Lazer Safe PCSS-F Series User manual

PCSS-F SERIES

Technical Manual

Additions

LS-CS-M-023

27 Action Road, Malaga WA 6090, Australia

PO Box 2368, Malaga WA 6944, Australia

PCSS-F Additions Technical Manual LS-CS-M-023

Page ii

Original Language Version: 1.02 Released: 03/12/2013

D

Do

oc

cu

um

me

en

nt

t

S

St

ta

at

tu

us

s

Document Reference Code:

LS-CS-M-023

Version:

1.02

Released:

03/12/2013

D

Do

oc

cu

um

me

en

nt

t

R

Re

ev

vi

is

si

io

on

n

H

Hi

is

st

to

or

ry

y

Date

Manual

Version

Software

Version

Summary of Change

01/01/2008

0.01

n/a

Initial release of addendum.

14/01/2008

0.02

n/a

Updated Option Compatibility Table to match latest kernel release.

17/01/2008

0.03

n/a

Changed communications protocol to ser4_a8.

21/01/2008

0.04

n/a

Corrections to document.

31/01/2008

0.05

n/a

Addition of error reset and changes to document.

06/02/2008

0.06

n/a

Added ser4_a9.

16/05/2008

0.07

n/a

Added down enable 17 and emergency stop 7 options for E Series

Trumpf Machines.

28/05/2008

0.08

FB 1.03.00

Back gauge and switch monitoring added to emergency stop option

7.

30/05/2008

0.09

n/a

Change to down enable 16 timing diagram and enabled valve monitor

2 for all hardware.

05/08/2008

0.10

n/a

Added details for emergency stop 6 –ON switch monitor.

26/09/2008

0.11

FB1.05.12

Correction to wiring in Figure 4-20 and 4-21.

Removed block laser limit switches Section 4.3.2.2

Added Error Reset Option 5 –No station indicators

Changed Down Enable Option 17 –Added Y06/Y07

19/11/2008

0.12

FB1.10.01

Added operations specifications, Section 6.

Added CNC brake activation for E-Stop option 7.

18/10/2010

0.13

FB1.17.10

Added robot gate switch operation for E-Stop option 6.

Added movement monitoring details.

Added down switch option 6.

23/06/2011

1.00

FB1.18.00

Release

30/06/2011

1.01

Additional page for Declaration of Conformity

03/12/2013

1.02

FB1.26.00

General document review

Removed Specifications section 7 as contained PCSS-F Technical

Manual

Removed Declaration of Conformity section 8 as contained PCSS-F

Technical Manual

Removed Option Compatibility section 4.1

Updated section 3 detailing the serial communications interface

LS-CS-M-023 PCSS-F Additions Technical Manual

Page iii

Original Language Version: 1.02 Released: 03/12/2013

C

Co

op

py

yr

ri

ig

gh

ht

t

I

In

nf

fo

or

rm

ma

at

ti

io

on

n

"Lazer Safe", "PCSS" and "Press Control Safety System" are trademarks of Lazer Safe Pty Ltd.

ISaGRAF is a registered trademark of ICS Triplex ISaGRAF Inc.

Microsoft and Windows are either registered trademarks or trademarks of Microsoft Corporation in the U.S.A. and / or other

countries.

The content of this manual is supplied for informational use only, is subject to change without notice and should not be construed

as a commitment by Lazer Safe Pty Ltd. Lazer Safe Pty Ltd assumes no responsibility or liability for any errors, inaccuracies or

omissions that may appear within this publication.

Copyright in this documentation is owned by Lazer Safe Pty Ltd. No part of this document may be reproduced or copied in any

form or by any means (graphic, electronic, or mechanical including photocopying, recording, taping, or information storage and

retrieval systems) without the written permission of Lazer Safe Pty Ltd.

Lazer Safe's copyright in this document is protected by Australian copyright laws (including the Copyright Act 1948

(Commonwealth)) and by international copyright treaties.

© 2008-2013 Lazer Safe Pty Ltd. All rights reserved.

PCSS-F Additions Technical Manual LS-CS-M-023

Page iv

Original Language Version: 1.02 Released: 03/12/2013

T

Ta

ab

bl

le

e

o

of

f

C

Co

on

nt

te

en

nt

ts

s

1 About This Manual ........................................................................................ 1-1

1.1 Document Objectives ......................................................................................................... 1-1

1.2 Guide to Notes, Cautions and Warnings............................................................................... 1-1

1.3 Obtaining Technical Assistance ........................................................................................... 1-1

2 FIO04 Input / Output Module ...................................................................... 2-1

2.1 CN1 Connections ............................................................................................................... 2-1

2.2 CN2 Connections ............................................................................................................... 2-1

2.3 CN3 Connections ............................................................................................................... 2-1

2.4 CN4 Connections ............................................................................................................... 2-1

2.5 CN5 Connections ............................................................................................................... 2-2

2.6 CN6 Connections ............................................................................................................... 2-2

2.7 CN7 Connections ............................................................................................................... 2-2

2.8 CN8 Connections ............................................................................................................... 2-2

2.9 CN9 Connections ............................................................................................................... 2-2

2.10 CN10 Connections .............................................................................................................. 2-2

2.11 I/O Module Specifications ................................................................................................... 2-3

3 CNC Press Controller Communications Interface ........................................ 3-1

3.1 Serial Communications Interface Option (ser4_a9) ............................................................... 3-1

4 PCSS Safety Function Options ...................................................................... 4-5

4.1 Down Enable Safety Function Options ................................................................................. 4-5

4.1.1 Down Enable Option 16 ................................................................................................. 4-5

4.1.2 Down Enable Option 17 ................................................................................................. 4-7

4.2 Emergency Stop Function Options ..................................................................................... 4-11

4.2.1 Emergency Stop Option 6 ............................................................................................ 4-11

4.2.2 Emergency Stop Option 7 ............................................................................................ 4-17

4.3 Error Reset Function Options ............................................................................................ 4-23

4.3.1 Error Reset Option 4 .................................................................................................... 4-23

4.3.2 Error Reset Option 5 .................................................................................................... 4-24

4.3.3 Error Reset Option 6 .................................................................................................... 4-25

4.4 Valve Monitoring Function Options .................................................................................... 4-27

4.4.1 Valve Monitoring Option 12 ........................................................................................ 4-27

4.5 Down Switch Function Options ......................................................................................... 4-28

4.5.1 Down Switch Option 5 - Dual Operator Foot Control Only ......................................... 4-28

4.5.2 Down Switch Option 6 - Four Operator Foot Control Only ......................................... 4-30

5 Auxiliary Connections .................................................................................. 5-1

5.1 Special Mode Operation Selection ....................................................................................... 5-1

6 Kernel Operation .......................................................................................... 6-2

6.1 Movement Monitoring ........................................................................................................ 6-2

6.2 Special Tools ..................................................................................................................... 6-2

LS-CS-M-023 PCSS-F Additions Technical Manual

Page 1-1

Original Language Version: 1.02 Released: 03/12/2013

1

1

A

Ab

bo

ou

ut

t

T

Th

hi

is

s

M

Ma

an

nu

ua

al

l

This section contains information about this manual. It contains the following sections:

•Document Objectives

•Technical Competence Requirements

•Prerequisites

•Document Organisation

•Related Documentation

•Guides to Notes, Cautions and Warnings

•Obtaining Technical Assistance

1

1.

.1

1

D

Do

oc

cu

um

me

en

nt

t

O

Ob

bj

je

ec

ct

ti

iv

ve

es

s

The PCSS-F Additions Technical Manual provides specific information on the hardware used

by Trumpf.

1

1.

.2

2

G

Gu

ui

id

de

e

t

to

o

N

No

ot

te

es

s,

,

C

Ca

au

ut

ti

io

on

ns

s

a

an

nd

d

W

Wa

ar

rn

ni

in

ng

gs

s

Note:

This symbol indicates helpful information that helps you make better use of your

Lazer Safe product.

Caution:

This symbol alerts you to situations that could result in equipment damage.

Warning:

This symbol indicates danger. You are in a situation that could cause bodily injury.

Before you work on any equipment, be aware of the hazards involved with electrical

circuitry and be familiar with standard practices for preventing accidents. To see

translations of the warnings that appear in this publication, refer to the translated

safety warnings that accompanied this device.

1

1.

.3

3

O

Ob

bt

ta

ai

in

ni

in

ng

g

T

Te

ec

ch

hn

ni

ic

ca

al

l

A

As

ss

si

is

st

ta

an

nc

ce

e

For technical support email customerservice@lazersafe.com.au detailing your specific

requirement.

LS-CS-M-023 PCSS-F Additions Technical Manual

Page 2-1

Original Language Version: 1.02 Released: 03/12/2013

2

2

F

FI

IO

O0

04

4

I

In

np

pu

ut

t

/

/

O

Ou

ut

tp

pu

ut

t

M

Mo

od

du

ul

le

e

2

2.

.1

1

C

CN

N1

1

C

Co

on

nn

ne

ec

ct

ti

io

on

ns

s

CN1 provides a power supply connection on the I/O module via a 5-way removable terminal

block, which is used for all inputs and outputs. A 24 VDC output is derived from this input

power supply connection and provided on the terminals for energising each of the standard

inputs. Each of these 24 VDC outputs has an on-board 5 Amp fuse. Should this current be

exceeded and the fuse triggered, the fuse can be reset by removing the power to the I/O

module and then re-applying.

The power supply input connection allows for 15 A maximum current for the I/O module.

Caution:

To ensure that the power supply chosen has the required current capability and the

maximum current for these inputs is not exceeded, it is important to give careful

consideration to the amount of current to be drawn by the outputs and supply

voltages from the I/O module.

A power supply LED indicator displaying the status of the power connection is located adjacent

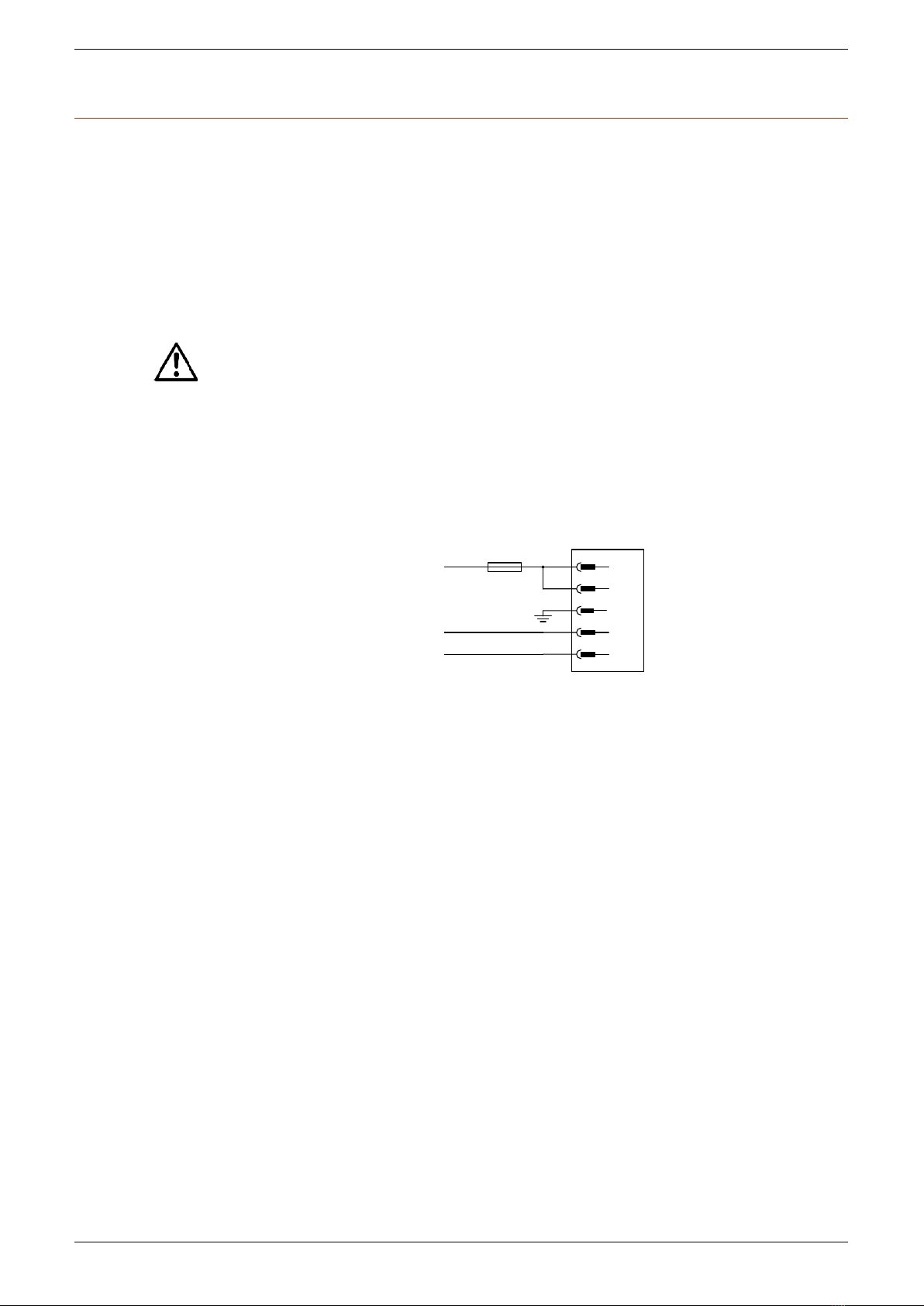

to CN1. Connections are shown in Figure 2-1 below.

24VDC

24VDC

PE

0VDC

FIO04 –CN1

1

2

3

4

0VDC

5

24 VDC Supply

0 VDC Supply

0 VDC Supply

15A

Figure 2-1: PCSS-F Series I/O Module Power Connections

Power Supply Specifications

Input points

2

Input voltage

24 VDC ± 10%

Input current

15 A total

2

2.

.2

2

C

CN

N2

2

C

Co

on

nn

ne

ec

ct

ti

io

on

ns

s

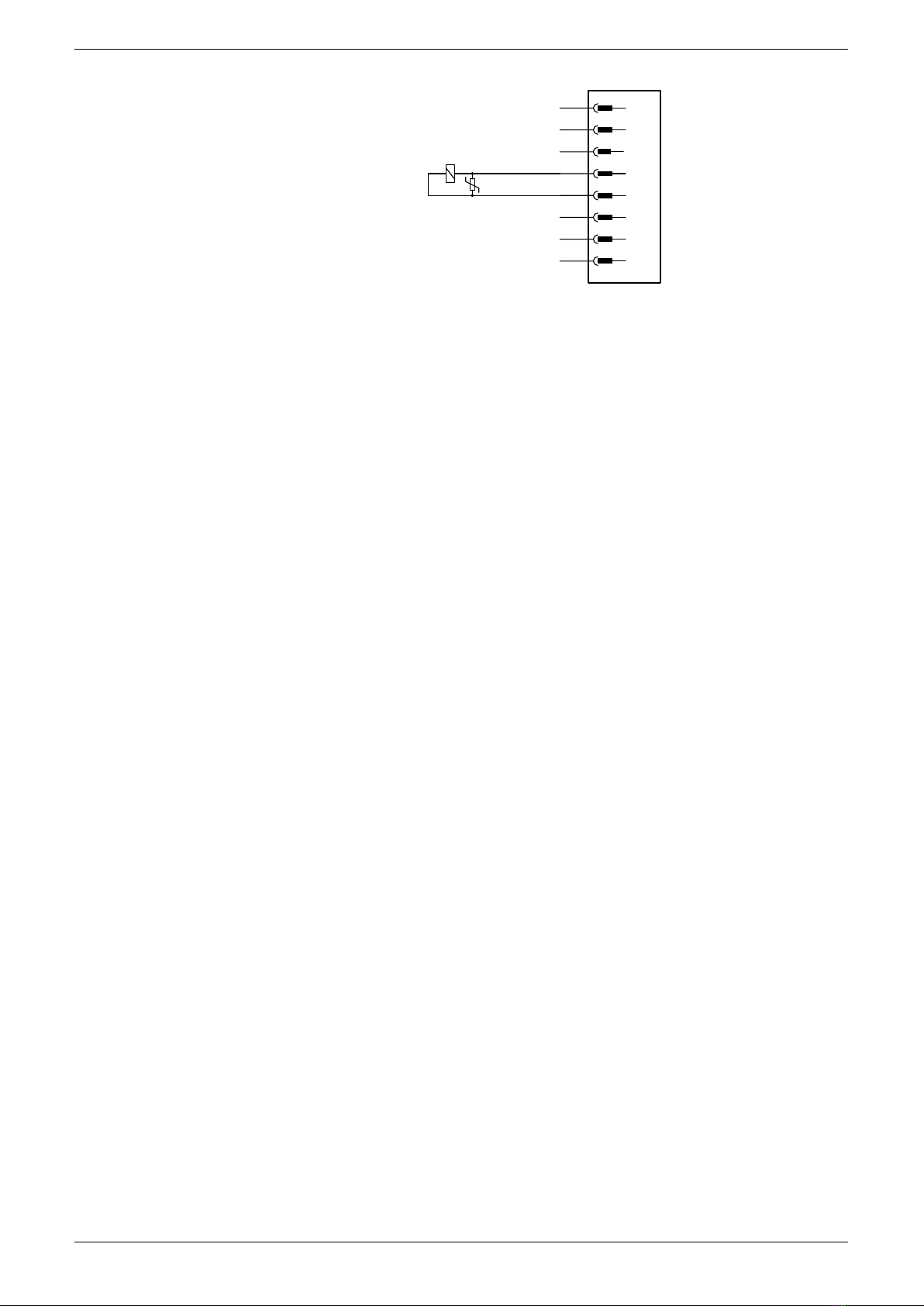

CN2 has connections for outputs to control the solenoid valves on the press brake via a 7way

removable terminal block. These outputs are a combination of three dual outputs (Y00 to Y02)

and one standard outputs (Y03).

2

2.

.3

3

C

CN

N3

3

C

Co

on

nn

ne

ec

ct

ti

io

on

ns

s

CN3 houses connections for an Emergency Stop contactor with feedback via an 8-way

removable terminal block. A single dual output (Y04) and pulsed input combination (X00 / P00)

is available for these connections.

2

2.

.4

4

C

CN

N4

4

C

Co

on

nn

ne

ec

ct

ti

io

on

ns

s

Foot switches, up and down and error reset switch connections are available on CN4 via a 14-

way removable terminal block. The connections consist of two pulsed input combinations (X01

to X02 / P01 to P02) and seven standard inputs (X03 to X09). A 24 VDC connection is also

provided for energising when switched to the standard input.

PCSS-F Additions Technical Manual LS-CS-M-023

Page 2-2

Original Language Version: 1.02 Released: 03/12/2013

2

2.

.5

5

C

CN

N5

5

C

Co

on

nn

ne

ec

ct

ti

io

on

ns

s

Connections on CN5 are provided for Door and Emergency Stop switches on the press brake

via an 8-way removable terminal block. Three pulsed input combinations (X10 to X13 / P10 to

P13) are available for these connections. A 24 VDC connection is also available for energising

when switched to the standard input.

2

2.

.6

6

C

CN

N6

6

C

Co

on

nn

ne

ec

ct

ti

io

on

ns

s

CN6 houses connections for the level switches via a 12-way removable terminal block. Three

sets of pulsed inputs (X14 to X16 / P14 to P16) and three standard inputs (X17 to X19) are

available for connection. CN6 also contains a 24 VDC connection for energising when

switched to the standard input.

2

2.

.7

7

C

CN

N7

7

C

Co

on

nn

ne

ec

ct

ti

io

on

ns

s

Valve monitor input connections are available on CN7 via a 15-way removable terminal block.

These connections consist of a single pulsed input (X20 / P20) and eleven standard inputs

(X21 to X31). A 24 VDC connection is also provided for energising when switched to the

standard input.

2

2.

.8

8

C

CN

N8

8

C

Co

on

nn

ne

ec

ct

ti

io

on

ns

s

CN8 houses the connections that are required for the special user mode via a 4-way

removable terminal block. These connections consist of a single pulsed input (X32 / P32) and

one standard input (X33). A 24 VDC connection is also provided for energising when switched

to the standard input.

2

2.

.9

9

C

CN

N9

9

C

Co

on

nn

ne

ec

ct

ti

io

on

ns

s

CN9 houses the connections that are required for hand button control (Normally Closed

Contacts) via a 10-way removable terminal block. These connections consist of four pulsed

input (X34 to X37 / P34 to P37). A 24 VDC connection is also provided for energising when

switched to the standard input.

2

2.

.1

10

0

C

CN

N1

10

0

C

Co

on

nn

ne

ec

ct

ti

io

on

ns

s

CN10 houses the connections that are required for hand button control (Normally Open

Contacts) via a 9-way removable terminal block. These connections consist of four standard

inputs (X38 to X41) and two standard outputs (Y08 and Y09). A 24 VDC connection is also

provided for energising when switched to the standard input.

LS-CS-M-023 PCSS-F Additions Technical Manual

Page 2-3

Original Language Version: 1.02 Released: 03/12/2013

2

2.

.1

11

1

I

I/

/O

O

M

Mo

od

du

ul

le

e

S

Sp

pe

ec

ci

if

fi

ic

ca

at

ti

io

on

ns

s

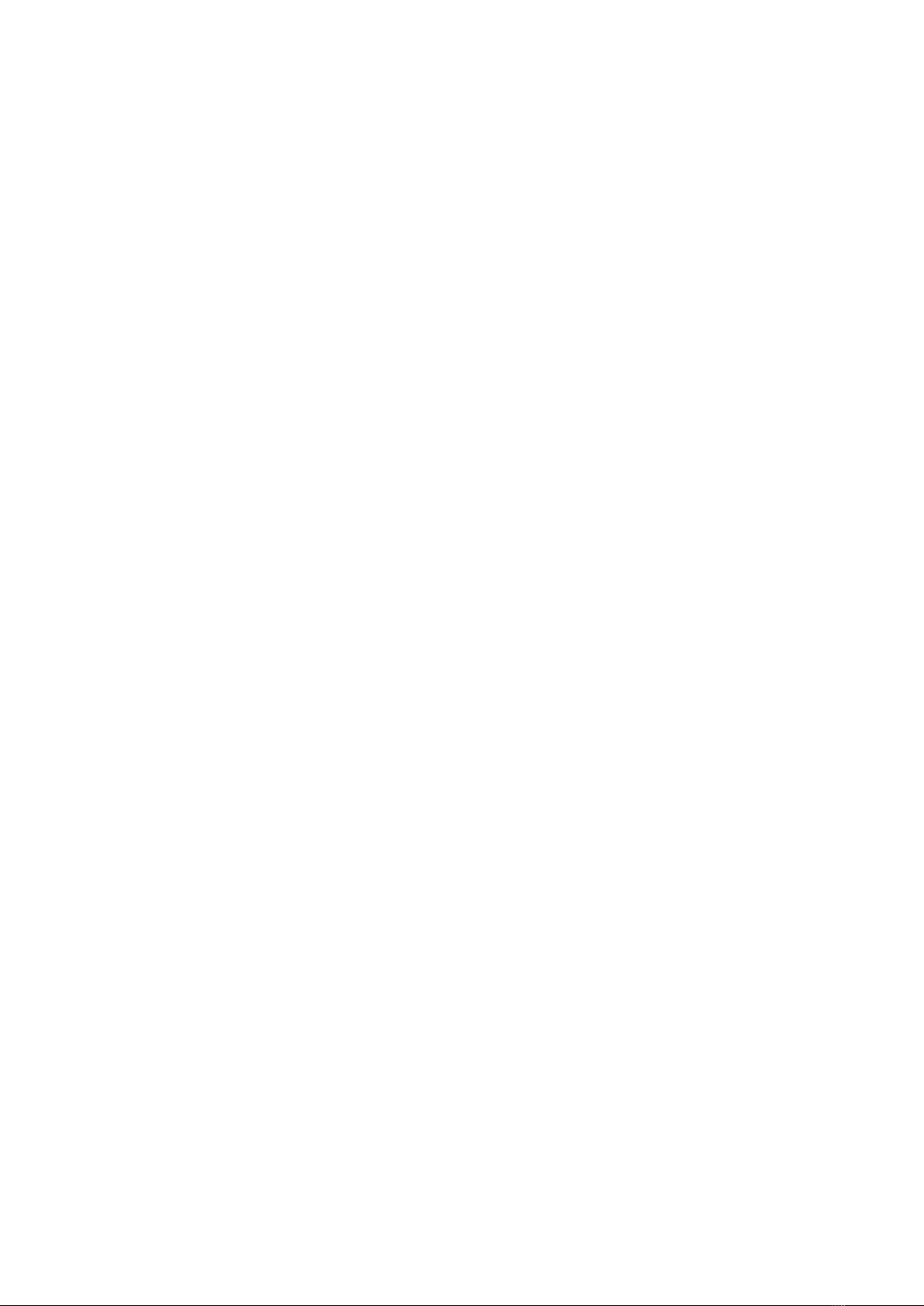

Standard Input Specifications

Input voltage

24 VDC ± 10%

Input current

15 mA

Voltage on

14 VDC minimum

Voltage off

12 VDC maximum

Delay on

0.02 ms

Delay off

0.02 ms

Isolation

Opto-coupler

On display

Red LED

Output supply voltage

24 VDC ± 10%

Max supply current

5 A

Pulsed Input Specifications

Inputs

Input voltage

24 VDC ± 10%

Input current

15 mA

Voltage on

14 VDC minimum

Voltage off

12 VDC maximum

Delay on

0.02 ms

Delay off

0.02 ms

Isolation

Opto-coupler

On display

Red LED

Pulsed Outputs

Switching voltage

24 VDC ± 10%

Max switching current

1.6 A

Leakage current

0 mA

Isolation

Opto-coupler

On display

Red LED

Dual Output Specifications

Switching voltage

24 VDC ± 10%

Max switching current

10 A Peak, 4.5 A Continuous

Leakage current

0 mA

Delay on

0.11 ms max

Delay off

0.16 ms max

Isolation

Opto-coupler

On display

Red LED

Standard Output Specifications

Switching voltage

24 VDC ± 10%

Max switching current

6 A Peak, 1.6 A Continuous

Leakage current

0 mA

Delay on

0.11 ms max

Delay off

0.16 ms max

Isolation

Opto-coupler

On display

Red LED

LS-CS-M-023 PCSS-F Additions Technical Manual

Page 3-1

Original Language Version: 1.02 Released: 03/12/2013

3

3

C

CN

NC

C

P

Pr

re

es

ss

s

C

Co

on

nt

tr

ro

ol

ll

le

er

r

C

Co

om

mm

mu

un

ni

ic

ca

at

ti

io

on

ns

s

I

In

nt

te

er

rf

fa

ac

ce

e

3

3.

.1

1

S

Se

er

ri

ia

al

l

C

Co

om

mm

mu

un

ni

ic

ca

at

ti

io

on

ns

s

I

In

nt

te

er

rf

fa

ac

ce

e

O

Op

pt

ti

io

on

n

(

(s

se

er

r4

4_

_a

a9

9)

)

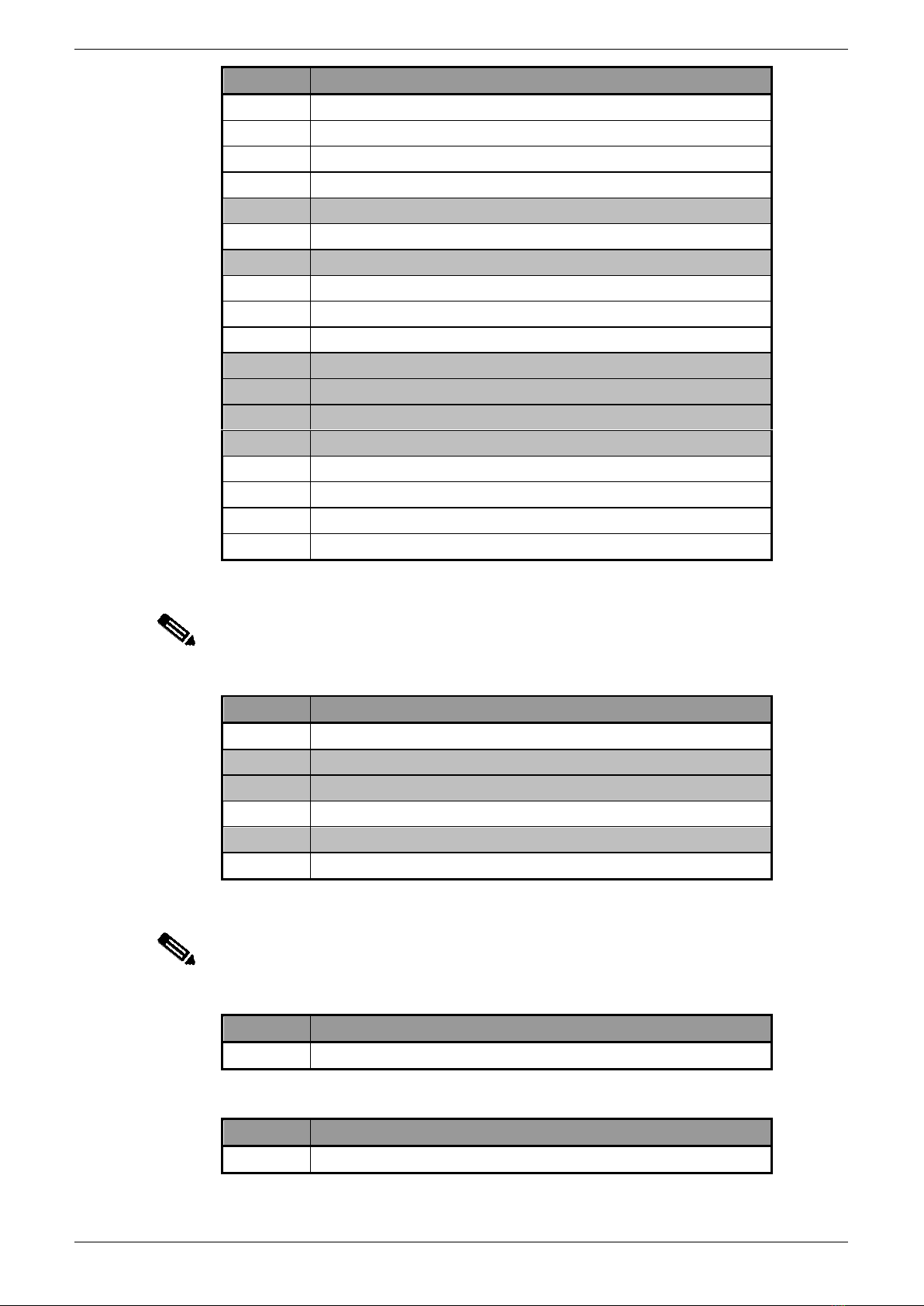

ISaGRAF driver

Driver name

ser4__a9

Driver description

Characteristics as shown below

Channel #

Description

0

Protocol options (4 = LzsBus2)

1

Baud rate option (0 = 9600; 1 = 19200; 2 = 38400; 3 = 57600; 4 =

76800; 5 = 115200bps)

2

Number of data bits (5, 6, 7 or 8)

3

Parity option (0 = None; 1 = Odd; 2 = Even)

4

Number of stop bits (1 or 2)

5

Hardware flow control (0 = Disabled; 1 = Enabled)

6

Non-zero: Reset all counts in ComErr board

Table 3-1: Analogue communication parameter outputs (ComParam)

Channel #

Description

0

Low level overrun error count

1

Low level framing error count

2

Low level parity error count

3

Invalid packet header count

4

Reserved

5

Checksum or CRC error count

6

Reserved

7

Reserved

8

Receive software buffer full error count

9

Receive synchronisation error count

Table 3-2: Analogue communications error count inputs (ComErr)

PCSS-F Additions Technical Manual LS-CS-M-023

Page 3-2

Original Language Version: 1.02 Released: 03/12/2013

Channel #

Units

Description

0

microns

Reference Y1

1

microns

Reference Y2

2

microns

Material thickness

3

microns

Die 01 height

4

microns

Die 02 height

5

microns

Punch 01 height

6

microns

Punch 02 height

7

microns

Tool reference

8

microns

CNC Mute position

9

microns

Upstand height

10

microns

Height of crowning

11

N/A

Reserved

12

microns

Decompression end height

Table 3-3: Analogue inputs received from the CNC (An_in)

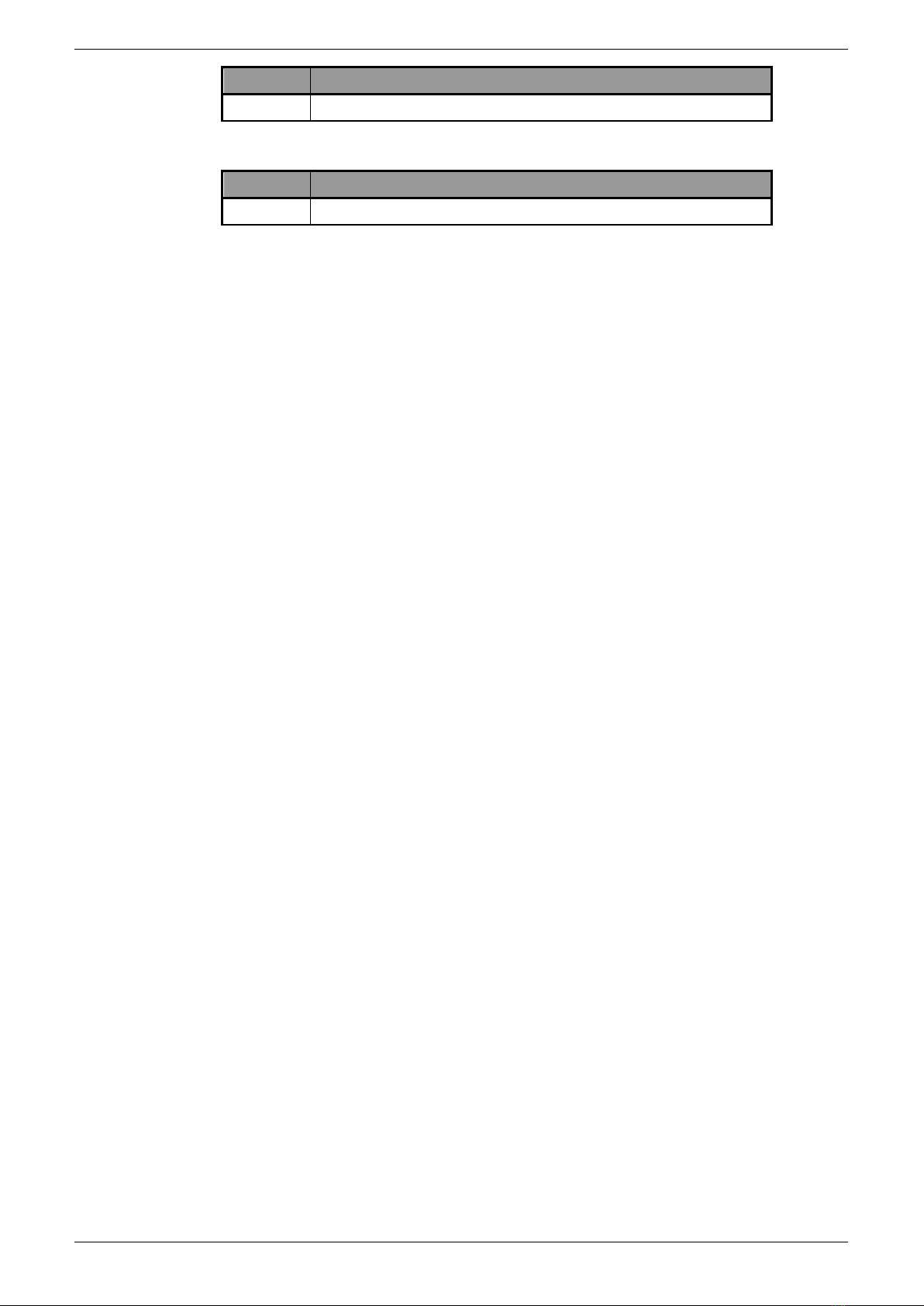

Channel #

Units

Description

0

microns

Mute position calculated by PCSS

1

N/A

Condition code from PCSS

Table 3-4: Analogue outputs sent by the PCSS (An_out)

Channel #

Description

0

Normal Mode

1

Tray Mode

2

Stop at Mute Mode

3

Reserved

4

Tool 2

5

Reserved

6

Controller (CNC) Not Referenced

7

Reserved

8

Robot Mode

9

Mode 2 foot - 2 foot

10

Mode 1 foot –1 foot

11

Mode 2 hand –1 foot

12

Mode 2 hand –2 hand

13

Mode 4 hand –2 foot

14

Mode 4 hand –4 hand

15

Power Up Parameters

16-31

Reserved

Table 3-5: PCSS operation parameters from the CNC (OperMode)

Note:

The highlighted fields above are used by the PCSS kernel software directly from the

serial communications so these should not be changed or modified.

LS-CS-M-023 PCSS-F Additions Technical Manual

Page 3-3

Original Language Version: 1.02 Released: 03/12/2013

Channel #

Description

0

CNC OK

1

CNC TDC

2

CNC Mute

3

CNC Axis in Position

4

CNC Moving Up

5

Spare

6

CNC 2 Station

7

CNC Hydraulics On

8

Spare

9

Spare

10

Foot Station 1

11

Foot Station 2

12

Foot Station 3

13

Foot Station 4

14

CNC Referenced

15

CNC Decompression

16

CNC Hydraulic Start

17-23

Spare

Table 3-6: CNC Status (CNC_ST)

Note:

The highlighted fields above are used by the PCSS kernel software directly from the

serial communications so these should not be changed or modified.

Channel #

Description

0-2

Spare

3

Down high speed (down enable option 16 only)

4

Down low speed (down enable option 16 only)

5-14

Spare

15

Condition changed

16-23

Spare

Table 3-7: PCSS Status to the CNC (PCSS_ST)

Note:

The highlighted fields above are used by the PCSS kernel software directly from the

serial communications so these should not be changed or modified.

Channel #

Description

0-31

Spare

Table 3-8: Generic Analog inputs (gA_in)

Channel #

Description

0-31

Spare

Table 3-9: Generic Analog outputs (gA_out)

PCSS-F Additions Technical Manual LS-CS-M-023

Page 3-4

Original Language Version: 1.02 Released: 03/12/2013

Channel #

Description

0-127

Spare

Table 3-10: Generic Digital inputs (gD_in)

Channel #

Description

0-127

Spare

Table 3-11: Generic Digital outputs (gD_out)

LS-CS-M-023 PCSS-F Additions Technical Manual

Page 4-5

Original Language Version: 1.02 Released: 03/12/2013

4

4

P

PC

CS

SS

S

S

Sa

af

fe

et

ty

y

F

Fu

un

nc

ct

ti

io

on

n

O

Op

pt

ti

io

on

ns

s

4

4.

.1

1

D

Do

ow

wn

n

E

En

na

ab

bl

le

e

S

Sa

af

fe

et

ty

y

F

Fu

un

nc

ct

ti

io

on

n

O

Op

pt

ti

io

on

ns

s

These options enable and control movement of the pressing beam when initiated by the

operator of the press brake. The down enable function option to be selected will depend on the

solenoid valve control strategy needed, which is based primarily on the hydraulic configuration

of the press brake on which the PCSS is being installed.

It is therefore important to review the hydraulic configuration and schematic for the machine

and determine the down enable function option that is required. Selecting the appropriate

down enable option should be based on the solenoid valve outputs that need to be controlled

and the control strategy for each of these outputs.

I/O channel 9 of the ANO I/O board for the Kernel Software Interface allows the down enable

option required to be selected. Entering the appropriate value for the Down Enable Option

Selection Variable as detailed in each of the options described below will initialise the desired

down enable option when the PCSS software is started.

Note:

Lazer Safe recommends varistor protection is fitted across all valves installed on the

press brake when connected to the PCSS. Whilst resistor/capacitor and diode

protection solutions are available, varistor protection provides superior reaction time

and suppression capabilities to generated valve voltages and transients compared to

other protection solutions. The varistor also provides protection for valves with

integrated electronics as well as reducing EMI/RFI.

Resistor/capacitor protection modules can also interfere with the hardware checks

that are performed by the PCSS on the outputs on each machine cycle causing

incorrect failure conditions to be reported.

The use of diode type protection modules can also have an effect on the stopping

performance of the press brake. This may lead to increased stopping distances or

times compared to the use of Varistor protection.

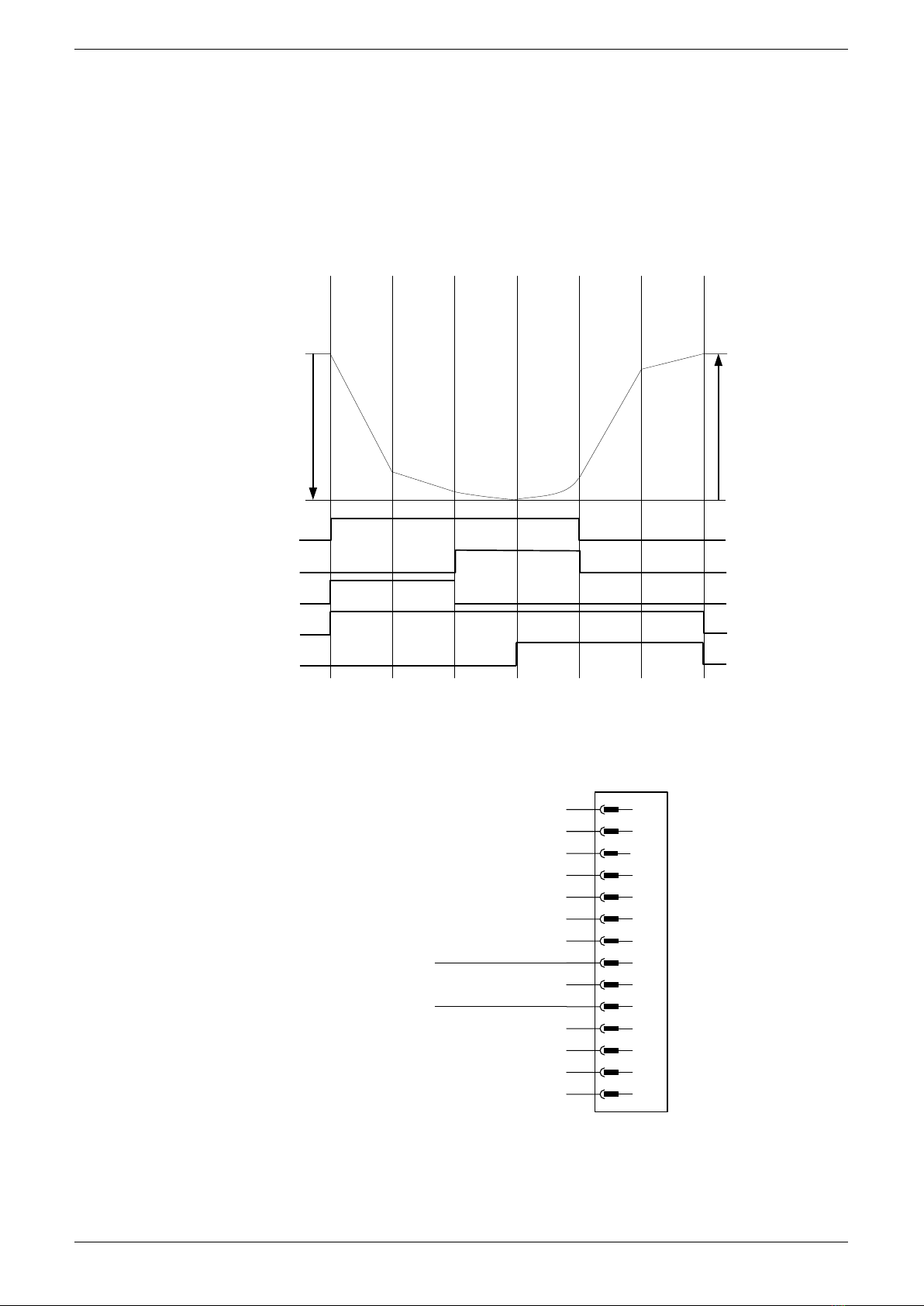

4.1.1 Down Enable Option 16

Solenoids –High Speed

Solenoids –Prefill

Solenoids –Proportional Enable

Y00H

Y00L

Y01H

Y01L

Y02H

FIO04 –CN2

1

2

3

4

5

Y02L

6

Y03

7

Figure 4-1: Down Enable Option 16 (CN2 - FIO04 Connections)

This down enable option provides outputs for control of the following solenoid valves on the

press brake:

•High Speed Solenoid;

•Low Speed Solenoid and;

•Proportional Solenoids Enable.

PCSS-F Additions Technical Manual LS-CS-M-023

Page 4-6

Original Language Version: 1.02 Released: 03/12/2013

The down enable condition from the down enable option is not physically connected to an

output but is one of the conditions that must be met before down movement is allowed by the

PCSS. This condition used from the down enable option indicates that the down switch has

been pressed and that down movement of the pressing beam can occur due to the required

safety conditions being met.

The down low speed condition is enabled when slow speed operation is required, but as with

the down enable condition, it is not physically connected to an output. This condition is used to

indicate that slow speed down movement is enabled. Any of the following variables being set,

will cause a latched condition to be set which is not reset until the TDC input to the Kernel

Software interface is set:

•Pressing speed;

•Crawl speed;

•CNC mute has been reached;

•CNC controller has not yet been referenced;

•Pressing of the material has begun; or

•High speed disable distance before mute position has been reached.

When this latched condition and the down enable condition are both set, then the down low

speed condition will be enabled or set.

The outputs used on the PCSS for the solenoid valves on the press brake provided by this

option are detailed below with the connections shown in Figure 4-1 for the FIO04 module. The

operation of these solenoid valve outputs during up and down movement of the pressing beam

is shown in Figure 4-2.

The high speed solenoid output is connected to a safety output on the PCSS and allows the

control of the high speed solenoid valves on the press brake. If the down enable condition has

been met but the down low speed condition has not been enabled, the high speed solenoid

output will be switched on and the pressing beam can move down at high speed. This output

will be switched off when down low speed is required.

The down low speed condition is enabled when slow speed operation is required, but as with

the down enable condition, it is not physically connected to an output. This condition is used to

indicate that slow speed down movement is enabled. Any of the following variables being set,

will cause a latched condition to be set which is not reset until the TDC input to the Kernel

Software interface is set:

•Pressing speed;

•Crawl speed;

•CNC mute has been reached;

•CNC controller has not yet been referenced;

•Pressing of the material has begun; or

•High speed disable distance before mute position has been reached.

When this latched condition and the down enable condition are both set, then the down low

speed condition will be enabled or set.

The proportional pressure output from the down enable option is set once the hydraulic pump

is running and if:

•The down enable condition is set; or

•The decompression command has been received from the CNC press controller; or

•The up command has been received from the CNC press controller after decompression.

LS-CS-M-023 PCSS-F Additions Technical Manual

Page 4-7

Original Language Version: 1.02 Released: 03/12/2013

It is also possible to have an additional delay when the proportional pressure output is switched

off from the PCSS by using a variable connected to I/O channel 23 of the ANO board for the

Kernel Software Interface.

The proportional enable output is used to enable the proportional solenoid on the press brake

and is connected to a standard output. Once the pump is running, this output remains on when

the down enable is on and is disabled if the CNC press controller has initiated the up command

after decompression.

1

0

1

0

1

0

1

0

TDC

BDC

RAPID SPEED

DOWN

TDC

BDC

DOWN ENABLE

DOWN LOW SPEED

FIO04 – Y01

DOWN HIGH SPEED

FIO04 – Y00

PROPORTIONAL ENABLE

FIO04 – Y03

DECELERATION

RAMP

PRESSING

DECOMPRESSION

RAPID SPEED

UP

SLOW STOP

POSITION

Figure 4-2: Down Enable Option 16 Output Operation

4.1.1.1 Option Selection

To select down enable option 16 during the PCSS configuration, set the initial value for Down

Enable Option Selection Variable to 16 as described the PCSS F Series Technical Manual.

This will ensure that this option and all required outputs are initialised when the PCSS software

is started.

4.1.2 Down Enable Option 17

Brake Set Y1-2

Quickstop

Y00H

Y00L

Y01H

Y01L

Y02H

FIO04 –CN2

1

2

3

4

5

Y02L

6

Y03

7

Brake Set Y1-1

Brake Set Y2-1

Figure 4-3: Down Enable Option 17 (CN2 - FIO04 Connections)

PCSS-F Additions Technical Manual LS-CS-M-023

Page 4-8

Original Language Version: 1.02 Released: 03/12/2013

Brake Set Y2-2

X00

X01

X02

Y04H

Y04L

FIO04 –CN3

1

2

3

4

5

Y05

6

P00

7

24VDC

8

Figure 4-4: Down Enable Option 17 (CN3 - FIO04 Connections)

This down enable option provides outputs for control of the following devices on the press

brake:

•Mechanical Brakes and;

•Electric Motor Quick Stop.

The down enable condition from the down enable option is not physically connected to an

output but is one of the conditions that must be met before down movement is allowed by the

PCSS. This condition used from the down enable option indicates that the down switch has

been pressed and that down movement of the pressing beam can occur due to the required

safety conditions being met.

The up enable condition is also controlled by this down enable option and although not

physically connected to an output, is one of the conditions that must be met before up

movement is allowed by the PCSS. This condition indicates that up movement of the pressing

beam can occur due to the required conditions being met.

The down low speed condition is enabled when slow speed operation is required, but as with

the down enable condition, it is not physically connected to an output. This condition is used to

indicate that slow speed down movement is enabled. Any of the following variables being set,

will cause a latched condition to be set which is not reset until the TDC input to the Kernel

Software interface is set:

•Pressing speed;

•Crawl speed;

•CNC mute has been reached;

•CNC controller has not yet been referenced;

•Pressing of the material has begun; or

•High speed disable distance before mute position has been reached.

When this latched condition and the down enable condition are both set, then the down low

speed condition will be enabled or set.

The down high speed condition is enabled when high speed operation is required, but as with

the down enable condition, it is not physically connected to an output. This condition is used to

indicate that high speed down movement is enabled. The following conditions must be satisfied

for high speed down movement:

•Moving Down;

•Down Enable active and;

•Down Low Speed is disabled.

LS-CS-M-023 PCSS-F Additions Technical Manual

Page 4-9

Original Language Version: 1.02 Released: 03/12/2013

The quick stop condition is enabled during up and down movement during normal operation

or when the static brake tests are performed on the machine. When the beam is moving

down and the dynamic brakes tests are active the quick stop condition is disabled for

determining the stopping performance of the mechanical brakes during down movement.

The outputs used on the PCSS for the mechanical brakes are shown in Figure 4-3 and

Figure 4-4 for the FIO04 module. The operation of the mechanical brakes occurs during

emergency braking and stopping of the machine in conjunction with the quick stop output.

1

0

1

0

1

0

1

0

1

0

TDC

BDC

RAPID SPEED

DOWN

TDC

BDC

DOWN ENABLE

DOWN LOW SPEED

DOWN HIGH SPEED

DECELERATION

RAMP

PRESSING

DECOMPRESSION

RAPID SPEED

UP

SLOW STOP

POSITION

QUICKSTOP

UP ENABLE

Figure 4-5: Down Enable Option 17 Output Operation

4.1.2.1 Down Low and High Speed Outputs

X03

X04

X05

X06

X07

FIO04 –CN4

1

2

3

4

5

X08

6

X09

7

Y06

8

0VDC

9

Y07

0VDC

P03

10

11

12

P04

13

24VDC

14

Down Low Speed

Down High Speed

Figure 4-6: Down Enable Option 17 (CN4 - FIO04 Output Connections)

When the Down Enable Option Selection Variable is set to 17 on the PCSS, with FIO04

hardware installed, the Y06 output is configured as the kernel down low speed, k_lsd and the

Y07 output is configured as the kernel down high speed, k_hsd.

PCSS-F Additions Technical Manual LS-CS-M-023

Page 4-10

Original Language Version: 1.02 Released: 03/12/2013

4.1.2.2 Option Selection

To select down enable option 17 during the PCSS configuration, set the initial value for Down

Enable Option Selection Variable to 17 as described the PCSS F Series Technical Manual.

This will ensure that this option and all required outputs are initialised when the PCSS software

is started.

Table of contents

Popular Safety Equipment manuals by other brands

Micro Detectors

Micro Detectors LS2 Series Installation and operation manual

Petzl

Petzl TIKKA manual

Merlino

Merlino RED-RL Series user manual

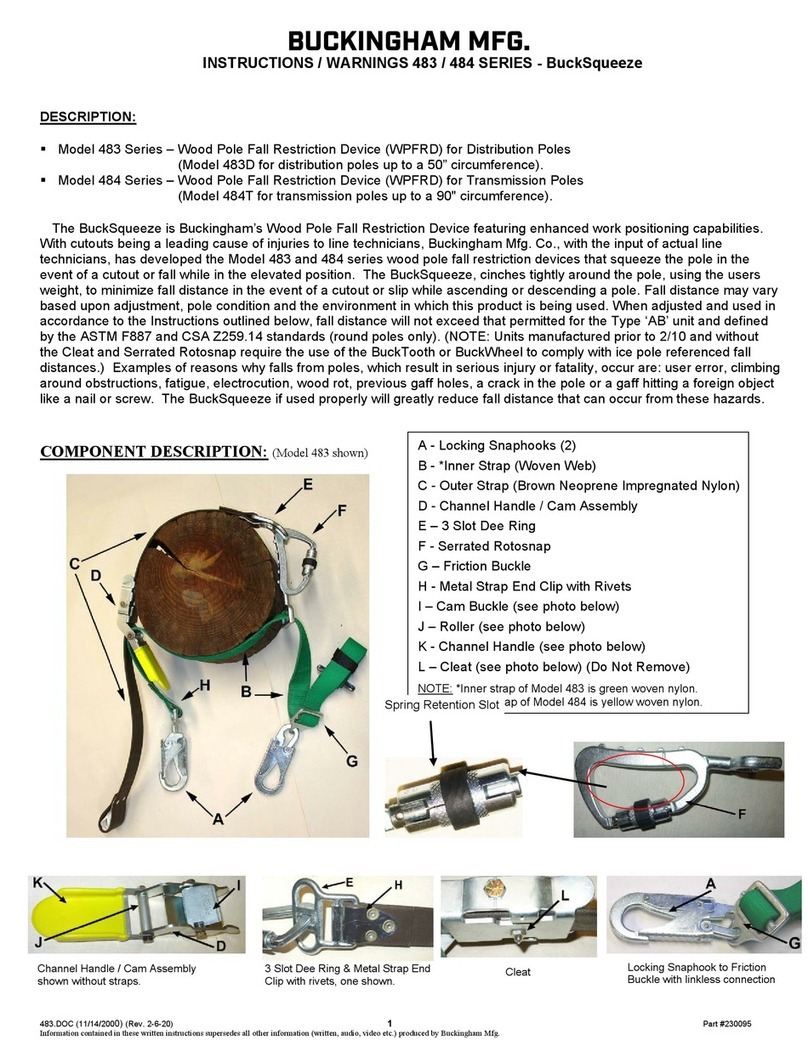

BUCKINGHAM MFG

BUCKINGHAM MFG BuckSqueeze 483 Series Instructions & warnings

Kapriol

Kapriol 32560 Instruction and Information Manual

Climbing Technology

Climbing Technology ORBITER F instruction manual

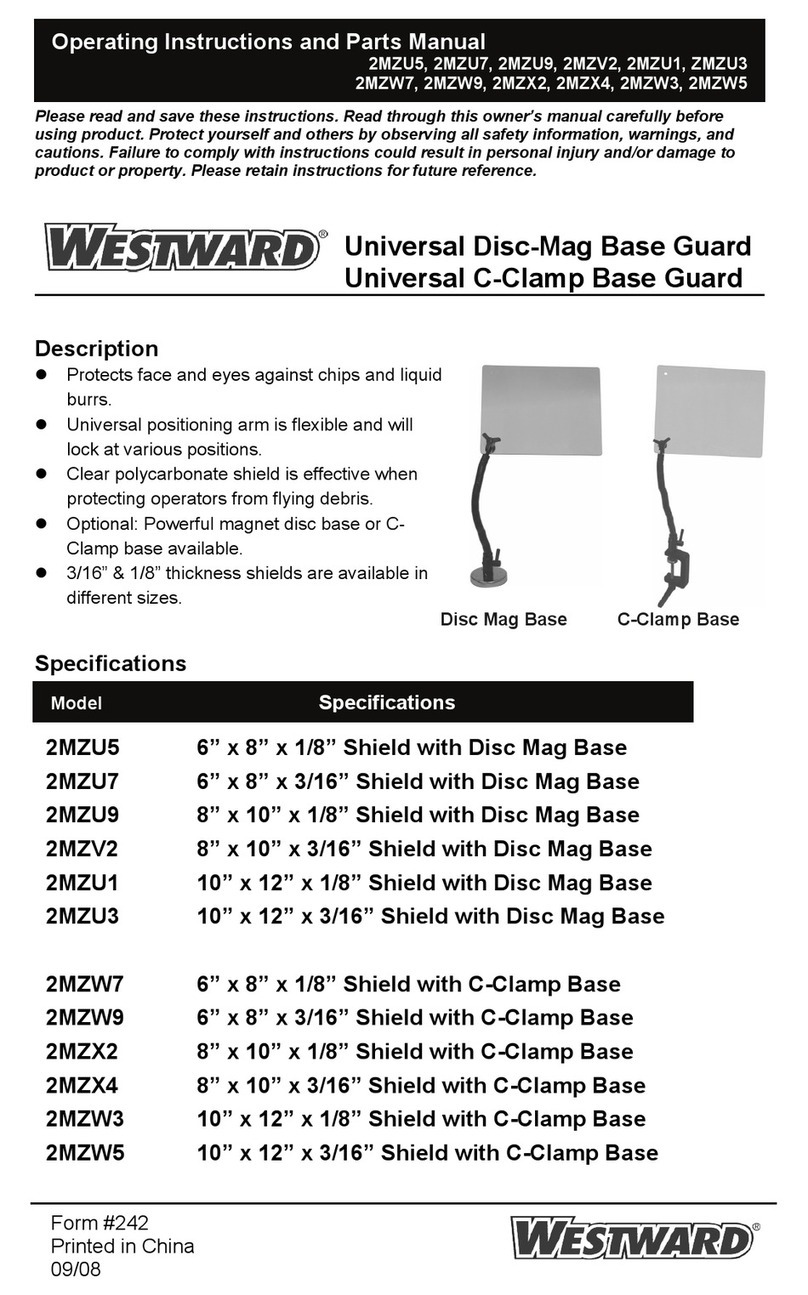

Westward

Westward 2MZU5 Operating instructions and parts manual

Guardian

Guardian G-SAL instruction manual

Singing rock

Singing rock FOOTER II quick start guide

SICK

SICK safeRS operating instructions

EUCHNER

EUCHNER LCA 2 Series operating instructions

Campbell

Campbell Advisor Guide Pedestrian Signal user manual