English ATK HydraPro | Instructions for Use

© Copyright LegWorks 2019 HYD-IFU-02

3

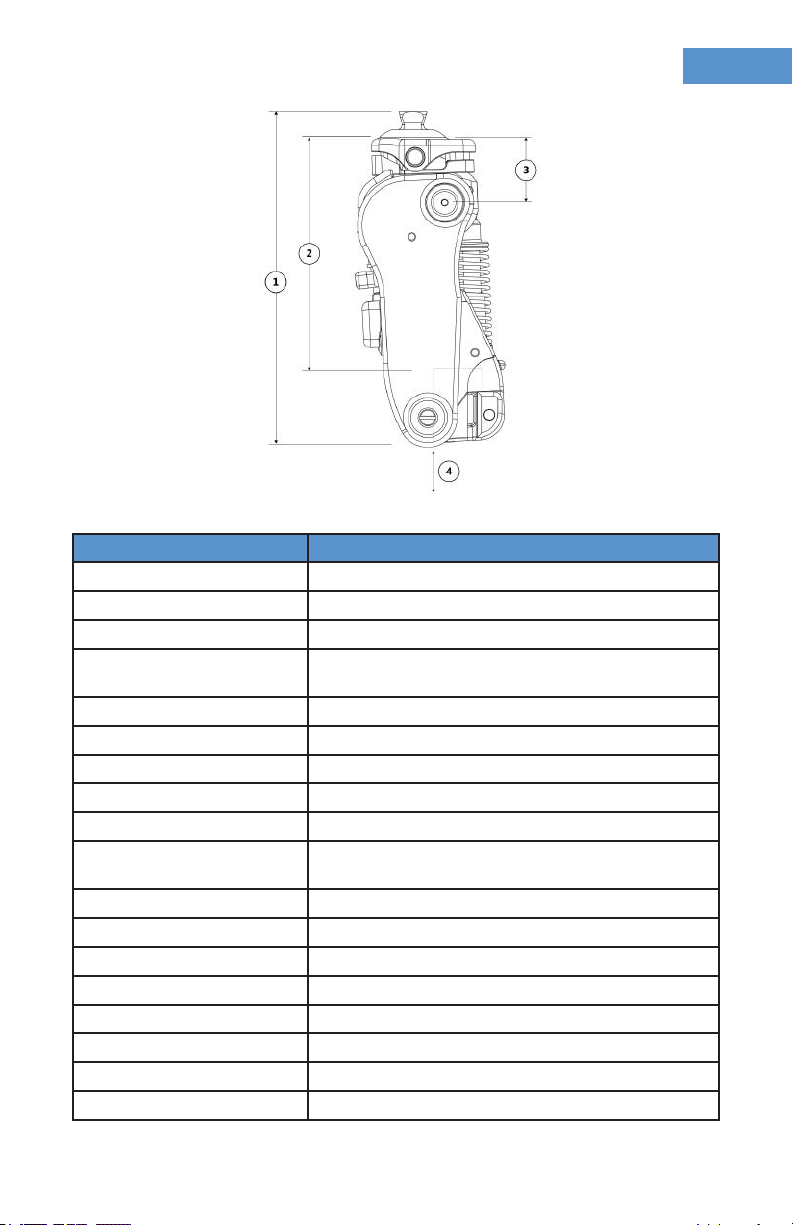

FIGURES

1. ATK HydraPro Anterior Overview...........................................................4

2. ATK HydraPro Posterior Overview.........................................................4

3. ATK HydraPro Build Height Diagram.....................................................7

4. HYD-PA-02 Technical Specications......................................................7

5. ATK HydraPro w/Stance Flexion Build Height Diagram..........................8

6. HYD-SF-02 Technical Specications.......................................................8

7. Stance Phase Function............................................................................9

8. Adjustable Stance Flexion Adaptor Assembly....................................11

9. Proximal Connection.............................................................................12

10. Sagittal Plane Alignment.....................................................................13

11. Lock Spring Set Screw.........................................................................13

12. Absence of Flexion Stop.....................................................................14

13. Malpositioned Flexion Stop...............................................................14

14. Appropriate Flexion Stop...................................................................14

15. Friction Mechanism.............................................................................15

16. Friction Mechanism Cap and Disc Springs.......................................15

17. Friction Mechanism Removal.............................................................16

18. Friction Mechanism Installation.........................................................17

19. Adjustable Extension Assist................................................................18

20. ATK HydraPro Cover Removal............................................................19

21. ATK HydraPro AutoLock Release.......................................................19

22. Manual Lock.........................................................................................20