LBX instruments INC-S User manual

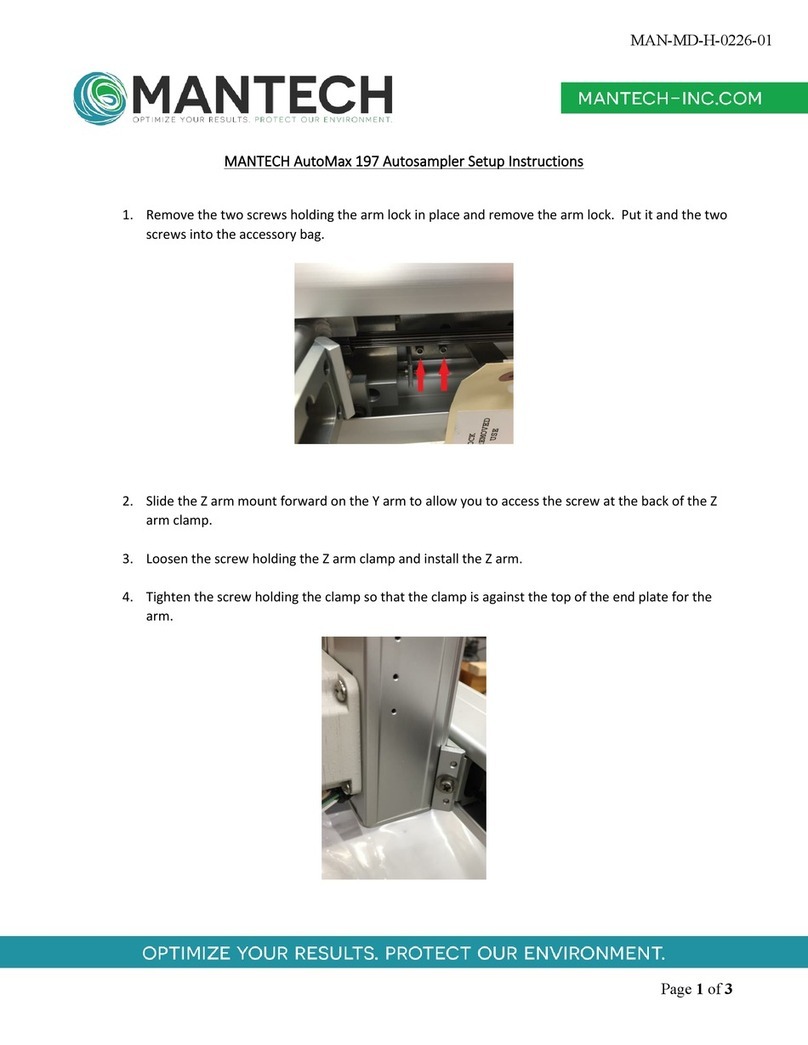

INC-S Shaking Incubator

Please read the User Manual carefully before use, and follow all operating and safety instructions!

user manual

english

2

User Manual

INC-S Shaking Incubator

Preface

Thank you for purchasing our product. Users should read this manual carefully, follow the instructions and

procedures, and beware of all the preventive measures when using this instrument.

Service

If help is needed, you can always contact your dealer or Labbox via www.labbox.com.

Please, provide the customer service representative with the following information:

▪Serial number

▪Description of the problem

▪Your contact information

Warranty

This instrument is guaranteed to be free from defects in materials and workmanship under normal use and

service, for a period of 12 months from the date of invoice. The warranty is extended only to the original

purchaser. It shall not apply to any product or parts that have been damaged due to improper installation,

improper connections, misuse, accident, or abnormal conditions of operation.

For claim under the warranty, please contact your supplier.

3

Introduction

Thank you for choosing to use our Shaking Incubator INC-S. This series of products combines temperature

control, incubation, and oscillation capabilities for use in a variety of biochemical applications. It is widely used

for bacterial culture, fermentation, hybridization, biochemical reactions, and research involving enzymes and cell

tissues with high requirements for temperature and oscillation frequency. It plays an important role in medicine,

biology, pharmaceuticals, food, the environment, and other scientific fields.

After you receive the product, please confirm whether it is the same as the one you ordered. Then, confirm

whether the appearance of the product is intact and the random accessories match the packing configuration list.

If the product model you received is inconsistent with your order or the appearance is damaged or there are not

enough accessories, please contact our sales staff in time.

Reminder

This manual provides detailed information on the product features, usage methods,

precautions, etc. To ensure a better understanding, convenient and safe use of this product,

please read this manual carefully before use.

4

1. Safety Instructions

•Read the product instruction manual before using this product.

•Do not put volatile, flammable, or explosive substances in the machine, as this could cause an explosion or

fire.

•Do not place the device in an area exposed to rain, moisture, or splashing, as this may result in electrical

leakage, short circuiting, or electric shock.

•Non-professional technicians must not disassemble, repair, or modify the equipment, as improper operation

may cause fire or electric shock to personnel.

•Do not damage the power plug or the power cord. If it becomes damaged, the power cord must be

replaced, otherwise it may cause fire or electric shock.

•This equipment should be installed on a firm ground, otherwise it could cause injury to personnel due to

equipment falling.

•Please use the designated power supply indicated on the nameplate. This equipment must be installed on

the ground to prevent electric shock and fire due to electrical leakage.

•Do not touch the power plug with wet hands, as there is a risk of electric shock.

•Before carrying out any repairs or maintenance, the power must be disconnected to prevent electric shock

or injury.

•Wear gloves when repairing or maintaining the equipment to prevent injury.

•Do not damage the power cord or use a non-specified power cord. Do not connect the power cord in the

middle section or use a long, flexible wire, as this may lead to electric shock or fire.

•Do not remove the power plug during operation or pull the power cord to unplug.

•If you notice the equipment running abnormally, unplug the power plug immediately and stop the

equipment.

•If the equipment will be idle for an extended period in an unsupervised area, ensure that the equipment

door is completely closed.

Other Necessary Considerations:

•Adjust the feet so that the equipment is installed horizontally, and all four feet should be in contact with the

support surface. There should be no gaps or imbalances.

•Use a separate power outlet fitted with a grounding wire. Tighten the power plug when in use.

•Turn off the power and unplug the power plug before removing the equipment.

•Only touch the inner wall of the door carefully as it may be hot.

•Non-professional technical staff should not disassemble the machine privately. Only professional staff should

repair and replace parts.

•The internal parameters must be set by a specific management person to prevent the controller program's

function from being disrupted by incorrect setting operations.

•The installation location of the equipment must be at least 20 cm away from the wall and other objects.

•Open or close the door gently. Forceful opening or closing of the door can easily damage the equipment.

•The surface of the equipment must not be exposed to volatile chemicals such as gasoline or thinner.

•Keep the inside and outside of the machine clean by regularly removing debris and smudges.

We strongly urge you to pay close attention to

the following instructions, as failure to do so could

cause serious damage or even death.

We strongly urge you to pay close attention to the

following instructions, as failure to do so could

cause personal injury, equipment damage and

related property damage.

We strongly urge you to pay close attention to

the following instructions, as failure to do so could

cause injury or equipment damage.

5

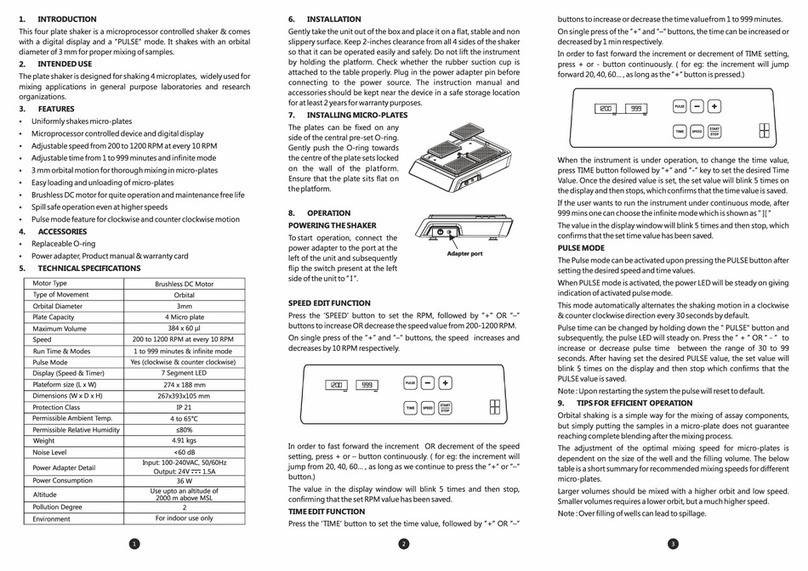

2. Main Product Features

1. The large LCD screen displays temperature, speed, and working time continuously and accurately in real-

time, and the menu interface is easy to operate.

2. The temperature and oscillation frequency are controlled by a microcomputer with a timing function and

built-in power failure protection, which can automatically resume operation after power is restored.

3. The unique workshop air duct provides gentle circulation for good temperature uniformity. The large

observation window allows for convenient observation of samples and easy opening and closing.

4. Speed control is achieved through intelligent feedback control of a DC brushless motor, ensuring high

speed accuracy. The slow start design prevents sudden spattering of the shake flask liquid and allows for

adjustable start speed, effectively ensuring the accuracy of quantitative experiments.

6

3. Technical Parameters

Model

CTSI-050-001

CTSI-070-001

Shaking Mode

Cyclotron Oscillation

Function

Amplitude

Ф20mm

Temp.Resolution

0.1℃

Temp. Motion

±0.1℃

Temp.Uniformity

±1℃

Temp. Range

RT+5~65℃

4~65℃

Rotary Speed

30~300rpm

30~300rpm

Rotary Speed Precision

±1rpm

Structure

Chamber Material

Mirror Stainless Steel

Outer Shell

ABS

Observation Window Material

Imported resin

Thermal Insulation Material

Polyurethane

Cooling System

No

Yes

Coolant

No

R134a

Heater

Stainless steel heating tube

Drive Mode

Three-axis level

Oscillating Plate

Spring Wire Rack

Air Circulation Mode

Horizontal convection

Power Rating

0.6kW

0.8kW

Controller

Temp. Control Mode

LCD PID intelligent control

Cyclotron Control Mode

Automatic changes of rotation direction

Setting Mode

Touch button setting

Temp. Display Mode

LCD display

Speed Display Mode

Timer

0~9999min

Temperature Sensor

Pt100

Speed Sensor

Hoare

Gating System

Yes

Specification

Inner Chamber Size (W*L*H) (mm)

455*380*290

560*390*320

Exterior Size (W*L*H) (mm)

500*640*480

600*770*500

Packing Size (W*L*H) (mm)

550*690*530

940*780*655

Shelf Size(mm)

380*320

480*315

Max capacity of Shelf for single

specification(ml/pc)

100ml*16/250*10/500*6

100ml*28/250*15/5

00*8/1000*6

Number of flask clamp as standard

(ml/pc)

250*8

250*12

Inside Volume

50L

70L

Shelf Load Bearing

≤10kg/layer

≤15kg/layer

Shelf Layer

1

Power Supply (50/60Hz)Current

Rating

AC220V/2.5A

AC220V/3.5A

NW/GW (kg)

25/35

65/85

7

4. Operation and Display Instructions

Shift key: Press the left arrow and click "Select" to move to the left. Press "Return" to go back to the main menu.

Decrease key: Press the down arrow to decrease the parameter value by one number. Holding down this key

will continuously decrease the parameter value.

Increase key: Press the upward arrow to increase the parameter value by one number. Holding down this key

will continuously increase the parameter value.

Time function key: Press the clock symbol to enter the timing parameter setting state. Press "Enter" until it returns

to the normal interface.

Temperature function key: Press the thermometer symbol to enter the temperature parameter setting state. Then

click "Return" to go back to the normal interface.

Speed function key: Press the circle with arrowhead symbol to enter the speed parameter setting state. Then

press "Back" to return to the normal interface.

Bactericidal function key: Press and hold the purple symbol with the light for 3 seconds to turn on the sterilization

lamp. Press and hold for another 3 seconds to turn off the sterilization lamp.

Lighting function key: Press the bulb symbol to turn on or off the light.

Operation start/stop key: Press this key to start or stop the device.

1.Temperature Internal Parameters Setting

Note: All internal parameters have been adjusted during factory testing. It is forbidden to

modify them except for the sensor correction parameter.

Press the "temperature" key for about 3 seconds. The temperature display area will show the password prompt

"Lc," and the speed display area will show the password value.

Use the add, reduce, and shift keys to modify the password value to the required value. Then press the

"temperature" key. If the password value is incorrect, the controller will automatically return to the normal

display state. If the password value is correct, enter the temperature internal parameter setting state and press

the "temperature" key to modify each parameter in turn. After modification, press the "temperature" button for

3 seconds to exit the internal parameter setting state, and the parameter values will be automatically saved.

8

Internal Parameter Table -1

Parameter

Indication

Parameter Name

Parameter Function Description

(Range) Factory Value

Lc

Password

The password to modify this parameter in this

table is "Lc=3".

0

AL-

Upper deviation

over temperature

alarm

If the "temperature measurement >

temperature setting value +AL", the alarm

light turns on, the buzzer sounds, and the

heating output disconnects.

(0~20.0℃)

5.0

Ct-

Compressor

start delay

The compressor start delay protection time is

the minimum time interval from compressor

stop to restart.

(0~600s)

180

uP-

Compressor

start threshold

When the compressor works intermittently,

If the "temperature measurement value ≥

temperature set value + uP" and the

compressor start delay time is up, the

compressor starts.

Note: This parameter is valid only in the

manual start and stop compressor mode and is

invalid in the automatic mode.

(-10.0~10.0℃)

0.4

dn-

Compressor

closing the threshold

When the compressor works intermittently,

Turn off the compressor if "temperature

measurement value ≤ temperature set value +

dn".

Note: This parameter is valid only in the

manual start and stop compressor mode and is

invalid in the automatic mode.

(-10.0~(uP-0.1))

0.2

Lt-

Floodlight

off-delay

The light turns on and automatically turns off

after the time delay Lt. "Lt=0", the delay is

invalid, and the lights must be turned off

manually.

(0~9999min)

0

St-

Sterilizing lamp

off-delay

The sterilization lamp turns on, and

automatically turns off after the time delay St.

"St=0", the delay is invalid, and the lamp must

be manually closed.

(0~9999min)

0

T-

Control cycle

Heating control cycle.

(1~60s) 5

P-

Proportional band

Time proportional adjustment.

(0.1~50.0) 15.0

I-

Integration time

Integral function adjustment.

(1~2000s) 380

d-

Differential time

Differential action regulation.

(0~2000s) 100

Pb-

Zero adjustment

Correction of errors caused by sensor (low

temperature) measurement.

Pb = actual temperature value - instrument

measurement value

(-99.9~99.9℃)

0

PK-

Full degree

adjustment

Correction of errors caused by sensor (high

temperature) measurement.

PK = 1000 * (actual temperature value -

meter measurement value) / meter

measurement value

(-999~999) 0

9

Internal Parameter Table -2

Parameter

Indication

Parameter

Name

Parameter Function Description

Factory Value

Lc

Password

When “Lc=9”, the parameter values can be viewed and

modified.

0

rES

Power down

memory function

0:No power down memory function.

1:Power-down memory function.

(0~1)

0

FAn

Fan type selection

0:The fan is a short-axis fan.

1:Fan is a long-shaft fan.

(0~1)

0

ndc

Compressor

operation mode

0: The compressor works intermittently.

1: The compressor works according to the CP value

(see below), which determines if the work of the

compressor is balanced or intermittent.

2: The compressor works according to the Htd value

(see below), which determines if the work of the

compressor is balanced or intermittent.

(0~2) 0

CP-

Compressor working

mode fixed switching

point

When "ndc=1",

If the "temperature set value ≥ CP", the compressor works in

an intermittently, and vice versa.

(0~100.0℃)

30.0

Htd

Compressor working

mode automatic

switching point

When "ndc=2":

If the "temperature set value ≥ ambient temperature + Htd",

the compressor works intermittently, and vice versa.

(-50.0~50.0℃)

0.0

Crc

Compressor

start and stop mode

When the compressor is working intermittently:

0: The compressor starts and stops automatically according to

the ambient temperature and set value.

1: The compressor starts and stops manually according to the

values of uP and dn in internal parameter table-1.

(0~1) 0

Cnp

Prohibit compressor

working temperature

point

When "temperature set value ≥ Cnp", the compressor is

prohibited from working.

Note: This mode of operation has the highest priority, that is,

the controller executes this command first and then judges the

balanced or intermittent operation of the compressor.

(0~100.0℃)

42.0

nP-

Maximum power

output

The maximum power percentage of the heating output.

(0~100%) 100

Co-

Turn off the heating

output deviation

When the "temperature measurement value ≥ temperature

set value + Co", the heating output is turned off.

(0.0~20.0℃)

5.0

SPL

Lower temperature

setting

Lower limit of temperature set point.

(-

50.0~100.0℃)

0.0

SPH

Upper temperature

limit

Upper limit of temperature set point.

(SPL~100.0℃)

60.0

Adr

Mailing address

The local communication address.

(1~16) 1

10

Internal Parameter Table -3

2.Temperature Internal Parameters Setting

Press and hold the “Speed” button for about 3 seconds. The temperature display area will display the password

prompt “Lc”, and the speed display area will display the password value. You can change the password value

to the required password by using the add key, decrease key, and shift key. Then, click the “Speed” button. If

the password value is incorrect, the controller will automatically return to the normal display state. If the

password value is correct, it will enter the speed internal parameter setting state, and then click the “Speed”

button to modify each parameter in turn. After modification, press and hold the “Speed” button for 3 seconds to

exit the speed internal parameter setting state, and the parameter value will be automatically saved.

Note: Note: Modifying the speed parameter during the controller's operation is forbidden. If it needs to be

modified, please stop the controller and then make the necessary modifications.

Speed –Internal Parameter Table (1)

Parameter

Indication

Parameter Name

Parameter Function Description

Factory Value

Lc

Password

The parameter value can be viewed and

modified when "Lc=3".

0

Pd-

Proportional gain

Speed proportional gain.

(1~100) 10

Id-

Integral coefficient

Speed integral coefficient.

(1~100) 5

InT

Acceleration time

The time it takes for the motor to

accelerate to the new setpoint.

(1~60) 10

dET

Deceleration time

The time it takes for the motor to

decelerate to the new setpoint.

(1~60) 10

SdL

Speed setting

lower limit

Minimum value of speed setpoint.

(20~6000) 20

SdH

Speed setting

upper limit

Maximum speed setting.

(SdL~6000) 600

Parameter

Indication

Parameter

Name

Parameter Function Description

Factory Value

Lc

Password

The ambient temperature can be viewed when "Lc=18".

Ht

Ambient

temperature

The ambient temperature at which the controller is located.

11

Speed –Internal Parameter Table (2)

Parameter

Indication

Parameter Name

Parameter Function Description

Factory Value

Lc-

Password

The parameter value can be viewed and

modified when "Lc=9".

0

EAr

Gear ratio

Big gear diameter / pinion diameter.

(1.0~10.0) 3.2

PoL

Motor pole number

DC brushless motor pole pairs.

(1~32) 4

dIF

Motor rotation

Reference direction

dIF=0: Specifies that the clockwise direction

of rotation is positive.

dIF=1: Specifies that the counterclockwise

direction of rotation is positive.

(0~1) 0

FdS

Speed feedback

value

Speed feedback coefficient value.

(0.1~10.0) 1.0

FdC

Current feedback

value

Current feedback system value.

(0.1~10.0) 1.0

FrE

Carrier frequency

Brushless motor carrier frequency,

Note: When the carrier frequency is

changed, the controller needs to be restarted.

(5~15) 15

Po-

Motor power

Brushless motor power,

Note: This parameter must be adjusted

according to the actual power of the motor.

(1~400)

Low voltage driver: 80

High voltage driver: 200

CL-

Overflow multiple

Allowable current multiplier for overcurrent

protection of motor.

(1.0~10.0) 5.0

Fr-

Rotation direction

selection of motor

0: The motor only runs in forward rotation.

1: The motor only runs in reverse.

2: The motor can run in reverse direction.

(0~2)

0

db-

Insensitive display

area

Speed display insensitive area.

(0~100) 2

dF-

False display interval

point

When the speed set value ≥ dF, both the

speed set value and the speed display value

are false display values.

(0~6000) 6000

3.Temperature Internal Parameters Setting

1. When Fr is set to "0" or "1" in "Speed - Internal Parameter Table (2)", the direction of rotation can only be

forward or reverse. Press the "Time" button to make the number on the right side of the time display area flash.

Use the "◀" shift button, "▼" decrease button, and "▲" increase button to set the running time. Press the "Time"

button again to return to the work interface, and the time display area will show the set total timing time. The

number will decrease as the running time progresses, and the integer part will stop when it reaches zero. Finally,

the buzzer will sound, and pressing any key will stop the buzzer.

2. When Fr is set to "2" in "Speed - Internal Parameter Table (2)", there is a positive and negative function. Click

the "Time" button to enter the total timing setting state, and the time display area will start flashing. You can use

the '◀' shift key, '▼' decrease key, and '▲' increase key to modify the desired set value. Then click the “Time”

button to enter the forward rotation time (the prompt Fd is displayed on the right) setting status, and modify the

desired setting value by shifting, reducing, increasing, etc. Next, click the “Time” button to enter the stop timing

time (the right display prompt p-) setting status, and modify it to the desired setting value. Then, click the “Time”

button again to enter the reverse timing time (the right display prompt Rd) setting state, and also modify it to

the desired setting value. Finally, click the “Time” button to return to the normal display state, and the time

setting will be completed.

Note: The total time can be set in minutes or hours; the forward, stop, and reverse timings are in minutes.

12

3. Press and hold the "Time" button for about 3 seconds. The temperature display area will show the password

prompt "Lc", and the password value can be modified to the required value using the increase, decrease, and

shift keys in the speed display area. Then, click the "Time" button. If the password value is incorrect, the

controller will automatically return to the normal display state. If the password value is correct, it will enter the

time internal parameter setting state, and each parameter can be modified in turn by clicking the "Time" button.

To exit this state, press and hold the "Time" button for 3 seconds, and the parameter values will be

automatically saved.

Time –Internal Parameter Table

Parameter

Indication

Parameter Name

Parameter Function Description

(Range)

Factory Value

Lc-

Password

The parameter values can be viewed and modified

when "Lc=3".

0

ndt

Timing mode

selection

0: Start timing after running. Running time is up, only

stop speed, not temperature.

1: Start timing after running. Run time arrives, stop

speed and temperature simultaneously.

2: The temperature starts to count after reaching the

set value. Running time is up, only stop speed, not

temperature.

3: When the temperature reaches the set value,

timing starts. Running time arrives, and speed and

temperature are stopped simultaneously.

When the timing starts, "m" or "h" flashes. After the

time is over, the time display area shows "End".

Note: This parameter is must not be modified during

operation.

(0~3)

1

Hn-

Total timing

Timing mode

0: Timing is measured in minutes.

1: Timing is measured in hours.

Note: This parameter is must not be modified during

operation.

(0~1) 0

rT-

Total timing

Time correction

Correct the total timing error using the following

formula:

Correction value = [(run time in seconds - actual time

in seconds) * 10] / (actual time in minutes)

(-999~999) 0

13

4.Button and Operation Instructions

1. Power on: Turn on the power, and the controller will power on. The temperature display window will display

"HY-2," the speed display window will display "8888," and the time display window will display "8888." All the

indicators will light up, and after about 3 seconds, it will enter the normal display status.

2. Temperature: Press the "Temperature" button, and the number on the right side of the temperature display

area will flash. Use the "◀" shift button, "▼" decrease button, and "▲" increase button to set the desired

temperature. Then press the "Temperature" button again to exit the temperature setting state. The set

temperature value will be automatically saved, and the instrument will operate according to this temperature

value.

3. Speed: Press the "Speed" button, and the number on the right side of the speed display area will flash. Use

the "◀" shift button, "▼" decrease button, and "▲" increase button to set the required speed. Then press the

"Speed" button again to exit the speed setting state. The set speed value will be automatically saved, and the

instrument will run at this speed value.

4. Time: If the total timing function is set to "0", it means that there is no timing function and the equipment runs

continuously. The timing function is set by referring to the description in item 8 above.

5. Sterilization: When "St=0", press and hold the "Sterilization" button for 3 seconds, the identifier "STERILIZE"

under the interface lights up, the UV lamp is turned on, and the device enters sterilization operation. Press the

"Sterilization" button again within 3 seconds, the identifier "STERILIZE" goes out and sterilization stops. The

sterilization lamp off delay setting is set by referring to the description in "Temperature - Internal Parameter

Table (1)".

6. Operation control: Press the "Run/Stop" button, the identifier "RUN" at the lower right of the interface lights

up and the equipment starts to rotate; press the "Run/Stop" button again, the identifier "STOP" at the bottom

right of the interface lights up, and the equipment stops rotating.

7. Gating: During operation, if the door is opened, the interface identifier "OPEN" lights up, the equipment stops

rotating, and when the door is closed, the identifier "OPEN" goes out and the equipment continues to rotate.

8. Lighting: When "Lt=0", click the "Lighting" button to turn the light on and off. The illumination off delay setting

is set by referring to the description in "Temperature - Internal Parameter Table (1)”.

5.Function Setting Description

1. Timing Function

When the total timing time is set to "0", it means that there is no timing function, and the device runs continuously.

When the total timing time is not "0", the timer starts according to the selected timing mode. The letter "m" (for

minutes) or "h" (for hours) will flash, and the motor will stop when the timer ends. The time display area will show

"End," and the buzzer will sound. Click the "Start/Stop" button to restart the operation.

Note:

1) If the set value of the timing time is changed during operation, the controller will restart the timer according to

the new set time.

2) The timing mode can be selected by modifying the "ndt" value in the "Time - Internal Parameter Table".

3) The timing mode can also be selected by modifying the "Hn" value in the "Time - Internal Parameter Table".

2. Refrigeration Function

The working mode of the compressor can be selected (intermittent, balanced, or disconnected), and the

compressor can be started manually or automatically during intermittent operation. For specific settings, please

refer to parameters such as "ndc," "CP," "Htd," "Crc," and "Cnp" in "Temperature - Internal Parameter Table

(2)".

14

3. Power failure memory function

You can select whether to have a power-down memory function by modifying the value of “rES” in

“Temperature-Internal Parameter Table (2)”.

1) Without power-down memory function (rES=0): the controller is powered off after a power failure, and the

speed stops.

2) With power-down memory function (rES=1): the controller is powered off after a power failure, and the

speed remains in the last state before the power failure.

6.Alarm and Shutdown

1. When there is a power module failure (Er-1), Er-2, Holzer error (Er-3), busbar undervoltage (Er-4), busbar

overvoltage (Er-5), or communication fault (Er-6), the identifier "ALM2" will light up, and the controller will

automatically stop with the buzzer sounding. Please turn off the power when the fault occurs, carefully check the

wiring of the motor, and make sure it is correct before turning on the power again.

2. When an over-temperature alarm occurs, the buzzer will sound, and the "ALM1" identifier will light up. If an

over-temperature alarm occurs due to changing the temperature set value, the "alarm" light will be on, but the

buzzer will not sound.

3. When the buzzer sounds, you can press any key to stop it.

4. If no key is pressed within 1 minute in the setting state, the controller will automatically return to the normal

display state.

5. If the display window of the controller shows "-" to indicate the fault of the temperature sensor or the

controller itself, please carefully check the temperature sensor and its wiring.

6. When turning off the machine, press the "run/stop" button to stop rotation, then turn off the power switch on

the right side of the instrument, and turn off the whole machine.

15

5. Wiring Diagram

CTSI-050-001 Wiring Diagram

CTSI-070-001 Wiring Diagram

16

6. General Fault and Troubleshooting

Failure Phenomenon

Fault Analysis

Troubleshooting

Equipment is ON but the

display is not

Power supply is not connected.

Check if the power outlet has power.

The power plug is not plugged in.

Check the contact between the

power plug and the socket.

The power switch is not on.

Turn on the power switch on the right

side of the instrument.

Damage of the fuse on the

Box.

Replacement of a power fuse with

the same specification.

Rolling plate does not rotate

Door switch does not work.

Check if the door is closed or not.

The bottom of the rolling plate is

stuck with an object.

Remove the object.

Belt damage.

Notify the factory to get the belt

replaced.

Control circuit fault.

Notify the factory to get it repaired.

Instability of the rolling plate

The instrument is not stable.

Adjust the foot of the instrument to

stabilize it.

External object at the bottom of the

plate.

Remove the object.

Control circuit fault.

Notify the factory to get it repaired.

The measured

temperature is higher

than the set temperature

or the system enters the

high temperature alarm

state

The door is not properly closed.

Close the door properly.

The instrument has not yet entered

the state of constant temperature.

Wait for a moment and check again.

Damage of the circulating fan.

Notify the factory to get the fan

replaced.

Failure of the refrigeration system.

Notify the factory to get it repaired.

The noise of the instrument is too loud

The instrument is not placed

properly.

Adjust the foot of the instrument to

stabilize the instrument.

Flask clamp fixing screw is loose.

Remove the flask and the plate and

tighten the screw.

Shake plate loosening.

Tighten the screws at the four corners

of the plate.

Bump on the bottom of the plate due

to an object.

Remove the object.

Mechanical failure.

Notify the factory to get it repaired.

17

.

www.labbox.com

Table of contents

Other LBX instruments Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Sterlitech

Sterlitech CF042A-FO Cell Assembly & operation manual

Munchkin

Munchkin 59S owner's manual

Agilent Technologies

Agilent Technologies 5890 troubleshooting guide

Dr. Brown's

Dr. Brown's Natural Flow Microwave Steam Sterilizer manual

PASCO

PASCO ME-9502 manual

Owen Mumford

Owen Mumford Autopen 24 Instructions for use