6

2 SAFETY INSTRUCTIONS

–

• Read this manual completely and the instructions before implementation and use of

the equipment.

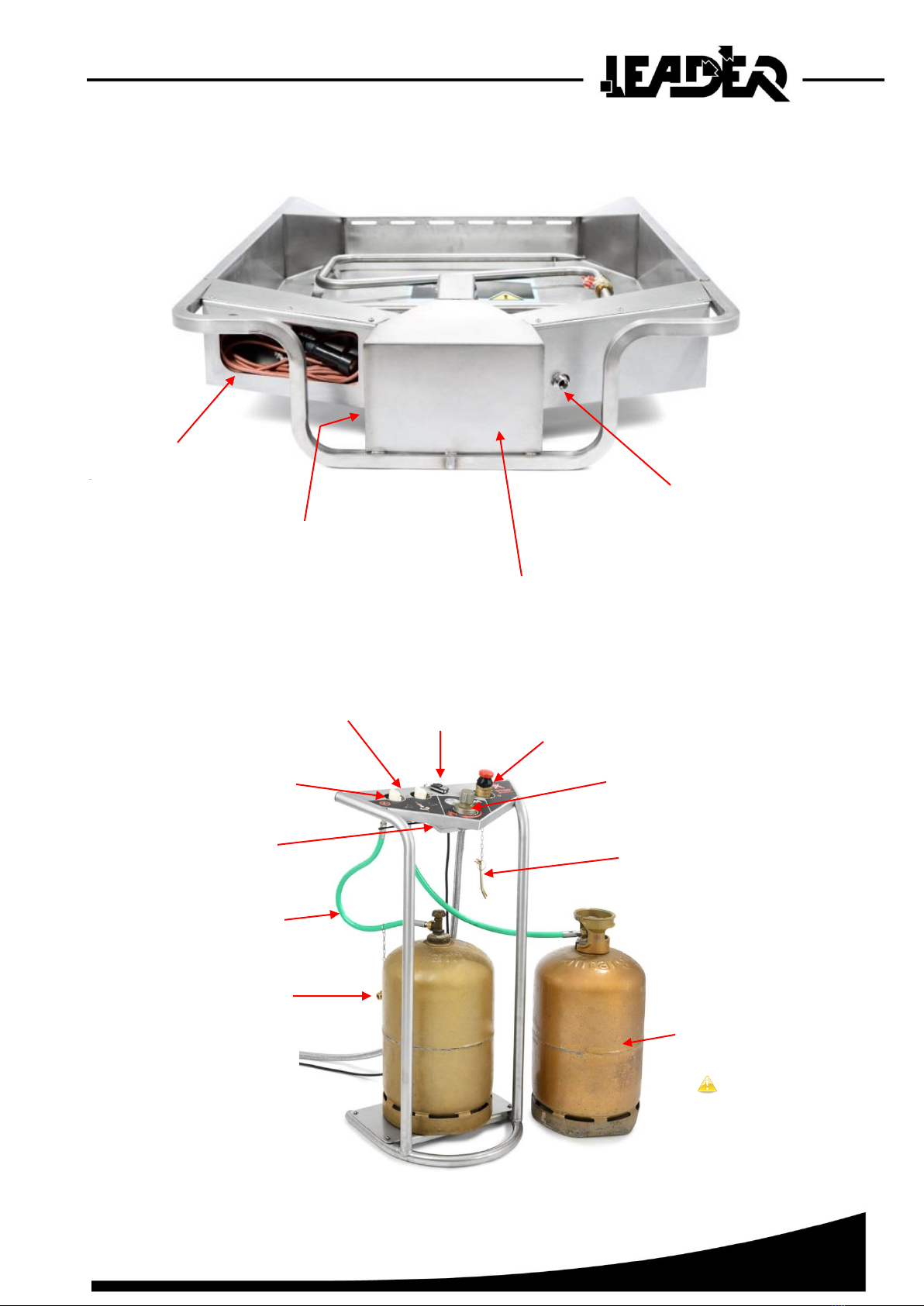

• Never use PYROS 3 tray without water.

• Regularly check the reinforced gas supply hose.

• The device only works with Propane gas.

• Use PYROS 3 only outdoors and away from flammable items.

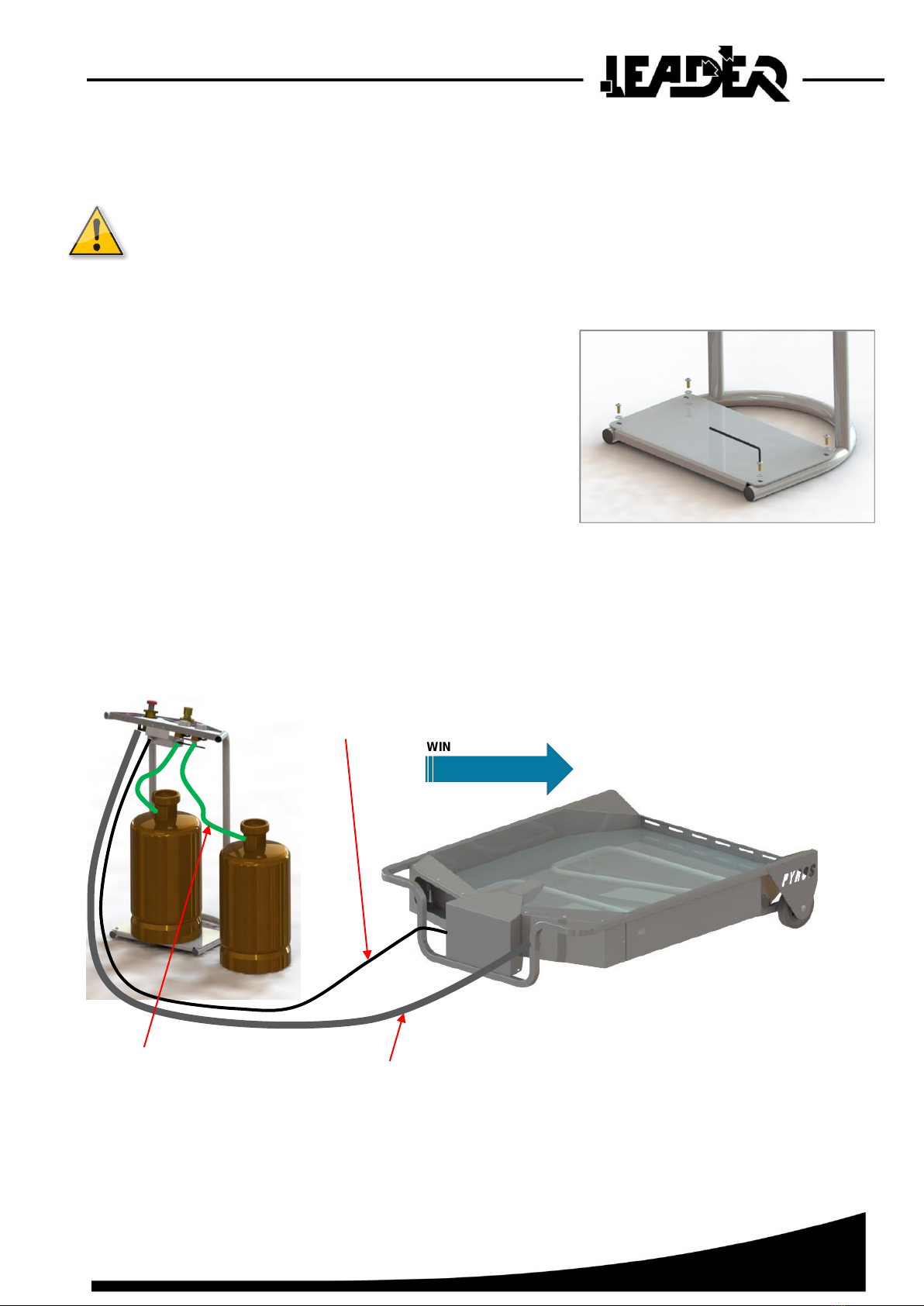

•Respect the safety distance tray / gas cylinder. It is given by the length of the 6 m gas

supply hose.

• Never use PYROS 3 beyond a pressure of 3 bar.

• Wear gloves for use and handling PYROS 3 elements to avoid any incident.

(cutting, burning ...)

• The trainer must permanently keep in hand the remote to control the fire.

• Never keep down the remote control button if no flame. This will remove the risk of spread

of non-ignited gas and its sudden inflammation outside fire tray.

• Any operation or attempt to disassemble, excluding consumable items such as the battery

or fuse, will void the manufacturer warranty.

• PYROS 3 operates only with gas in gaseous phase.

It is forbidden to feed your flame generator with propane in liquid form, especially with

carburetion bottles.

For good supply of the tray, the gas cylinders must be positioned upright. Never lie on the

side the gas cylinders. The PYROS 3 would work with gas in liquid phase and would be

irreparably damaged.

• Take care not to introduce sand or gravel in the gas supply hose or fittings of the unit. This

could damage the internal valve.

• The battery can be discharged to a minimum limit of 10 volts. Below this voltage, it will not

charge correctly anymore.

• Always replace defective parts with original parts supplied by LEADER.

• Keep the unit away from children.

• Do not use PYROS 3 in windy weather.

• Activate the emergency stop button before handling the tray (installation or removal of such

accessories)

• Do not smoke while handling the PYROS 3

REMINDER:

• Do not store propane gas cylinders inside a room. Provide an external storage.

• Training equipment using explosive fuels are intended for use by experienced

professionals. LEADER declines all responsibility for accidents or damage involving people

or property.