8

CORRECT INSPECTION

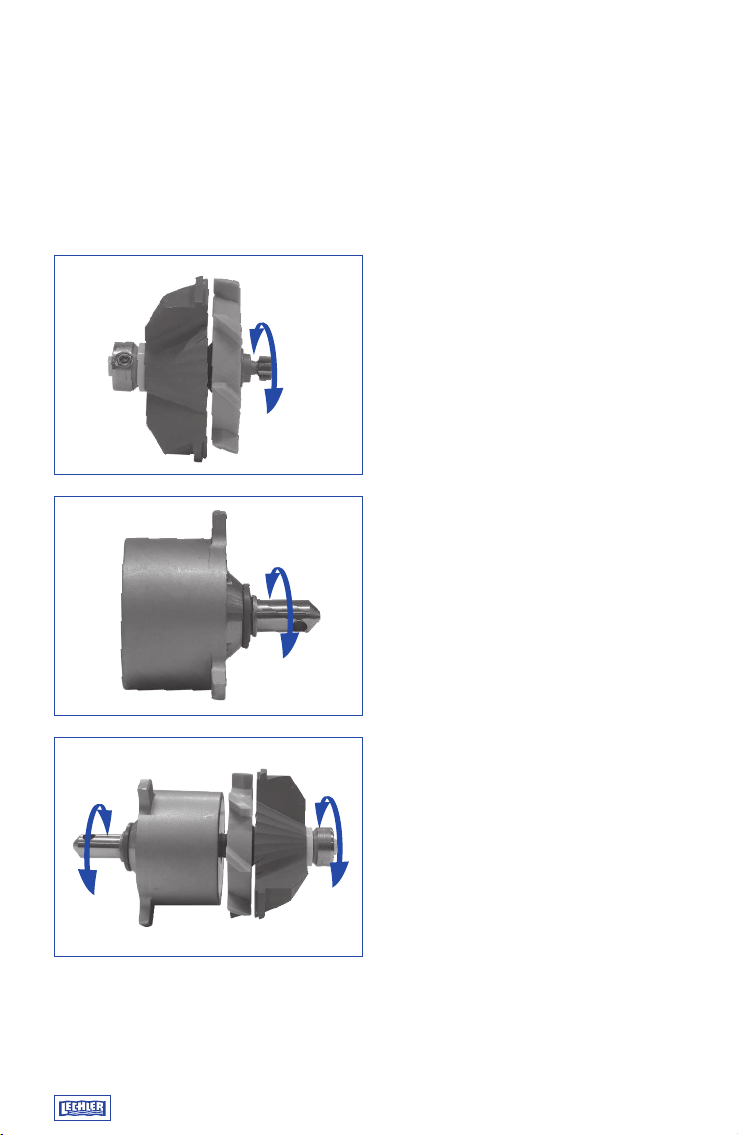

To check the function of the gear unit,

turn the output shaft while holding the

gear unit housing. It is normal for the

rotation to be stagnant. However, the

spindle should be rotatable.

Rotate the beige colored part while hol-

ding the blue one to check the function of

the turbine. The rotation should be smoo-

th with minimal friction. There should be

very little play in the turbine head.

If the turbine cannot be turned by hand

easily or if there is strong wear and tear

of the turbine, it must be replaced.

The second and more reliable way to

check whether the gearbox is working

is to insert the turbine unit‘s gear into

the gearbox. The next step is to turn the

spindle of the turbine unit for a few re-

volutions. This should work with minimal

eort and rotate without much eort and

friction.

If it cannot be turned by hand, small

particles, e.g. sand, may have accumu-

lated between the gears. These can be

removed by soaking and rinsing or by

means of an ultrasonic bath. Do not use

excessive force, as this may destroy the

gear unit.

If the gearbox cannot be turned by hand,

it must be replaced.

17

18

19