C. Low Voltage DC can be used to turn the

control ON and OFF. Move jumper "J1" from

terminal 7, to terminal 5, (6 remains the

same).

Connect a +5 to 30VDC (10mA) signal to

terminal 12 and the reference (GND) to

terminal 11 of TB2. The control will now turn

ON when the DC signal is present at terminals

11 and 12 of TB2. This input is optically

isolated. Refer to Section C of the OFF/ON

CONTROL GUIDE.

D. AC Voltage may be used to turn the control

ON and OFF. This requires a 105-250VAC

signal, with 2mA leakage maximum. Set up

the control by moving the jumper "J1" from

terminal 7, to terminal 5, (6 remains the

same). Connect the 105-250VAC Signal to

terminal 12 (L1) and the common (L2) to

terminal 10 of TB2. The FC-40 control will

now turn ON whenever the AC signal is

applied to terminals 10 and 12 of TB2. This

input is optically isolated. Refer to Section D

of the OFF/ON CONTROL GUIDE.

TB-2 terminals 5-7 are transformer isolated from

the line voltage circuit.

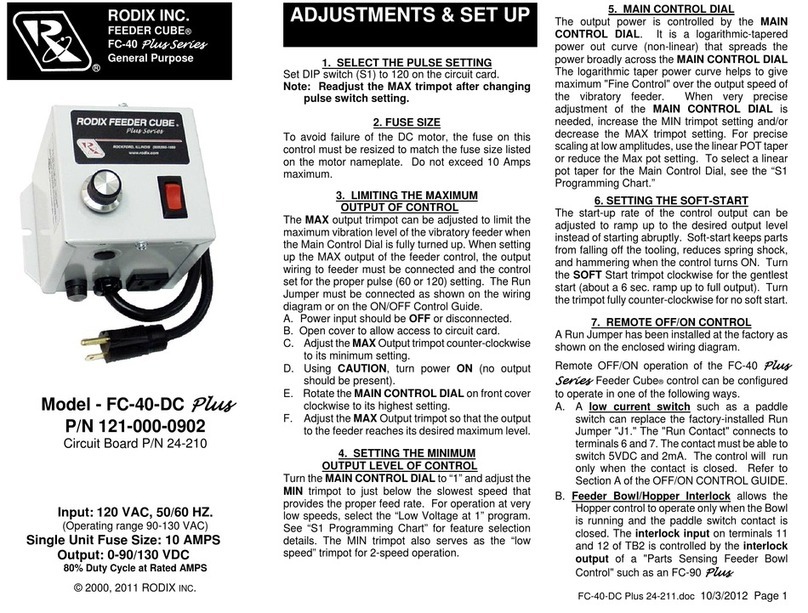

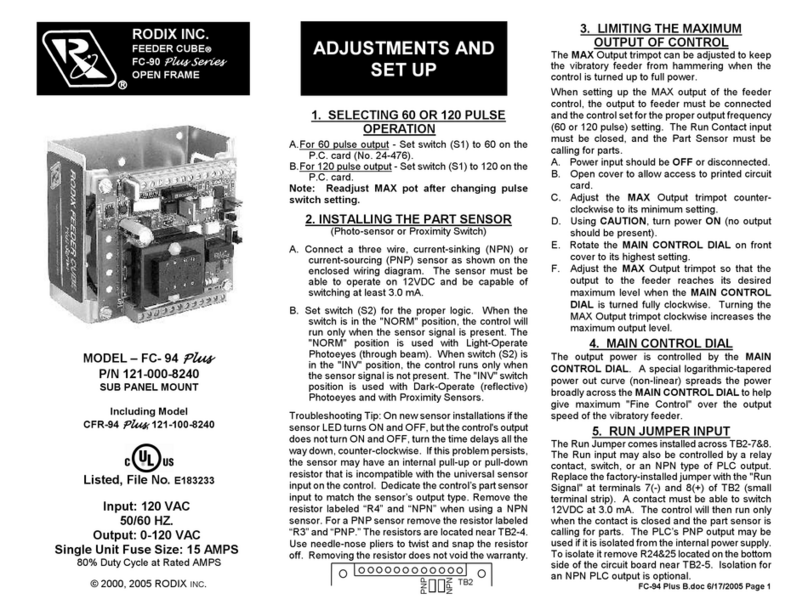

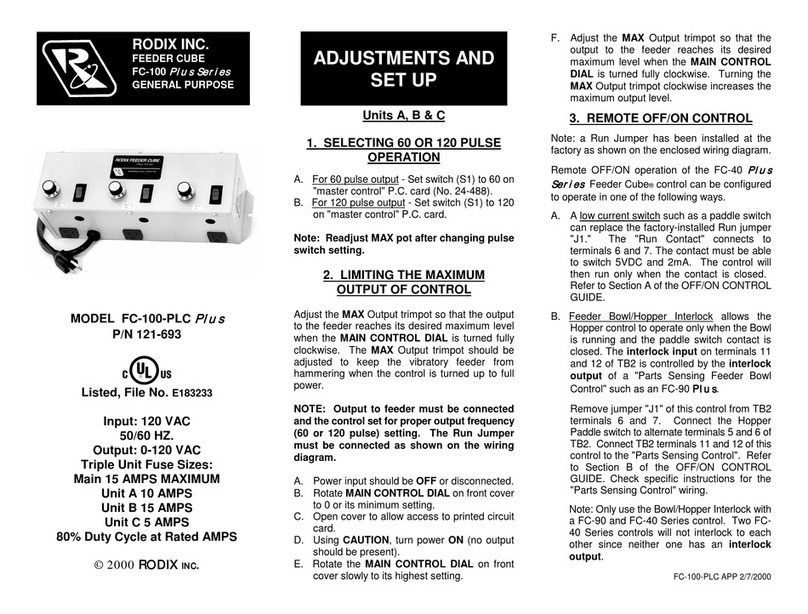

4. MAIN CONTROL DIAL

The output power is controlled by the MAIN

CONTROL DIAL. A special logarithmic-tapered

power out curve (non-linear) spreads the power

broadly across the MAIN CONTROL DIAL to help

give maximum "Fine Control" over the output

speed of the vibratory feeder.

5. SETTING THE SOFT-START

The start-up of the control output can be adjusted

to ramp up to the desired output level instead of

starting abruptly. This keeps parts from falling off

the tooling of a vibratory feeder when it turns on; it

can reduce hammering during turn on; it can also

simulate a paddle switch ON delay. Adjust the

SOFT Start trimpot clockwise for the gentlest start

(about a 10-second ramp up to full output). Turn

the trimpot fully counter-clockwise for no soft start.

6. LINE VOLTAGE COMPENSATION

Fluctuations in the line Voltage can cause a feeder

bowl to vary its feed rate. The line voltage

compensation feature adjusts the control's output

to help compensate for fluctuations in the supply

voltage. If it becomes necessary to disable this

feature, remove resistor R4 from the bottom of the

board with a pair of pliers, twist R4 to snap it off.

7. REMOTE SPEED CONTROL

Remote control of the power signal level can be

accomplished by the following methods:

A. 0-5VDC Analog input signal may be applied in

place of the Main Control Dial. For further

information, contact RODIX.

B. 4-20mA signal from a PLC can be used to

remotely vary the output of the control instead

of the Main Control Dial. This feature is

automatically turned on whenever a 4-20mA

signal is applied to the control. To return

control to the Main Control Dial, remove the 4-

20mA signal by turning it off or use a switch to

open the circuit. The 4-20mA input is

transformer isolated from the power line.

C. Remote control of the output power level can

be accomplished by using an optional Step

Up/Down Remote Speed Interface P/N 123-

148. WARNING:

Fuses should be replaced with Littelfuse 3AB

"Fast Acting" type or equivalent of

manufacturer's original value.

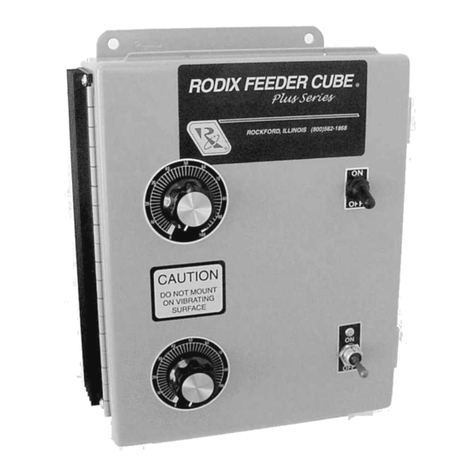

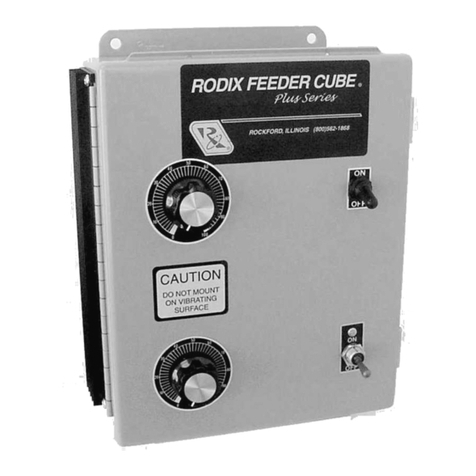

Mounting this control on a vibrating surface

will void the warranty.

WARRANTY

Rodix Control Products are Warranted to be

free from defects in material and workmanship

under normal use for a period of two years

from date of shipment. For the full description of

the warranty, terms, and software license, please

contact the factory.

For assistance installing or operating your Rodix

Control please call the factory. Technical help is

available to answer your questions and Fax any

needed information. To return a control for IN or

OUT of Warranty Service, please ship it prepaid

to: Rodix Inc., ATTN: Repair Department

If under Warranty, Rodix will repair or replace your

control at no charge; If out of Warranty, we will

repair it and you will be billed for the repair charges

(Time and Material) plus the return freight. Quotes

for repairs are available upon request. A brief note

describing the symptoms is appreciated by our

Technicians.

Feeder Cube®is a registered TM of Rodix Inc.

DIMENSIONS

RODIX, INC.

2316 23rd Ave, Rockford, IL 61104

Toll Free (800) 562-1868

FAX (815) 316-4701

www.rodix.com

FC-41H-PLC DOC JANUARY 2000