MA860 MicrosteppingDriverManual V1.0

Tel:+086 0755-264343693WebSite: www.leadshine.com

EliminationofHeat

lDriver sreliableworkingtemperatureshouldbe<70 (158℉),and motorworkingtemperature

shouldbe<80 (176℉);

lItisrecommendedtouseautomaticidle-currentmode,namelycurrentautomaticallyreduceto

60%whenmotorstops,soastoreducedriverheatingandmotorheating;

lIt isrecommendedtomountthedriververticallytomaximize heatsinkarea. Useforcedcooling

methodtocool thesystem ifnecessary.

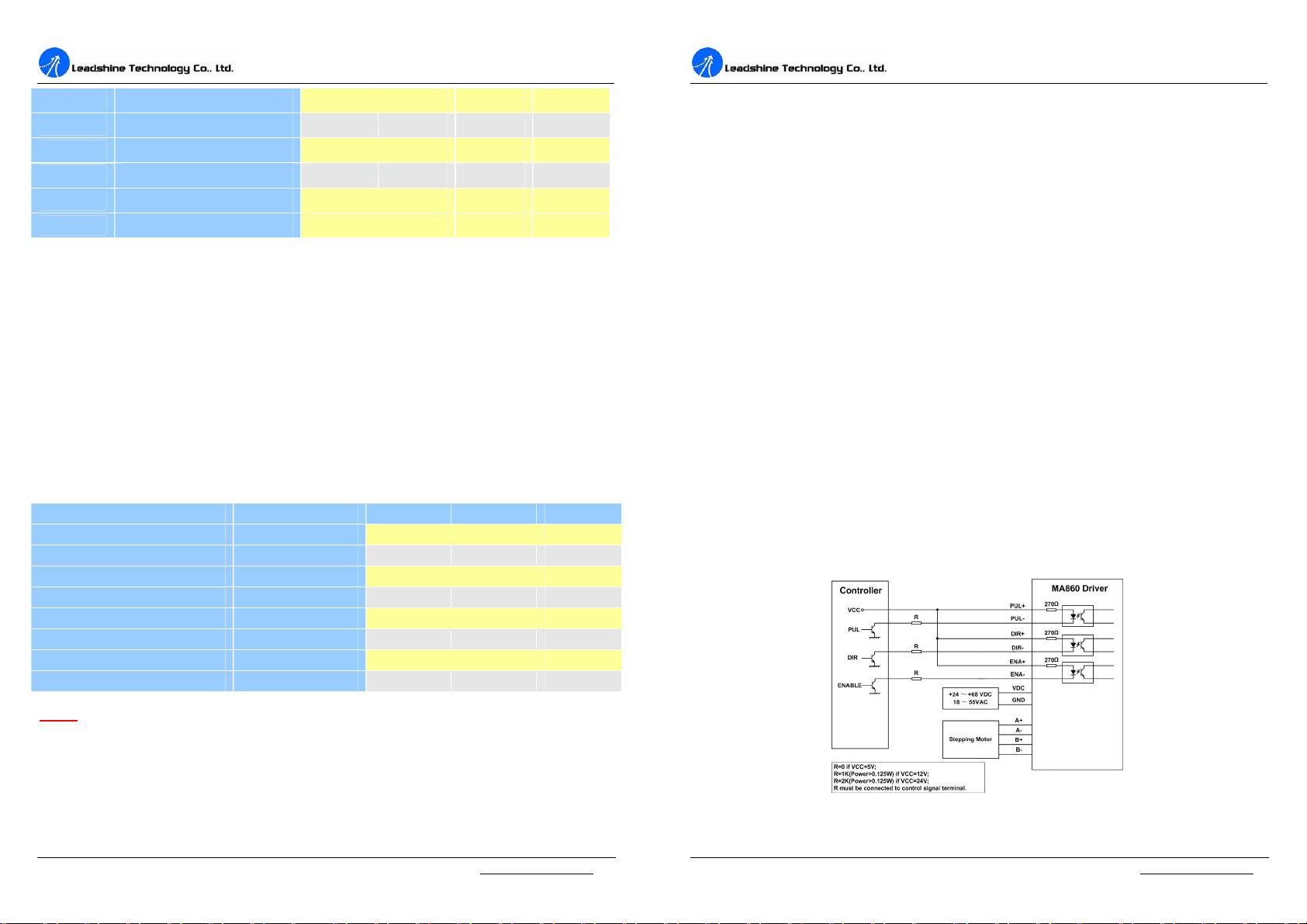

3. PinAssignmentand Description

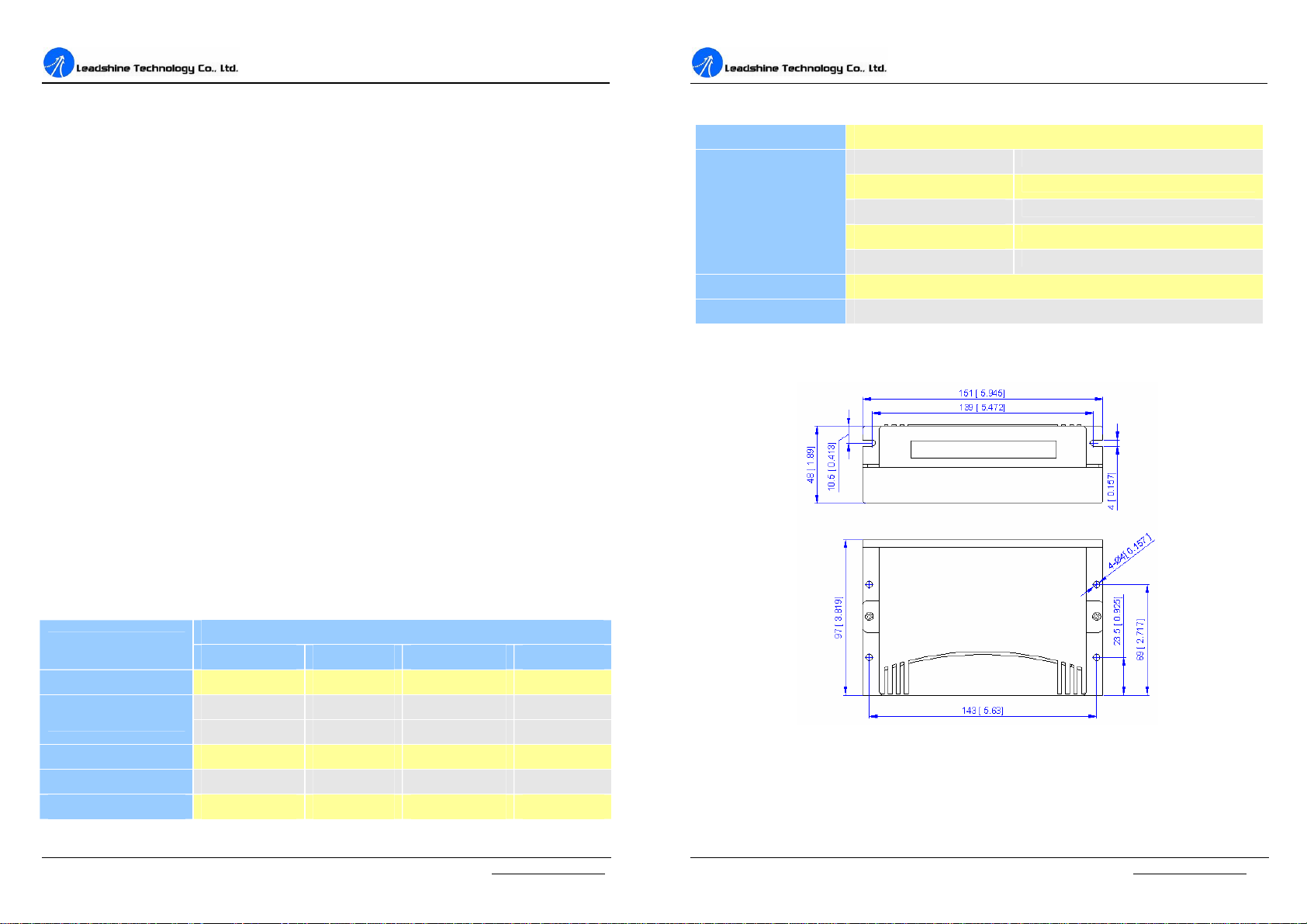

TheMA860 hastwoconnectors,connectorP1forcontrolsignalsconnections,and connectorP2for

powerandmotorconnections.Thefollowingtablesarebriefdescriptionsofthetwoconnectors.

Moredetaileddescriptionsofthepinsandrelatedissuesarepresentedinsection4,5, 9.

ConnectorP1 Configurations

PinFunction Details

PUL+

PUL-

Pulsesignal: Insinglepulse(pulse/direction)mode,thisinputrepresentspulse

signal,activeateachrisingorfallingedge(setbyinsidejumperJ3);4-5V

whenPUL-HIGH,0-0.5VwhenPUL-LOW.Indoublepulsemode

(pulse/pulse), thisinputrepresentsclockwise(CW)pulse,activeat highlevel

orlowlevel(setbyinsidejumperJ3).Forreliableresponse,pulsewidth

shouldbelongerthan1.5μs.Seriesconnectresistorsforcurrent-limitingwhen

+12Vor+24Vused. ThesameasDIRandENAsignals.

DIR+

DIR-

DIRsignal: Insingle-pulsemode,thissignalhaslow/highvoltagelevels,

representingtwodirectionsofmotorrotation;indouble-pulsemode(setby

insidejumperJ1),thissignaliscounter-clock(CCW)pulse,activeathigh

levelorlowlevel(setbyinsidejumperJ3).Forreliablemotionresponse,DIR

signalshouldbeaheadofPULsignalby5μsatleast.4-5VwhenDIR-HIGH,

0-0.5VwhenDIR-LOW.Pleasenotethatmotion directionisalsorelatedto

motor-driverwiringmatch.Exchangingtheconnectionoftwowiresforacoil

tothedriverwill reversemotiondirection.

ENA+

ENA-

Enablesignal: Thissignalisusedforenabling/disablingthedriver.Highlevel

(NPNcontrolsignal,PNPand Differentialcontrolsignalsareonthecontrary,

namelyLowlevelforenabling.)forenablingthedriverandlowlevelfor

disablingthedriver.Usuallyleft UNCONNECTED (ENABLED).

Selecting EffectivePulseEdgeorEffectiveLevelandControlSignalMode

TherearetwojumpersJ1andJ3insidetheMA860specificallyforselectingactivepulseedgeor

effectiveleveland controlsignalmode,asshowninfigure2.DefaultsettingisPUL/DIRmodeand

upward-risingedgeactive.(Note:J2insidethedriverisusedtoreversethedefaultrotationdirection.)

MA860 MicrosteppingDriverManual V1.0

Tel:+086 0755-264343694WebSite: www.leadshine.com

(a)J1, J3opencircuit (b)J1opencircuit, J3shirtcircuit

PUL/DIRmode andActive atrisingedge (NPN) PUL/DIRmode andactive atfalling edge (NPN)

(c)J1shortcircuit, J3opencircuit (d)J1, J3shortcircuit

CW/CCWmode andactive atlowlevel(The fixedlevel)CW/CCWmode and active athigh level(The fixedlevel)

Figure 2:J1andJ3jumpers

ConnectorP2 Configurations

PinFunction Details

AC

AC

Powersupply,18~60VACor24~80VDC,Includingvoltagefluctuation

and EMFvoltage.

A+,A- MotorPhaseA

B+, B- MotorPhaseB

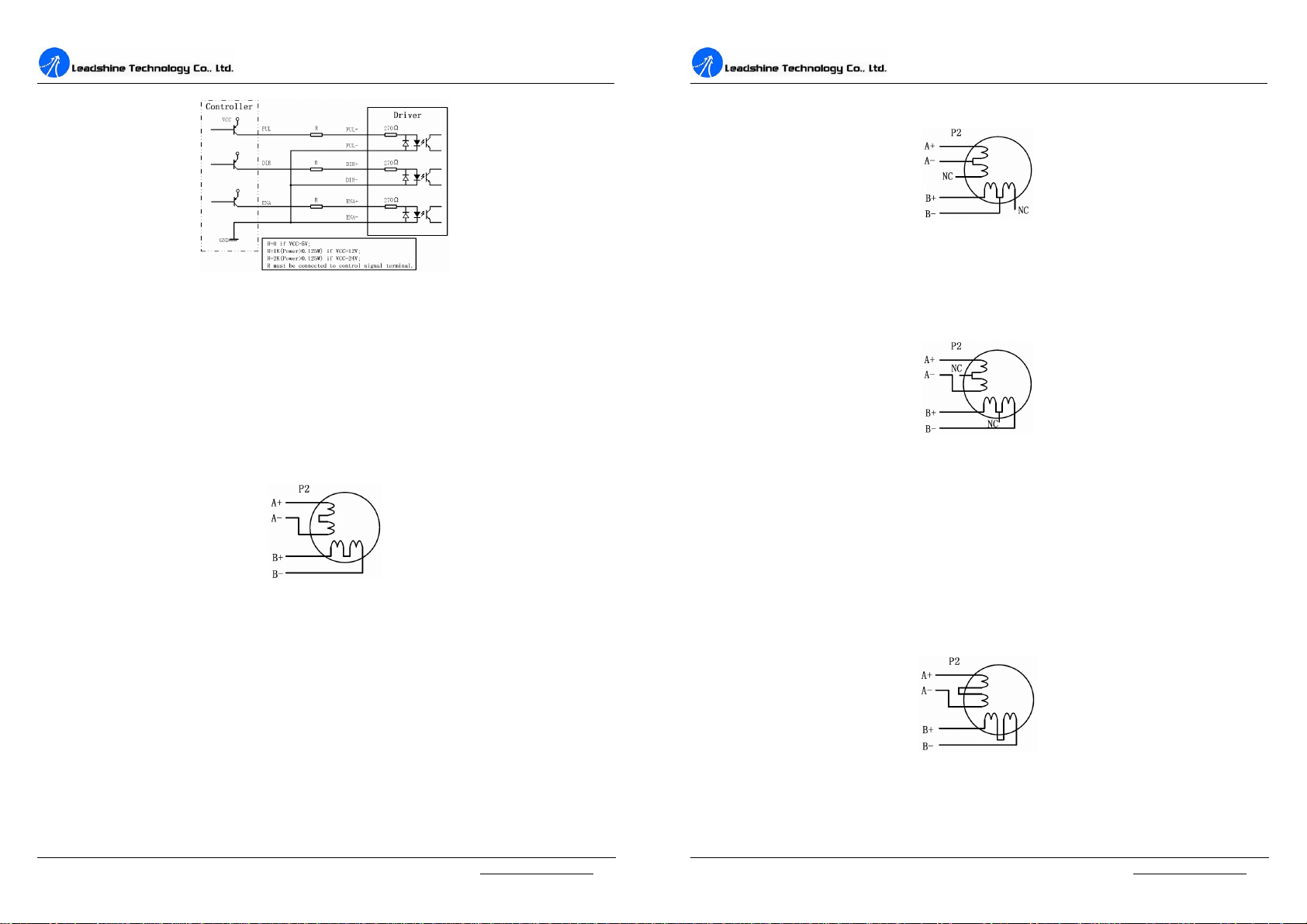

4. ControlSignalConnector(P1)Interface

TheMA860 canacceptdifferentialandsingle-endedinputs(includingopen-collectorandPNP

output). TheMA860 has3opticallyisolatedlogicinputswhicharelocatedonconnectorP1toaccept

linedrivercontrol signals.Theseinputsareisolatedtominimizeoreliminateelectricalnoisescoupled

ontothedrivecontrolsignals.Recommend uselinedrivercontrolsignalstoincreasenoiseimmunity

ofthedriverininterferenceenvironments. Inthefollowingfigures,connectionstoopen-collectorand

PNPsignalsareillustrated.

Figure 3:Connectionstoopen-collectorsignal(common-anode)