Micro Detectors LS2 Series User manual

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 2539 3

www.microdetectors.com

LS2 SERIES

SAFETY LIGHT CURTAIN TYPE 2

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors CAT8ELS1250901 1/34

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 2539 3

www.microdetectors.com

LS2 SERIES

SAFETY LIGHT CURTAIN TYPE 2

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors CAT8ELS1250901 2/34

CONTENTS

1.0 ABOUT THIS DOCUMENT ............................................................................................................. 3

1.1 Function of this document ................................................................................................................ 3

1.2 Symbols used in this document ......................................................................................................... 3

2.0 WITH REFERENCE TO SAFETY ....................................................................................................... 4

2.1 Skilled personnel ............................................................................................................................... 4

2.2 Fields of use of the device ................................................................................................................. 4

2.3 General safety instructions and measures of protection .................................................................. 5

2.4 Disposal.............................................................................................................................................. 5

3.0 DESCRIPTION OF THE PRODUCT ................................................................................................... 5

3.1 rief description ................................................................................................................................ 5

3.2 Coding system.................................................................................................................................... 6

3.3 Availability of models with IP65 + IP67 protection ........................................................................... 7

3.4 Availability of models with IP69K protection .................................................................................... 7

3.5 Possibility of interconnection of the available models ..................................................................... 8

4.0 INSTRUCTIONS FOR POSITIONING THE SAFETY LIGHT CURTAINS .................................................. 9

4.1 Respecting the safety distance .......................................................................................................... 9

4.2 How to calculate the safety distance S in conformity with EN ISO 13855 and EN ISO 13857 ........ 10

5.0 MINIMUM DISTANCE FROM REFLECTING SURFACES .................................................................. 13

5.1 How to calculate the minimum distance from reflective surfaces ................................................. 13

6.0 COMMISSIONING ...................................................................................................................... 14

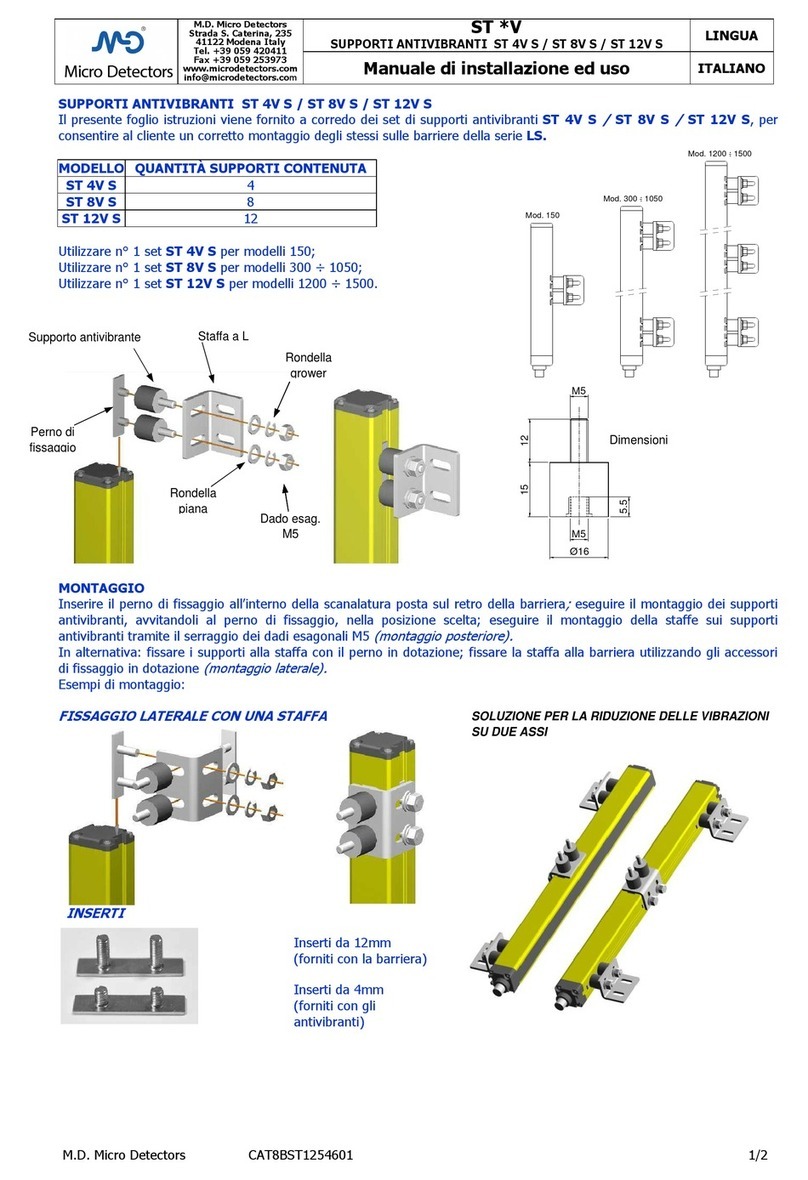

6.1 Mechanical mounting ...................................................................................................................... 14

6.2 Alignment ........................................................................................................................................ 14

6.3 Electrical installation. ...................................................................................................................... 15

7.0 TECHNICAL SPECIFICATIONS. ..................................................................................................... 19

.0 PANEL AND DIAGNOSTICS INDICATIONS .................................................................................... 20

8.1 Symbols used to indicate the LED indicators modes ....................................................................... 20

8.2 Indications of the panels ................................................................................................................. 20

8.3 Interpretation of error codes .......................................................................................................... 21

9.0 LISTS OF AVAILABLE MODELS AND MAIN CHARACTERISTICS ....................................................... 22

10.0 MECHANICAL DIMENSIONS, BARRIERS AND STANDARD ACCESSORIES ....................................... 29

10.1 IP67 models ..................................................................................................................................... 29

10.2 IP69K models ................................................................................................................................... 31

11.0 LIST OF ACCESSORIES APPLICABLE TO THIS PRODUCT ................................................................. 32

12.0 CONTENT OF THE PACKAGE ....................................................................................................... 32

13.0 CHECKING THE SYSTEM ............................................................................................................. 33

13.1 Purpose of the checks...................................................................................................................... 33

13.2 Checks prior to commissioning ........................................................................................................ 33

13.3 Regularity of the checks by qualified personnel ............................................................................. 33

13.4 Regular checks on the effectiveness of the protection device........................................................ 33

14.0 CE DECLARATION OF CONFORMITY............................................................................................ 33

15.0 GUARANTEE .............................................................................................................................. 34

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 2539 3

www.microdetectors.com

LS2 SERIES

SAFETY LIGHT CURTAIN TYPE 2

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors CAT8ELS1250901 3/34

1.0 ABOUT THIS DOCUMENT

Please read t is document carefully before mounting, starting, using and servicing LS2 safety lig t curtains; it contains

detailed instructions t at must be followed wit care.

In addition, pay special attention to C apter 2 “With reference to safety”.

THIS DOCUMENT IS NOT IN ITS ORIGINAL LANGUAGE

1.1 Function of this document

T is document provides t e tec nical personnel of t e manufacturer of a mac ine or t e manager of t e mac ine wit

t e necessary instructions for safe mounting, electrical connection, starting and normal operation and maintenance of LS2

safety lig t curtains.

T e design and use of safety devices t at utilize LS2 safety lig t curtains require specific knowledge, but t is is not

entirely provided in t is document.

T e prescriptions of aut orities and of t e law must also be fundamentally respected for t e installation and during

normal operation of LS2 safety lig t curtains.

1.2 Symbols used in this document

Warning to avoid danger!

A warning indicates real or potential azards.

Its task is to indicate procedures and be aviour t at can avoid accidents.

Read and follow t ese instructions carefully.

Indication

Indications t at can elp ac ieve better performance.

Emitter

symbol

T is symbol identifies devices t at ave t e function of an Emitter.

Receiver symbol

T is symbol identifies devices t at ave t e function of a Receiver.

Body detection

T is symbol marks devices designed to detect a body entering a protected area.

It refers to multi-beam safety lig t grids wit 2, 3 or 4 beams.

T ese safety lig t grids are usually cost-effective and feature a long range, t ey enable creating

protection for extensive areas and on more t an one side, using diverter mirrors.

T ese models are available in t e LS2 series.

Limb or presence detection

T is symbol marks devices designed to detect limbs entering a protected area or detect uman

presence in a protected area.

For presence detection, wit safety lig t curtains in a orizontal position, resolutions of between 50

and 116mm are to be used, t e eig t off t e ground is calculated in relation to t ese values.

For t is function t e LS2 series features models wit resolutions of 50 and 90mm.

Hand detection

T is symbol marks devices designed to detect a and entering a protected area.

It refers to safety lig t curtains wit a resolution less t an or equal to 30mm and 40mm; t ese

resolutions allow safety distances compatible wit s ort loading and unloading times and a low level of

operator fatigue.

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 2539 3

www.microdetectors.com

LS2 SERIES

SAFETY LIGHT CURTAIN TYPE 2

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors CAT8ELS1250901 4/34

2.0 WITH REFERENCE TO SAFETY

Warning!

T e level of protection of t e safety lig t curtain must be compatible wit t e dangerousness of t e

system to control, devices downstream from t e must be compatible wit t e safety lig t curtain itself

and wit t e required safety level.

- T e mac ine must be able to be controlled electrically.

- It must be possible to stop t e dangerous parts of t e mac ine wit an electric control ac ievable in a

definite time and if necessary verified directly.

Warning!

T e features of t e safety lig t curtains must be c osen according to t e size of t e access area to t e

dangerous zone, t e part of t e uman body subjected to t e danger, t e distance of t e point of

access from t e dangerous point, t e response time of t e safety lig t curtains , t e response time of

t e downstream devices and t e time for stopping t e dangerous movement.

Warning!

All t e remaining azardous conditions of t e mac ine must be verified and suitable equipment must be

used to neutralize t em.

It must not be possible to reac t e dangerous zone wit out going t roug t e protection surface

controlled by t e safety lig t curtains.

For an operator must not be possible to remain between t e surface of t e protection controlled by t e

barrier and t e danger zone wit out being detected.

Warning!

C eck t at t e environmental conditions are compatible wit t e features of t e safety lig t curtains .

C eck t e effect of reflective surfaces to t e side of t e pat of t e lig t beams, in general respect t e

indicated safety distances.

Consider t e effect of putting transparent panels or t e like in between t at can c ange t e beam angle

of t e safety lig t curtains .

Prevent t e safety lig t curtain's optical window from getting damaged or altered wit scratc es and

opacifications.

Do not expose t e Receiver to strong natural or artificial sources of lig t, including flas ing stroboscopic

sources.

Avoid exposing t e Receiver directly to t e projection of optical beams of ot er optical devices.

C eck t at t e ambient temperature does not exceed t e stated limits.

Consider t e effect of smoke, vapours, liquids and powders t at can alter t e transparency of t e air or

foul t e optical window.

Warning!

Periodically perform t e procedures for c ecking t e functionality of t e safety lig t curtain.

2.1 Skilled personnel

Only qualified personnel are aut orized to mount, start up, use and service t e

LS2

safety lig t curtain

.

A qualified person is one w o:

- as adequate tec nical training

- as been educated by t e person in c arge of Mac ine Safety on its use and t e current safety directives

- accesses t e operating instructions.

2.2 Fields of use of the device

T e LS2 safety lig t curtains are Type-2 electro-sensitive protection equipment (ESPE) in accordance wit

IEC 61496-1 and IEC 61496-2. T ey can be employed in safety applications up to Category 2 in conformity wit

EN ISO 13849, up to SIL CL 2 in conformity wit EN 62061 or up to PL d in conformity wit EN 13849.

T ey meet t e requirements of t e Mac inery Directive 2006/42/EC and are used to:

- protect t e area of access to dangerous points.

- detect uman presence in dangerous zones.

- protect t e accesses to dangerous zones.

Use to standard

LS2 safety lig t curtains

must be used only in accordance wit C apter 2.2 “Fields of use of t e device”. If t e

device is used for ot er purposes or if it is modified, even in t e p ase of mounting or installation, t is

invalidates all warranty rig ts wit M. D. Micro Detectors.

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 2539 3

www.microdetectors.com

LS2 SERIES

SAFETY LIGHT CURTAIN TYPE 2

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors CAT8ELS1250901 5/34

2.3 General safety instructions and measures of protection

Safety instructions!

To ensure LS2 safety lig t curtain

s are used to standard and in a safe manner it is necessary to observe t e following

points:

• For t e installation and use of t e LS2 safety lig t curtain

as for commissioning it and t e repeated tec nical tests,

national and international regulations apply, particularly:

– Mac inery directive 2006/42/EC

– t e Directive on work equipment operators 2009/104/EC

– t e accident prevention prescriptions and safety rules

– ot er important safety prescriptions.

• T e manufacturers and operators of t e mac ine on w ic t e LS2 safety lig t curtain

is used must, in agreement wit

t e relevant aut ority and under t eir own responsibility, apply all t e current safety rules and prescriptions and are also

in c arge of t eir observance.

• It is absolutely necessary to observe t e guidelines on c ecking

t ese operating instructions (see c apter 6

“Commissioning”).

• T e c ecks must be carried out by qualified persons, t at is by aut orized and specially appointed persons, and t ey

must be documented so as to be compre ensible at any moment.

• T e operating instructions contained in t is manual must be set at t e disposal of t e operator of t e mac ine used

wit LS2 s.

T e mac ine operator must be educated by qualified personnel and urged to read t e operating instructions.

2.4 Disposal

Dispose o

f unusable or unrepairable devices always in observance of current national prescriptions on t e subject of

waste disposal.

3.0 DESCRIPTION OF THE PRODUCT

3.1 Brief description

T e LS2 series curtains are multiple lig t beam safety devices, built in compliance wit t e IEC 61496-1 and 2

standards, are Type 2 and t erefore applicable for t e protection of t e operators of systems or dangerous mac ines.

According to t e requirements of t e EN 61496-1 standard, a Type-2 safety lig t curtain must be able to carry out

periodical testing on its internal circuits to detect t e presence of any dangerous faults.

LS2 safety lig t curtains ave a slim profile of 28x30mm, t e distance of 28mm refers to t e front side, t ey ave a

rear groove for fastening, t ey are extremely reliable devices, t e Receivers provide two protected static safety PNP

outputs, so t ey are not subject to output contact wear or affected by strong vibration, t ey are able to detect

internal faults, control external contacts and, in t e event of a fault, ensure safe be aviour in any case. Wit a free

area t e level of t e two outputs is enabled to be ig (status ON, outgoing current), wit an occupied area or in case

of fault t e level is low (status OFF).

T e Emitters ave a Test input, t at can be used if it is necessary to control t e devices downstream from t e

Receiver.

T ere are models wit different resolutions (smaller diameter of t e detectable object) dedicated to certain detection of

ands, limbs and body; t e different resolution for models of t e same type enables c oosing different safety

distances.

Safety lig t curtains are available wit resolutions of 30, 40, 50, 90 mm, eig ts from 160 to 1510mm, maximum

ranges of 3, 4, 10, 12m. Multi-beam safety lig t greed are available wit 2, 3, 4 beams dedicated to access control.

T e Base and standard models can be used individually, t e Master, Slave and Final slave models can be used in

a c ain of two or t ree elements, also wit different types of optics; t is enables creating complex applications in a

simple cost-effective manner, for ig ly integrated protected zones even wit different resolution or range

requirements.

T e Base models ave only t e automatic restart function wit out controlling t e external contacts (EDM).

On t e standard and Master models it is possible to combine all t e functions by wiring as preferred: external

contact control (EDM), automatic starting, manual starting.

All t e models use M12 connectors with 5 or 8 poles, for t e supply/output cables and t e interconnection cables

in a c ain no s ielding is required, t e output cable can reac lengt s of 100m, t e interconnection cable 50m, t ese

features also allow great operational flexibility.

T e required operational voltage is 24V

DC

±20%, t e absorbed power is moderate, at most 3W per pair; t e

maximum output current is 400mA, suited to drive even power contactors directly; t e restart interlock and EDM

function, present on t e standard and Master models, enable making versatile and integrated protection systems.

Normally, t e degree of protection of t e ousing is IP65+IP6 , suitable also for dusty environments or compatible

wit p enomena of condensation, except for t e front surface t at as strict optical requirements.

Models are available wit IP69K protection t at can be subjected to was ing wit jets of ot water up to 80°C and

pressure up to 80 bar; wit t is level of protection models are also available wit an integrated t ermal auto-control

system t at moreover enables working at temperatures as low as -25°C and avoiding condensation on t e optics.

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 2539 3

www.microdetectors.com

LS2 SERIES

SAFETY LIGHT CURTAIN TYPE 2

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors CAT8ELS1250901 6/34

3.2 Coding system

Tab.:1 gives t e meaning of t e codes of t e available models.

T e models are supplied in kit form composed of a pair (Emitter/Receiver), t e single elements are available only to

make up for a return.

For an overview of t e main features of t e models ready for delivery or available on request, see Tab.:2 and 3 in t is

c apter.

For a complete and detailed list of t e actually coded models and t eir related features, see C apter 9.

Directly contact M. D. Micro Detectors for any explanation.

LS2 SERIES CONSTRUCTION OF MODEL CODES

POSITION CODE DESCRIPTION

1 LS2 Type-2 safety lig t curtains in ousing of cross-section 28x30mm

2

R Receiver (single element only available for t e replacement of return goods)

E Emitter (single element only available for t e replacement of return goods)

ER Emitter/Receiver pair

3 / Separator

4

30, 40 Lig t curtain, resolution in mm; and protection

50, 90 Lig t curtain, resolution in mm; limb protection

0A, 0B, 0C

Multiple beams

lig t grid

, number of beams 2, 3, 4; body protection

Corresponding centre distance of t e beams 500, 400, 300mm

5 - Separator

6

015 to 150

Nominal eig t of controlled area in cm for

lig t curtain

models:

015, 030, 045, 060, 075, 090, 105, 120, 135, 150

050, 080, 090 Centre distance of t e end beams in cm for lig t grid models

Single element wit selectable functions (Standard)

B

Single element wit only Base functions

(Automatic restarting only)

(For t e Emitters t e Standard and Base models are identical, t e code of t e

pair is defined by t e Receiver)

M Master element wit selectable functions

S Intermediate Slave element

F Final Slave element

8

IP65 + IP67 Operating Temp. -10…55°C

K

Models in transparent cylindrical ousing, IP69K, suitable for applications in t e

food industry.

Resistance to was ing wit water at 100 bar, 80 ° C

Housing in PMMA, caps in POM C wit silicone seals.

Brackets in stainless steel AISI 316L.

Operating temperature -10 ... 55 ° C.

H

Models in transparent cylindrical casing, IP69K protection, t ermostated, suitable

for applications in t e food industry.

Resistance to was ing wit water at 100 bar, 80 ° C

Housing in PMMA, POM C caps and silicone seals.

Brackets in stainless steel AISI 316L.

Operating temperature -10 ... 55 ° C.

Tab.:1; Chap.:3

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 2539 3

www.microdetectors.com

LS2 SERIES

SAFETY LIGHT CURTAIN TYPE 2

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors CAT8ELS1250901 7/34

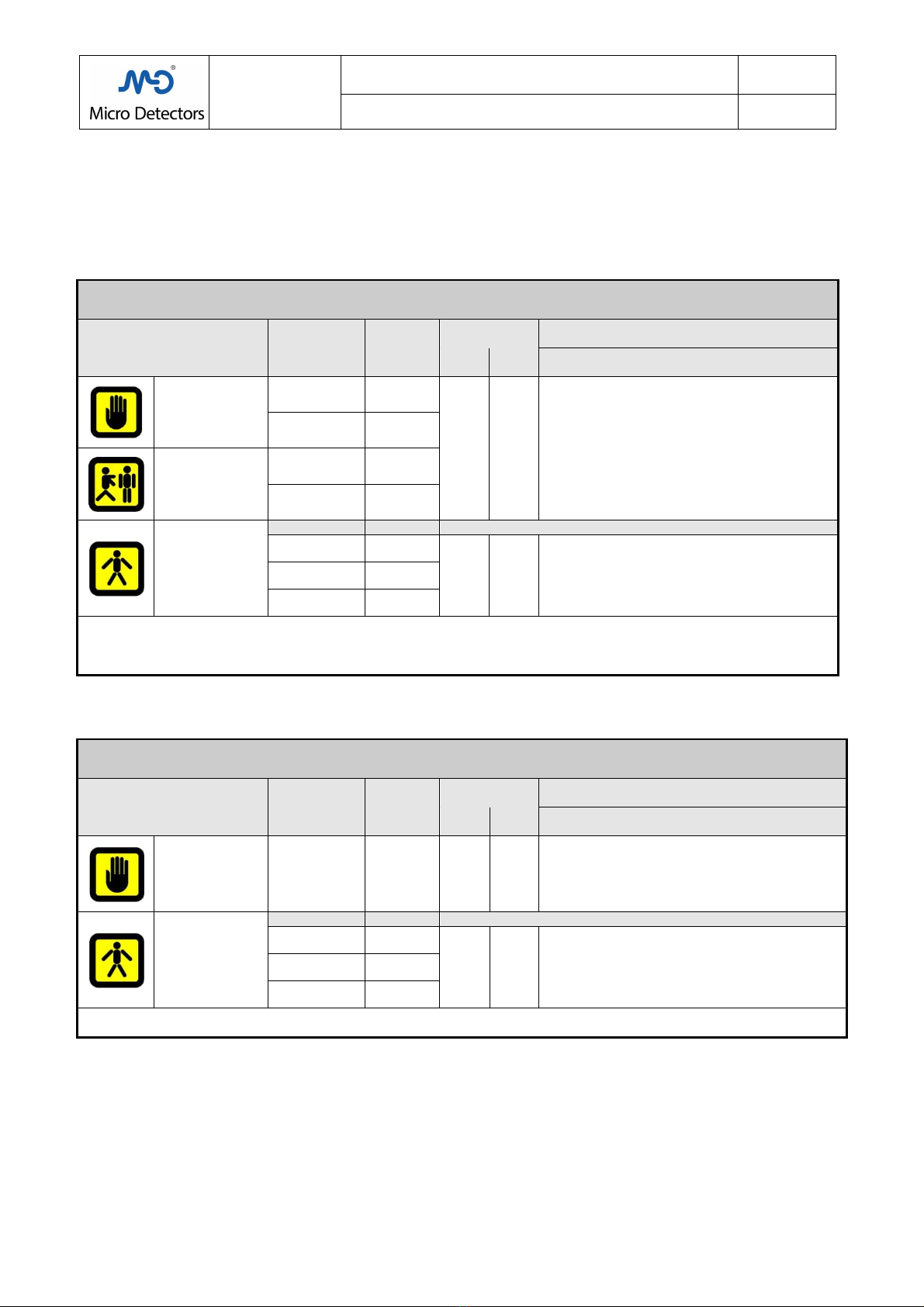

3.3 Availability of models with IP65 + IP6 protection

Tab: 2 and 3 give t e actually available models wit reference to t e optical parameters. T e selection between t e two

“Low” and “Hig ” ranges is performed via t e cables in t e Emitter. Models wit an extended range are not available,

w ic are instead available in t e LS4 series.

See the tables of Chap.:9 for a complete list of the available models.

LS2 SERIES

IP65+IP6

OPTICAL FEATURES

APPLICATION

RESOLUTION

HEIGHT

OF OPTICS

SELECTABLE

RANGES AVAILABLE MODELS

(mm) (mm)

Low

(m)

Hig

(m) SEE ALSO NOTES

HAND

PROTECTION

Curtain of beams

30 160 to 1510

0 to 4 0 to 12

LS2*/**-*** Standard

LS2*/**-***B Base

(1)

LS2*/**-***M Master

(2) (3)

LS2*/**-***F Final Slave

(3)

LS2*/**-***S Intermediate Slave

(2) (3)

40

(1)

160 to 1510

LIMBS AND

PRESENCE

PROTECTION

Curtain of beams

50 160 to 1510

90 310 to 1510

ACCESS

PROTECTION

Multiple beams

No. of BEAMS

PITCH

2 500

0 to 4 0 to 12

LS2*/**-*** Standard

LS2*/**-***B Base

(1)

LS2*/**-***M Master

LS2*/**-***F Final Slave

LS2*/**-***S Intermediate Slave

3 400

4 300

NOTES:

T e

Base

[B]

models ave limited functions (automatic restart only).

(1): For all models wit resolution 40mm and Base models it is necessary to verify availability; (2): For t e Master and

Intermediate Slave models t e optical eig t 160 is not available; (3): for t e Master, Slave and Final Slave models wit

resolution 90mm t e optical eig t 1510 is not available.

Tab.:2; Chap.:3

3.4 Availability of models with IP69K protection

LS2 SERIES

IP69K

OPTICAL FEATURES

APPLICATION

RESOLUTION

HEIGHT

OF OPTICS

SELECTABLE

RANGES AVAILABLE MODELS

(mm) (mm)

Low

(m)

Hig

(m) SEE ALSO NOTES

HAND

PROTECTION

Curtain of beams

30 160 to 1510

0 to 3 0 to 10

LS2*/30-***K standard, wit out eater (-10 to 55°C)

LS2*/30-***H standard, wit eater (-25 to 50°C)

Models wit standard range only

ACCESS

PROTECTION

Multiple beams

No. of BEAMS

PITCH

2 500

0 to 3 0 to 10

LS2*/**-***K standard, wit out eater (-10 to 55°C)

LS2*/**-***H standard, wit eater (-25 to 50°C)

Models wit standard range only

3 400

4 300

NOTES:

All models are specified for applications in t e food industry, IP69K, (was ing at ig pressure: 100 bar, 80 ° C)

Only Standard models available (wit complete functions: Automatic, Restart, EDM in all combinations)

Tab.:3; Chap.:3

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 2539 3

www.microdetectors.com

m

M.D. Micro Detectors

CAT8ELS12509

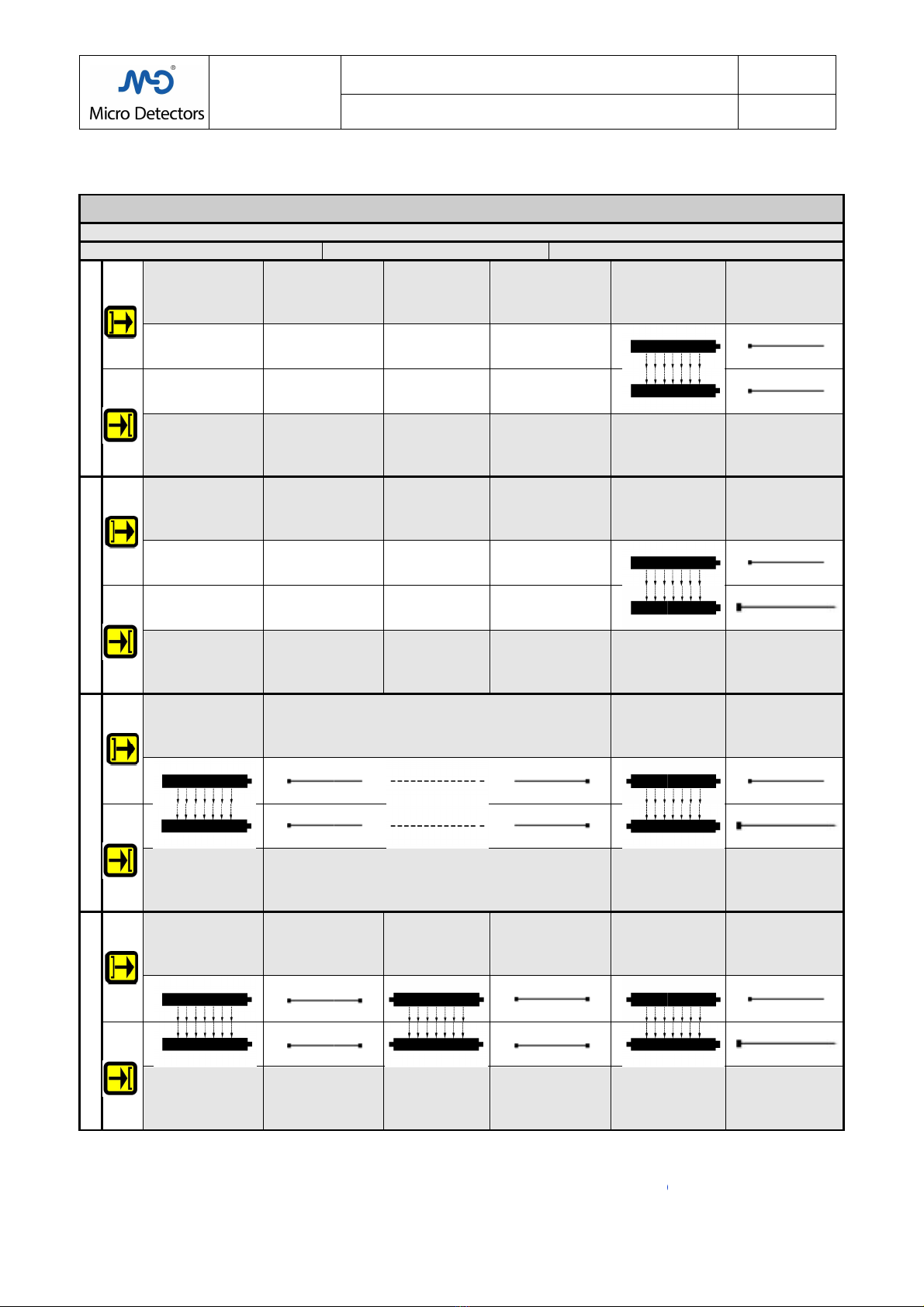

3.5

Possibility of interconnection of the available models

Tab: 4 shows the possible interconnections between models and their supply and extension cables

LS2 SERIES

AVAILABLE MODELS,

UPSTREAM devices

CONNECTOR

BASE

LS2ER/**-***B

LS2ER/**-***

LS2ER/**-***#

Final Slave model

LS2E/**-***F

Final Slave model

LS2R/**-***F

LS2ER/**-***#

Final Slave model

LS2E/**-***F

Extension

M12 5p F/F

Straight

CDP12/0H

-

Final Slave model

LS2R/**-***F

Extension

M12 5p F/F

Straight

CDP12/0H

-

Tab.:4; Chap.:3

NOTES:

For t e curtains

codes see Tab.:1, C ap. 3 and all C ap.:9, t e variables “**

eig t.

For t e complete cable codes see Tab.:1, C ap.:11, t e variable “***” indicates t e cable lengt in dm.

www.microdetectors.com

m

LS2 SERIES

SAFETY LIGHT CURTAIN TYPE 2

Installation and Operation

Manual

CAT8ELS12509

01

Possibility of interconnection of the available models

Tab: 4 shows the possible interconnections between models and their supply and extension cables

AVAILABLE MODELS,

CONFIGURATION, CONNECTORS, CABLES

DOWNSTREAM devices

HEAD

CONNECTOR

BASE HEAD

CONNECTOR

Base model

LS2E/**

Base model

LS2R/**

Standard model

LS2E/**

Standard model

LS2R/**

M12 5p F/F extension

Straight

CDP12/0H-***AC

Master model

LS2E/**

M12 5p F/F extension

Straight

CDP12/0H-***AC

Master model

LS2R/**

Extension

M12 5p F/F

Straight

-

*** AC

Intermediate

Slave model

LS2E/**-***S

Extension

M12 5p F/F

Straight

CDP12/0H-*** AC

Master model

LS2E/**

Extension

M12 5p F/F

Straight

-

*** AC

Intermediate

Slave model

LS2R/**-***S

Extension

M12 5p F/F

Straight

CDP12/0H-*** AC

Master model

LS2R/**

codes see Tab.:1, C ap. 3 and all C ap.:9, t e variables “**

-

***” indicate resolution and

For t e complete cable codes see Tab.:1, C ap.:11, t e variable “***” indicates t e cable lengt in dm.

LANGUAGE

Manual

ENGLISH

8/34

Tab: 4 shows the possible interconnections between models and their supply and extension cables

.

CONFIGURATION, CONNECTORS, CABLES

DOWNSTREAM devices

CONNECTOR

BASE

Base model

LS2E/**

-***B

M12 5p F cable

Straight

CD12M/0H-***A3

Right-angle

CD12M/0H-***C3

Base model

LS2R/**

-***B

M12 5p F cable

Straight

CD12M/0H-***A3

Right-angle

CD12M/0H-***C3

Standard model

LS2E/**

-***

M12 5p F cable

Straight

CD12M/0H-***A3

Right-angle

CD12M/0H-***C3

Standard model

LS2R/**

-***

M12 8p F cable

Straight

CD12M/0E-***A1

Right-angle

CD12M/0E-***C1

Master model

LS2E/**

-***M

M12 5p F cable

Straight

CD12M/0H-***A3

Right-angle

CD12M/0H-***C3

Master model

LS2R/**

-***M

M12 8p F cable

Straight

CD12M/0E-***A1

Right-angle

CD12M/0E-***C1

Master model

LS2E/**

-***M

M12

5p F cable

Straight

CD12M/0H-***A3

Right-angle

CD12M/0H

-

***C

3

Master model

LS2R/**

-***M

M12 8p F cable

Straight

CD12M/0E-***A1

Right-angle

CD12M/0E-***C1

***” indicate resolution and

For t e complete cable codes see Tab.:1, C ap.:11, t e variable “***” indicates t e cable lengt in dm.

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 2539 3

www.microdetectors.com

LS2 SERIES

SAFETY LIGHT CURTAIN TYPE 2

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors CAT8ELS1250901 9/34

4.0 INSTRUCTIONS FOR POSITIONING THE SAFETY LIGHT CURTAINS

4.1 Respecting the safety distance

A safety distance must be maintained between t e protection surface composed of t e beams of t e optico-

electronic

safety lig t curtain and t e point of danger.

T is distance must ensure t at, considering a maximum approac speed defined by t e standard, t e point of danger

can only be reac ed w en sufficient time as elapsed so t at t e dangerous state of t e mac ine as ended.

The safety distance in accordance with EN ISO 13855 depends:

-

in direct proportion on t e total time for stopping t e mac ine or system, w ic corresponds to t e sum of t e

individual times

of reaction of t e w ole safety c ain (t e individual response times are indicated in t e tec nical

documentation of t e safety devices and of t e mac ine itself or must be verified wit specific measures).

- in direct proportion on t e approac speed.

- in direct proportion on t e resolution of t e safety lig t curtain

, or inversely to t e number of beams for t e unit of

eig t.

If t e mac ine is subject to a specific standard of type C, t e indications of t is standard must be followed.

Danger of f

ailed recognition!

Particularly in access protection applications, people may stop in t e danger area, but not in t e optical

beam between t e Emitter and t e Receiver, and t eir presence mig t not be recognized.

Make sure t at dangerous states can only occur w en t ere are no persons in t e danger area.

Make sure t at t e system restart control is effected from a point providing full visibility of t e danger

area and t at t is control cannot be reac ed from wit in said area.

No protection function

is secure if the safety distance is not correct!

It is indispensable to mount t e safety lig t curtains at t e correct safety distance to ensure t e function

of protection.

If there is a C

-

type standard for the application you are creating, follow

its instructions!

T e following instructions apply only to an industrial environment, t at is to say w ere only adults of

normal constitution are expected to be present.

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 2539 3

www.microdetectors.com

LS2 SERIES

SAFETY LIGHT CURTAIN TYPE 2

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors CAT8ELS1250901 10/34

4.2 How to calculate the safety distance S in conformity with EN ISO 13855 and EN ISO 1385

Here we give t e general procedures for calculating t e minimum safety distance S

, t ese instructions must be followed

if t ere is not a specific standard of type C for t e mac ine to make safe.

Depending on t e application it is necessary to use different calculation sc emes.

In general t e formula as t is form:

S = K * T+ C

W ere…

S = [mm] Safety distance

K = [mm/s] Approac speed, a speed of 2000mm/s is indicated for t e upper limbs and 1600 for t e lower limbs.

T = [s] Total stopping time: response time of t e entire safety device + mac ine stopping time.

C = [mm]

Safety distance supplement, to ensure t at t e dangerous zone cannot be reac ed by climbing over t e

beams or inserting limbs between t e beams. It is provided by t e standard, it

takes on a fixed value or is calculated

according to t e optical features of t e safety lig t curtain and its utilization in t e application.

The reaction time of the safety light curtain alone is stated on the product label of the

Receivers and in this document in the tables of Chap.:9.

In the case of a chain connection the reaction time of the safety light curtains corresponds to

the sum of all the individual times of the Receiver elements in the chain.

The standard considers different methods of approach:

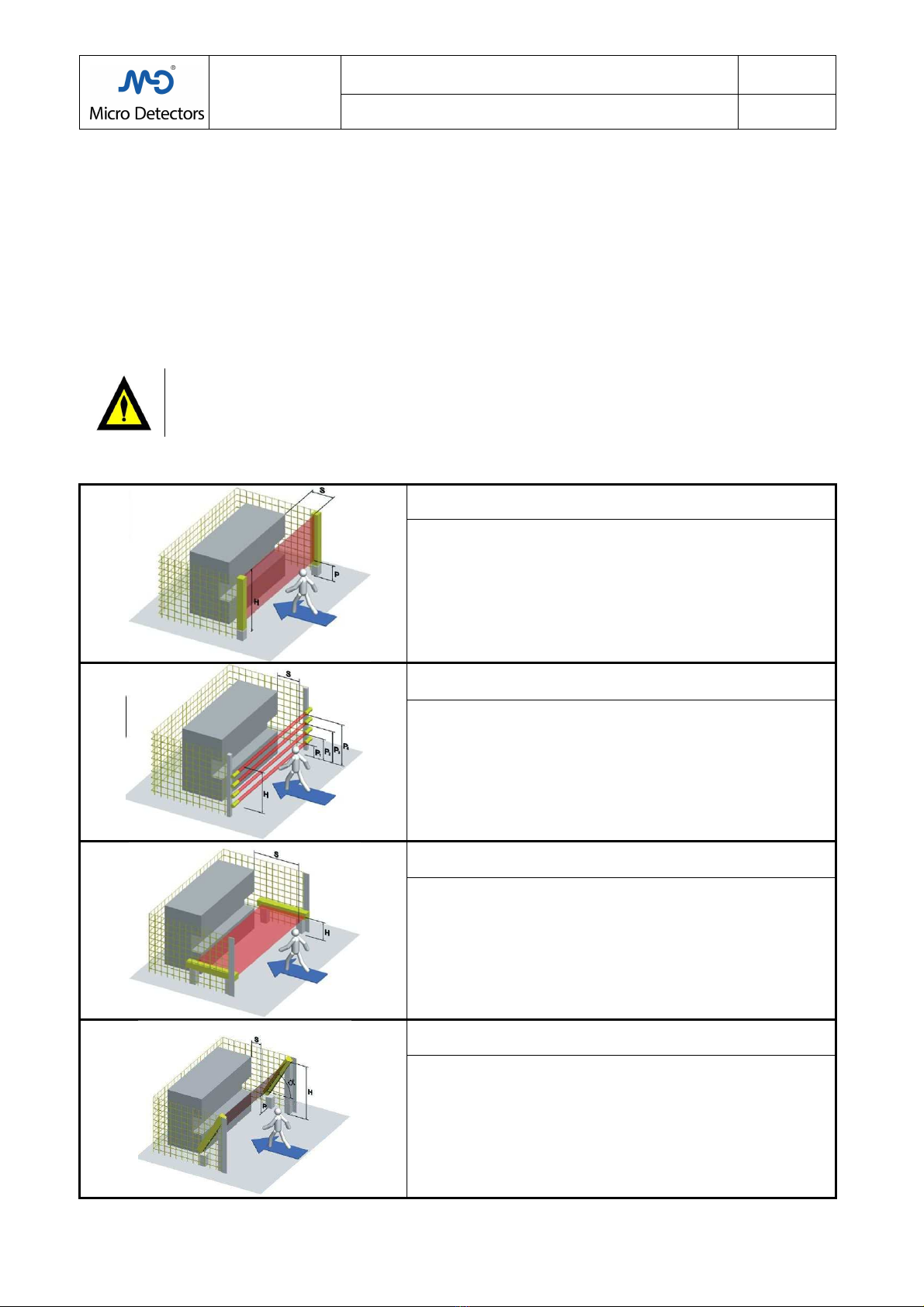

1) PERPENDICULAR APPROACH

Safety light curtain in vertical position.

Angle between safety lig t curtain and surface of 90° ±5°

2) PERPENDICULAR APPROACH

Safety light grid in vertical position.

Angle between safety lig t curtain and surface of 90° ±5°

3) HORIZONTAL APPROACH

Safety light curtain in horizontal position.

Angle between safety lig t curtain and surface of 0° ±5°

4) OBLIQUE APPROACH

Safety light curtain in angled position.

Two cases are considered for different angle values α

αα

α

Wit α

αα

α ≥30° we ave t e perpendicular approac

Wit α

αα

α <30° we ave t e orizontal approac

Tab.:1; Chap.:4

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 2539 3

www.microdetectors.com

LS2 SERIES

SAFETY LIGHT CURTAIN TYPE 2

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors CAT8ELS1250901 11/34

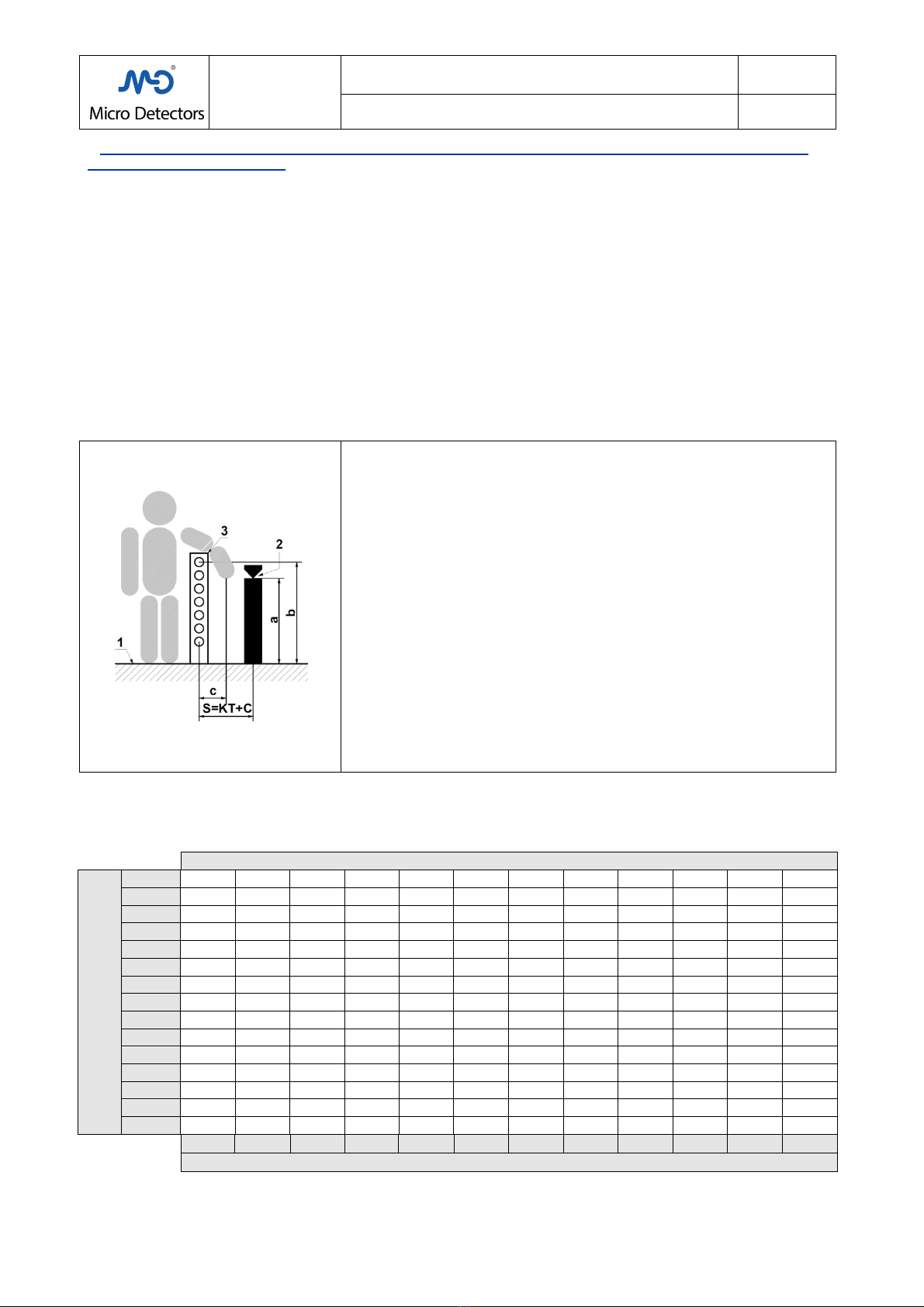

●

Calculate S with the following procedure for applications of protection with

safety light

curtain

s over

which it is possible to climb.

If a safety lig t curtain

is installed wit out any supplementary mec anical protection on t e top, and t erefore it is

possible to enter t e protected area from above, it is necessary to define t e safety distance considering two met ods:

- Access from above.

- Access t roug t e beams.

-

Access from below, not considered now, can be excluded if t e lowest beam as a maximum eig t of 200mm from

t e surface, or by installing mec anical protection.

T e safety distance, considering access from above, must be suc as not to allow rea

c ing t e danger area; t is safety

distance is obtained from Tab,:2 of ISO 13855, ere Tab.:3; C ap.:4

T e safety distance, considering access between t e beams, is obtained from t e procedures indicated below t at

envisage access only t roug t e beams.

T e safety distance to c oose will be t e greater one of t e two.

To ave indications of t e dimensions of any mec anical protection to superimpose on t e safety lig t curtain

or only

mec anical protection not closed on t e top part, please refer to standard EN ISO 1385 .

1)

Reference surface

2)

Dangerous point or danger area

3)

P oto-electric safety lig t curtain

a)

Heig t above t e surface of t e dangerous point or of t e ig er point

of t e danger area

b)

Heig t above t e surface of t e top of t e optical window of t e

safety lig t curtain.

c)

Minimum safety distance so as not to reac t e danger area from

above is obtained from Tab.:2 of ISO 13855 ere Tab.:3; C ap.:4

C)

Lengt of t e pat of t e limb

t roug t e beams, from t e level of

t e optics until t e two optics are completely darkened (resolution)

KT)

Route of t e limb t roug t e

safety lig t curtain

during t e total time

T of t e response to stopping, considering a specific approac speed

K

S)

Minimum safety distance between t e

safety lig t curtain

and danger

area calculated considering access t roug t e beams, see t e

following cases

Tab.:2; Chap.:4

Tab.:2 from ISO 13855/ EN999

[c] MINIMUM DISTANCE TO IMPLEMENT BETWEEN THE CURTAIN AND DANGER AREA

[a] HEIGHT OF THE DANGER AREA

2600 0 0 0 0 0 0 0 0 0 0 0 0

2500 400 400 350 300 300 300 300 300 250 150 100 0

2400 550 550 550 500 450 450 400 400 300 250 100 0

2200 800 750 750 700 650 650 600 550 400 250 0 0

2000 950 950 850 850 800 750 700 550 400 0 0 0

1800 1100 1100 950 950 850 800 750 550 0 0 0 0

1600 1150 1150 1100 1000 900 800 750 450 0 0 0 0

1400 1200 1200 1100 1000 900 850 650 0 0 0 0 0

1200 1200 1200 1100 1000 850 800 0 0 0 0 0 0

1000 1200 1150 1050 950 750 700 0 0 0 0 0 0

800 1150 1050 950 800 500 450 0 0 0 0 0 0

600 1050 950 750 550 0 0 0 0 0 0 0 0

400 900 700 0 0 0 0 0 0 0 0 0 0

200 600 0 0 0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 0 0 0 0 0

900 1000 1100 1200 1300 1400 1600 1800 2000 2200 2400 2600

[b] HEIGHT OF THE TOP EDGE OF THE OPTICAL WINDOW OF THE CURTAIN

Tab.:3; Chap.:4

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 2539 3

www.microdetectors.com

LS2 SERIES

SAFETY LIGHT CURTAIN TYPE 2

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors CAT8ELS1250901 12/34

●

Calculate S with the following procedure for finger or hand protection applications, with vertical

curtains (90° ±5°) having the stated resolution D.

Resolution Formula Description

D≤40 (mm) S (mm) = 2000 * T + 8x(D-14)

From finger protection to and

protection

If t ere is a value S<100mm, use S=100mm.

If t ere is a value S>500mm, it is permissible to calculate again using t e approac speed 1600 m/s:

S (mm) = 1600 * T + 8x(D-14)

If from t is new calculation t ere is a value S<500mm, use S=500mm.

If t ere are any remaining uncontrolled access areas, t ey must ave an access widt of ≤ 5mm

to prevent limbs from

reac ing t e danger zone, ot erwise it is necessary to add more protection.

● Calculate S with the following procedure for upper limb protection applications, with vertical curtains

(90° ±5°) having the stated resolution D.

Resolution Formula Description

40< D (mm) ≤ 0 S (mm) = 1600 * T + 850 Limb Protection

T e eig t off t e ground of t e lowest beam must be P≤300mm.

T e eig t off t e ground of t e ig est beam must be H≥900mm.

● Calculate S with the following procedure and use the beam height indicated off the reference surface for

access protection applications, with vertical curtains (90° ±5°) having stated resolution D.

Resolution Formula Description

D> 0 (mm) S (mm) = 1600 * T + 850 Access protection

For curtains in a row, t e lowest beam must be no ig er t an 300mm

and t e ig er one must be no lower t an

1200mm.

W en using curtains wit multiple beams, it is necessary to observe t e eig ts of t e beams off t e

reference surface

indicated in t e following table:

No. of

Beams

P1

(mm)

P2

(mm)

P3

(mm)

P4

(mm)

2

400

900

3

300

00

1100

4

300

600

900

1200

Tab.:4; Chap.:4

● Use S and the beam height off the roller conveyor as stated for curtains with two or three beams in

protection applications for passageways for palletizers and depalletizers (machines subject to the C-type

product standard: EN 415-4).

No. of

Beams

P1

(mm)

P2

(mm)

P3

(mm)

S

(mm)

2

400

900

1200

3

400

800

1200

900

Tab.:5; Chap.:4

●

Calculate S with the following procedure for body protection applications, with

curtain

s parallel to the

direction of approach (0° ±5°) having height H off the surface and resolution D.

Resolution Formula Description

116≥ D≥50 (mm)

S (mm) = 1600 * T + C

C (mm) = (1200-0,4*H); C ≥ 850

D (mm) ≤ (H/15) + 50

15* (D – 50) ≤ H (mm) ≤ 1000

Access and presence protection

If C takes on values below 850 (mm), use C=850.

T e eig t of t e curtain off t e ground must be H≤1000 (mm).

For H>300mm install supplementary protection to avoid t e risk of access from beneat .

It is possible to use smaller resolutions t an 50mm, but t is brings no advantage (t e minimum distance off t e

ground is null even wit a resolution of 50mm).

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 2539 3

www.microdetectors.com

LS2 SERIES

SAFETY LIGHT CURTAIN TYPE 2

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors CAT8ELS1250901 13/34

5.0 MINIMUM DISTANCE FROM REFLECTING SURFACES

T e optical beams of t e Emitter

, aving a beam angle t at is not null, can partly be diverted by reflective surfaces

located near to t e curtains. T is may mean t at a break in t e direct pat of t e optical beam is not d

etected, w ic is

w y all reflective surfaces and reflective objects (in any position t ey may ave wit respect to t e controlled area,

above, under, inside or outside) must respect a minimum distance from t e direct pat of t e beams of t e

safety lig t

curtain.

Indication

It is likewise important to respect t e minimum distance between t e Emitter and Receiver

indicated by

t e manufacturer, in some cases t e minimum distance may be greater t an zero, especially for long-

range models.

At smaller

minimum distances t an t e ones stated, t e beam angle may ave an unpredictable breadt

and so t e safety distance may not be definable wit certainty.

W en using diverter mirrors, consider t at t e minimum distance from reflective surfaces must be

respec

ted for all t e rectilinear segments of t e beams, considering t e sides bot inside and outside t e

protected zone.

A reflective surface is any s iny surface, even a black one.

Any damage or opacification of t e optics or inclusion of slabs of transparent

or, even worse,

semitransparent material on t e optical pat can produce an increase in t e beam angle.

C ecking t e capacity of detection wit t e test rod, performed in t e intermediate

and at t e ends of t e

controlled area, is an effective procedure t

o exclude t e presence of dangerous reflections, see also

C ap.:13.4.

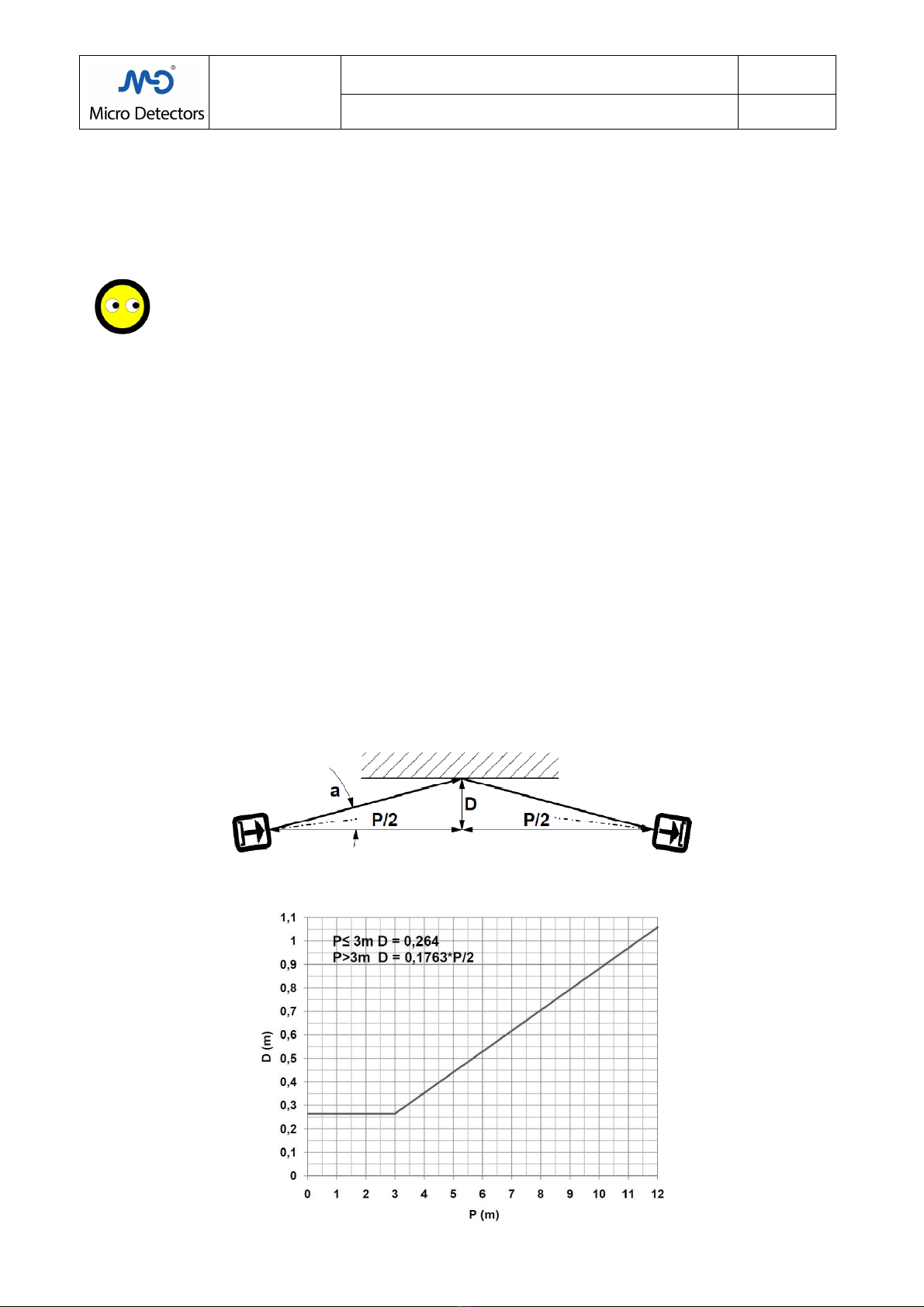

5.1 How to calculate the minimum distance from reflective surfaces

T e safety lig t curtains LS2 respect t e maximum beam angle defined by IEC / EN 61496-2 for Type 2 (a/2=±5°),

or

less.

T e safety distance D is calculated considering t e entire beam angle a=10° and t e safety lig t curtain

s reciprocally

orientated towards t e reflective surface by an angle a

, in t is way we consider t e case of alignment at t e limit of

reciprocal visibility between t e Emitter and Receiver, but w ic is more dangerous due to t e effects of t e reflection.

T e safety distance D to take P ≥3m is calculated as follows:

D=tan(10°)*P/2 = 0.1 63*P/2

For ranges less t an 3m t e value calculated at 3m applies:

D = 0.1 63*1.5=0.264m

Fig.:1; Chap.:5; t is figure s ows t e worst borderline case t at can occur: safety lig t curtains not perfectly aligned,

but tilted by an angle a/2 towards a reflective surface

.

Fig.:2; Chap.:5; minimum distance “D” to maintain for t e reflective surfaces in relation to t e range “P”.

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 2539 3

www.microdetectors.com

LS2 SERIES

SAFETY LIGHT CURTAIN TYPE 2

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors CAT8ELS1250901 14/34

6.0 COMMISSIONING

6.1 Mechanical mounting

T is device is suited to work in protected environments, not outdoors.

It is extremely important to secure t e safety lig t curtains to a rigid structure, not subject to deformation or strong

vibration.

C oose t e position of t e Receiver so as not to subject it to strong sources of natural or artificial lig t or to luminous

interference by ot er sensors.

Mount t e Emitter and Receiver facing eac ot er, at t e same eig t off t e reference surface and wit t e same

orientation (refer to t e BASE side t at is t e display side), t e reciprocal distance must be wit in t e field of t e

specification. To secure t e safety lig t curtains to a support use t e specific inserts to apply to t e rear groove and t e

brackets normally provided.

If t ere is vibration in t e application, but still compatible wit t e optical alignment, use t e damping supports

available as accessories.

In t is p ase classic tools suc as a plumb line and/or a spirit level may be useful.

To facilitate t e first p ase of alignment, it is possible to use t e specific LASER STL 01 S accessory for safety lig t

curtains wit a profile of 28x30mm.

Temporarily block t e Emitter and Receiver so t ey are aligned wit and parallel to eac ot er.

Danger!

To perform t e next steps it is necessary to power t e Emitter and Receiver, make sure t at during t is

p ase t e mac ine's movements are blocked irrespective of t e state t at t e Receiver will take on; an

effective manner to obtain t is is to p ysically cut off t e supply to t e actuators by permanently

disconnecting t eir supply cables.

6.2 Alignment

1) W en switc ing on t e LED 1 of t e Emitter will be RED for t e duration of t e power-on, if afterwards t e LED

makes two s ort GREEN flas es t e Hig range function is active, if t e LED makes 2/3 RED flas es, t e TEST is

probably open and t ere is no emission (jumper TEST to proceed), if t e LED is illuminated GREEN it means t at t e

Emitter is working. In case of difficulty wit alignment it is advisable to temporarily activate t e Hig range function, if

it is not already enabled, so as to facilitate it. Refer to C ap.: 6.3 to verify t e Emitter and Receiver configuration mode

and to C ap.:8 for t e meaning of t e indications.

2) If it is possible to c oose or temporarily c ange t e configuration of t e Receiver, it is advised to use t e “Automatic

Restart wit out EDM” mode, t at is able to clearly signal t e state of LIGHT and outputs ON lig ting up LED 3, t at in

t is case will be GREEN; if t e Receiver as been configured differently (restart interlock wit or wit out EDM), observe

instead LED 2, t at in t is case will be YELLOW, indicating t e state of LIGHT, but outputs OFF; YELLOW LED 2 will be

blinking in case of MASTER on LIGHT connected to slaves on DARK.

To simplify any Receiver will be on light if LED 3 is GREEN or LED 2 is YELLOW on steady or blinking.

3) Now try adjusting t e Receiver around t e original position and define a zone in w ic t e Receiver is in t e LIGHT.

More careful alignment t an as obtained normally could be ensured by temporarily darkening t e optics of t e Receiver

wit opaque ad esive tape precisely covering alf of t e optical window and t en seeking t e condition of lig t under

t ese conditions; on obtaining t e condition of LIGHT, on removing t e tape t e signal will be at least wit margin 2.

Now c eck t at wit moderate mec anical stresses applied to t e safety lig t curtain it remains in t e LIGHT. Now

proceed wit step 5).

4) If you are not able to bring t e Receiver into t e lig t or to ensure an adequate level of margin, correct t e position

of t e Emitter and try to align t e Receiver again, step 3).

5) Again temporarily lock t e Receiver in t e intermediate of t e found zone and c eck it as an acceptable

arrangement. If it is acceptable proceed wit step 6), if it is not acceptable correct t e alignment of t e Emitter

accordingly and realign t e Receiver, step 3).

6) After alignment, permanently lock t e safety lig t curtains and restore all t e required conditions for t e application,

including t e electric connections.

) Have complete functional testing carried out on t e safety lig t curtain, including a resolution test and c ecking for

t e presence of reflective surfaces, using a test rod, of t e same diameter as t e rated resolution.

8) Make sure t at during normal use no unfavourable conditions arise around, suc as:

- presence of ot er Emitters or ot er brig t or modulated sources of lig t able to it t e Receiver,

- presence or movement of reflective objects near t e area,

- transparent or semi-transparent materials inserted in t e pat of t e beams,

- systematic presence of dust or spray of liquids able to foul t e surface of t e optics.

Indication

Correct optical alignment wit good excess gain enables avoiding instability in t e be aviour of t e

safety

lig t curtain

, reducing optical interference, reflections from s iny surfaces and in general ensuring greater

safety.

Danger!

Remember to restore t e wiring and c eck t e required met ods of operation of t e application again.

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 2539 3

www.microdetectors.com

LS2 SERIES

SAFETY LIGHT CURTAIN TYPE 2

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors CAT8ELS1250901 15/34

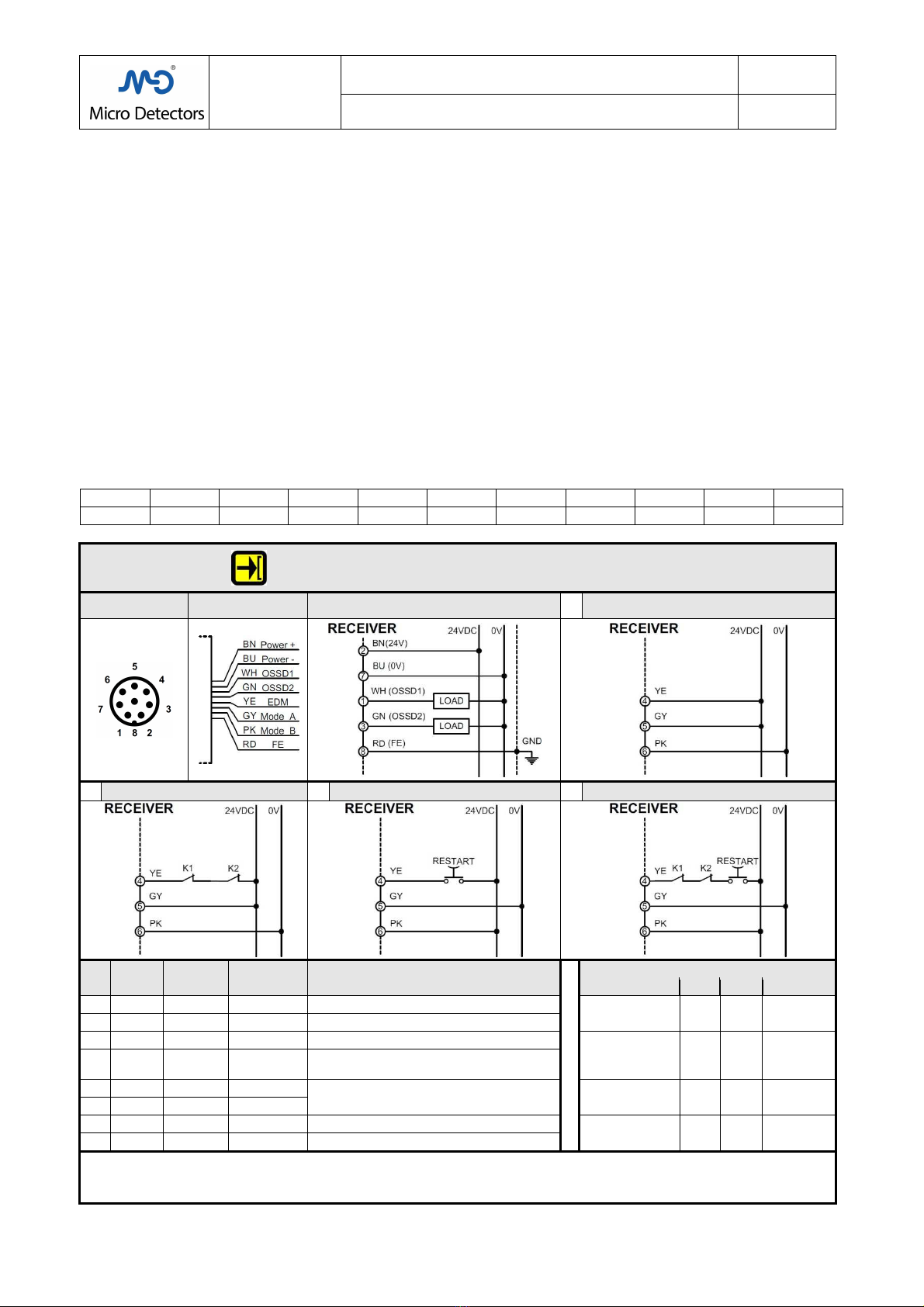

6.3 Electrical installation.

Before proceeding carefully read t e data of Tab.:1; C ap.:7 in t e sections: Supply, Outputs and Connections.

See Tab.: 1-4 in t is c apter to make t e required connections for t e supply, load and configuration for t e

connectors. Preferably use prewired connectors; for t e Master/Slave connections use only extensions.

Use PELV power supplies, in accordance wit C ap.6.4. of EN 60204-1.

If using a non-stabilized power supply, t e transformer must ave double insulation and adequate power, t e

secondary winding must be 18V, use a bridge rectifier, use a filtering capacitor wit a minimum value of 2200µF for

absorptions up to 1A, for ig er absorptions add 2200µF for every extra Ampere.

Connect t e supply cables directly to t e source and not downstream of ot er power or ig ly inductive devices.

Run t e cables of t e safety lig t curtains in dedicated raceways or, w ere only signals run; do not use raceways t at

carry power cables.

Make sure t e functional eart cable (FE) is connected directly to t e general ground terminal.

Before inserting t e connector, c eck t at t e mains voltage and t e supply voltage are wit in t e required limits, apply

t e connector and c eck again t at t e supply voltage as a correct nominal value and remains wit in t e limits defined

in all t e working conditions, c eck t e limits in t e two extreme conditions of minimum and maximum absorption of all

of t e devices connected to t e same power supply, especially if t is is not a stabilized power supply.

In t e following tables t e colours of t e cables and LEDs are indicated wit t e abbreviations defined in IEC 60707 in

Englis

BK BN RD YE OG GN BU GY WH PK VT

Black Brown Red Yellow Orange Green Blue Grey W ite Pink Violet

SERIE LS2

RECEIVER

CONNECTOR AND CABLE EXIT WITH EIGHT POLE

S

Standard and Master models: LS2R/**-***; LS2R/**-***M (connector exit)

Standard models, IP69K: LS2R/**-***K (cable exit)

M12, 8

pole

Male connector

8

-

wire cable

Only K models Power supply and loads 1

Automatic restart without EDM

2

Automatic restart with EDM

3

Manual restart without EDM

4

Manual restart with EDM

Pin

Color Signal Type Description

CONFIGURATION

LOGIC

Pin 4 Pin 5

Pin 6

Function

1 WH OSSD1 OUT

First safety static output (PNP)

24V

DC

24V

DC

0V AUTO

2 BN 24V

DC

POWER

Power supply input

3 GN OSSD2 OUT

Second safety static output (PNP)

K1+K2

+24V

DC

24V

DC

0V AUTO

+ EDM

4 YE EDM IN

Connection to Restart

and/or external

control contacts (EDM).

5 GY Mode_A IN Selection of t e Start/Restart/EDM mode Restart

+24V

DC

0V 24V

DC

MANUAL

6 PK Mode_B IN

BU 0V POWER

Supply voltage reference

K1+K2+Restart

+24V

DC

0V 24V

DC

MANUAL

+ EDM

8 RD FE GND

Functional eart

NOTE:

On t ese Standard and Master models it is possible to c oose t e operating modes by c anging t e wiring. By using t e EDM

function it is possible to extend t e safety control to t e contactors controlled downstream, t at must be t e type wit guided

contacts and approved for safety applications.

With this model of curtain you can use the relay module SB300, but the EDM input must be connected.

Tab.:1; Chap.:6

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 2539 3

www.microdetectors.com

LS2 SERIES

SAFETY LIGHT CURTAIN TYPE 2

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors CAT8ELS1250901 16/34

SERIES

LS2

RECEIVER

CONNECTOR EXIT WITH FIVE POLES

Base models: LS2R/**-***B

M12, 5 pole male Diagram Wiring

Pin

Colour Signal Type Description

1 BN 24V

DC

POWER Power supply input

2 WH OSSD1 OUT First safety static output (PNP)

3 BU 0V POWER Power supply reference

4 BK OSSD2 OUT Second safety static output (PNP)

5 GY FE GND Functional eart

NOTE:

T ese Base models wit automatic restart do not ave t e EDM function, t e device downstream must t erefore be able to

control its own safety integrity independently.

With this model of curtain yo

u can not

use the relay module SB300

, because the EDM input is not available.

Tab.:2; Chap.:6

SERIES LS2

RECEIVER

CABLE EXIT WITH TEN POLES

Models IP69K, thermostated: LS2R/**-***H

10-wire cable Power supply and loads Heater power 1

Automatic restart

without EDM

2

Automatic restart with EDM

3

Manual restart without EDM

4

Manual restart with EDM

Colour

Signal Type Description

CONFIGURATION LOGIC

YE GY PK

Function

BN 24V

DC

POWER

Power supply input

24V

DC

24V

DC

0V

AUTO

BU 0V POWER

Supply voltage reference

WH OSSD1 OUT

First safety static output (PNP)

K1+K2

+24V

DC

24V

DC

0V

AUTO

+ EDM

GN OSSD2 OUT

Second safety static output (PNP)

YE EDM IN

Connection to Restart and/or external control

contacts (EDM). Restart

+24V

DC

0V

24V

DC

MANUAL

GY Mode_A IN Selection of t e Start/Restart/EDM mode

PK Mode_B IN

K1+K2

+Restart

+24V

DC

0V

24V

DC

MANUAL

+ EDM

BK Heater 0 POWER Heater supply common

VT Heater P POWER

Heater supply 24V DC o AC

X 0V 0V NOT

ALLOWED

RD FE GND

Functional eart

X 24VDC 24VDC

NOTA:

On t ese Standard models it is possible to c oose t e operating modes by c anging t e wiring. By using t e EDM function it

is possible to extend t e safety control to t e contactors controlled downstream, t at must be t e type wit guided contacts

and approved for safety applications.

T e supply voltage of t e t ermostated eater can be indifferently 24VDC or 24VAC.

With this model of curtain you can use the relay module SB300, but the EDM input must be connected.

Tab.:3; Cap.:6

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 2539 3

www.microdetectors.com

LS2 SERIES

SAFETY LIGHT CURTAIN TYPE 2

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors CAT8ELS1250901 17/34

SERIE LS2

EMITTER

CONNECTOR AND CABLE EXIT WITH FIVE POLE

S

Standard and Master models: LS2E/**-***; LS2E/**-***M (connector output)

Models IP69K: LS2E/**-***K (cable output)

For the emitters the Base and Standard models have identical functions.

M12, 5 pole

Male connector

5-pole cable

Only models K Wiring for high range Wiring for low range

Pin

Colour

Signal Type Description CONFIGURATION LOGIC

WH BK Function

1 BN 24V

DC

POWER

Power supply input

LO LO

Test

2 WH Range L/Test IN

Range or Test selection

input

LO HI

Hig range

3 BU 0V POWER

Supply voltage reference

HI LO

Low range

4 BK Range H/Test IN

Range or Test selection input

HI HI

Not admitted

5 GY FE GND

Functional eart

Levels: LO = <5V or open; HI = 11 to 30V

NOTE: T e Test contact is necessary only if t e safety c ain of t e receiver downstream must be periodically c ecked. If t e Test is

not necessary (t e safety lig t curtain as already been tested independently) replace t e contact wit direct wiring at

+24V

DC

.

Tab.:4; Chap.:6

SERIE LS2

EMITTER

CABLE EXIT WITH EIGHT POLES

Models IP69K, thermostated: LS2E/**-***#H

8-pole cable

Only models H Wiring for high range Wiring for low range

Colour

Signal Type Description CONFIGURATION LOGIC

WH BK Function

BN 24V

DC

POWER Power supply input LO LO

Test

WH Range L/Test IN Range or Test selection input LO HI

Hig range

BU 0V POWER Supply voltage reference HI LO

Low range

GN Range H/Test IN Range or Test selection input HI HI

Not admitted

PK None N.C. Not connected

Levels: LO = <5V or open; HI = 11 to 30V

YE Heater 0 POWER Heater supply common

RD

Heater

P

POWER

Heater

suppl

y

24V DC o AC

GY FE GND Functional eart

NOTA:

T e Test contact is necessary only if t e safety c ain of t e receiver

downstream must be periodically c ecked. If t e Test is

not necessary (t e safety lig t curtain as already been tested independently) replace t e contact wit direct wiring at

+24V

DC

.

T e supply voltage of t e t ermostated eater can be indifferently 24VDC or 24VAC.

The PK cable is not connected internally.

Tab.:5; Chap.:6

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 2539 3

www.microdetectors.com

LS2 SERIES

SAFETY LIGHT CURTAIN TYPE 2

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors CAT8ELS1250901 18/34

LS2

SERIES

RECEIVER

AND EMITTER

CONNECTORS FOR INTERCONNECTION OF MASTER/SLAVE/FINAL

WITH FIVE POLES

LS2*/**-***M; LS2*/**-***S; LS2*/**-***F

M12, 5 pole male Head connector

Master/Slave

Base connector

Slave/Final

Pin

Colour Signal Type Description

1 BN 24V

DC

POWER

Power supply (supply line for t e upstream device)

2 WH Line 1 IN/OUT

Communication line 1

3 BU 0V POWER

Power supply reference (supply line for t e upstream

device)

4 BK Line 2 IN/OUT

Communication line 2

5 GY FE GND

Functional eart

NOTE: Preferably use Female/Female pre-wired extension cables (it is not permitted to access t e connection lines).

Tab.:6; Chap.:6

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 2539 3

www.microdetectors.com

LS2 SERIES

SAFETY LIGHT CURTAIN TYPE 2

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors CAT8ELS1250901 19/34

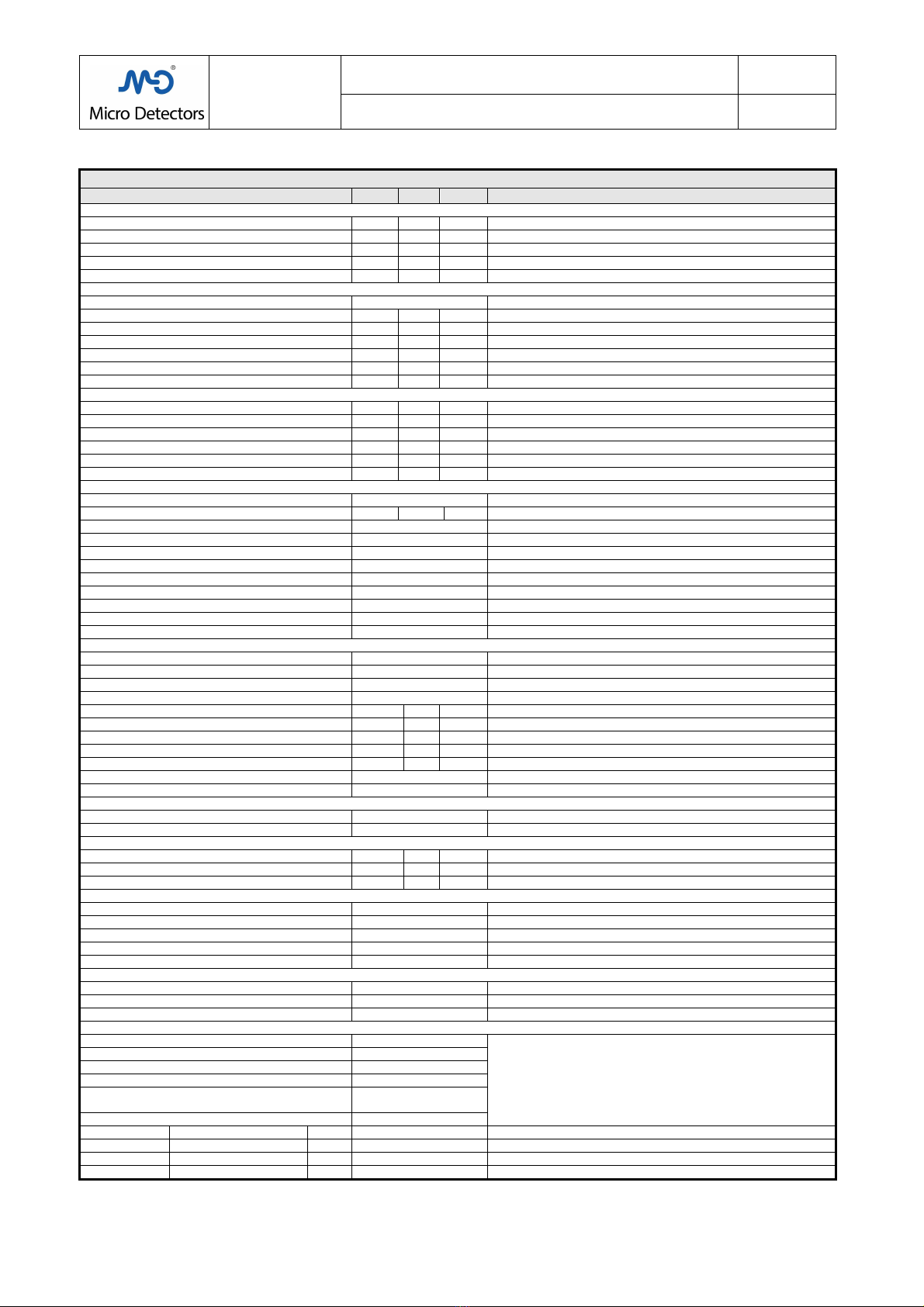

.0 TECHNICAL SPECIFICATIONS.

LS2 SERIES TECHNICAL SPECIFICATIONS

PARAMETERS

Min.

Nom.

Max.

NOTES

Power supply

Supply voltage

V

DC

19.2

24

28.8

From PELV power supply according to EN 60204

-

1 C ap.6.4

Residual

ripple

V

1.2

T e limits of t e supply

voltage

must not be exceeded

Absorbed power, Receiver

W

2

Excluding t e load

Absorbed power, Emitter

W

1

Absorbed power, Heater

W

2

10

Models H, IP69K wit eater, see C ap.:10, Tab.: 4

Outputs

(OSSDs)

Output type

2 x PNP

Completely protected safety outputs.

Current

mA

400

Hig er values are interpreted as overload or s orting

Voltage drop @400mA

V

1.2

Reduction in output voltage compared to t e supply

voltage

Equivalent resistive load

Ω

60

Lower values are interpreted as s orting

Leakage current

mA

2

Value at

w ic t e OFF state of t e load must be guaranteed

Voltage OFF

V

0.5

Value at w ic t e OFF state of t e load must be guaranteed

Tolerated capacitive load

µF

0.82

Hig er values can be interpreted as s orting.

Reaction times

Time delay before

availability

ms

500

After application of t e power supply

DARK response time (OSSDs OFF)

ms

2.5

20

Depending on t e number of optics, see tables in C ap.9

LIGHT response time

(OSSDs ON)

ms

400

It guarantees t is minimum duration of DARK pulse

Duration of t e test pulse of OSSDs

µs

100

S ould be ignored by downstream devices.

Restart control duration

s

0.1

5

Valid for input sequence

L

►

H

►

L

and indicated duration

H

Test input signal duration

ms

4

Valid if it as at least t e stated

duration

Safety parameters

Type

2

IEC 61496

-

1, 2004; IEC 61496

-

2, 2006

Optical beam angle

Deg

.

±5°

IEC 61496

-

2, 2006

Inco erent lig t emitted

nm

950

LED, RG 0 (Exempt Group), IEC 62471: 2006

-

07

Internal self

-

test

period

s

0.5

IEC 61496

-

1, 2004

Safety integrity level

SIL 2

IEC 61508, 1998

Safety integrity level

SILCL 2

IEC 62061, 2005

Performance level

PL d

ISO 13849

-

1 2006

Class

2

ISO 13849

-

1 2006

Reliability,

MTTFd

Y

ears

100

ISO 13849

-

1 2006

Resistance to faults in com. mode,

CCF

Score

80

ISO 13849

-

1 2006, IEC 62061, 2005 (min. score: 65)

Service time,

T

M

Y

ears

20

ISO 13849

-

1 2006

Ambient

Artificial lig t immunity

Acc

.

to

IEC 61496

-

2

It respects t e limits and conditions of t e stated standard

Natural lig t immunity

Acc

.

to

IEC 61496

-

2

It respects t e limits and conditions of t e stated standard

Models wit standard protection

IP65 and IP6

Dust and water protection (immersion at 1m for 60min.)

Models wit special protection

IP65, IP6 , IP69K

Transparent casing

wit standing ig

-

pressure was ing (100 bar)

Working temperature

°C

-

10

55

Wit out condensation

Working temperature IP69K models

°C

-

1

0

55

Wit out condensation, models wit out eater

Working temperature IP69K models

°C

-

25

5

5

Models wit

t ermostatic

eating

Storage temperature

°C

-

25

0

To be respected also during transportation

Humidity

%

95

Wit out condensation

Vibration

Acc.

to

IEC 61496

-

1

It respects t e limits and conditions of t e stated standard

Impact

Acc.

to

IEC 61496

-

1

It respects t e limits and conditions of t e stated standard

Range correction factors

Use of diverter mirrors

0.85

For eac diversion wit a mirror

Environmental factors

0.50 / 0.25

For t e presence of dust, vapours

/ mist, fumes (indicative

)

Connections

mm

2

0,34

To ensure t e stated maximum lengt

Total lengt of cables for supply&output

m

100

Wit cables of indicated section

Intermediate cable lengt (extensions)

m

50

Wit cables of indicated section

Dimensions / Materials,

IP6 models

Housing section

mm

28 (front) x 30

Painted aluminium; colour:

yellow

RAL 1012

Groove for fixing

mm

2/10

/

One in t e posterior side, dept / widt / widt of entry

Front window widt

mm

18mm

Useful central widt 13mm:

material

:

PMMA IR

End closings

No.

2

Material: PP + 30%GF

Closing screws

No.

4+4

Material:

Burnis ed

FE37

Dimensions / Materials, IP69K models

Housing

mm

Ø56

Material: PMMA

Sealing caps

N°

2

Material: POM C , silicone gaskets

Bridles and screws

N°

2

Material:

stainless steel AISI 316L 1.4404

Connectors

Models: LS2E/…._, B, F

1xM12 5p male

Material: Nickel-plated brass

Models: LS2E/…._, M, S

2xM12 5p male

Models: LS2R/….B, F

1xM12 5p male

Models: LS2R/…._

1xM12 8p male

Models: LS2R/….M

1xM12 8p male

1xM12 5p male

Models: LS2R/….S

2xM12 5p male

Modelli: LS2E/….K

Cable

Material: PVC, Ø 5mm, L 10

m, 5

poles

, 0,34mm

2

Modelli: LS2R/….K

Cable

Material: PVC, Ø 5mm, L 10

m, 8 poles, 0,34mm

2

Modelli: LS2E/….H

Cable

Material: PVC, Ø

6mm, L 10

m, 8 poles, 0,34mm

2

Modelli: LS2R/….H

Cable

Material: PVC, Ø 6mm, L 10

m, 10 poles, 0,34mm

2

Tab.:1; Chap.:

M.D. Micro Detectors

Strada S. Caterina, 235

41122 Modena Italy

Tel. +39 059 420411

Fax +39 059 2539 3

www.microdetectors.com

LS2 SERIES

SAFETY LIGHT CURTAIN TYPE 2

LANGUAGE

Installation and Operation Manual

ENGLISH

M.D. Micro Detectors CAT8ELS1250901 20/34

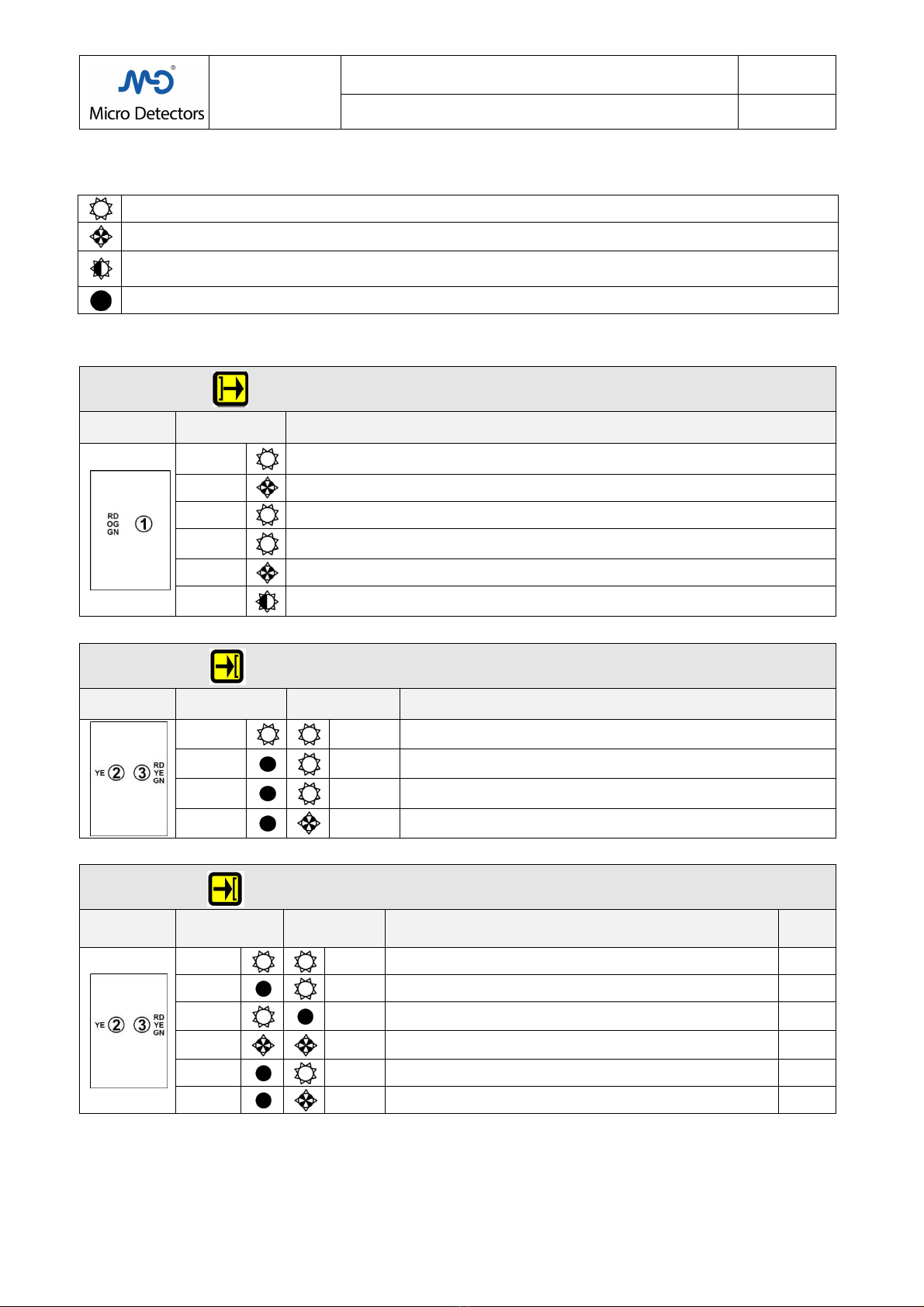

8.0 PANEL AND DIAGNOSTICS INDICATIONS

8.1 Symbols used to indicate the LED indicators modes

Indication of LED lit steadily

Indication of

LED lit intermittently wit periodical blinking.

T e number of consecutive blinks in t e period indicates an error code, see Tab.: 7 and 8

Indication of LED wit continual blinking

It is indicative of a specific error code, see Tab.: 7

Indication of LED off

Tab.:1; Chap.:8

8.2 Indications of the panels

LS2

SERIES

EMITTER MODELS DISPLAY

All models: LS2E/**-***#

Display LED_1 colour

and blink Meaning

RED or

ORANGE

RED at Power_ON, as initial test of LEDs for Standard and Master models

ORANGE at Power_ON as initial test of LEDs for Slave models

GREEN

Later during Power_ON, double initial blink if t e ig range is c osen

GREEN

Standard operation

ORANGE

Test in progress (test contact open, t e test con

tact must remain closed during Power

-

ON

ot erwise an error code is signalled)

RED

Fault condition, see t e corresponding error code in Tab.:6

ORANGE

Fault condition, see t e corresponding error code in Tab.:6

Tab.:2; Chap.:8

LS2

SERIES

RECEIVER MODELS DISPLAY

Base, Slave, Final Slave models: LS2R/**-***(B,S,F)

Display LED_2 colour

and blink

LED_3 colour

and blink

Meaning

For wiring of the Base Model see Tab.:2; Chap.:6

YELLOW

RED Power_ON, as initial test of LEDs

OFF RED Broken beams, DARK and OSSDs OFF: “BREAK”

OFF GREEN

Clear beams, LIGHT

for s

lave models

, (for Master see Tab.:5)

Clear beams, LIGHT and OSSDs ON: “GUARD” for Base models

OFF RED Fault condition, see t e corresponding error code in Tab.:7

Tab.:3; Chap.:8

LS2

SERIES

RECEIVER MODELS DISPLAY

Standard models: LS2R/**-***

Display Colour LED_2

Blink

Colour LED_3

Blink Meaning

Wiring

See Tab.:1

Chap.:6

YELLOW

RED Power_ON, as initial test of LEDs 1, 2, 3, 4

OFF

RED Broken beams, DARK, OSSDs OFF: “BREAK” 1, 2, 3, 4

YELLOW

OFF

Wit manual Restart, wit o wit out EDM.

Clear beams, LIGHT, OSSDs OFF: “CLEAR”, awaiting RESTART 3, 4

YELLOW

YELLOW

Wit automatic restart and EDM

Signal level ig , LIGHT, OSSDs OFF: “CLEAR”, awaiting EDM closed

2

OFF

GREEN Clear beams, LIGHT, OSSDs ON: “GUARD” 1, 2, 3, 4

OFF

RED Fault condition, see t e corresponding error code in Tab.:7 1, 2, 3, 4

Tab.:4; Chap.:8

Table of contents

Other Micro Detectors Safety Equipment manuals