Contents

1) Introduction to Instrument, Unpacking and Installing.................................................... 1

1.1 Introduction to Instrument............................................................................................ 1

1.2 Unpacking................................................................................................................. 1

1.3 Power Connection .....................................................................................................1

1.4 Fuse...........................................................................................................................1

1.5 Environment.............................................................................................................. 1

1.6 Use of Test Fixture.....................................................................................................2

1.7 Warm‐up..................................................................................................................2

1.8 Other Features.......................................................................................................... 2

2) Introduction to Front and Rear Panels.........................................................................3

2.1 Introduction to Front Panel.........................................................................................3

2.2 Introduction to Rear Panel .........................................................................................4

2.3 Display Zone .............................................................................................................4

2.4 Introduction to Buttons on Front Panel .................................................................... 5

2.4.1 [MEAS DISP]..........................................................................................................5

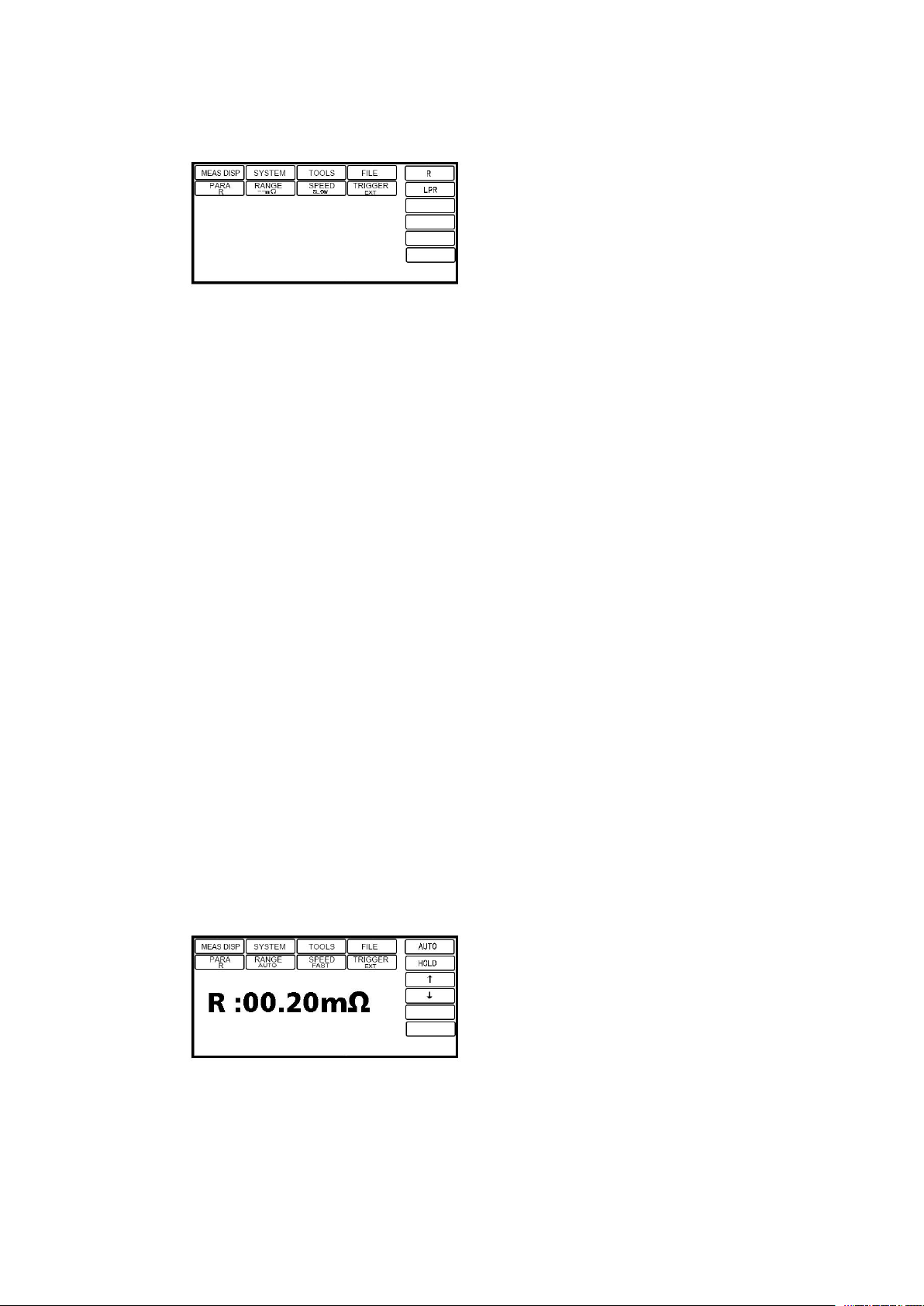

2.5 Simple Operation.......................................................................................................5

3)Basic Operation ..............................................................................................................6

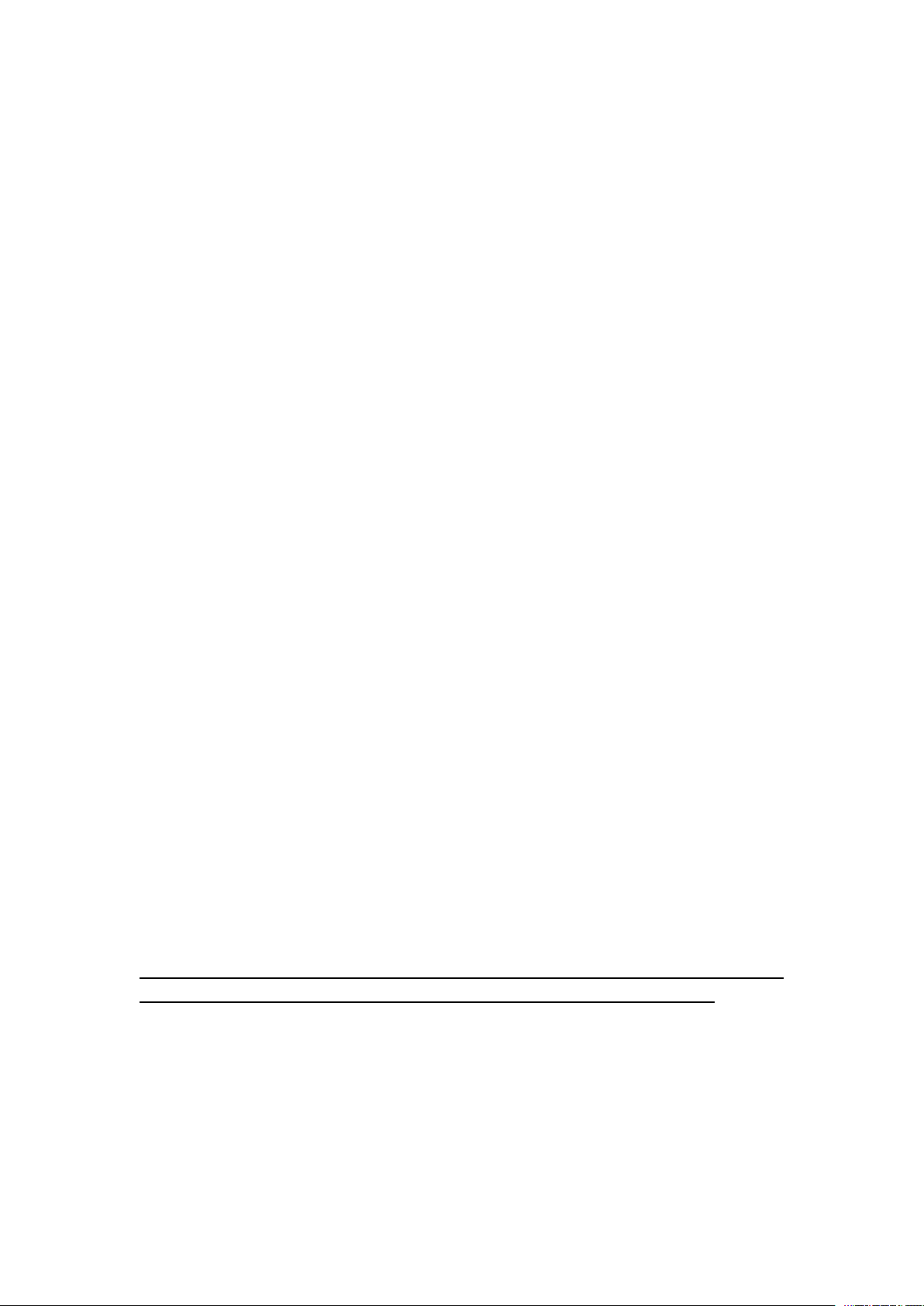

3.1 <MEAS DISP> ...........................................................................................................6

3.1.1 Measurement Functions............................................................................................6

3.1.2 Measurement Range ................................................................................................ 7

3.1.3 Measurement Speed ..............................................................................................8

3.1.4 Trigger settings .........................................................................................................8

3.2 <COMP DISP>..............................................................................................................8

3.2.1 COMP (ON/OFF) ....................................................................................................8

3.2.2 Compare Mode and SETTINGS of ABS & Percent Error........................................ 8

3.2.3 up super and low super settings ..............................................................................10

4) Performance Index.......................................................................................................10

4.1 Measurement Function.............................................................................................. 10

4.1.1 Measurement Parameters and Notations................................................................ 10

4.1.2 Measurement Groups..............................................................................................10

4.1.3 Equivalent Mode......................................................................................................10

4.1.4 Range.......................................................................................................................11

4.1.5 Trigger....................................................................................................................11

4.1. 6 Mode of Test Terminal ............................................................................................ 11

4.2 Test Signal.................................................................................................................. 11

4.2.1 Current range...........................................................................................................11

4.2.2 Output Voltage of Open Circuit.................................................................................11

4.2.3 Maximum Display Range........................................................................................ 11

4.3 Measurement Accuracy.............................................................................................. 11

4.3.1 Basic Accuracy for Resistance Measurement..........................................................12

4.3.2 Accuracy for Resistance Tested at Low Voltage Measurement .............................. 13

5) Package Contents and Warranty.................................................................................14