Lavor SUPERWASH 160 User manual

GB

1

Index

Introduction

Intended usepage 2

Equipment page 2

Technical specifications page 2

Safety

Safety guidelines pag. 3

Additional safety information pag. 3

Before using for the first time

Assembling the appliance pag. 4

Usage

Connecting to the water mains page 5

Installing the gun page 6

Automatic Stop System page 6

Gun with pressure-gauge page 6

Gun safety catch page 6

At the end of a job page 7

Maintenance Cleaning pag. 7

Disposal pag. 8

Troubleshooting pag. 8

Additional information

Guarantee terms page 11

Certificate of compliance page 11

GB

2

Introduction

Introduction

Please read this instruction manual

thoroughly, referring to it whenever

necessary before starting a job. This is

because, as with all appliances, the high-

pressure cleaner must be used correctly in

order to ensure optimum performance.

First of all, open both fold-out pages

containing the illustrations, and study then

carefully until you are familiarised with how

the machine works. These pages fold out

in front of and behind the cover of the

instruction manual.

Intended use

The high-pressure cleaner is ideal for all

outdoor cleaning requirements. It may be

used to clean dirty surfaces such as house

walls, verandas and roads.

A range of optional gun-mounted accessories

is available for foam and rotary brush

washing applications.

The appliance may also be used to clean

walls, swimming pools, garden furniture and

tools, and to wash vehicles.

Always observe all applicable local legislation

concerning cleaning products.

The machine must never be used for any

purposes other than those specified or

modified, as this may be extremely

dangerous. The manufacturer cannot be

held responsible for damages or injury

resulting from inappropriate use or

modifications.

Do not direct the nozzle toward mechanical

parts containing lubricant grease, as the

grease will dissolve and spread over the

surrounding ground.

Vehicle tyres/tyre valves may only be cleaned

from a minimum distance of 30 cm, otherwise

the vehicle tyre/tyre valve could be damaged

by the high-pressure jet. The first indication

of this is a discoloration of the tyre. Damaged

vehicle tyres/tyre valves can be deadly

dangerous.

Standard equipment

Turbo nozzle

Rotary brush

Nozzle with pressure regulator

Gun with pressure gauge

Hose reel stand

Crank handle

Hose reel

Wheel axle

Hook for power lead

Wheel lock plug

Wheel

Handle

Nozzle cleaning pin

Accessory holder

(a) Nozzle holder

(b) Nozzle stand

Rotary regulator

Tank cap

Concentrated car washing detergent

Quick release water inlet connector

Technical specifications

Year of manufacture 2005

Rated voltage 230V 50 Hz

Power rating 2550 W

Max. delivery max. 8.83 l/min

(530 l/h)

Operating pressure 135 bar

(+/-10%)

(13,5 MPa)

Minimum intake pressure 1 bar

(0,1 MPa)

Maximum intake pressure 10 bar

(1 MPa)

Jet recoil on spray gun 20N

Minimum intake rate 12 l/min

Max. intake water

temperature 40°C

Storage temperature away from frost

Not below 0°C

Weight 21.35 Kg

Acoustic pressure LWA 95db (A)

LPA 76db (A)

˜

S

U

R

T

High pressure washer

SUPERWASH 160

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

GB

3

Safety

Protection rating IPX5

Vibration transmitted

to operator 0.56 m/s2

Technical specifications plate

Ensure that the specifications listed on the

plate match those of the mains water and

power supplies you will be connecting the

machine to.

• Only use clean water.

Caution: Failure to comply with the

above will cause severe damage to the

machine and voids the guarantee.

Safety

Specific safety guidelines for the

appliance

How to prevent fatal electric shock hazards:

•Do not use the appliance if the power lead

or plug is damaged. Have damaged leads

repaired by a customer service centre (e.g.

if the appliance does not work correctly or

if it is damaged). For the contact details

of your nearest authorised customer care

centre, please refer to the chapter

“Guarantee” or to the attached guarantee

documents.

•Do not leave the appliance out in the rain

and never use in damp or wet conditions.

Ensure that the high-pressure cleaner

power lead is never wet or damp while the

appliance is in use.

•Never spray water towards the mains plug

and socket.

•Do not cover the appliance or its air vents,

as this will cause the machine to overheat.

•Never pull on the cable to unplug the

appliance from the mains. Always grip the

plug itself and pull it out of the socket to

disconnect.

How to prevent injury

•Never leave the appliance unattended

•Caution! Keep children well away from

the power lead and the appliance. Children

are often not aware of the hazards that

household appliances may present.

•This appliance is intended for outdoor use

only.

•Never use the appliance if the power lead

or any major components are damaged

(e.g. safety systems, high-pressure gun

hose, etc).

•Never try to repair a damaged hose

yourself.Always replace a damaged hose

with a new one.

•For reasons of safety, irrespectively of the

type of job you are about to carry out,

always use both hands to assemble the

nozzle and the gun .

•When you have finished a job, always

disconnect the appliance from the mains

water and electricity.

•CAUTION: This appliance has been

designed to be used with the detergent

supplied or specified by the manufacturer

(a neutral, biodegradable anionic surfactant

based shampoo type detergent). The use

of any other detergent or chemical product

may render the appliance unsafe.

•CAUTION:

High-pressure water jets may

be dangerous. Never direct the water jet

towards persons, animals, powered

electrical appliances or the high-pressure

cleaner itself.

•CAUTION: Only use hoses, accessories

and connectors approved by the

manufacturer. To prevent injury, it is vital

that all components are kept in good

condition.

•CAUTION: the high pressure hose,

accessories and connectors are all

important for the safety of the appliance.

Use only manufacturer approved high

pressure hoses, accessories and

connectors.

•CAUTION: do not operate the machine if

there are persons within its working range

not wearing appropriate protective

garments.

•This appliance is equipped with the following

safety features: spray gun with safety catch,

43

GB

4

Safety Before using for the first time

an electrical overload cutout system (CL.

I) and pump bypass valve or stop system.

•CAUTION: The spray gun is

equipped with a safety catch.

When the appliance is not in use,

always engage the safety catch

to prevent the machine from being started

unintentionally.

•Never direct the jet towards yourself or

any other person to clean clothing or

footwear.

•Never allow children or persons without

the necessary skills to operate the

machine.

•CAUTION: Do not leave the appliance in

standby mode for more than 5 minutes.

•CAUTION:Always switch off the appliance

completely (main switch OFF) whenever

leaving it unattended.

•CAUTION: This machine uses high-

pressure fluids. Always grip the gun

firmly to counteract the recoil. Only use

the high-pressure nozzle supplied with the

machine.

Additional safety information

Water supply

•See chapter “Technical specifications”.

• Only use clean water.

Caution: Failure to observe the above

conditions will cause serious mechanical

damage to the pump and will void the

guarantee.

High-pressure hose

Caution: The high-pressure hose

has been specially designed to resist

high pressures. Treat with particular care

to prevent damaging it.

•Avoid tangling.

•Do not bend the hose or subject it to high

stress or strain

•Never start the high-pressure cleaner

without first completely unwinding the high-

pressure hose .

•Before unwinding or winding the hose,

switch the machine off and release the

pressure in the hose itself (pull spray

gun trigger 2-3 times).

Caution:

Inappropriate use may cause

damage or untimely breakage and voids

the guarantee.

Electrical power supply

•Warning: Before connecting the appliance,

ensure that the specifications listed on the

identification plate match those of the mains

electric supply and that the socket is

protected by a differential magneto-thermal

circuit breaker with a trip threshold less

than 0.03A - 30ms.

•If the mains power lead or plug is damaged,

have it repaired or replaced by a customer

service centre.

•

Do not use the appliance at temperatures

lower than 0°C.

Caution: Non-approved extension leads

may be dangerous and must never be

used.

•If an extension lead is used, both the plug

and the socket must be waterproof and the

cable cross section must be as specified

in the following table.

Before using for the first time

Warning:

•Before assembly, ensure that all

appliances and accessories listed in the

chapter “Equipment” are present

•Each unit is test run after manufacture,

therefore you may find some residual water

in the water intake.

230 - 240V

1,5 mm2max 20 m

2,5 mm2max 30 m

18

26

26

4

4

GB

5

Before using for the first time Usage

Assemble the appliance

1. Photo sequence D:

• Fit the wheel onto the axle

•Fit the other wheel, ensuring that the pin

fits into the recess in the axle.

•Push the plugs into the wheel centres

until they fit into place (as shown in the

cross-section drawing)

• Fit the tank .

2. Photo sequence E:

Note: Turn the appliance around to face

the rear of the unit for the following sequence

of instructions.

•Securely mount the nozzle holder (a)

(with the Phillips screw and washer) onto

the bottom right hand side of the unit,

fitting it onto the relative lug

•Securely attach the accessory holder

(with the rounded side facing down) at

the rear of the unit

•Fix the accessory support to the cable

winder on the left and to the nozzle

holder on the right (b).

3. Photo sequence F:

• Nozzle cleaning pin fixture

•Securely attach the hose reel support

to the rear of the unit, using 2 Phillips

screws. Ensure that the side with the round

and rectangular openings is installed on

the left hand side

•Completely unwind the hose from the hose

winder before assembling the 2 parts.

•Take the 2 sections of the hose reel

•Fit the 2 sections together and feed the

hose out through the aperture

•Now secure the 2 sections with 4 Phillips

screws

•The high-pressure hose end will be

attached to the gun.

4. Photo sequence G:

•Turn the drum , keeping the hose

connector on the left hand side

•Fit the previously assembled drum

onto the bracket at the rear of the unit.

Press on the drum to secure it into its

mountings on the bracket.

•Fit the hose connector underneath and

screw securely onto the outlet connector

•Fit the crank handle to the right hand

side of the drum with a Phillips screw

•Rewind the hose with the handle, without

tightening excessively.

•Connect the short high-pressure hose

connector to the spray gun quick release

connector. Lift the ring on the spray gun

mount

, insert the end of the hose

and release the ring. Check that it

has engaged correctly.

•Secure the handle to the rear of the

unit with 3 Phillips screws.

Usage

Caution: For safety reasons, always use

both hands to assemble the nozzle and

spray gun before starting a job.

Connection to the water mains

Main ON / OFF switch

High-pressure water outlet (OUTLET)

Plug/wall socket

Water tap

Water supply hose

Water inlet (INLET)

Water filter

Mounting

Snap-on hose connector

Detergent tank

High-pressure hose

Spray gun safety catch

Spray gun trigger

•Check that the main switch is “OFF”;

•The water inlet hose must be fitted to

the snap-on hose connector

Caution: use a hose with a minimum

pressure resistance of 15 bar / 200 psi,

and an internal diameter of at least 13

14

10

15

5

12

14

15

13

4

3

26

16

T

9

26

7

7

7

16

17

18

19

20

21

22

23

24

20

25

26

27

28

4

24

11 86

GB

6

Usage

mm (1/2").

Caution: Inlet water temperature must

never exceed 40°C;

•Ensure that the high-pressure hose

and the hose connector are securely

connected as described in chapter

“Appliance assembly” (photos F and G);

•Screw the mounting tightly by hand

onto the inlet connector.

•Fit the quick-release hose connector

onto the garden hose (not supplied).

•

Fit the hose connector into the mounting

.

• Open the tap ;

•Fit the nozzle onto the spray gun. Twist

the nozzle clockwise to secure on the gun;

•Attach the power plug to the socket ;

•Switch the machine on by turning the main

switch to “ON”.

•If the unit motor starts up even without

operating the spray gun , this is probably

due to air bubbles in the system.

•Press the spray gun lever to purge any

air and residual pressure in the hosing;

•Fill the detergent tank with manufacturer-

approved products, suitable for the type of

job in hand;

•Caution: Ensure that the spray gun is

open every time that the unit is turned on

(main switch “ON”).

•Avoid opening and closing the gun

repeatedly over a short period.

Spray gun accessories

Caution: Never use the spray gun

without an accessory!

Rotary brush

The brush is particularly suitable for

cleaning small surfaces, such as car wheels,

plastic garden furniture, etc.

The rotary spray gun head automatically

aspirates and mixes the detergent.

Nozzle with pressure regulator

You may adjust the operating pressure by

turning the knob at the end of the nozzle

(see also photo C)

“-” To reduce operating pressure:

Turn the knob towards “-” for light dirt

and cleaning delicate surfaces (e.g. car)

“+”Increase operating pressure:

Turn the knob towards “+” for stubborn

dirt (e.g. house facings).

Turbo nozzle

The turbo nozzle is particularly suitable

for cleaning very dirty surfaces.

Caution: As this nozzle is not fitted with

a pressure regulator, do not use it to clean

delicate surfaces (e.g. cars).

Automatic Stop System

This appliance is equipped with an AS

system. This system immediately starts the

unit whenever the gun trigger is operated

and switches it off when the trigger is

released.

•Even though the unit is equipped with this

system, never leave it unattended.

•If the machine is left unused for more than

5 minutes, turn the main switch to “OFF”.

Spray gun with pressure gauge

The spray gun is equipped with an

integrated pressure gauge. This makes it easy

to check the pressure while you are working.

Spray gun trigger safety catch

The spray gun is equipped with a manually

engaged trigger mechanism lock system .

This is used to lock the trigger and to prevent

accidental activation.

To engage catch

Press the lock button on the right hand

side of the gun . Check that the trigger

mechanism is blocked.

25

18

16

19

3 R

1 2 3

4

2

2

28

4

26

23

23

24

24

16 16

28

4

4

27

1

1

27

4

28

3

GB

7

Usage Maintenance Cleaning

To disengage the catch

Press the lock button on the left hand

side of the gun .The trigger is released.

Detergent pick-up

1)Fill the detergent tank (see photo B, pos.

24).

Caution: This appliance has been

designed to be used with a neutral,

biodegradable anionic surfactant based

shampoo. The use of any other detergent

or chemical product may render the

appliance unsafe.

2) Caution: Before enabling detergent

pick-up, ensure that the regulator knob

is turned towards “-” (low pressure).

•Suck detergent by pulling the spray gun

trigger

•Note: A few seconds may be required

before pick-up starts.

3) Adjust the pressure with the regulator

knob (see chapter “Nozzle with pressure

regulator”).

At the end of a job

1)Switch the unit off by turning the main

switch to OFF

2)Disconnect the unit from the water supply

3)Disconnect the power plug .

4)Purge any residual pressure by pulling

the spray gun trigger repeatedly

5)Clean the waterinlet filter (seeparagraph

“Cleaning the water filters” in chapter

“Maintenance and Cleaning”)

6)Store the high-pressure cleaner in a dry

safe place (temp.>0°C), out of the reach

of children.

Maintenance Cleaning

•Before starting any maintenance work on

the high-pressure cleaner, purge the

pressure and disconnect the unit from the

mains electricity and water.

•Ensure that the air intake vents are always

clean so that air can circulate freely inside

the unit.

•To ensure safe operation, only use original

replacement parts supplied or approved

by the manufacturer.

•When starting the unit for the first time, a

little water may leak from the pump; this

may last a few hours. If you are unable to

adjust the settings and stop this leak,

contact an authorised customer support

centre (see chapter “Guarantee terms”).

•The electric motor is equipped with an

overload cutout system (CL. I). In the event

of malfunction, the unit is stopped. Wait

5-10 minutes before restarting the

appliance. If the trouble persists, refer to

chapter “Troubleshooting” for help. If you

are still unable to resolve the problem,

contact an authorised customer support

centre.

Cleaning the appliance water filter:

•To ensure that the pump works correctly,

it is very important that you regularly check

and clean the water filter.

1)Unscrew the water inlet connector .

2)Pull the filter out of its mounting with

an appropriately sized pair of pliers

3)Clean the filter thoroughly under running

water.

4)Refit the filter in its mounting and screw

the connector back on.

Cleaning the nozzle orifice:

•Aclogged nozzle may impair function and

must therefore always be kept clean.

1)Turn the unit off and remove the nozzle

16

18

27

428

28

22

23

22

GB

8

Maintenance Cleaning Disposal Troubleshooting

from the gun.

2)Clean the nozzle orifice with the nozzle

cleaning pin provided.

3)Rinse the nozzle under running water.

Disposal

•Disposal must be carried out in accordance

with applicable environmental legislation.

•The appliance and its accessories must

be disposed of in accordance with the

materials used in their construction.

•Disposal must be carried out in accordance

with applicable local legislation. Contact

your municipality for the nearest refuse

dumping site.

•As owner of an electrical or electronic

product, you are not allowed by law

(according to EU-Directive 2002/96/EC of

27 January 2003 on waste electrical and

electronic equipment and the particular

national laws of the EU-Member States

transforming this Directive) to dispose of

this product or its electrical/electronic

accessories as unsorted domestic waste.

You shall use the designated gratis

possibilities for return instead

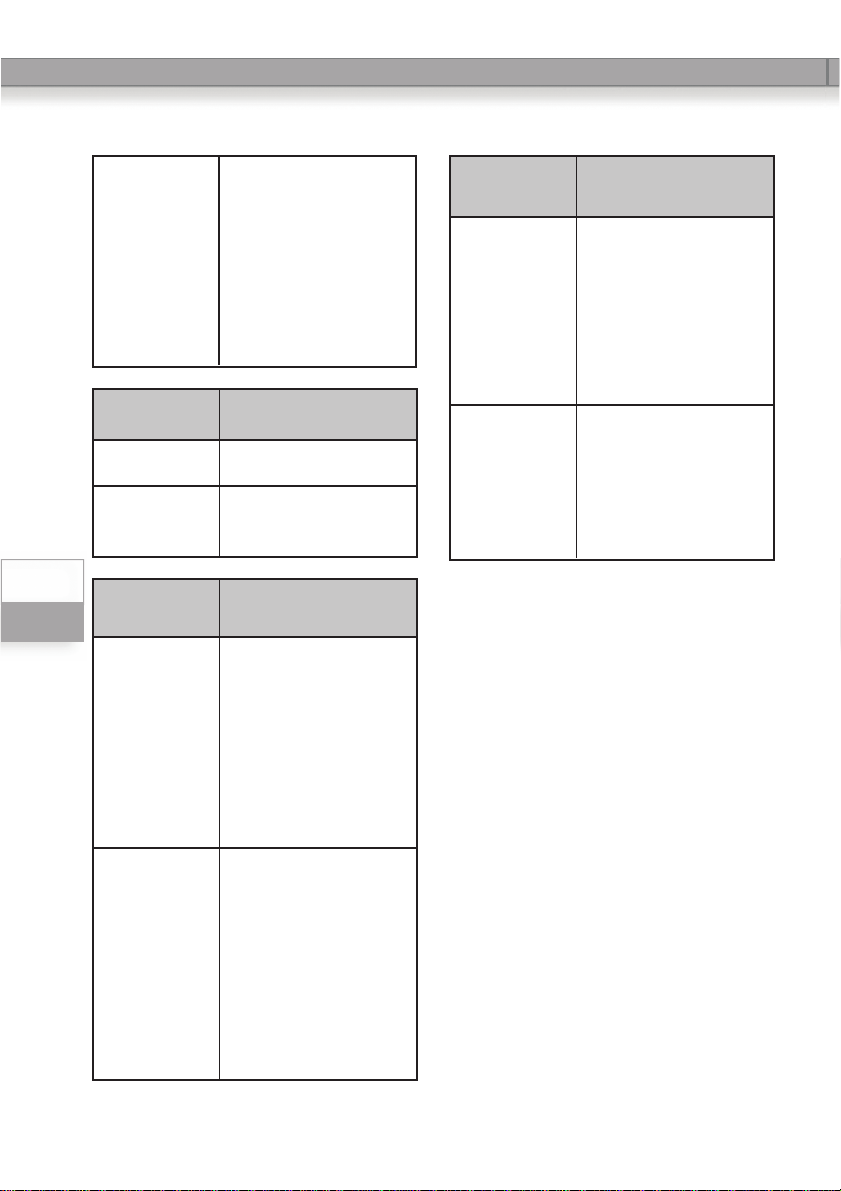

Troubleshooting

Fault

Cause

Repair

The pump does not

start when the switch

is pressed.

•The plug is not properly

connected to the

socket.

• Faulty electric plug.

• The mains voltage is

insufficient.

• The gauge of the

electrical power lead is

too small.

•The pump has cut out.

•Connect the plug to the

power socket correctly.

•Have the electrical

socket checked.

•Check that the system

is suitable.

•See paragraph “Safety

notes / electrical

connection”.

•Turn the switch to ON

while keeping the gun

lever pressed; if the

problem persists

contact an authorised

service centre.

Fault

Cause

Repair

The machine starts, but

no water comes out.

• Pump, hoses or

accessories frozen.

• No water supply.

•Unitwaterfilter clogged.

• Nozzle or spray gun

orifice clogged.

• Allow the pump and

hoses to thaw.

•Connect the machine to

thewater supplysystem

and turn on the tap.

3

13

3

GB

9

Troubleshooting

Repair •Remove and clean the

filter (see paragraph

“MAINTENANCE /

CLEANING”).

•Remove the lance from

the gun and clean the

nozzle with the pin

provided.

Fault

Cause

Repair

The pump runs but

there is no pressure.

• Insufficient water.

• Suction filter fouled.

•Nozzle regulator valve

in lowest pressure

setting.

• Lance nozzle worn.

• Suction or delivery

valves fouled or worn.

•Check that the delivery

rate is at least 12 l/min.

•Remove and clean the

filter.

• Increase pressure by

turning the pressure

regulator on the

nozzle.

• Contact your

authorised customer

service centre.

Fault

Cause

Uneven working

pressure.

•Lance nozzle fouled or

dirty.

• Air in intake water.

• Suction filter fouled.

• Suction or delivery

valves fouled or worn.

• Gaskets worn.

• Pressure regulator

valve gaskets worn.

Repair •Remove the lance from

the gun and clean the

nozzle with the pin

provided.

• Supply the machine

with water correctly.

•Remove and clean the

filter (see paragraph

“MAINTENANCE /

CLEANING”)

• Contact your

authorised customer

service centre.

Fault

Cause

Repair

The motor stops

suddenly.

• The appliance has

been automatically

stopped by the

overload cutout

system.

• Unsuitable electrical

extension lead.

• Let the motor cool for

a few minutes. Contact

your authorised

customer service

centre if the problem

persists.

• See chapter “Safety

guidelines / electrical

power supply”.

Fault

Cause

Abnormal noise.

• Suction filter fouled.

• Intake water

temperature too high.

• Suction or delivery

valves fouled or worn.

• Bearings worn.

GB

10

Troubleshooting

Repair •Remove and clean the

filter (see paragraph

“MAINTENANCE /

CLEANING”).

• Use water at a

temperature lower than

40°C.

• Contact your

authorised customer

service centre.

Fault

Cause

Repair

Water contaminated

with oil.

• O-ring seals worn.

• Contact your

authorised customer

service centre.

Fault

Cause

Repair

The machine restarts

with the gun released.

•Water leak from hose-

gun connection

(except models with

hose and gun supplied

ready-connected).

• Air in intake water.

•Water leak from the

gun.

•Water leak from the

pump.

•Tighten the connection

ahead of the quick

release connector

using 2 suitable

spanners.

• Connect the machine

to a suitable water

supply.

• Contact your

authorised customer

service centre.

Fault

Cause

Repair

The machine does not

suck in detergent.

•Tank empty.

•Nozzle regulator knob

turned to “+”.

• The transparent pick-

up tube inside the

appliance is damaged

or disconnected.

• The drain hole of the

tank is plugged.

• Fill the tank.

•Turn the regulator

knob to the low-

pressure setting.

• Contact your

authorised customer

service centre.

Table of contents

Other Lavor Pressure Washer manuals

Lavor

Lavor SQUALO 140 User manual

Lavor

Lavor Tormenta User manual

Lavor

Lavor Mystic-R User manual

Lavor

Lavor STM Series User manual

Lavor

Lavor THERMIC 22 H Instruction manual

Lavor

Lavor INDEPENDENT 2800 User manual

Lavor

Lavor MCHPV User manual

Lavor

Lavor INDEPENDENT 2800 User manual

Lavor

Lavor EPIC User manual

Lavor

Lavor STM User manual

Lavor

Lavor SPACE User manual

Lavor

Lavor LVR COSMOS User manual

Lavor

Lavor INDEPENDENT 2000 User manual

Lavor

Lavor STM 160 WPS User manual

Lavor

Lavor Giant 20 PRO User manual

Lavor

Lavor Vulcano User manual

Lavor

Lavor LVR User manual

Lavor

Lavor Alaska User manual

Lavor

Lavor Giant 20 PRO User manual

Lavor

Lavor Advanced Warm up User manual