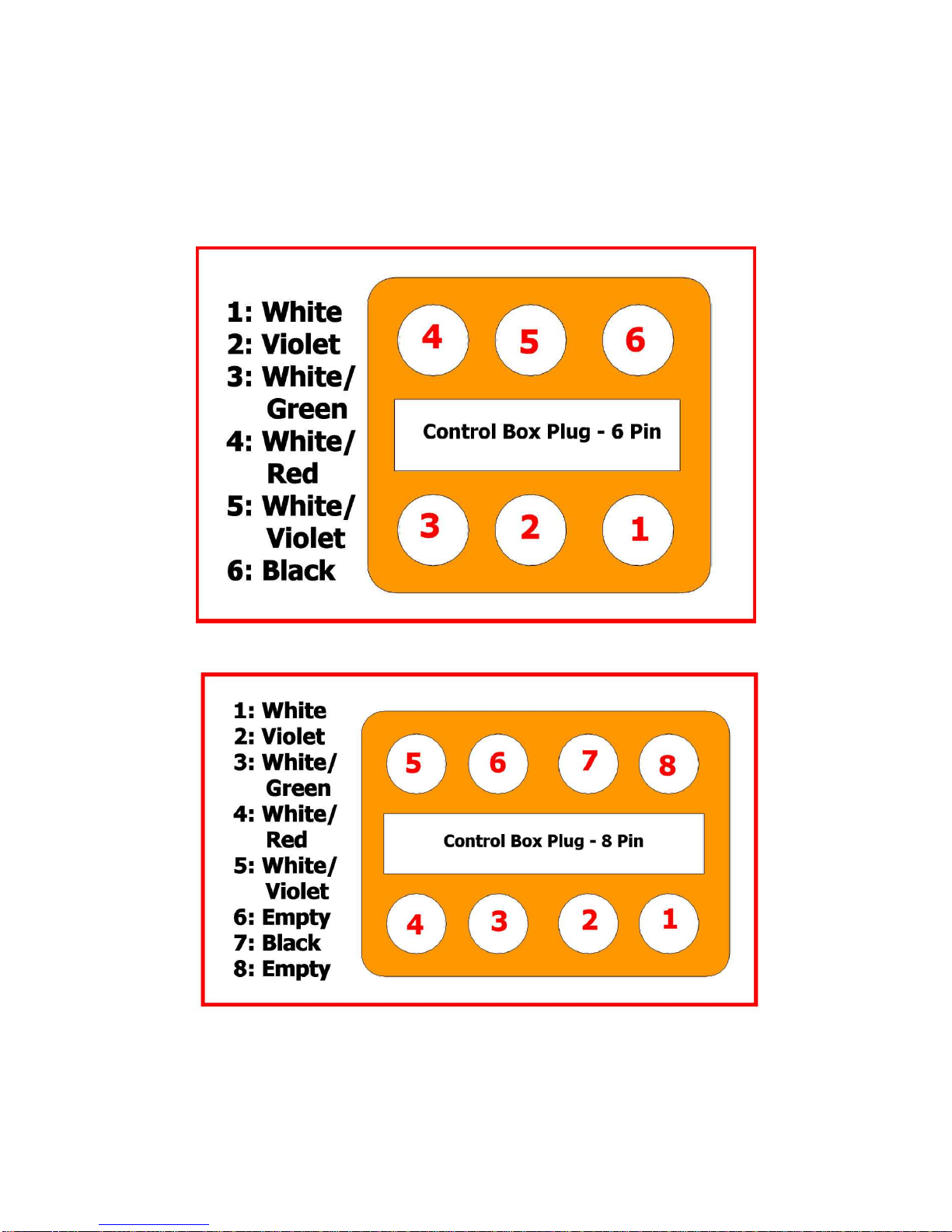

8

CONTROL SWITCH BOX

NOTE: ON pre 1996 models as well as 2014 and up models, you will need a bracket to

mount the switch housing, which we should have supplied. In this case, remove the

bolts that secure the clutch perch clamp on the left side, install the supplied bolts

through the bracket that has the box mounted to it, through the supplied spacers, and

into the clutch perch (Blue Loctite here). Once tightened, follow the rest of these

instructions.

If your bike requires no bracket as mentioned above, remove the bolt on the top of the left

switch housing on the handlebar. Find the long chrome bolt, thread it through the Control

Switch Box, insert the spacer on the bolt and (with a drop of Blue Loctite), and thread the bolt

into the switch housing. Square the box before tightening the bolt (you may have to re-align the

mirror for clearance).

Route the wire inside the clutch lever and down the bar. Use wire ties to hold the wire to the

bar. Run the wire through the top triple tree if you can to control it. The idea here is to get the

wires neatly to the front of the tank and routed

under the tank. (It may be easier to remove the plug

end and tape the silver plug ends together for this).

We have some pictures below to give you an idea

of what this looks like.

On some bikes it is easier to loosen or remove

some of the tank mounting bolts. Make sure the

wires do not interfere with anything under the tank,

and that there is nothing that would scuff the wires.

Once the wires are under the seat area, you

can assemble the plug, if disassembled,

according to the diagrams on the next page.

Some folks will have a 6-pin plug and others

will have the 8-pin version. More mistakes

occur putting these plugs together than

anything else. The pins are pushed through

the rubber holes into the plug until they click.

The pins need to be completely flush with the

edge of the plug. Then the insert is pushed

into the opening. The wiring details are found on the next page. Be VERY careful to get the

wires in the correct hole; all the colors match to the mating plug!