6

MAINTENANCE 3

It is recommended to perform maintenance 3 after 1.500 operating hours.

The spare parts package 3 contains the following parts:

Spare parts package 3

Name Quantity Product number Order number

Pin 1 pc. 5S5.000.K8.00.25.0

5S5.000.1Y.00.70.0

O-ring 45 x 1.5 mm 4 pcs. 095.015.E9.11.53.0

O-ring 50 x 1.5 mm 4 pcs. 095.015.E9.11.54.0

Bearing unit 1 pc. 5S5.000.1Y.00.30.0

O-ring 27.5 x 1.5 mm 1 pc. 095.015.E9.11.55.0

O-ring 31 x 1.5 mm 1 pc. 095.015.E9.08.34.0

O-ring 25 x 1.0 mm 1 pc. 095.015.E9.06.97.0

The following steps from this maintenance manual are necessary for carrying out

maintenance 3:

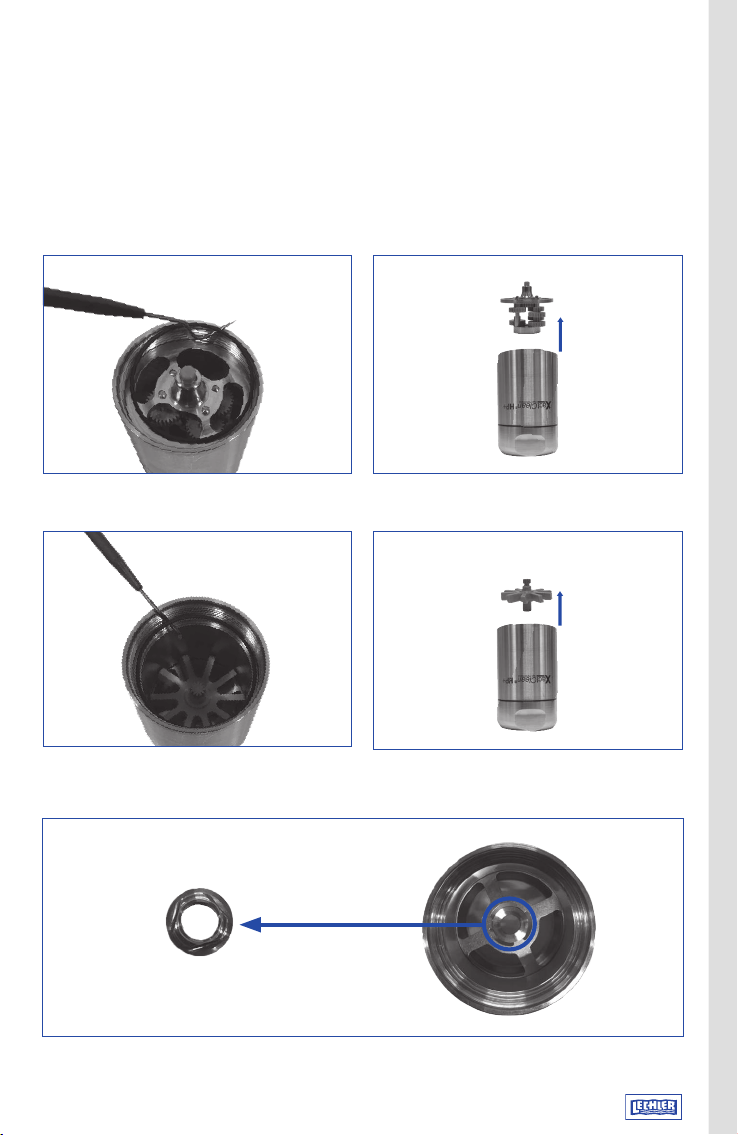

Disassembly of housing Steps 1 – 9

Disassembly of spray head and bearing unit Steps 14 – 18

Correct inspection Steps 19 – 20

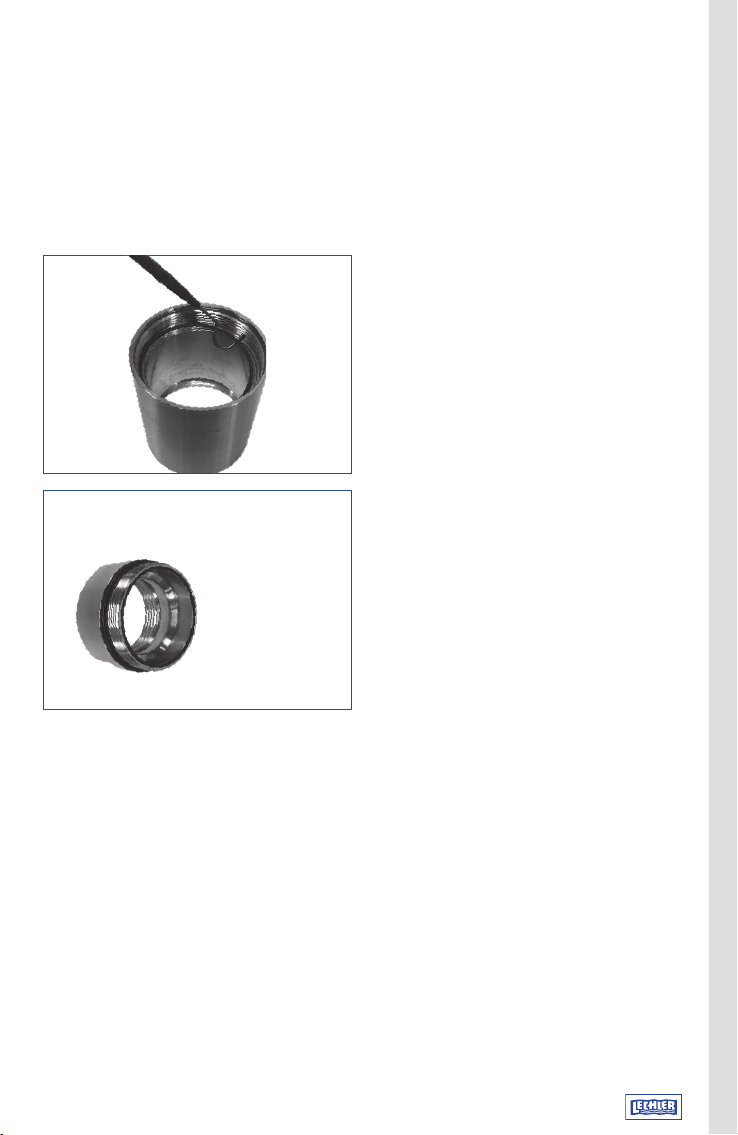

Assembly of spray head with bearing unit Steps 21 – 27

Mounting of housing Steps 33 – 36

Assembly of spray head with housing Method A or B

For maintenance 3 the Lechler assem-

bly tool order no. 05S.590.16.00.00.0.

is required.

Tip

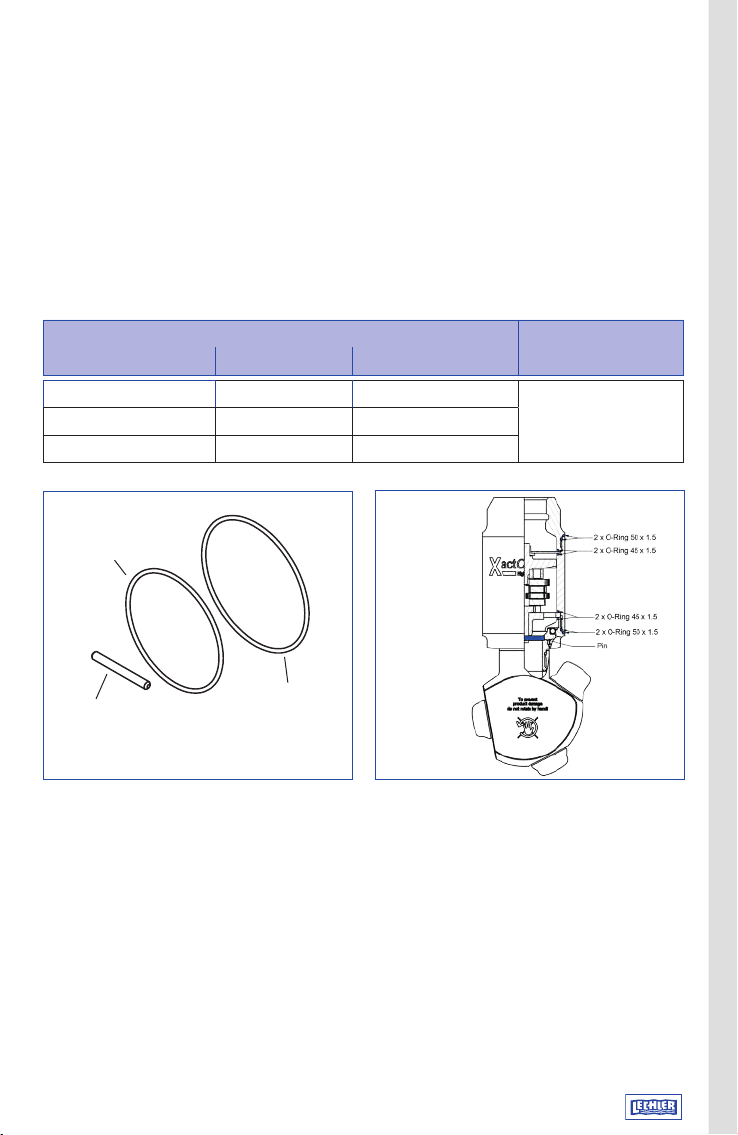

1x Pin

Material: PEEK

5S5.000.K8.00.25.0

1x O-ring ø 27.5x1.5mm

Material: EPDM

095.015.E9.11.55.0

1x O-ring ø 25x1mm

Material: EPDM

095.015.E9.06.97.0

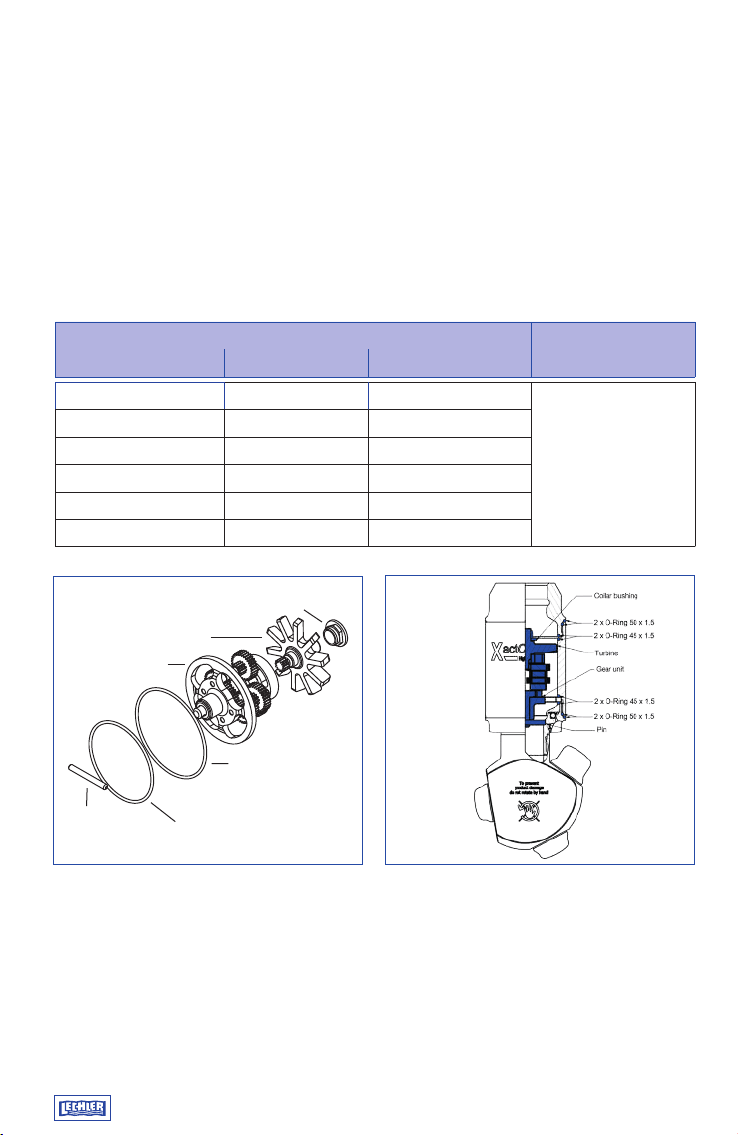

1x Bearing unit

Material: 1.4404

5S5.000.1Y.00.30.0

4x O-ring ø 50x1.5mm

Material: EPDM

095.015.E9.11.54.0

4x O-ring ø 45x1.5mm

Material: EPDM

095.015.E9.11.53.0

1x O-ring ø 31x1.5mm

Material: EPDM

095.015.E9.08.34.0