54

Important Notice

This is not a consumer machine. Only qualied

personnel trained in the recovery or pumping of

refrigerant may operate this machine.

Read and understand this operator’s manual

in its entirety before using MR45CAN to prevent

injury or damage to you or equipment.

What’s Included

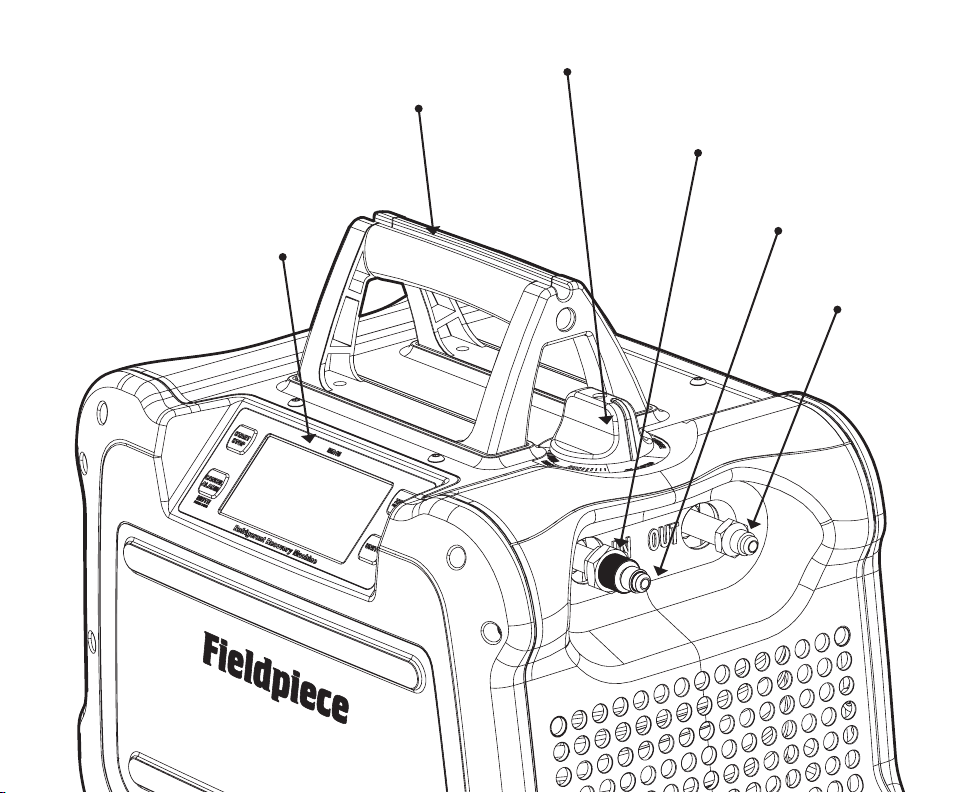

MR45CAN Refrigerant Recovery Machine

10 Extra Mesh Screens for Input Port

3 Extra O-ring for Input Port

Operator’s Manual

1 Year Warranty

Specifications

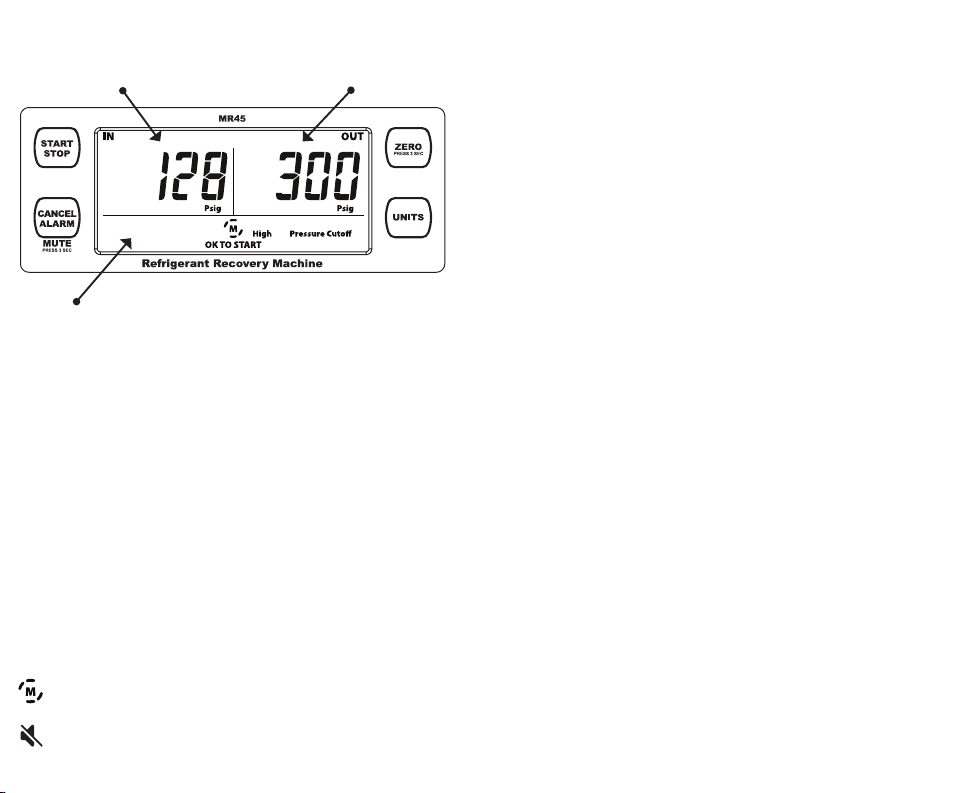

Display: 2 x 10000 count LCD with status messages

Backlight: Blue color

Measurement rate: 3.3 times per second, nominal

Input Port Pressure Sensor Range:

-30”Hg to 600 psig (-76 cmHg to 4100 kPa)

Output Port Pressure Sensor Range:

-30”Hg to 600 psig (-76 cmHg to 4100 kPa)

High Pressure Cutoff: 558 psig (3850 kPa), nominal

Resolution and Units: 1 psig (1”Hg), 0.05 bar (2 cmHg),

0.01 Mpa (2 cmHg), 5 Kpa (2 cmHg)

Pressure Sensor Accuracy:

± 0.5“ Hg, ± 1.3 cmHg (Vacuum)

± (0.6% of reading +2 psig), ± (0.6% of reading +14 kPa)

Final Recovery Vacuum: 14.9”Hg, 38 cmHg

Compressor: Twin cylinder reciprocating (oil-less)

DC Motor: 1 HP (variable smart speed)

Power Source: 120 VAC @ 60 Hz 1 phase

Nominal Current Draw: 12.0 AAC

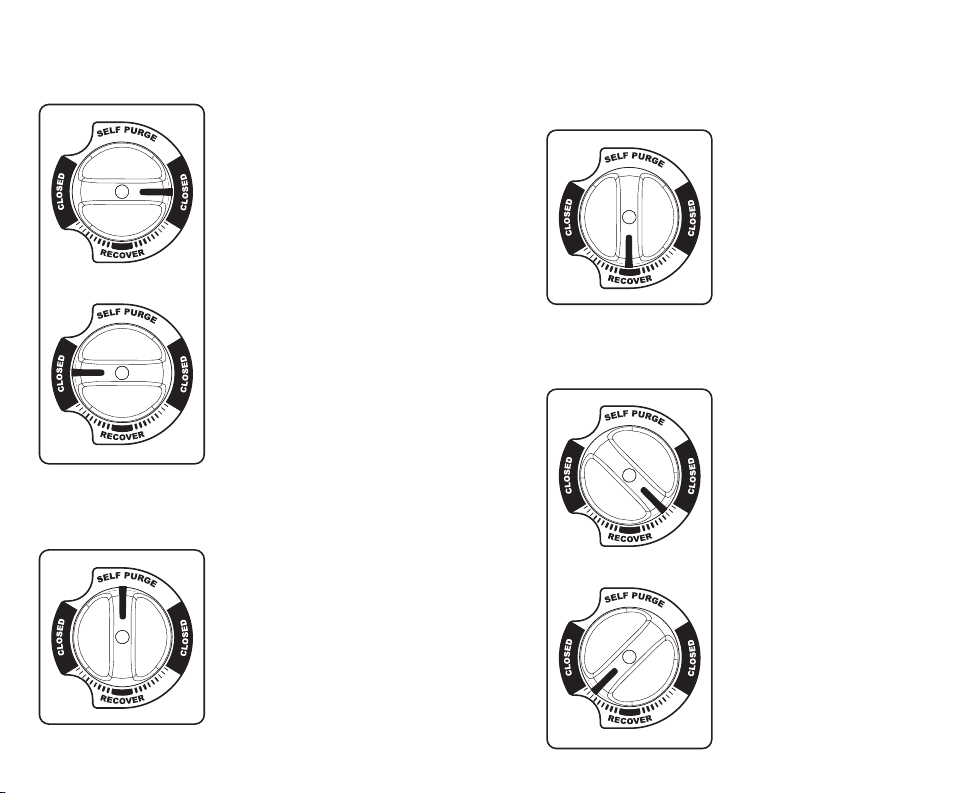

Valve: Single dual-route ball valve

Input Port Filtration: 9 mm mesh screen, stainless

Dimensions: 14.8 inch x 9.8 inch x 13.5 inch

376 mm x 250 mm x 344 mm

Weight: 22 lbs, (10kg)

Operating Environment: 32°F to 104°F (0°C to 40°C)

Storage Environment: -4°F to 140°F (-20°C to 60°C)

Approved Refrigerants: R12, R134A, R22, R401A (MP39), R401B,

R401C, R402A, R402B, R404A, R406A, R407A, R407B, R407C,

R407D, R408A, R409A, R410A, R411A, R411B, R412A, R500, R502,

R507, R509.

US Patent: www.fieldpiece.com/patents

WARNINGS

Ensure proper equipment grounding, electrical shock risk.

Do not expose to rain, electrical shock risk. Store indoors.

Do not use to pump hydrocarbons, explosion risk.

Do not use to pump flammable media, explosion risk.

Inhalation of high concentrations of refrigerant vapor can

block oxygen to the brain causing injury or death.

Refrigerant liquid can cause frostbite.