Leader Electronics Corp. LTC-906 User manual

LEADER ELECTRONICS CORP.

2-6-33 TSUNASHIMA-HIGASHI. KOHOKU-KU,

YOKOHAMA. JAPAN.

LEADER INSTRUMENTS CORP.

HEAD OFFICE

151 DUPONT ST.. PLAINVIEW. N.Y. 11803 U.S.A,

(516) 822-9300

)

J

I

MODEL LTC-906

>TRANSISTOR CHECKER

INSTRUCTION MANUAL

LEADER ELECTRONICS CORPORATION

77110.8K® Printed in Japan,

LTC-906 TRANSISTOR CHECKER

OPERATING INSTRUCTIONS

1. General

1.1 Transistor checker LTC-906

The LTC-906 is atransistor tester which is capable of determining

good/bad of transistor, FET, UJT, diode, etc. and also perfoming

automatic determination of the proper leads in-circuit and

out-of-circuit. This tester is also capable of DC parameter

measuring transistor and diode out-of-circuit.

1.2 Features

a. Auto-measurement which automatically scans electrode.

Electrode change-over by switch is not required.

b. Automatic determination Good/Bad of specimen.

c. Automatic identification of the lead configuration.

d. Both transistor and diode can be measured.

e. Audible indication of test result. This permits the operator

to pay his attention to the end of probe.

f. Drive power can be selected either at LOW/HIGH.

g. In measuring VgE transistor and Vj) of diode, Silicon

type and Germanium type can be distinguished.

h. Leak current of transistor and diode can be measured.

i. hpE of transistor can be measured.

j. 2way power supply system of internal battery/ external

power supply.

2. Specifications

2.1 Auto-test

AUTO-test can be accomplished both in-circuit and out-of-circuit

1

operation.

a. Semiconductors which can be tested

Bipolar transistor, J-FET, MOS-FET, UJT, SCR, Diode

b. Item of test

GOOD/BAD

Polarity (PNP/NPN, PCHANNEL/N CHANNEL)

Base/Collector of transistor

Gate/Drain of FET

Cathode/Anode of diode

c. Measurement mode

Transistor and diode

d. Measurement voltage

Approx. ±2V, duty ratio about 10%

e. Measurement current

LOW DRIVE ... Maximum 4.5mA, average 0.45mA

HIGH DRIVE ... Maximum 60mA, average 6mA,

f. Measurement speed 1-10 times/second

g. Display

Light emitting diodes and sound by buzzer

2.2

EX2 parameter measurement

Out-of-circuit operation alone. VbE> ICEO ^FE of bipolar

transistor and Vg and LEAK of diode are indicated by meter.

a. Measurement mode

Transistor and diode

b. Polarity to be measured

PNP and NPN transistors and forward and backward diodes

c. Measuring range

^D’ ^BE 0—3Vdc 1range. Accuracy ±6% of FS

2

LEAK, IcEO O-IOOaiA, 0-1,000juA, 0-10,000mA

3ranges Accuracy ±6% of FS

hpE 0—100, 0—1,000, 0—10,000 3ranges

Accuracy ±20%

d. Measuring current

Vd> VbE Maximum 2mA

hpE Base current ±ljuA

Collector current Maximum 30mA

e. Measuring voltage Maximum ±5V

2.3 Power supply

Internal battery Standard 9-volt transistor radio battery

(EVEREADY 216,

MALLORY MN1604)

External DC 8—lOV, 25mA

2.4 Diemsion and weight

152(H) XIIO(W) X60(D) mm (excluding handle)

About 0.4 kg.

2.5 Accessory

3-lead test cable 1 ea.

2.6 Options

AC adapter LPS-169A DC9V, 25mA

In-circuit probe LP-11

3

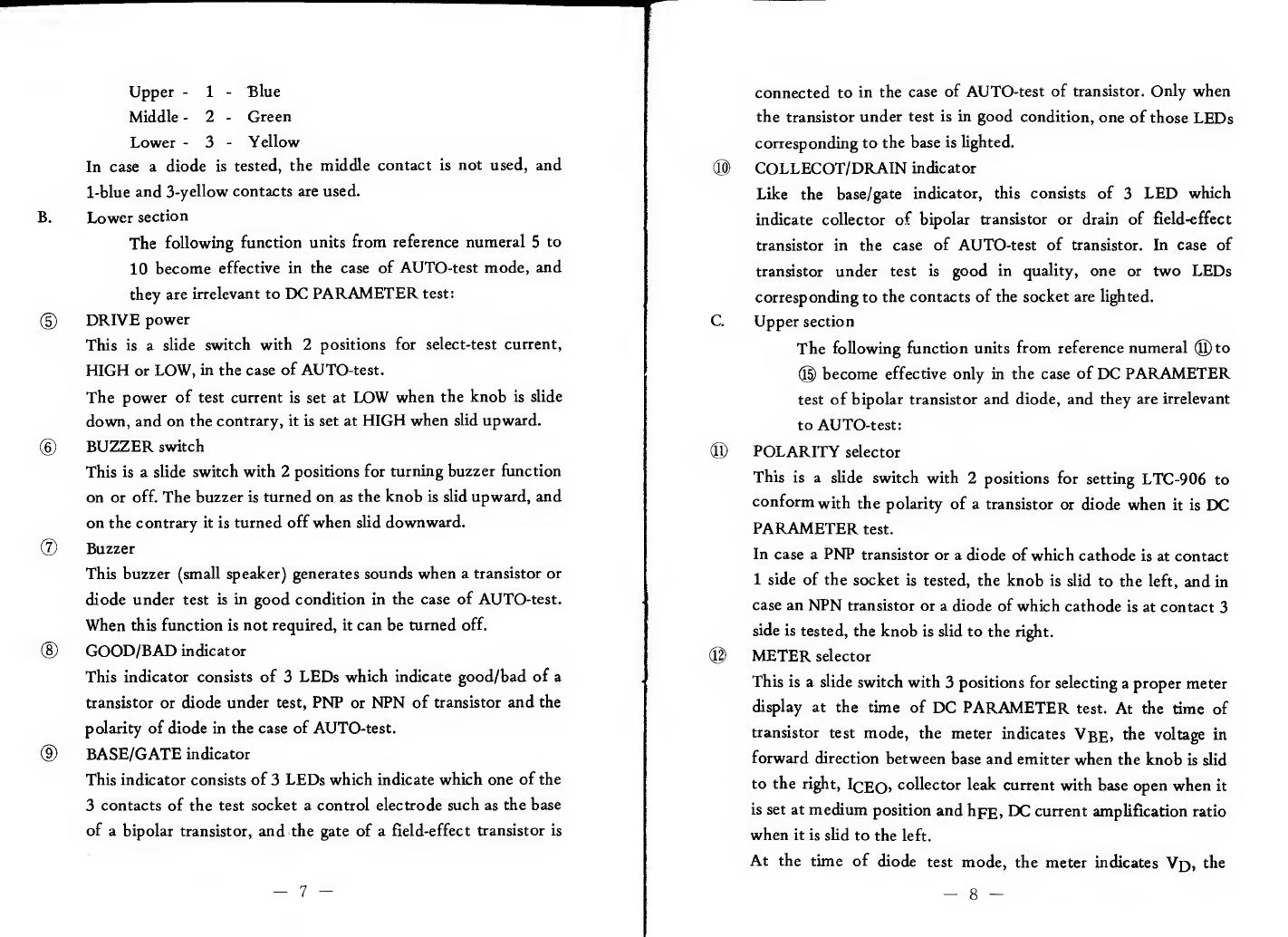

LTC-906

FUNCTIONAL

BLOCK

DIAGRAM

4. Description of panel

4.1 General

The front panel of LTC-906 is divided into three functional

sections, upper, middle and lower as shown in Fig. 4.1.

In the middle portion of the panel, those functions which are

related to all types of test are concentrated.® -®. In the lower

portion painted in brown, functions which are related to auto-test

of good or bad of transistor and leads identification are installed

®- @•

In the upper portion of the panel painted in green, functions

which are related to DC parameter test of bipolar transistor and

diode are concentratedly installed. ®-®.

(D AUTO/DC PARAMETER selector

-

@TRANSISTOR/DIODE selector-

®POWER switch —

®Test socket—

®External power jack

@Handle

(Q) Meter

(g) Meter-zero adjuster

©RANGE selector

51 POLARITY selector

5^ METER selector

5|i Mounting screw

®DRIVE level

®COLLECTOR/DRAIN indicator

(g) BASE/GATE indicator

(f) GOOD/BAD indicator

•® BUZZER

BUZZER switch

Fig. 4.1 Front Panel of LTC-906

5

4.2 Description of each functional section

A. Middle section

®POWER switch

This is aslide switch with 3positions for turning power on or off.

When the switch is slid to the left, power is turned off, at the

middle position battery can be checked, and at the right, power is

turned on.

Under battery check condition, the meter indicates whether the

voltage of abattery in operative condition or that of external

power supply is within aproper range or not.

@TRANSISTOR/DIODE selector

This is aslide switch with 2positions for setting the tester’s test

mode either to transistor or diode.

Test mode is set at transistor when the knob is slid to the left and

at diode when at the right.

@AUTO/DC PARAMETER selector

This is aslide switch with 2positions for setting the tester’s test

mode either to Auto-test for judging good/bad of transistor and

diode and identifying the proper leads, or DC PARAMETER test

for measuring forward voltage, leak current and current

amplification ratio. Test mode is set at Auto-test when the knob

is slid to the left and at DC parameter test when at the right.

®Test socket

This is asocket into which atransistor or diode to be tested is

inserted. In the case of in-circuit test, aplug of test lead is

connected to this socket.

The socket has 3contacts divided into upper, middle and lower,

and they are numbered from upper in sequence as 1, 2and 3for

identification. In addition to numbers, these are also identified by

color for matching with test leads as follows:

6

upper -1-Blue

Middle -2-Green

Lower -3-Yellow

In case adiode is tested, the middle contact is not used, and

1-blue and 3-yellow contacts are used.

Lower section

The following function units from reference numeral 5to

10 become effective in the case of AUTO-test mode, and

they are irrelevant to DC PARAMETER test:

DRIVE power

This is aslide switch with 2positions for select-test current,

HIGH or LOW, in the case of AUTO-test.

The power of test current is set at LOW when the knob is slide

down, and on the contrary, it is set at HIGH when slid upward.

BUZZER switch

This is aslide switch with 2positions for turning buzzer function

on or off. The buzzer is turned on as the knob is slid upward, and

on the contrary it is turned off when slid downward.

Buzzer

This buzzer (small speaker) generates sounds when atransistor or

diode under test is in good condition in the case of AUTO-test.

When this function is not required, it can be turned off.

GOOD/BAD indicator

This indicator consists of 3LEDs which indicate good/bad of a

transistor or diode under test, PNP or NPN of transistor and the

polarity of diode in the case of AUTO-test.

BASE/GATE indicator

This indicator consists of 3LEDs which indicate which one of the

3contacts of the test socket acontrol electrode such as the base

of abipolar transistor, and the gate of afield-effect transistor is

connected to in the case of AUTO-test of transistor. Only when

the transistor under test is in good condition, one of those LEDs

corresponding to the base is lighted.

@COLLECOT/DRAIN indicator

Like the base/gate indicator, this consists of 3LED which

indicate collector of bipolar transistor or drain of field-effect

transistor in the case of AUTO-test of transistor. In case of

transistor under test is good in quality, one or two LEDs

corresponding to the contacts of the socket are lighted.

C. Upper section

The following function units from reference numeral (U)to

@become effective only in the case of DC PARAMETER

test of bipolar transistor and diode, and they are irrelevant

to AUTO-test:

(U) POLARITY selector

This is aslide switch with 2positions for setting LTC-906 to

conform with the polarity of atransistor or diode when it is DC

PARAMETER test.

In case aPNP transistor or adiode of which cathode is at contact

1 side of the socket is tested, the knob is slid to the left, and in

case an NPN transistor or adiode of which cathode is at contact 3

side is tested, the knob is slid to the right.

®METER selector

This is aslide switch with 3positions for selecting aproper meter

display at the time of DC PARAMETER test. At the time of

transistor test mode, the meter indicates Vbe, the voltage in

forward direction between base and emitter when the knob is slid

to the right, ICEO> collector leak current with base open when it

is set at medium position and hpE) DC current amplification ratio

when it is slid to the left.

At the time of diode test mode, the meter indicates Vp), the

voltage in forward direction, when the knob is slid to the right,

and indicates leak current in the reverse direction, LEAK when it

is set at medium position. In the case of diode test, the left

position of this meter selector has no fiinction.

RANGE selector

This is aslide switch with 3contact points for selecting one of

three meter scale magnification ratios, xl, xlO or xlOO, to

indicate hpE ICEO transistor and LEAK of diode at the

time of DC PARAMETER test.

Its ratio is set at xl when the knob is slid to the left, and at xlO

when it is set at medium position and at xlOO when the knob is

slid to the right. The magnification ratio for Vbe and Vj) is xl

regardless the range selector.

Meter

This is aDC ammeter for indicating hpE> ICEO VgE ^

transistor and LEAK and Vp) of adiode in the case of DC

PARAMETER test. When the power switch is at the battery

check position, the meter indicates whether the voltage of battery

in operative condition or that of external power supply is within

proper range or not regardless the position of other switches.

Meter-zero adjuster

This mechanically adjusts the meter needle to zero. When the

power switch is off, adjust the meter needle to zero by rotating

the screw.

Other parts

External power jack

This is an external power jack to which external DC power supply

of DC9V can be connected. AC adapter, LPS-169A is fitted to

this jack.

Handle

-9-

@Mounting screw

The battery compartment can be opened by loosening 2

mounting screws located at left and right when abattery is

replaced.

5. Operation of LTC-906

5.1 General

5.1.1 For safety

In making atest of an electronic apparatus, it involves arisk in

many cases. There is apossibility that ahigh voltage is being

generated at unexpected parts in the equipment which is out of

order. Please pay attention to the following points:

(1) The power switch of an apparatus to be tested should be

turned off and apower supply cord should be disconnected

from AC oudet when atest lead is connected or

disconnected from the apparatus. If this is impractical do

not touch metal portions of such an apparatus and work

should be performed on the floor of good insulation to

reduce the influence of electric shock.

(2) Electric charge of filter capacitors should be discharged

before connecting atest cord to the apparatus. Such a

condenser may be fuUy charged up to adangerous degree.

(3) It is necessary to keep atest instrument in good condition.

Atest lead which is partly broken or its covering is partially

missing may accidentally come to contact with adangerous

potential.

(4) Upon completion of test, the test leads should be

immediately disconnected from an apparatus.

5.1.2 Replacement of battery

The LTC-906 can be operated on one unit of astandard 9volt

transister radio battery. Prior to operating the checker, anew

battery must be installed as it has no battery installed. Abattery

-10 -

can be mounted by the following procedures. Replacement of

battery after 2nd time can be accomplished in the same manner.

(1) Be sure to turn the power switch off. This is important. If

this is neglected, the LTC-906 may be damaged by an

unexpected accident such as inverted connection or

shortcircuit of abattery.

(2) Loosen the 2 screws at the left and right of battery case

with ascrew driver and remove the case.

(3) if an old battery is mounted, remove it from abattery

holder located at the bottom of case, and then disconnect

from abattery snap connected to the main unit of checker.

(4) Connect anew battery with proper polarity set to the

battery snap and set the battery in the battery holder at the

bottom of case.

(5) Place the case in the checker with care exercised not apply

undue force to printed circuit board and lead wire of

battery snap and fix it with 2screws.

5.1.3 Battery check

Tile voltage of abattery required to have LTC-906 perform

correct operation is 7V or larger. If the battery voltage decreases,

the proper operation of LTC-906 will be hampered.

When the power switch is set at battery check position, the meter

indicates the range of battery voltage under an optional operation

condition of LTC-906 (or the voltage of an external DC power

source when used.).

The battery is in good condition if the meter needle is within the

range of GOOD of the battery scale, and it must be replaced with

anew one if the needle indicates the range of REPLACE.

The terminal voltage of abattery becomes smaller in inverse

proportion to its current due to voltage decrease of internal

-11 -

resistance even if its internal electromotive force is the same.

Consequently, the battery voltage of LTC-906 when it is in such

operational condition in which alarge battery current is being

consumed becomes lower than that of such acase in which a

small current is being consumed.

Acurrent being consumed by LTC-906 under no load;

DC PARAMETER test About 2mA at 9V

AUTOtest About 15 mA at 9V.

When aload is connected, its power consumption is further

increased, and it may exceed 30mA depend on the type of load

and way of connection.

As aforementioned, the battery current^ of LTC-906 varies

considerably depend on its operative condition, and its operation

time is fairly long as much as several tens hours if its current is

small, and on the contrary it becomes shorter less than one hour

if its current is large.

In order to use the battery economically and lengthen its life,

measurement should be carried out quickly as short as possible

and the power switch should be turned off upon completion of

measurement.

5.1.4 External DC power supply

The LTC-906 can be operated by external DC power supply

which is 7to lOV and more than 25mA connected to the

external power source jack. The outer circumference of the jack

is positive and its internal pin is negative in polarity. The

LTC-906 may be damaged if an external power source is

inadvertently connected inverse position.

As an external power source suitable for the LTC-906, AC

adapter type LPS-169A (option) is available.

LPS-169A Input AC 50/60Hz 100-120V 4.5VA

Output DC 9A 25mA

-12 -

In case the checker is used for along time, it will be economical

to utilize AC adapter than battery operation which require

battery replacement.

5.1.5 Other prec autions

(1) Aused-up battery may g^ve bad influence to the LTC-906

by its leaked battery liquid, therefore, such abattery

should be immediately removed from the checker. By the

same reason, abattery should be kept removed when the

checker is not used for along time.

(2) It is dangerous to cause abattery to short or to throw it

into fire.

(3) When the LTC-906 is carried, its power switch should be

kept off regardless the presence or absence of abattery.

With the power switch set at off position, the moving coil

of the meter is made short, and by its brake action, adverse

influence of mechanical shock while in transit to the meter

will be reduced.

(4) The LTC-906 should be carefully handled not to give strong

mechanical shock.

(5) Please do not place the checker near afire or leave it inside

acar under the blazing sun. Plastic portion may be

deformed by heat.

(6) Do not use solvent such as alcohol, theinner, benzine, etc.

for cleaning the checker. These solvents may dissolve the

paint or plastics of the checker.

The checker should be cleaned with aslighdy wet cloth.

5.2 Auto-test

The LTC-906 is capable of making in-circuit and out-of-circuit

test of bipolar transistor, field-effect transistor (FET), SCR, UJT,

diode, etc.

For AUTO-test, there are 2modes of transistor and diode which

can be selected by the TRANSISTOR/DIODE selector.

The AUTO-test unit automatically scans test signal being

impressed to the electrode of asemiconductor to be measured

and determines whether it is good or bad, and identifies the

electrode, if it is good, and causes LEDs to display its results.

Together with LED display, the result of test is notified by the

sound of abuzzer (small speaker) when asemiconductor^ good

in quality. Consequendy, the operator can concentrate his

attention to perform testing without looking at the display panel

for confirming the result of each test, and it is possible to

perform efficient in-circuit test.

When this buzzer sound is not required, this founction is turned

off by the buzzer switch.

For making in-circuit test, connect the plug of the attached test

lead to the test socket iwith its lead wires adjusted to

corresponding colors displayed on the panel, and then connect its

clip to atransistor of diode to be measured.

When an in<ircuit probe Model LP-11, an option, is used being

connected to the end of the test lead, semiconductors installed on

the printed circuit board can be easily measured as the probe’s tip

can be freely moved depend on the arrangement of legs of such

semiconductors.

The attached test lead should be used when atransistor or diode

cannot be directly inserted into the test socket for out-of-circuit

test.

Caution for in-circuit test

(1) Prior to connecting the test clip or probe to an circuit

under test, be sure to turn the power switch of the circuit

off and cause electric charge accumulated in the capacitores

to completely discharge through aresistor of several tens

-13 --14 -

ohms.

The LTC-906 may be damaged if avoltage of more than

±5V is externally applied to it.

(2)

Upon completion of test, the test clip of LTC-906 should

be disconnected from the circuit before its power switch is

turned on.

5.2.1 Transistor auto-test

(1) Set the AUTO/DC PARAMETER select at AUTO.

(2) Set the TRANSISTOR/DIODE selector at TRANSISTOR.

(3) Turn the power switch on.

(4) Turn the BUZZER switch on when audible GOOD signal is

desired. Keep it off if not so desired.

(5) Set the drive level at LOW.

(6) Insert atransistor directly into the test socket (out-of-

circuit). Or, connect 3clips of test lead coming from the

test socket or 3tips of test probe to the 3legs of a

transistor to be measured. Connection of electrode must

continue more than 2seconds.

(7) The GOOD/BAD indicator should display GOOD signal if

the transistor is good, if aGOOD LED located at upper

flashes, the transistor is of PNP or Pchannel, and on the

contrary the lower GOOD LED flashes, it is on NPN or N

channel. At the same time, LEDs of the base/gate indicator

and collector/drain indicator flash and the electrode of the

transistor corresponding to test leads can be identified. If

the buzzer switch is on, intermittent sounds are generated.

(8) If the BAD display LED is kept lighted (the buzzer does

not generate sound), the transistor is bad or drive level is

inadequate due to aheavy load in the circuit around the

transistor.

(9) Change-over the drive level to HIGH and repeat test from

(6) to (8) in the case of the in-circuit test.

(10) If it is judged as BAD again, the transistor is bad or drive

level is still inadequate.

(11) In the case of in-circuit test, disconnect the transistor wdiich

has been judged as BAD by the step (10) from the circuit,

and test it again by out-of-circuit AUTO-test at LOW and

HIGH drive level.

if the transistor is judged as BAD at both LOW and HIGH

drive level, it should be short-circuit, broken or

deteriorated. If transistor is of bipolar type, perform DC

PARAMETER test described in Par. 5.3.1 to make sure it

is really bad or not.

(12) To test another transistor, return to Step (5).

(13) Identification of leads

a. Bipolar transistor/ FET

When the base bipolar transistor and field-effect

transistor of MOS type or junction type are in good

condition, one of the three LED of the base/gate

indicator corresponding to contacts 1to 3of the test

socket flashes.

Similarly, when the collector of bipolar transistor or

the drain of FET is in good condition, a

corresponding LED of the collector/drain indicator

flashes. In this case, the collector/drain indicator

displays one electrode excluding base, or 2electrodes

at the same time. The reason why it displays 2

electrodes simultaneously is that the collector and

emitter of abipolar transistor and the drain and

source of an FET have amplification function even if

-15 —-16 -

they are exchanged. Especially, the drain and source

of junction type FET have aperfect symmetry in

many cases.

In the case of out-of-circuit, the collector/drain

indicator frequendy displays 2LEDs at the same

time, and in the case of in-circuit test, it displays 1or

2depend on the condition of circuits.

In order to identify the emitter and collector, cannot

be identified by AUTO-test, of abipolar transistor,

hpE of the transistor is measured by DC PARA-

METER test. From agenerally known fact that hpg

of such atransistor becomes lower than that of

normal operation when its collector is caused to

operate as emitter, the collector and emitter of a

bipolar transistor can be distinguished,

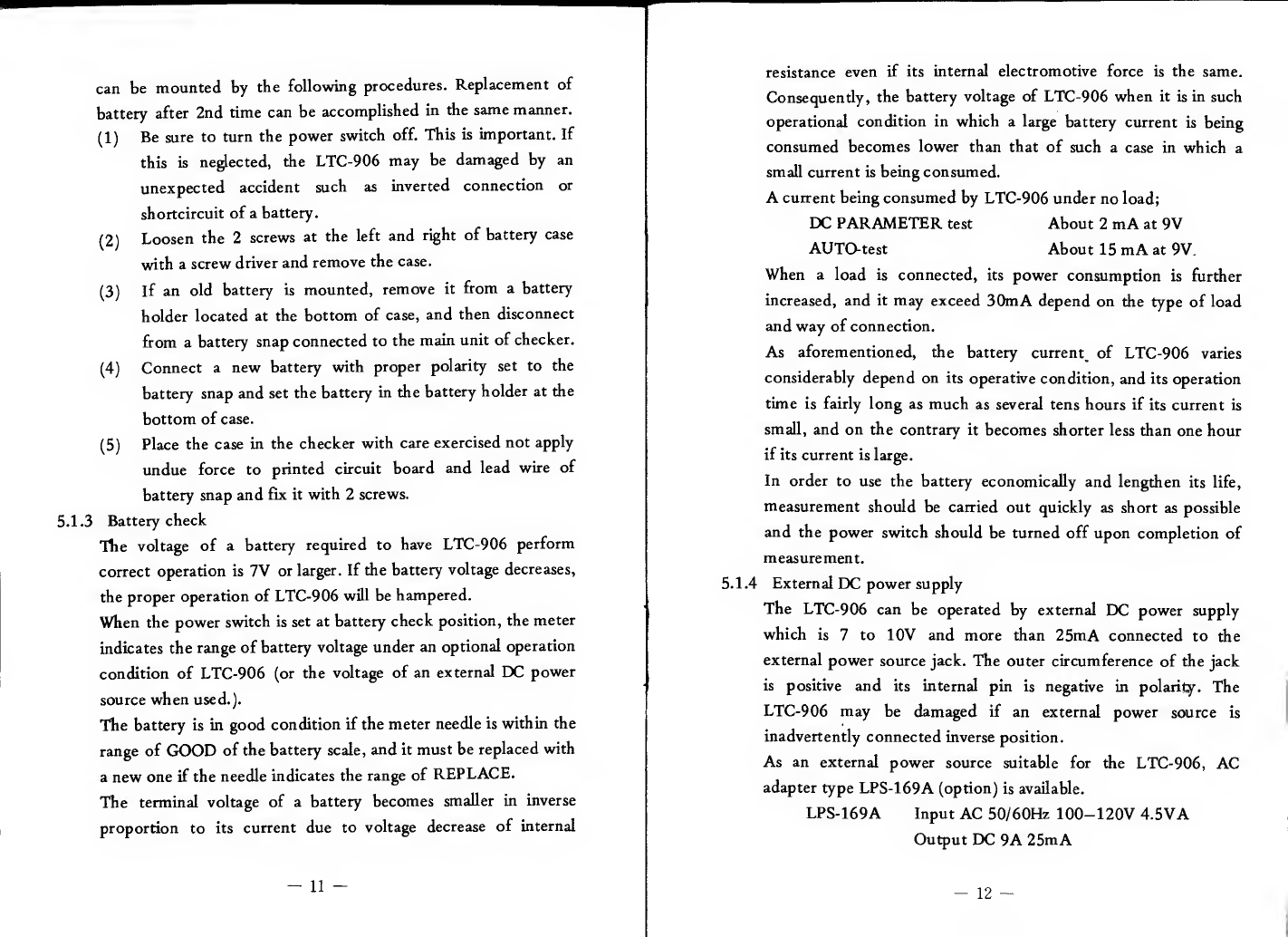

b. SCR or thyristor

In the case of SCR or thyristor test, both GOOD

indicators of Ptype and Ntype flashes alternately

when it is in good condition.

The base/collector indicator flashes simultaneously at

2points and this corresponds to anode or gate. Also

the codector/drain indicator flashes at 1point, and

this corresponds to cathode.

Fig. 5.2.1-1 SCR

-17 -

1

J

1

i

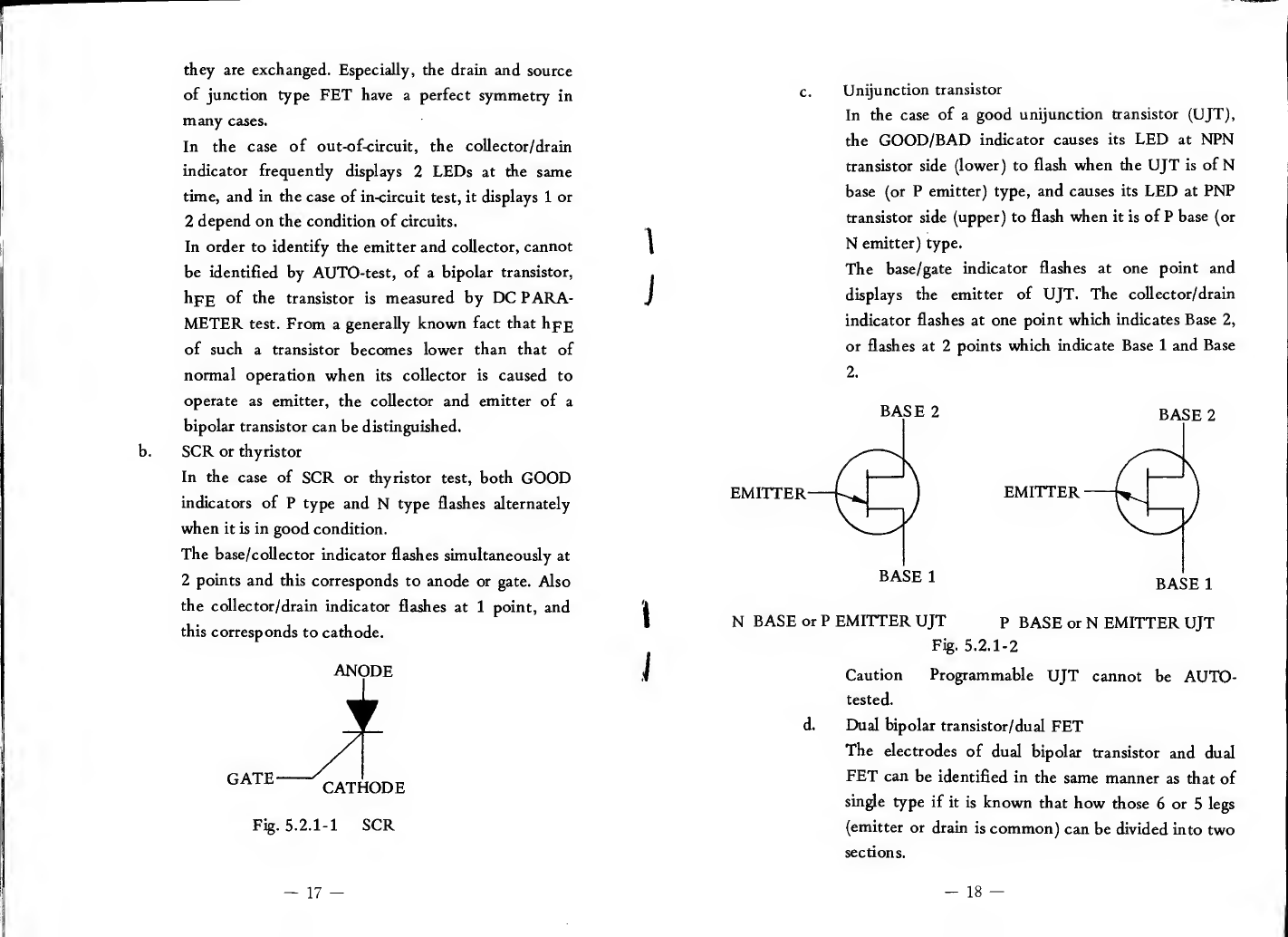

c. Unijunction transistor

In the case of agood unijunction transistor (UJT),

the GOOD/BAD indicator causes its LED at NPN

transistor side (lower) to flash when the UJT is of N

base (or Pemitter) type, and causes its LED at PNP

transistor side (upper) to flash when it is of Pbase (or

Nemitter) type.

The base/gate indicator flashes at one point and

displays the emitter of UJT. The collector/drain

indicator flashes at one point which indicates Base 2,

or flashes at 2points which indicate Base 1and Base

2.

NBASE or PEMITTER UJT pBASE or NEMITTER UJT

Fig. 5.2.1-2

Caution Programmable UJT cannot be AUTO-

tested.

d. Dual bipolar transistor/dual FET

The electrodes of dual bipolar transistor and dual

FET can be identified in the same manner as that of

single type if it is known that how those 6or 5legs

(emitter or drain is common) can be divided into two

sections.

-18 -

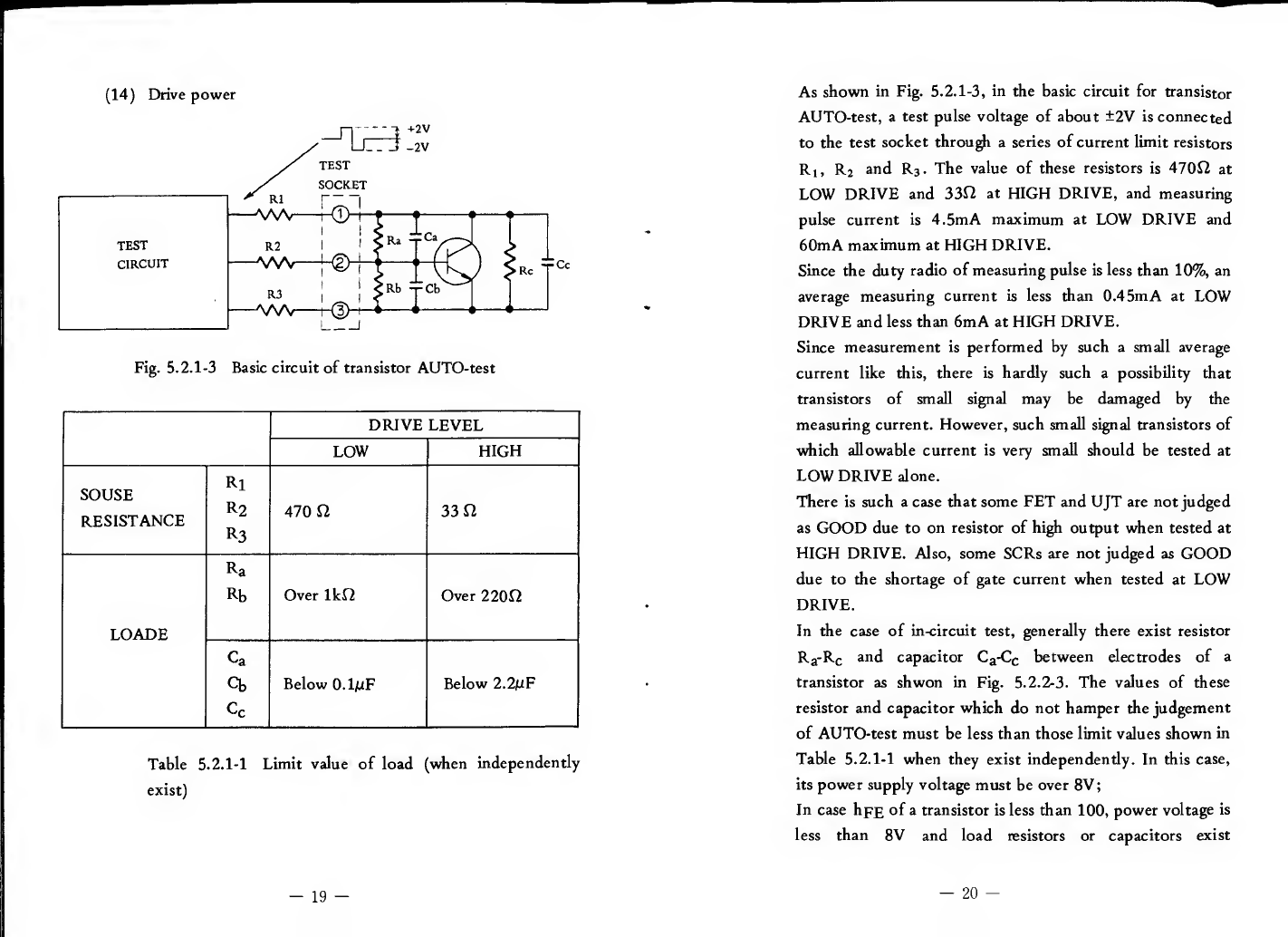

(14) Drive power

Fig. 5.2.1-3 Basic circuit of transistor AUTO-test

DRIVE LEVEL

LOW HIGH

SOUSE

RESISTANCE

Rl

R2

R3 470 n33

LOADE

Ra

Rb Over Ikn Over 220f2

Ca

Cb

Cc

Below 0.1/iF Below 2.2mF

Table 5. 2. 1-1 Limit value of load (when independently

exist)

As shown in Fig. 5.2. 1-3, in the basic circuit for transistor

AUTO-test, atest pulse voltage of about ±2V is connected

to the test socket through aseries of current limit resistors

Ri, Rj and R3.The value of these resistors is 470S2 at

LOW DRIVE and 33f2 at HIGH DRIVE, and measuring

pulse current is 4.5mA maximum at LOW DRIVE and

60mA maximum at HIGH DRIVE.

Since the duty radio of measuring pulse is less than 10%, an

average measuring current is less than 0.45mA at LOW

DRIVE and less than 6mA at HIGH DRIVE.

Since measurement is performed by such asmall average

current like this, there is hardly such apossibility that

transistors of small signal may be damaged by the

measuring current. However, such small signal transistors of

which allowable current is very small should be tested at

LOW DRIVE alone.

There is such acase that some FET and UJT are not judged

as GOOD due to on resistor of high output when tested at

HIGH DRIVE. Also, some SCRs are not judged as GOOD

due to the shortage of gate current when tested at LOW

DRIVE.

In the case of in-circuit test, generally there exist resistor

Rj-Rc and capacitor C^-Cc between electrodes of a

transistor as shwon in Fig. 5.2. 2-3. The values of these

resistor and capacitor which do not hamper the judgement

of AUTO-test must be less than those limit values shown in

Table 5. 2.1-1 when they exist independently. In this case,

its power supply voltage must be over 8V

;

In case hpE of atransistor is less than 100, power voltage is

less than 8Vand load resistors or capacitors exist

-19 --20 -

simultaneously more than 2, the value of allowable load

resistance will be larger than those shown in the table and

the value of capacitor will be smaller.

5.2.2 Diode AUTO test

(1) Set the AUTO/DC PARAMETER selector at AUTO.

(2) Set the TRANSISTOR/DIODE selector at DIODE.

(3) Turn the power switch on.

(4) Turn the BUZZER switch on when audible GOOD signal is

desired. Keep it off if not desired.

(5) Set the drive level at LOW.

(6) Connect the 2electrodes of adiode to directly 1or blue

and 3or yellow of contacts of the test socket, or connect

them by means of atest lead or probe in the same manner.

Connection of electrodes must continue longer than 1

second.

(7) One of the 3LEDs of the GOOD/BAD indicator which

coincides with the direction of the connected diode should

flash if the diode is good. At the same time, the buzzer

generates short intermittent sounds indicating good

condition if it is on.

(8) If the BAD indicator is kept lighted, the diode is bad or

DRIVE power is inadequate.

(9) Change-over the DRIVE power to HIGH and repeat test.

(10) In the case of in-circuit test, drive level may become

inadequate even if it is set at HIGH if aload is heavy. In

such acase, disconnect the diode from the circuit, and test

it under out-of-circuit at LOW or HIGH level.

(11) If the diode is judged as BAD at both LOW/HIGH under

out-ofcircuit test, it should be short-circuit, open or

deteriorated, or it may of special type which cannot be

identified by this instrument.

The reason for BAD may be clarified if it is tested by DC

PARAMETER measurement described in Par. 5.3.2 for

confirmation.

(12) To test another diode, return to Step (5).

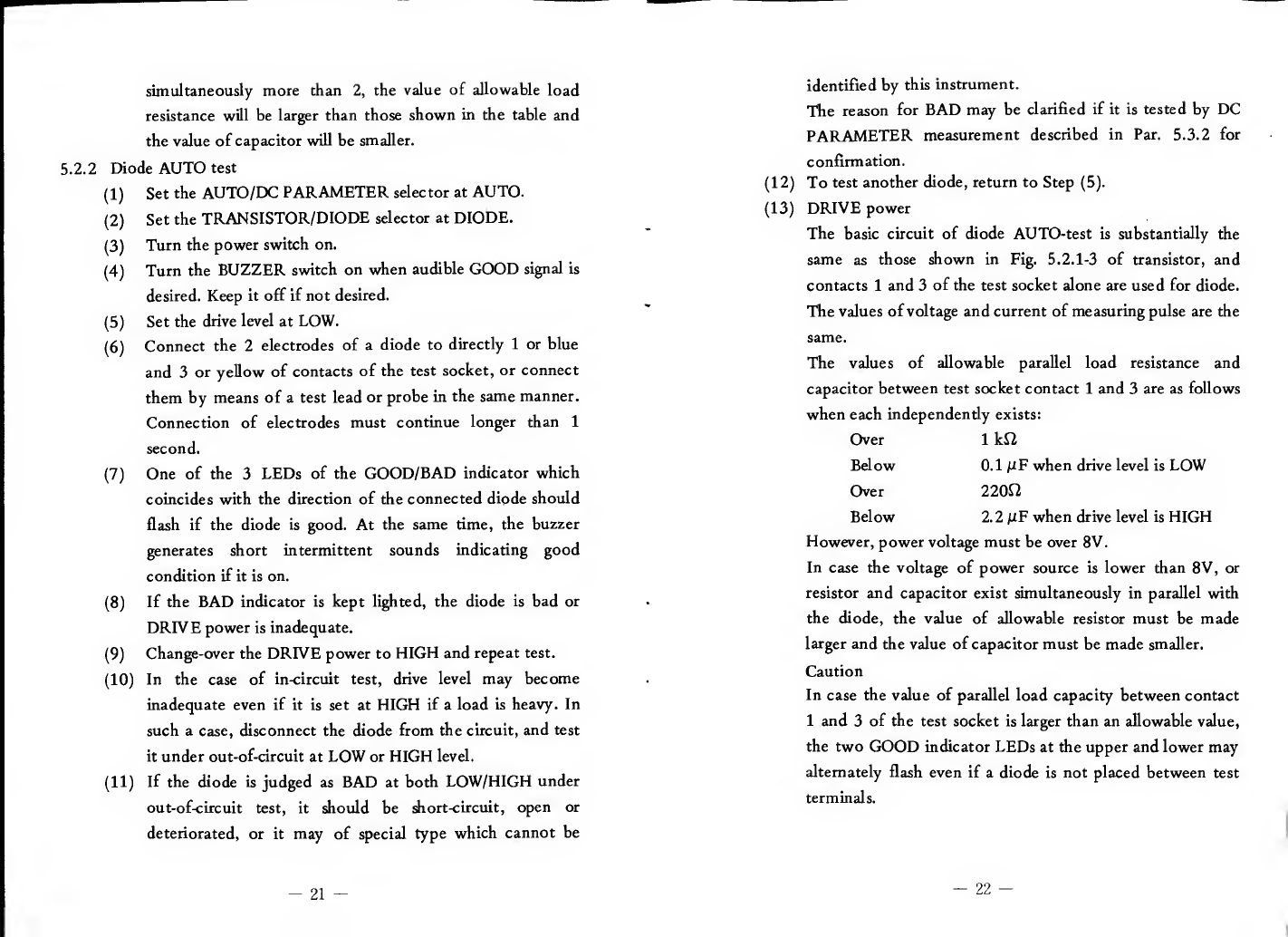

(13) DRIVE power

The basic circuit of diode AUTO-test is substantially the

same as those shown in Fig. 5. 2. 1-3 of transistor, and

contacts 1and 3of the test socket alone are used for diode.

The values of voltage and current of measuring pulse are the

same.

The values of allowable parallel load resistance and

capacitor between test socket contact 1and 3are as follows

when each independently exists:

Over 1kf2

Below 0.1 juF when drive level is LOW

Over 220f2

Below 2.2 jUF when drive level is HIGH

However, power voltage must be over 8V.

In case the voltage of power source is lower than 8V, or

resistor and capacitor exist simultaneously in parallel with

the diode, the value of allowable resistor must be made

larger and the value of capacitor must be made smaller.

Caution

In case the value of parallel load capacity between contact

1and 3of the test socket is larger than an allowable value,

the two GOOD indicator LEDs at the upper and lower may

alternately flash even if adiode is not placed between test

terminals.

-21 -—22 —

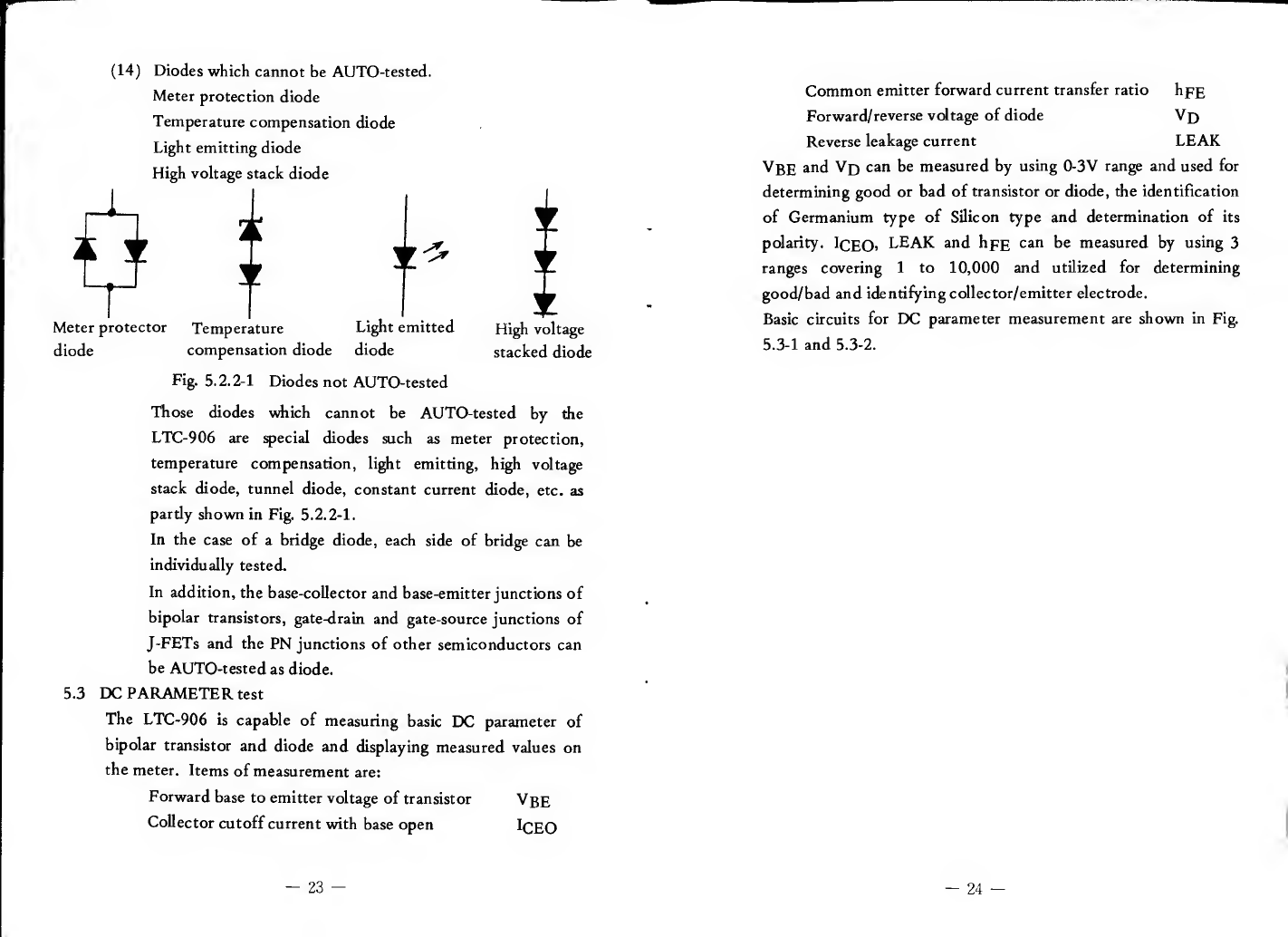

(14) Diodes which cannot be AUTO-tested.

Meter protection diode

Temperature compensation diode

Light emitting diode

High voltage stack diode

Meter protector Temperature Light emitted High voltage

diode compensation diode diode stacked diode

Fig. 5. 2.2-1 Diodes not AUTO-tested

Those diodes which cannot be AUTO-tested by the

LTC-906 are fecial diodes such as meter protection,

temperature compensation, light emitting, high voltage

stack diode, tunnel diode, constant current diode, etc. as

pardy shown in Fig. 5.2. 2-1.

In the case of abridge diode, each side of bridge can be

individually tested.

In addition, the base-collector and base-emitter junctions of

bipolar transistors, gate-drain and gate-source junctions of

J-FETs and the PN junctions of other semiconductors can

be AUTO-tested as diode.

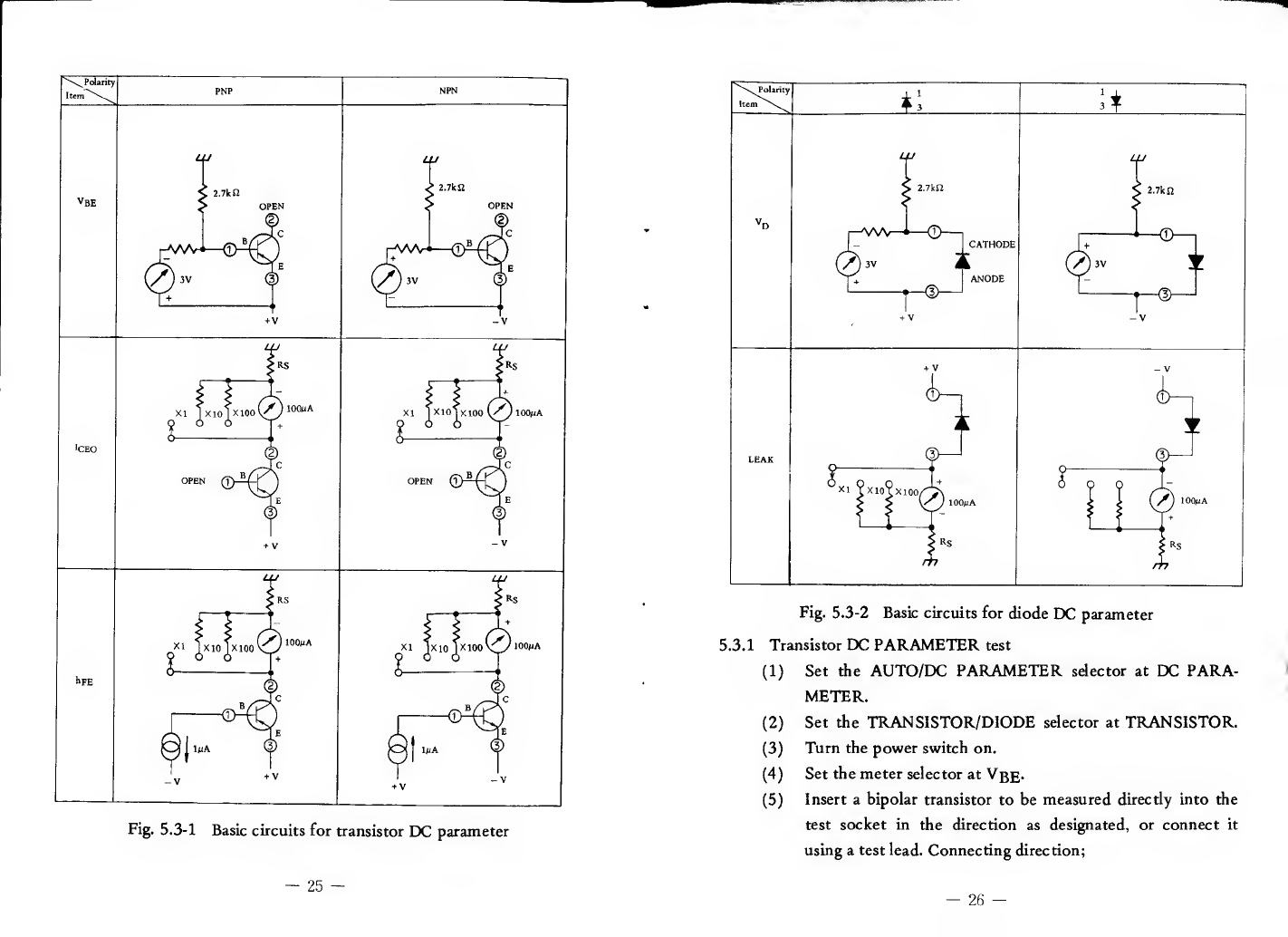

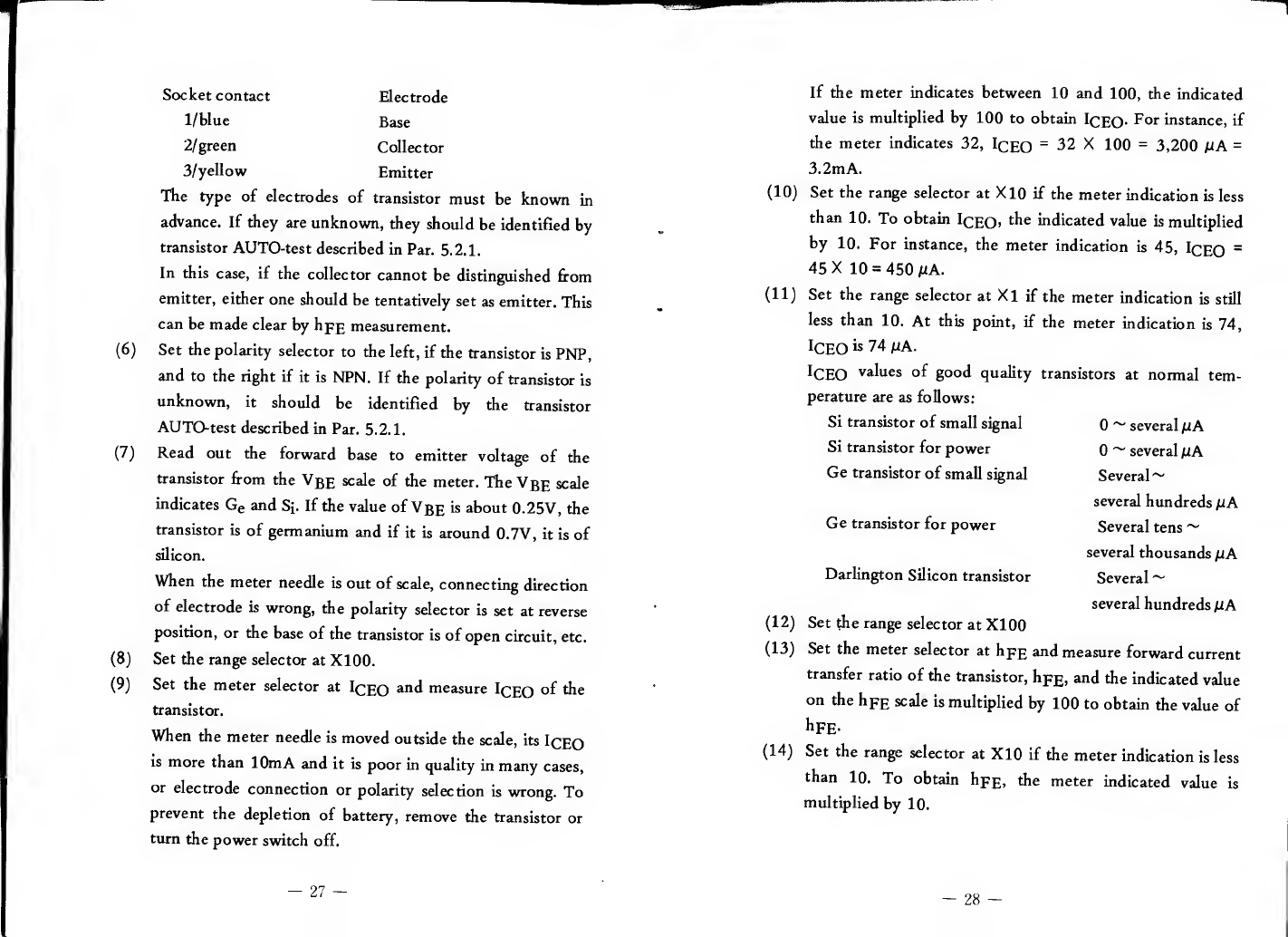

5.3 DC PARAMETER test

The LTC-906 is capable of measuring basic EXH parameter of

bipolar transistor and diode and displaying measured values on

the meter. Items of measurement are:

Forward base to emitter voltage of transistor VgE

Collector cutoff current with base open ICEO

Common emitter forward current transfer ratio hpg

Forward/reverse voltage of diode Vj)

Reverse leakage current LEAK

Vbe and Vj) can be measured by using 0-3V range and used for

determining good or bad of transistor or diode, the identification

of Germanium type of Silicon type and determination of its

polarity. ICEO> LEAK and hpE can be measured by using 3

ranges covering 1to 10,000 and utilized for determining

good/bad and identifying collector/emitter electrode.

Basic circuits for DC parameter measurement are shown in Fig.

5.3-1 and 5.3-2.

—23 —-24 —

Fig. 5.3-1 Basic circuits for transistor DC parameter

!,7kn

Fig. 5.3-2 Basic circuits for diode DC parameter

5.3.1 Transistor DC PARAMETER test

(1) Set the AUTO/DC PARAMETER selector at DC PARA-

METER.

(2) Set the TRANSISTOR/DIODE selector at TRANSISTOR.

(3) Turn the power switch on.

(4) Set the meter selector at VgE-

(5) Insert abipolar transistor to be measured directly into the

test socket in the direction as designated, or connect it

using atest lead. Connecting direction;

Socket contact Electrode

1/blue Base

2/green Collector

3/yellow Emitter

The type of electrodes of transistor must be known in

advance. If they are unknown, they should be identified by

transistor AUTO-test described in Par. 5.2.1.

In this case, if the collector cannot be distinguished from

emitter, either one should be tentatively set as emitter. This

can be made clear by hpg measurement.

(6) Set the polarity selector to the left, if the transistor is PNP,

and to the right if it is NPN. If the polarity of transistor is

unknown, it should be identified by the transistor

AUTO-test described in Par. 5.2.1.

(7) Read out the forward base to emitter voltage of the

transistor from the Vbe scale of the meter. The VgE scale

indicates Ge and Sj. If the value of VgE is about 0.25V, the

transistor is of germanium and if it is around 0.7V, it is of

silicon.

When the meter needle is out of scale, connecting direction

of electrode is wrong, the polarity selector is set at reverse

position, or the base of the transistor is of open circuit, etc.

(8) Set the range selector at XI00.

(9) Set the meter selector at ICEO measure ICEO of 'll®

transistor.

When the meter needle is moved outside the scale, its ICEO

is more than 10mA and it is poor in quality in many cases,

or electrode connection or polarity selection is wrong. To

prevent the depletion of battery, remove the transistor or

turn the power switch off.

-27 —

If the meter indicates between 10 and 100, the indicated

value is multiplied by 100 to obtain ICEO- For instance, if

the meter indicates 32, IcEO =32 X100 =3,200 /tA =

3.2mA.

(10) Set the range selector at X10 if the meter indication is less

than 10. To obtain ICEO> indicated value is multiplied

by 10. For instance, the meter indication is 45, IcEO =

45 X10 =450 M.

(11) Set the range selector at Xl if the meter indication is still

less than 10. At this point, if the meter indication is 74,

ICEO is 74 iJiA.

ICEO values of good quality transistors at normal tem-

perature are as follows:

Si transistor of small signal 0~several /l/A

Si transistor for power 0~several jiA

Ge transistor of small signal Several ~

several hundreds /tA

Ge transistor for power Several tens

several thousands fxA

Darlington Silicon transistor Several ~

several hundreds fiA

(12) Set the range selector at XlOO

(13) Set the meter selector at hpg and measure forward current

transfer ratio of the transistor, hpg, and the indicated value

on the hpE scale is multiplied by 100 to obtain the value of

hpE.

(1^) Set the range selector at XIO if the meter indication is less

than 10. To obtain hpp, the meter indicated value is

multiplied by 10.

-28 -

(15) Set the range selector at XI if the meter indication is still

less than 10. For instance, if the meter indication is 70, its

hpE =70.

The LTC-906 is capable of measuring hpE in 3ranges up to

10,000, and these values cannot be regarded as the same as

those listed in the data book due to different measuring

conditions.

Measured values by this instrument are between several tens

and several hundreds for ordinary small signal transistor and

between several hundreds and several thousands for

Darlington transistor.

In the case of apower transistor of which hpg depends on

collector current, its hpp is shown with afairly small value

(less than 100) since measurement is done by avery small

base current of 1flA.

(16) Distinction of collector and emitter

In case the collector and emitter of atransistor are

unknown, they can be distinguished by the difference in

hpg. The value of hpg of atransistor when it is connected

inverse direction with its emitter assumed as collector is

decreased to 50 to 5% of that of hpp to be obtained by

normal connection.

When atransistor is unknown about its collector and

emitter, its hpp is measured with one of the two electrodes

other than the base tentatively assumed as emitter and the

other as collector. Again, hpp is measured with those

electrodes exchanged. One of these two cases in which is

larger hpp has been obtained shows the correct connection

of the transistor.

(17)

Correction of hpp

By the hpp measuring method of LTC-906, an apparent

hpp is indicated larger than the tme hpp due to Ip;pQ

especially in the case of agermanium transistor.

Atrue hpp can be easily obtained by deducting l^pQ

shown by the unit of fiA from ameasured value of hpp.

For instance, if ameasured value of hpp is 280 and Iq^q is

45mA, its true hpp will be; 280-45 =235.

(Note) When base current is Ip and collector current is

Ip,; the following relationship exists;

^C^'^FE^B *CEO (a)

^C “*CEO

II (b)

In the LTC-906, abase current of 1(lA is caused to flow

and collector current is measured by the unit of /nA,

therefore, the value of hpp can be direcdy read out as the

value of collector current from which the unit of nA is

eliminated by ignoring Ip;£Q, If bpp cannot be ignored, a

value which is obtained by deducting Iq£q from Iq will be

atrue hpp.

(18)

Calculation of IQpQ

The collector cutoff current with emitter open IpjgQ,

which is another EXi: parameter of transistor, can be

obtained by the following computation:

-29 —-30 -

^BO “^CEO

True hpg (c)

For instance, I(^gQ in the case of example (17) will be

45 mA

235 0.19 HA

(19) To start anew measurement, return to Step (4)

5.3.2 Diode DC PARAMETER test

(1) Set the AUTO/DC PARAMETER selector at EXD PARA-

METER’

(2) Set the TRANSISTOR/DIODE selector at DIODE.

(3) Turn the power switch on.

(4) Set the meter selector at Vq.

(5) Insert the two electrodes of adiode to be measured directly

into contact 1and 3of the test socket, or connect them by

using atest cable.

(6) Set the polarity selector in the same direction as that of the

connected diode if its polarity is known. If the polarity of

diode is unknown, it should be round out by the diode test

described in Par. 5.2.2, or it should be estimated from the

value of forward/reverse shown in (9).

(7) Read out the forward voltage of diode Vq from the Vq

scale of the meter. The meter needle is moved outside the

scale when adiode is not connected, connection is in

revsrse direction or it is made as open circuit.

(8) Set the polarity selector to the other side and read out the

value of Vj^ again. This value is areverse direction voltage

of the diode. In the case of diodes of which leak current is

small such as silicon diode, etc., the meter needle is moved

outside the scale in most cases when their reverse direction

voltage is measured.

(9) Distinction of polarity

Since the forward voltage of adiode is generally larger than

its reverse voltage, the polarity of adiode of which polarity

is unknown can be estimated by comparing its forward

voltage with its reverse voltage. In other words, the

connection is which the value of Vj^ is smaller than the

other is in forward, and at this time, it can be known from

the direction of diode displayed by the polarity selector

that the cathode of diode is connected to contact 1or 3of

the test switch. For instance, if the value of Vp is smaller

when the polarity selector is set at the lefr position, the

cathode electrode is connected to contact 1side of the test

switch.

(10) Identification of type of diode

The type of diode can be presumed by the amount of

forward voltage or reverse voltage as shown in Table

5. 3. 3-1. The scale of the meter indicates the

representative ranges of forward voltage to serve as

guideline to identify germanium and silicon diode.

(11) Set the polarity selector at the same direction as that of the

connected diode.

(12) Set the range selector at XIOO.

(13) Set the meter selector at LEAK and measure reverse leak

current of diode on the LEAK scale of the meter.

When the meter needle is moved outside the scale,

a. Setting of the polarity selector is reverse.

b. Leak current of diode is larger than 10mA.

—31 —-32 -

c. Diode is short-circuit

d. Diode is of special type such as meter protection,

tunnel, trigger, etc.

In such acase, immediately stop measurement to protect

the diode from damage and prevent the depletion of

battery and remove the diode or turn the power switch off.

If the meter indicates between 10 and 100 on the LEAK

scale, the indicated value is multiplied by 100 to obtain a

leak current, for instance, if the meter indication is 35, a

leak current =35 X100 =3,500 iiA =3.5mA.

(14) Set the range selector at XIO if the meter indication is less

than 10, and multiply the meter indication by 10. For

instance, if the meter indication is 85, leak current will be

85 X10= 850/xA.

(15) Set the range selector at XI if the meter indication is still

less than 10, and read out the meter indication.

For instance, if the meter needle indicates 15 on the LEAK

scale, its leak current is 15 fiA.

In the case of asilicon diode, its leak current is very small

at normal temperature, and the meter needle hardly moves

in many cases.

In the case of agermanium diode, it is between several and

several hundreds ^lA.

(16) To start anew measurement, return to Step (4).

(Note) At the time of diode DC parameter test, the left

hand side position of the meter selector does not

have any function.

Diode Forward

voltage (V)

Reverse

voltage (V)

Leak

current {(J-A)

Germanium small

signal

0.1 -0.5 1—full scale Several —Several 100

Germanium power 0.2 ~0.7 1—full scale Several 10 —

Several 1000

Silicon small signal 0.3-1 Full scale 0—Several 10

Silicon power 0.5 -1.5 Full scale 0—Several 100

Light emitting 1.5-3 Full scale 0—Several 10

Meter protection 0.2 -0.7 same as forward voltage

Zener 0.3-1 FuU scale 0—Several 100

Temperature com-

pensation Zener

Full scale Full scale 0—Several 10

(Caution) 1. The light emitting diode generates weak light when its

forward voltage is measured. In measuring aleak current,

the l^ht emitting diode emits strong light by alarge

forward current which is caused to flow by setting the

polarity switch in reverse.

2. The forward voltage of atemperature compensation

Zener diode becomes full scale as it is atemperature

compensation diode.

3. In the case of abridge diode, each side of the bridge can

be individually measured.

4. DC parameter can be measured by assuming PN junction

of base-collector and base-emitter of bipolar transistor

and gate-drain and gate-source of junction type FET as

diode. In this case, for measuring aleak current, if a

large forward current is caused to flow by mistake, such

acurrent may damage junctions.

—33 ——34 —

Battery +1—

^

006P TYPE -p

0106 }

\2SC372-0(

V^102 A

•T2SC372 -0

iR108.

*102 ,50k;

»-l>iA^

\ADjH

LJ^

6 6 66

Jt&BCHECK I

I1O9PJ05 50r,R1» 82K

has aa

I<Rit6^$i5e^isae

iiSLLZL

y»PO»iAADj t6-J? 66

o^.ES ;«o J~”^

ol; JU

0-T041 {2

/j)

LEADER ELECTRONICS CORP.

VIC303B

'BCD COUNTtR

>j IC305 h6_ Xc3I1

ii<i Vdecade counter /driver oT0X>IJ'

'•0'^ -V

VTO Tl 12 T3 MT5 T6 T7 TB TBCffrl ,,

13 12 f4 17 IK. h15 _I6 T9 mll2 LooEJ-^SmJ

|40^

220*^ '

fHian^L.3

Ss 3C313Dhl .2IC5t3A^li

4066] ]]406&P [

RSC^

“SsfrsRgF

220K .

™a9*vL

^iocrt/^ 1

)ic3a&^

R321 IM ^.J._ R322 lOOK *

v-wi-flh +V-W^h

Model LTC -906 0-104T(3/3 )

leader electronics CORP.

Other Leader Electronics Corp. Test Equipment manuals