, do not use metal instruments. Always

ensure you use a tool that is softer than brass.

3. Adjust the fluid needle valve so that when the gun is triggered airflow occurs before fluid

flow.

1. Always take care when re-assembling the spray gun. Avoid cross-threading by screwing

the parts hand tight. If a part cannot easily be turned by hand, check that you have the

correct part, or unscrew, realign and try again. DO NOT use excessive force when

re-assembling.

2. With a light machine oil, lubricate the spray gun daily.

3. If you change the nozzle size, ensure the complete nozzle set is exchanged. Before

putting the paint needle in, insert the paint nozzle.

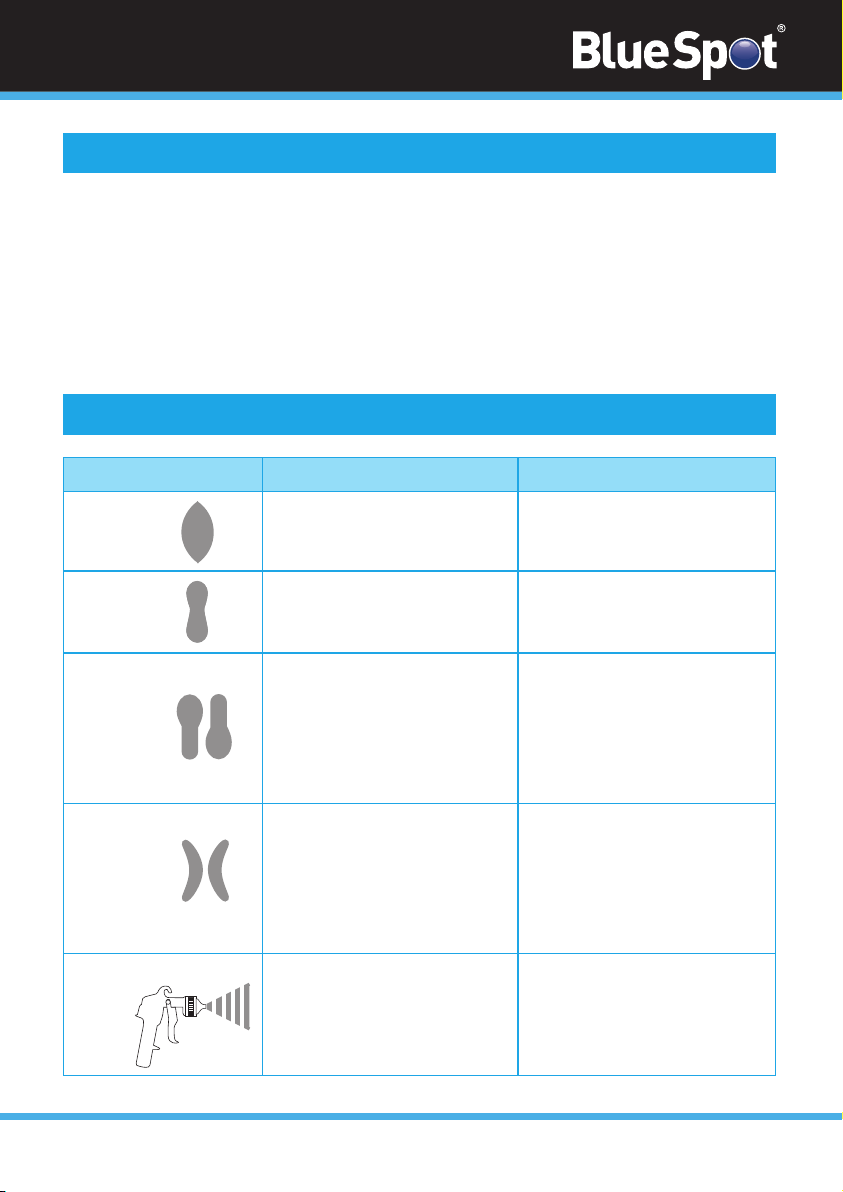

Problem Possible Causes Solution

1. The paint may be too thick

2. The Air pressure is too low

1. Thin paint according to the

manufacturer’s instructions

2. Increase air pressure

1. Loose or damaged air nozzle

2. Low paint level

1. Tighten or replace

2. Refill paint cup

1. The air pressure is too high

2. The adjustment screw is not

open enough

1. Reduce the air pressure

2. Open the adjustment screw

Heavy

centre

pattern

Light

centre

pattern

1. Air nozzle blocked

2. Air nozzle loose or the seal

is dirty

3. Dried paint on air nozzle

over the fluid tip

4. Fluid needle damaged

1. Clean the air nozzle

2. Clean and tighten the air

nozzle and seal

3. Clean the air nozzle

4. Replace the fluid needle

and fluid tip

1. Dirt on one side of the air

nozzle – blocking the fluid

tip

2. The holes on the air nozzle

are blocked

3. Damaged fluid needle

1. Use a non-metallic point to

clean the fluid tip

2. Use a non-metallic point to

clean the air nozzle

3. Replace the fluid needle

and fluid tip

Heavy top

/ bottom

pattern

Pattern on

right or

left only

Fluttering

Spray

07

ContactDistance to Spot SizeDisposal

ALWAYS make sure that the spray gun is cleaned immediately after every use. Delayed or

inadequate cleaning of the spray gun will cause blockages and affect the performance of the

product in the future.

ALWAYS disconnect the spray gun from the air supply before attempting to clean or

perform maintenance.

ALWAYS follow the paint manufacture’s recommendations for cleaning, solvent and

disposal.

Cleaning the spray gun cup

1. Make sure any solvent used is recommended by the paint manufacturer.

2. Remove the cup, as well as any tubes.

3. Scrape the paint out of the cup carefully. Dispose of this excess paint properly.

4. Clean the cup with the solvent.

5. Allow to dry.

Cleaning the spray gun

1. Immerse the front end of the spray gun only in solvent.The solvent should just cover the

fluid connection. DO NOT immerse the entire spray gun in solvent. This can cause the

lubricants on the rubber seals to dissolve. The dirty solvent may also clog narrow

passages in the spray gun.

2. To wash off any paint that has accumulated on the spray gun use a bristle brush and

solvent.

3. Flush the spray gun through with clean thinners.

4. With a dampened solvent rag wipe the outside of the spray gun.

5. Allow to dry.

Air nozzle, fluid nozzle and needle assembly

1. To clean the nozzles soak them in solvent to dissolve any dried material then blow them

clean with air. Carefully handle all nozzles and do not make any alterations to the gun.

2. If you need to probe the holes in the nozzles, do not use metal instruments. Always

ensure you use a tool that is softer than brass.

3. Adjust the fluid needle valve so that when the gun is triggered airflow occurs before fluid

flow.

1. Always take care when re-assembling the spray gun. Avoid cross-threading by screwing

the parts hand tight. If a part cannot easily be turned by hand, check that you have the

correct part, or unscrew, realign and try again. DO NOT use excessive force when

re-assembling.

2. With a light machine oil, lubricate the spray gun daily.

3. If you change the nozzle size, ensure the complete nozzle set is exchanged. Before

putting the paint needle in, insert the paint nozzle.

Maintence

ContactDistance to Spot SizeDisposal

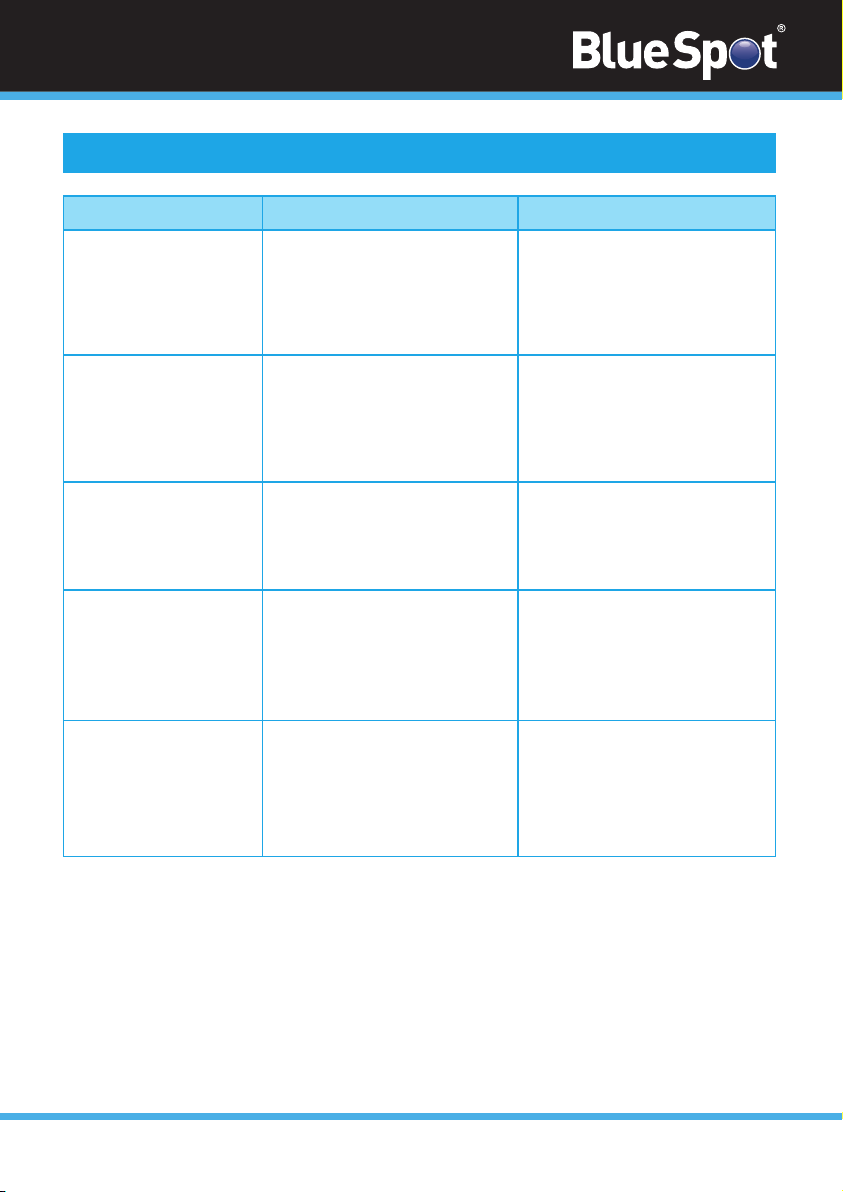

Troubleshooting - Spray pattern diagnosis

1. Clean air valve

2. Lubricate air valve

3. Replace air valve spring

4. Replace air valve assembly

5. Replace air valve stem

1. Dirty air valve

2. Sticking air valve

3. Damaged air valve spring

4. Worn/damaged air valve

5. Bent air valve stem

Problem Possible Causes Solution

1. Refill with paint

2. Hold the spray gun upright

3. Clear air vent hole

4. Adjust or replace fluid tip

and fluid needle

Spluttering spray 1. Paint level low

2. Tipped cup

3. Air vent clogged on cup

4. Loose/damaged fluid tip

1. Check the air hoses

2. Open adjustment screw

3. Thin fluid or increase air

pressure. (Do not exceed

the maximum)

Will not spray 1. No pressure at spray gun

2. Adjustment screw not open

enough

3. Fluid too thick

1. Use a non-metallic point to

clean fluid tip

2. Replace fluid needle spring

3. Replace fluid tip and fluid

needle

Fluid tip leak 1. Fluid tip dirty

2. Broken fluid needle spring

3. Worn or damaged fluid tip

Air leaking from

air nozzle

1. Move moderately and

parallel

2. Adjust distance

3. Reduce air pressure

Overspray

(paint drifting to

unintended objects)

1. Improper application speed

2. Improper distance from

workpiece

3. Too much air pressure

08

ContactDistance to Spot SizeDisposalContactDistance to Spot SizeDisposalGeneral Troubleshooting

09

Notes

Contact

Find out more about the BlueSpot® Lifetime Guarantee at www.BlueSpot.uk.com

Tel: 0800 093 0115

Email: [email protected]

Orme Business Centre,

Greenacres Road,

Oldham,

OL4 3NT

ContactDistance to Spot SizeDisposal

Recycle unwanted materials instead of disposing of them as waste. All tools, accessories and

packaging should be sorted, taken to a recycling centre and disposed of in a manner which is

compatible with the environment. When the product becomes completely unserviceable and

requires disposal, drain any fluids (if applicable) into approved containers and

dispose of the product and fluids according to local regulations.

Environmental Protection

Always check and adhere to national regulations when disposing of any tools that are no longer

functional and cannot be repaired.

• Contact your local waste disposal authority for information on how to correctly

dispose of tools.

Disposal

Table of contents

Other BlueSpot Paint Sprayer manuals

Popular Paint Sprayer manuals by other brands

ActiveProducts

ActiveProducts PRO Series quick start guide

Worx Nitro

Worx Nitro WX020 Safety and operating manual

GardenMate

GardenMate GMKS16L user manual

FLORABEST

FLORABEST 280272 Operation and safety notes

Greenleaf

Greenleaf Workhorse UTV425HM Assembly / operation instructions / parts

EUROPRO

EUROPRO Compact-Pro 120 user manual