-2-

1. Place a 3/8″wooden dowel

rod into center of thermo-

stat then place in 85° F

water. Make a reference

mark on the rod as shown

in g. A.

2. Now insert thermostat into

hot water that is at least

20°F higher than the set

temperature stamped on

label.

3.

The rod should move out

of the thermostat approxi-

mately 1/8″. If the rod shows

no movement or can be

pushed inward, a new ther-

mostat is required.

Figure A

Checking Cold Water Shut-Off (Cont.)

b. Spring #13 has lost its strength and should

be replaced.

Note: Lack of water ow can be normal on the rst

test if the temperature of the cold water is

below 75°F. A quick test is to momentarily

turn on the hot water to warm the thermostat.

If ow then starts, the thermostat is good;

failure to obtain ow when rst starting, or

when valve is cold, is a normal reaction.

Checking Hot Water Shut-Off

Allow full hot and cold water to ow through the

valve for one minute. Shut off the cold water stop

and check valve only. The hot water should be

reduced to a negligible amount.

Failure to do so will indicate:

a. The hot water supply is not 20

°

F above the

required maximum temperature setting.

b. The plunger is sticking and requires cleaning

or replacement.

Inspection and Cleaning Valve

Shut off the hot and cold water supply to the controller.

Remove bonnet #19. To replace pusher O-ring #18,

remove pusher #21 from bonnet #19 and replace

O-ring. Reassemble in reverse order.

With the bonnet assembly off the valve, remove

thermostat #22 and check and clean (see g. A).

Unscrew bottom plug #14 and remove valve spring

#13 and plunger #12 (see g. C). If the assembly

does not slide out, remove the plunger with liner #11

and gently tap plunger until it becomes free. Clean

and polish the liner and plunger with very ne em-

ery cloth until the plunger moves freely in the liner.

With the liner out of the valve, replace liner O-ring #10.

Note: If the piston or liner is nicked or shows signs

of excessive wear, it should be replaced.

Caution: The liner and plunger cannot be dropped

please handle carefully. The liner must be in-

serted correctly. Carefully examining the outside

of the liner will reveal a very small difference in

diameter between the upper half and the lower

half. On reassembly, the smaller diameter must

be inserted rst through bottom plug opening.

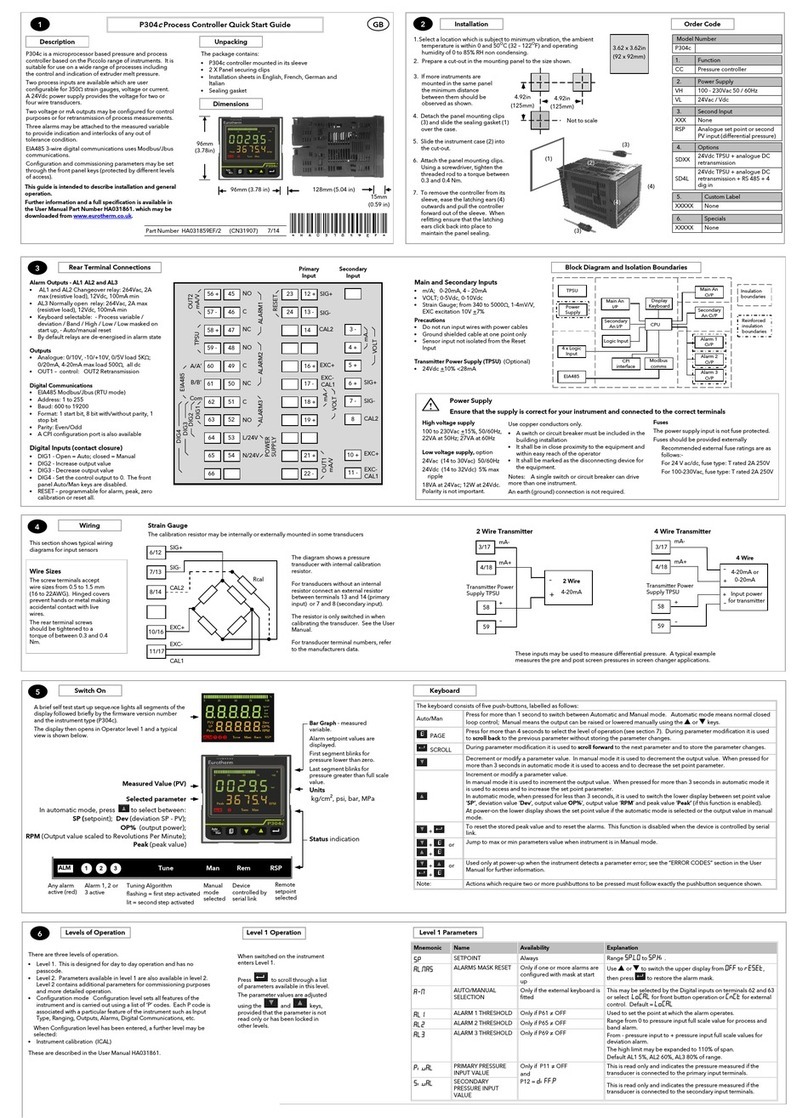

Temperature Adjustment

Valves are normally factory set for a maximum 110°F outlet tem-

perature, or that stamped on the label. If it is desired to change

this setting, proceed as follows:

1. Insert key and turn to set mode. (Power light should illuminate)

2. Turn off recirculation pump. (Flow light should illuminate)

3. If ow light is not illuminated, create sufcient demand on the

system.

4. To increase set temperature, press actuator switch up for

3-5 seconds. Wait for a response from temperature indicator.

Repeat until the desired set temperature is reached. (Note:

Both power light and ow light must be illuminated to permit

temperature adjustment.)

5. To decrease set temperature, press actuator switch down for

3-5 seconds. Wait for a response from temperature indicator.

Repeat until the desired set temperature is reached. (Note:

The set point must have a 20°F temperature differential

between hot and cold inlet temperatures and is limited to a

range of 90-120°F).

6. Once the desired set point is reached and stabilized, turn

the key to operate mode and remove key.

Note: If outlet temperature desired is 15°F or more higher than that

stamped on the label, contact the factory or a representative

for a special thermostat.

REFERENCE

MARKS

THERMOSTAT

Warning: This product contains chemicals known to the

State of California to cause cancer and birth defects or

other reproductive harm.

(Installer: California law requires that this warning be

given to the consumer.)

For more information: www.oehha.org/prop65

19

18

21

Figure B