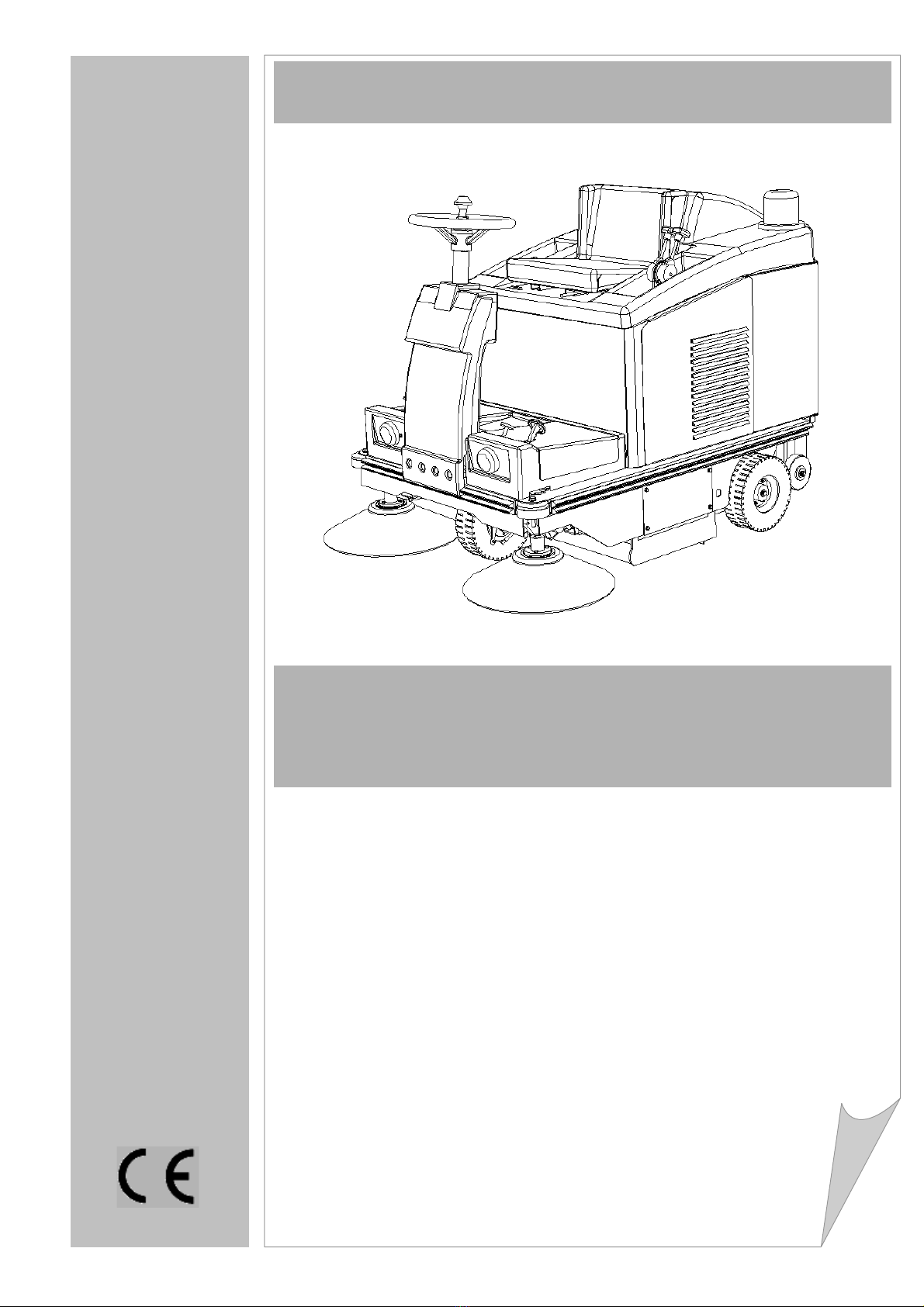

SWL R1000 ET/SW R 6200 BT – SWL R1000 ST/SW R 8300 SC Instructions and Operating Manual

Page 8

The central brush Part. 2 Fig. 4 is the main machine component for loading the dust and waste into the

collection bin. It is available in various degrees of hardness and bristle types, depending on the type of

material to be collected up and on the type of floor. It is height adjustable in case of wear (See Chapter 13).

IMPORTANT: do not pick up cords, wires, packaging straps, sticks, etc., longer than 25 cm as these

could wrap around the centre and side brushes and damage them.

FILTER SYSTEM:

During operation, the filter system ensures that the machine does not raise dust in the surrounding areas. It

consists of six cartridge filters Part. 1 Fig. 5. The filter system can be disengaged by pulling knob Part. 1, seen

in Fig. 6.

IMPORTANT: Disengage the filter system when passing with the machine over wet or very damp

areas to prevent dampening and therefore deteriorating the paper filters.

DUST SEALS:

See Part. 4 Fig. 6. These seals surround the central brush and are very important for ensuring good machine

operation, making possible as they do the suction effect. Frequently check to make sure they are in good

condition.

COLLECTION BIN:

The container or collection bin Part. 1 Fig. 7, made of resistant plastic, holds all the material picked up by the

central brush and the filter dust. It can be easily removed thanks to a wheeled frame Part. 2 Fig. 7.

IMPORTANT: container emptying must always be done with the motor shut off. Wear gloves and

possibly a face mask to protect the airways from dust (always present in this operation).

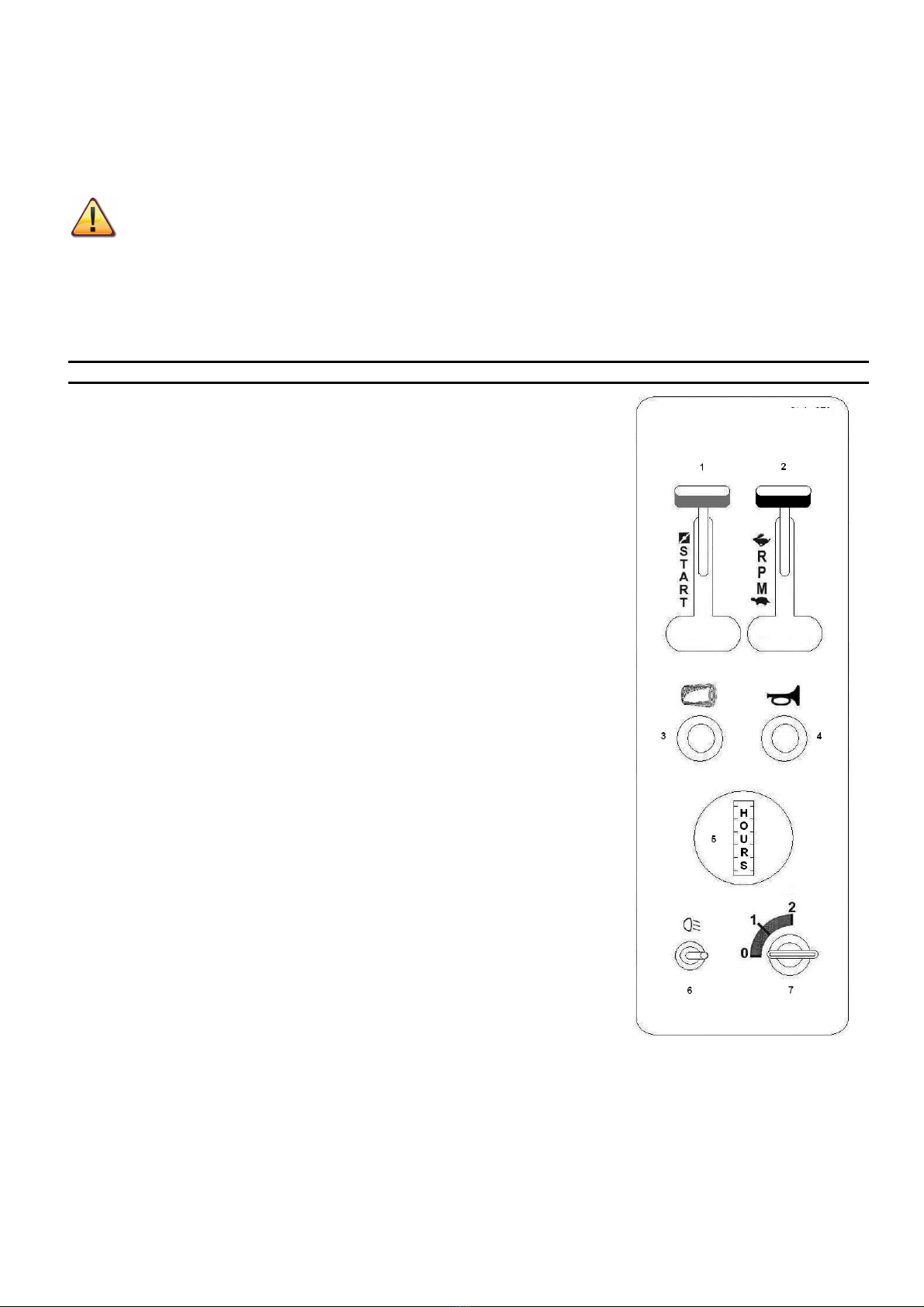

DESCRIPTION PF THE MANUAL CONTROLS

For Both Models

FLAP-LIFT PEDAL:

By pressing the flap-lift pedal Part. 1 Fig. 9, the front seal Part. 2 Fig. 9 lifts up for picking up a large objects.

Suitable for collecting leaves, cigarette packets, etc.

BRAKE PEDAL:

By pressing this pedal Part. 1 Fig. 10, the machine slows down and stops (until the pedal is released).

PARKING BRAKE:

To leave the machine in parking position, proceed as follows: press the brake pedal with the left foot and then

insert the stop tooth with the right foot by pressing lever. To release the parking brake, simply press the pedal

Part. 4 Fig. 10 again.

FORWARD AND REVERSE PEDAL: (only for battery version)

Part. 3 Fig. 10. This pedal has two functions depending on the position of the operation switch Part. 1 of

switchboard: when the switch is in forward position, the machine moves forward when the pedal is pressed.

When switch is positioned in reverse, the machine reverses. For safety reasons, the reverse speed of the

machine is very low. When the switch is in central position, the machine moves neither forward not in

reverse.

FORWARD AND REVERSE PEDAL: (only for internal combustion engine)

Part. 3 Fig. 10. This pedal has two functions depending on the position. By pressing the right side (with arrow

pointing UP) the machine goes forward while by pressing the left side (with arrow pointing DOWN) the machine

withdraws. For safety reasons, the reverse speed of the machine is very low.

SIDE BRUSH ENGAGEMENT LEVER: (for all models)

The engagement lever Part. 1 Fig. 10 makes it possible to lower the brush from the driving seat. Remember

that the side brush must only be used for cleaning edges, profiles and corners and that it continues to rotate

when the machine motor is rotating. To lower and then activate the side brush push forward lever Part. 1 fig.

10; to disconnect the side brush bring back the lever in the initial position by pulling it back.