LDARtools phx42 User manual

UNCONTROLLED IF PRINTED

phx42UserManual

Rev.Date:January31,2023

Version

2.27

To confirm that this is the most current

version, please go to

http://www.ldartools.com/documentation/

OR

Go to the Customer Portal and Open the

“Docs” section.

UNCONTROLLED IF PRINTED

UNCONTROLLED IF PRINTED

Table of Contents

Welcome to the LDARtools Family............................................1

LDARtools Technical Support...................................................2

LDARtools Customer Portal............................................................3

User Login Information....................................................................4

Add to Firewall Whitelist..................................................................5

The Big Picture..........................................................................6

Start-up Guide...........................................................................7

Intended Use...................................................................................7

External Parts .................................................................................8

Connecting the Probe .....................................................................9

Preparing for Extension Probe Use.................................................9

Probe Care and Routing ...............................................................10

Disconnecting the Probe...............................................................10

Power Button ................................................................................11

Power Button Indicators................................................................12

Filling the phx42 with H2................................................................13

Charging the phx42.......................................................................16

Replacing the Probe Tip Filter.......................................................17

FAQs while Monitoring..................................................................17

Continuous Monitoring..................................................................18

phxApp....................................................................................19

Starting the phxApp ......................................................................19

What’s in the phxApp ....................................................................20

Menu Options on phxApp..............................................................20

Firmware Updates.........................................................................21

Prepare to Ship.............................................................................21

Setting a PPM Alarm.....................................................................22

Igniting the phx42..........................................................................22

A Word About the Self-check........................................................23

UNCONTROLLED IF PRINTED

Self-check Process .......................................................................24

Manual Calibration........................................................................25

Creating Daily Calibration Reports................................................26

Filter Detection..............................................................................26

Application Error Codes................................................................27

Negative PPM Value Errors..........................................................27

Level 1 Repair Procedures......................................................28

Before You Begin..........................................................................28

Requirements of Level 1 Certification ...........................................28

phx42 Level 1 Repair Tech Pledge...............................................29

How to Take the Level 1 Certification Test....................................30

Required Spare Parts....................................................................31

Tool Kit Inventory..........................................................................31

Identify Internal phx42 Parts .........................................................32

Level 1 Repair Procedures............................................................33

Storage .........................................................................................33

Technical Specifications..........................................................34

phx42 Operating Parameters........................................................35

Certifications and Markings...........................................................36

General Specifications..................................................................37

Electrical Parameters....................................................................37

Battery and Charging....................................................................37

Design Characteristics..................................................................37

Electrostatic Requirements...........................................................38

Special Conditions of Use.............................................................39

Applicable Standards and Directives.............................................40

Environmental Conditions Affecting Use.......................................42

Chemical Exposure.......................................................................42

Comprehensive List of phx42 Skills ..............................................43

Index.............................................................................................44

UNCONTROLLED IF PRINTED

UNCONTROLLED IF PRINTED 1

Welcome to the LDARtools

Family

We are excited you have chosen the phx42 as your VOC analyzer. The phx42 is

designed to work for you.

If you are not getting the results you want, we WANT TO HEAR ABOUT IT—

immediately.

UNCONTROLLED IF PRINTED 2

LDARtools Technical Support

At LDARtools, we want to ensure you get the maximum performance from all of the software and

equipment we offer. We have made every effort to provide a comprehensive manual to assist you with

using our products. If you experience issues with any of our products, please contact us for assistance

right away.

For general questions, you can consult a member of the LDARtools Technical Support team by

For equipment issues, and before beginning any repair, contact the LDARtools Technical Support

team by following these directions:

1. Do either:

a. Self-check and submit an issue using the phxApp.

b. Report an issue at LDARtools.com. Click Support, Customer Portal, log

in, and then click New Issue to submit a new hardware issue.

Note: Only use this method if the self-check option is not possible and will

likely result in an immediate RMA with no possible on-site troubleshooting.

2. If a confirmation email is not received within 30 minutes, please email support

(support@ldartools.com).

3. Stand by for instructions from the LDARtools Technical Support team.

REMINDER: Equipment being shipped to LDARtools for repair must have a Return Merchandise

Authorization (RMA) label printed and in the box. Failure to do so will result in extra processing and

diagnostic expense and time. The only exception would be written instructions from the LDARtools

Technical Support team.

UNCONTROLLED IF PRINTED 3

LDARtools Customer Portal

The Customer Portal allows you to:

•Create Support tickets.

•List/Export assets purchased from LDARtools.

•Track assets.

•Check activated warranties.

•Check outstanding orders requiring action.

•See what Cores are due.

•View a Support Case status (Log in, go to Hardware Issues →Status)

•Track phx42 repairs.

•Edit user information.

Customer Portal Registration

Follow the steps below to generate your personal Customer Portal login.

1. Go to LDARtools.com.

2. Click on Support.

3. Select Customer Portal Registration.

4. Fill in the required fields.

5. Click Save.

–OR–

Use the Site Login provided with your phx42.

UNCONTROLLED IF PRINTED 4

User Login Information

Use the following fields to document your personal user login information.

LDARtools Customer Portal

LDARtools.com → Support → Customer Portal (or log in with the phxApp)

Username/Company-

Provided Email*

Password

Online Training

Online training and certifications.

LDARtools.com → Support → Online Training (refer to “Don't have an account? Sign up for free!”

beneath the login entry fields)

Username/Company-

Provided Email*

Password

* REMINDER: The username (your company-provided email address) on your Customer Portal and

Online Training accounts must match so certification records can sync between the two systems.

LDARtools Store

Log in to your store account to track order history and expedite the checkout process.

StoreLDAR.com → My Account → Returning Customer (use Proceed to button for user registration)

Username

Email

Password

UNCONTROLLED IF PRINTED 5

Add to Firewall Whitelist

The following sites must be whitelisted by your site IT Department for effective on-site

troubleshooting and support.

•ldartools.talentlms.com

•storeldar.com

•ldartools.agiloft.com

•ldartools.com

•ldartools.app.box.com

•time.windows.com

•time.nist.gov

•splashtop.com

•inteset.com

•216.239.35.4

UNCONTROLLED IF PRINTED 6

The Big Picture

UNCONTROLLED IF PRINTED 7

Start-up Guide

Intended Use

The phx42 analyzer can be used to safely collect data in Class 1, Division 1 hazardous locations.

This includes:

•Refineries and chemical plants

•Gas or oil pipelines

•Compressor and pump stations

•Oil field production facilities

•Anywhere VOCs are present

•Indoor and outdoor environments

The phx42 must be installed in a backpack while in hazardous locations.

•Use a Backpack Plate (LDAR#4207)to protect the connection to the phx42.

•The phx42 should be upright in the backpack with the north end (with probe port) facing up.

•The phx42 must not share a pocket with any other items or tools.

•The backpack should fit snugly so the phx42 does not tilt away from the tech or tip over. This

can cause probe kinks.

Overnight equipment storage and calibration should be done indoors at or near room ambient

conditions (15-25 °C or 59-77 °F) with a maximum humidity of 85%.

Section

1

UNCONTROLLED IF PRINTED 8

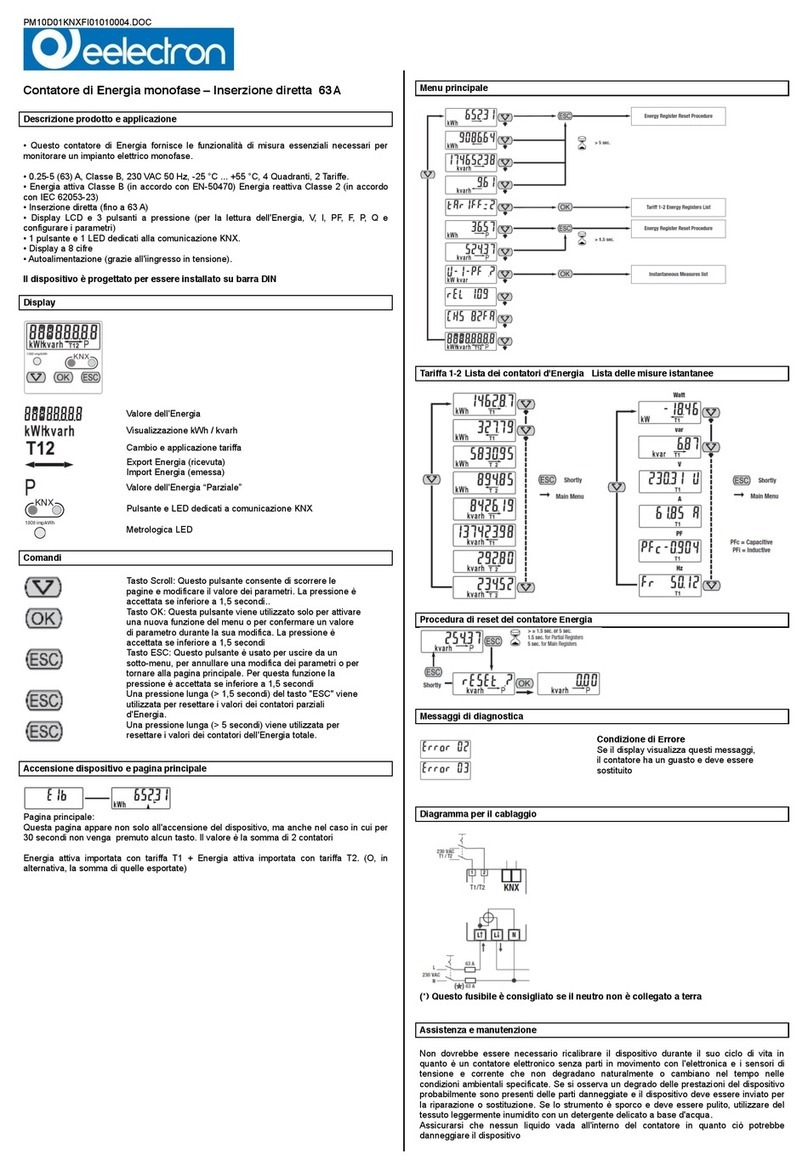

External Parts

⚫The connection end (north end) contains the following:

A. H2fill port / H2Quick Fill

B. Charging port / Charging Port Cover, tether

C. Bluetooth® antenna

D. Probe port

⚫Side panels contain the following:

E. Scrubber (west end)

F. Power button (west end)

G. The FID exhaust (east end)

H. Vent (east end)

(Flame Arrestor Cap assembly is located on the side of the enclosure)

•Reminder: Never remove the Flame Arrestor Cap unless instructed to by LDARtools

Technical Support within the context of a support case. Damage to the Glow Disk is

likely, if not certain.

⚫The phx42 enclosure

oThe enclosure is a two-part (cover and base) aluminum housing with a serial number on top.

It also has important manufacturer information and certification labeling at the bottom.

TECHTIP:TheH2QuickFillCoverandtheChargingPortCovermustalwaysbeinplace whenworking

in a hazardous location.

F

E

G

B

H

A

B

C

D

UNCONTROLLED IF PRINTED 9

Connecting the Probe

1. Snap the quick disconnect (A) into the probe port.

REMINDER: The probe and a probe tip filter must be connected to the phx42

before igniting the device.

Never operate the phx42 pumps without a filter in place. Do not remove the filter on a

running phx42 (unless performing filter detection calibration).

FAQ

Can I use an extension / other probe on the phx42?

Any device certified for use in hazardous environments using modern standards is done so

with accessories defined or attached. The phx42 was certified with the basic probe. You

should consult your safety department for a hazard assessment before using a different

probe.

Any extension should not exceed 20ft of tubing with minimum ID of 1/8”. The tubing in the

standard probe is 1/16” and cannot be used as a base for an extension probe. The extension

probe should utilize the same filters as the standard probe.

See Probe Integrity Inspection, Manual Calibration, Cal5.0 Manual for further instructions.

Why is the probe handle so heavy?

The probe handle was made from stainless steel to comply with the applicable safety

standards.

Preparing for Extension Probe Use

Whenever preparing for using an extension probe with your phx42:

1. Log in to the Customer Portal and click Unit Settings.

2. Locate the phx42 on the list and click the Edit icon.

3. Open the Multi Products tab and select Extension Probe.

4. Using the dropdown, change to Extension and enter the Probe length of extension from the tip of

the Probe Filter to the unit.

5. Click Save.

6. Next, use your Android tablet with the phxApp installed.

•Note: The tablet must have a network connection and be connected to the network.

7. Start the phxApp and connect to your phx42.

A

UNCONTROLLED IF PRINTED 10

Probe Care and Routing

When using the probe, a few basic points should be kept in mind:

8. Make sure the phx42 is oriented in the backpack so the hose can run straight out of the analyzer and

over your shoulder to avoid crimps and/or tears. Use the supplied D-rings to keep the hose in place.

9. When moving from place to place, the probe handle should be attached to the backpack to avoid

drops.

10. Avoid snagging or pulling on the probe hose.

11. Dropping the probe onto the filter could break the filter or cause leaks at the filter interface.

Use a Backpack Plate (LDAR#4207) to protect the connection to the phx42.

Disconnecting the Probe

1. Pull the collar on the quick disconnect to release probe.

2. Pull the probe off gently.

UNCONTROLLED IF PRINTED 11

Power Button

Unit is

And You

Then

OFF

Press and Hold for 2 seconds

Unit will turn ON.

ON

Triple Tap

Unit will ignite.

ON

Quadruple Tap (4x)

SLEEP MODE*

Unit shuts off solenoid, stopping flow of H2.

Flame will go out.

Pump will run for an additional 30 seconds (to evacuate

moist air from the FID).

Bluetooth will stay active.

THIS is the typical end-of-day process if you are going to be

charging overnight.

Allow unit to recover to ambient ppm readings before

entering Sleep Mode. If the unit does not recover to ambient

readings, run a self-check and leave the unit running until

Support responds with instructions.

ON

Press and Hold for 5-8

seconds

POWER DOWN

Note: If the machine is lit, use the Quad Tap to exhaust

the moisture from the FID before you power down.

Unit will power down. This is a hard power-off.

This process should be avoided unless in these situations:

•If working more than 10 hours, power off when

not in use.

•When putting aside to store (not plugged in to a

charger) or for shipping.

•When you are having connection issues.

UNCONTROLLED IF PRINTED 12

Power Button Indicators

The light pattern on the power button provides an indication of the machine’s state so that you can

give commands using the power button.

*Once the battery is fully charged but connected to a charger then it will cycle between

OFF/ON/OFF/ON and Breathing. This is because once the battery is fully charged it stops charging

(even though it is still plugged in) and the light goes OFF/ON/OFF/ON until the battery is depleted a

minimal amount and charging resumes, the light will then return to breathing.

Light Pattern

Ignited

Bluetooth Status

Charging

OFF/2 Pulses/OFF/2 Pulses

Yes

Discoverable

No

OFF/ON/OFF/ON*

No

Discoverable

No

Steady On (Solid)

Yes

Connected

No

ON/2 Pulses/ON/2 Pulses

(Solid/then flickering)

No

Connected

No

Breathing*

No

Either

Yes

No Light

Unit is Off.

Rapid Fast blink then OFF

Unit has detected a very low battery and automatically powered down.

In order to restart, you will have to attach the charger for at least 90

minutes before powering back on.

UNCONTROLLED IF PRINTED 13

Filling the phx42 with H2

Gases are typically stored under pressure in metal cylinders. Cylinders are designed to withstand high

pressures. Improper handling and use of compressed gases can result in devastating consequences. Be

sure to follow all safety guidelines outlined by your facility.

TECH TIP: Be sure to use only ULTRA HIGH PURE (99.999%) H2with a CGA-350 fitting when filling the

phx42.

Initial Setup of Newly shipped phx42

The battery and the H2cylinder are drained for shipping. Special charging and fill procedures are required.

Charge the battery:

1. PULL the Charging Port Cover (LDAR# 42013) to access the Charging Port.

Twisting/turning the cover to remove will damage the tether. It does “click” into the Charging

Port, so some effort will be required to remove the Charging Port Cover.

2. Align the red lines on the phx42 Charger and the Charging Port. Push gently and you will

feel a click.

3. Wait 90 mins.

4. Turn on the machine.

Filling Empty Cylinder with H2

The motor needle valve for the H2cylinder will need time to adjust from an empty to a full cylinder.

Follow the standard “Filling the phx42 with H2” procedure, with the following exceptions:

•Fill as described in the normal fill procedure described below, but when the needle on the

gauge stops moving, wait 3 minutes with the valve open.

TECH TIP: After you have filled the unit with H2, it may take several attempts to ignite. This is because

the H2pressure must stabilize. The best approach is to wait 2 minutes between each ignition attempt. If

Ignition Failure continues after 3 tries, perform a self-check, and submit a failure with comments to the

LDARtools Support team.

UNCONTROLLED IF PRINTED 14

Fill Adapter maintenance is critical for successful operation of your phx42. See the H2Fill Adapter

(LDAR#1260) Maintenance and Installation guide via LDARtools.com → Resources →

Documentation.

1. Remove the H2quick-fill cover (LDAR#42908).

2. Ensure the following:

(a) Verify no dust or debris is in the H2Fill Port.

(b) Verify no dust or debris is in the H2Fill Adapter.

(c) Verify the arrow on the red handle is pointing to the

breather side of the fill valve (see photo).

(d) Verify the gauge nearest the cylinder reads ≤ 1800

psi. If not, adjust the regulator.

•Note: Do NOT exceed 1800 psi or the pressure

relief valve will vent.

(e) If pressure has bled off the H2 Fill Adapter, turn the red handle 180° for 2 seconds

to bleed any air from the system before connecting to the phx42.

3. Power on the phx42.

4. Connect the H2Fill Adapter to the H2fill port, then verify the connection by slightly

pulling on the 3-way valve and spinning the collar.

5. Turn the red handle 180° to open valve. The arrow should point toward the fill hose.

6. Wait until the needle on the gauge stops moving.

7. Turn the handle back 180° to close the valve. There will be a slight hiss from the release of

pressure.

8. Pull on the collar of the H2Fill Adapter to release it.

9. Twist the H2quick fill cover onto the H2fill port.

10. Close the bottle. There is no need to bleed pressure off the H2fill Adapter.

REMINDER: The phx42 MUST have the H2quick-fill cover in place at all times unless filling.

UNCONTROLLED IF PRINTED 15

A very small amount (as little as possible) of O-ring grease should be applied to the phx42 side

of the quick connect once a month.

Your phx42 is now filled with H2, and while it has been designed to minimize possible leaks, you

should handle and store it with caution.

Note: The pressure sensor on the phx42 will max out at about 1200 psi. The unit can actually hold up to 1800

psi. Use the regulator on your fill adapter to confirm you have filled to 1800 psi.

TECH TIPS:

•Fill your cylinder at end-of-day to accomplish the following:

oThe analyzer will have enough H2for end-of-day drift.

oBeing full overnight allows the calibrating tech to see if the pressure is stable or

dropping (leak test).

•Many successful users have adopted a 2-fill practice: Mid-day and End-of-day.

•If the H2Quick Fill Cover pops off, it’s likely there’s a H2leak. Report an issue to

LDARtools Technical Support and send the log files.

•For best results, DO NOT operate the phx42 with a H2supply of less than 400 psi. That much

pressure is required to optimize the phx42’s ability to stabilize its lower H2pressure.

•If the H2Quick Fill Cover is missing, replace it.

•If using the v2 H2Fill Port and the filter is missing (figure c below), report an issue

immediately.

v1 H2Fill Port

v2 H2Fill Port with the

filter in place

v2 H2Fill Port missing

the filter

Other manuals for phx42

1

This manual suits for next models

1

Table of contents

Other LDARtools Measuring Instrument manuals