3

General Information

This kit is designed to be installed by a competent technician. Improper installation can affect

the safe operation of your trike, which could also result in serious injury or death. Make sure you

have a complete understanding of the work to be preformed. Unqualified installers are urged to

have the unit installed by a trained technician.

• Always protect yourself when the vehicle is in the air. Make sure the vehicle is properly supported

anytime you use a hoist or jack.

• Always use the proper tools.

• Protect your eyes by using proper safety glasses or goggles.

• Read through the installation instructions before you begin. Make sure you have all the proper tools,

parts and skill set to perform the installation safely and completely.

• Verify that you have all components before assembly.

• Before installing your new Lehman kit, we recommend that your motorcycle be inspected and ser-

viced by a qualified technician. Replace any worn or damaged parts before installing the trike kit.

• If the motorcycle has more than 12,000 miles, Lehman Trikes recommends installing a new drive

belt during the trike conversion.

• CAUTION: This kit is not designed for use on lowered motorcycles. Interference between the

tires and body may occur.

OverallWidth 57.75"

OverallLength(w/EZ‐Steer)106"

WheelBase(w/EZ‐Steer)67"

CurbWeight1170lb

RearTireSize 205/70‐15

RearTirePressure26PSI

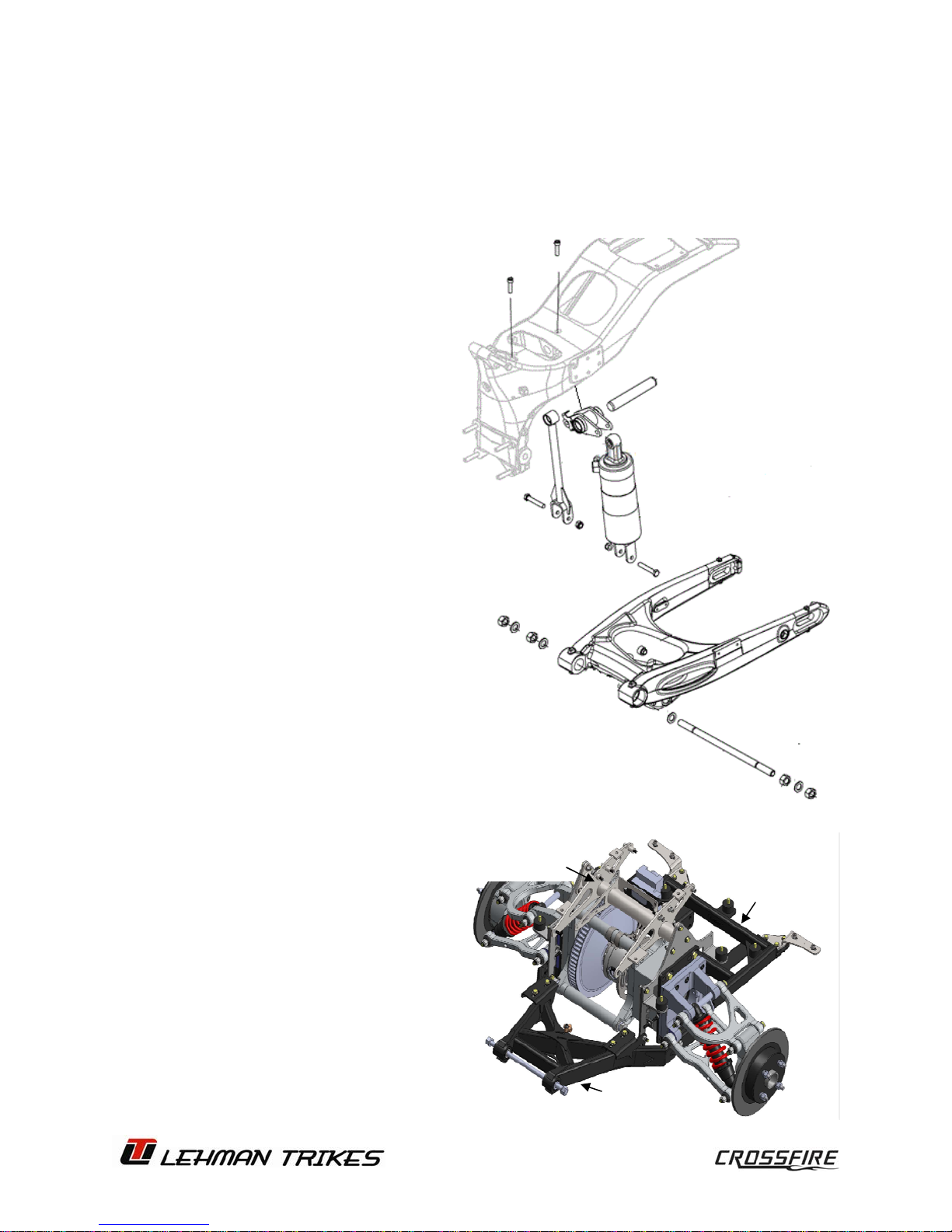

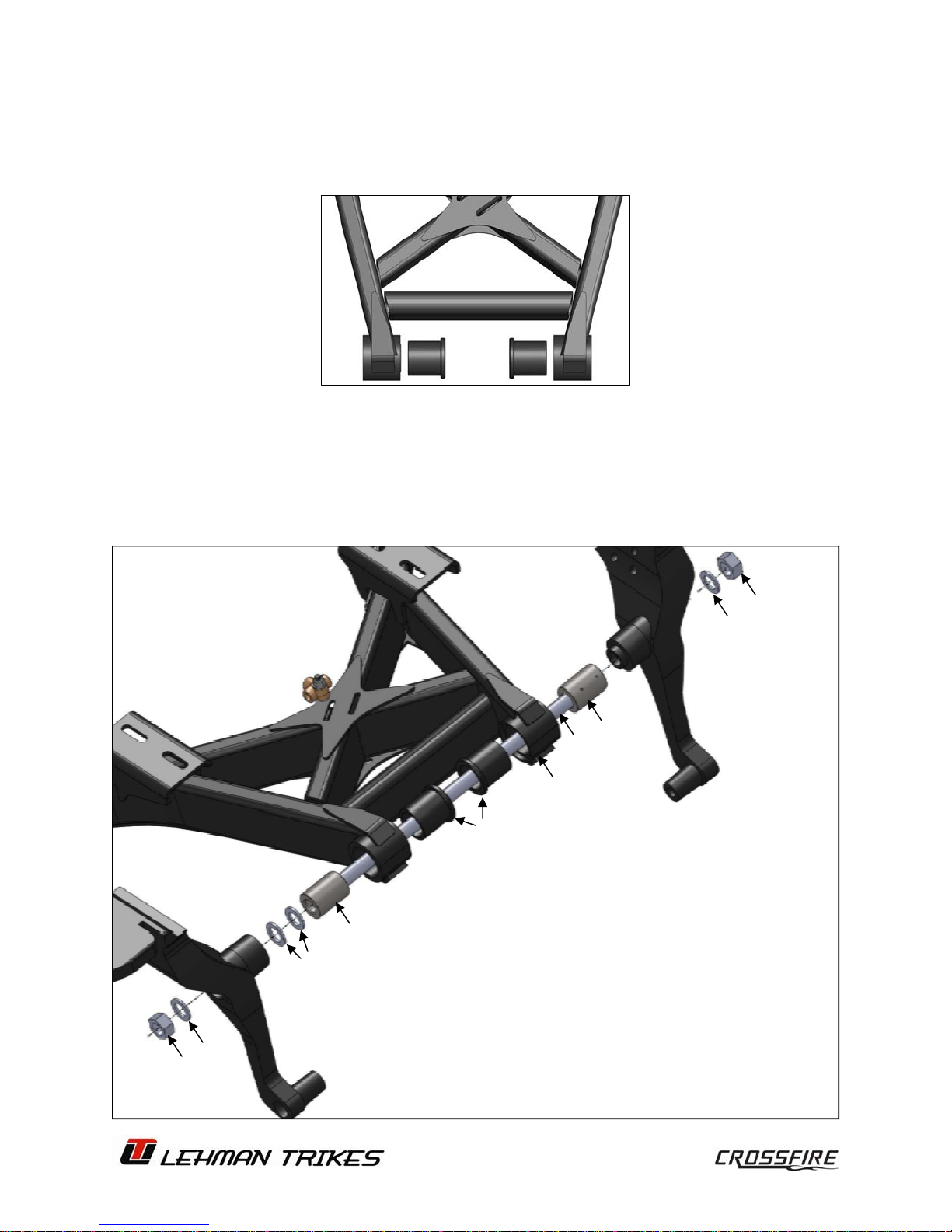

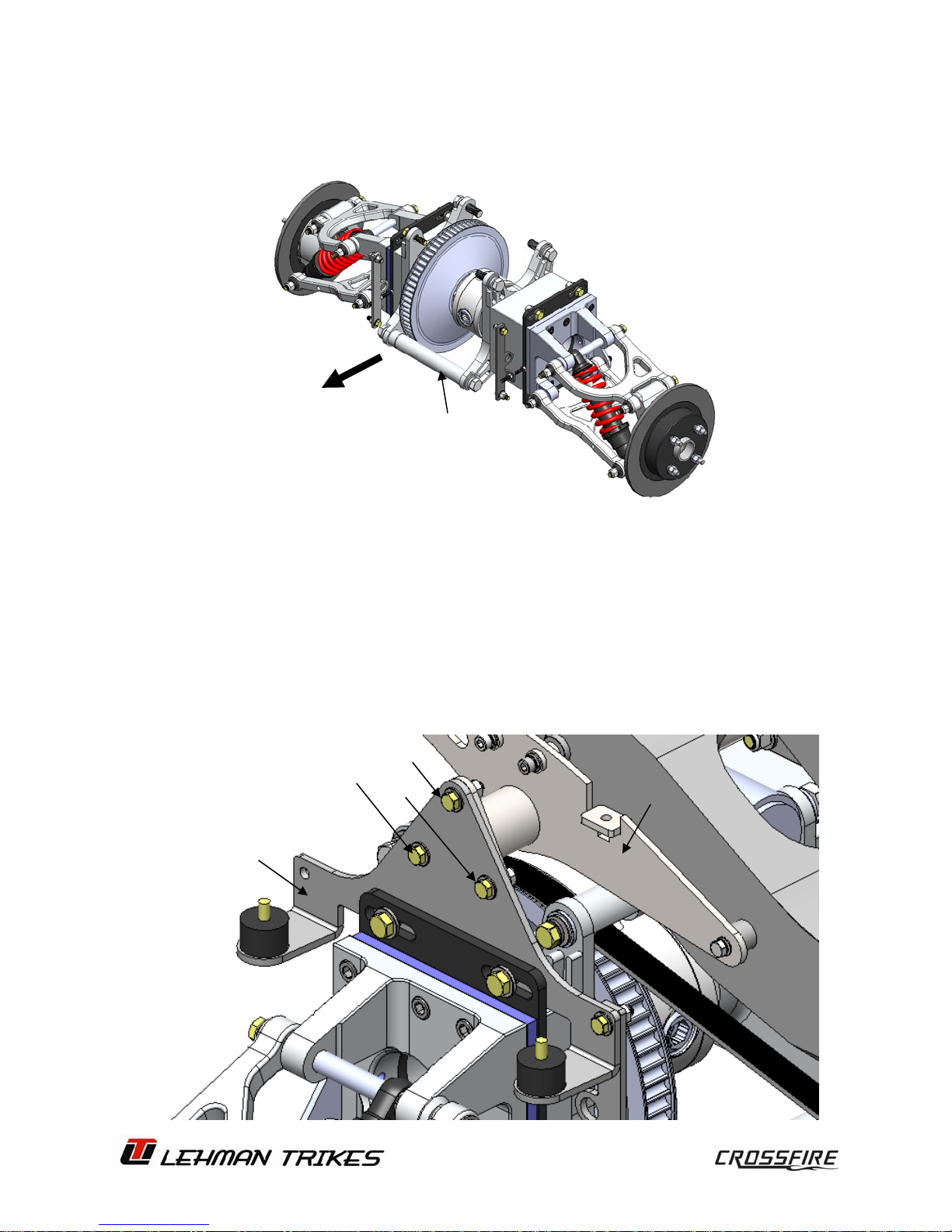

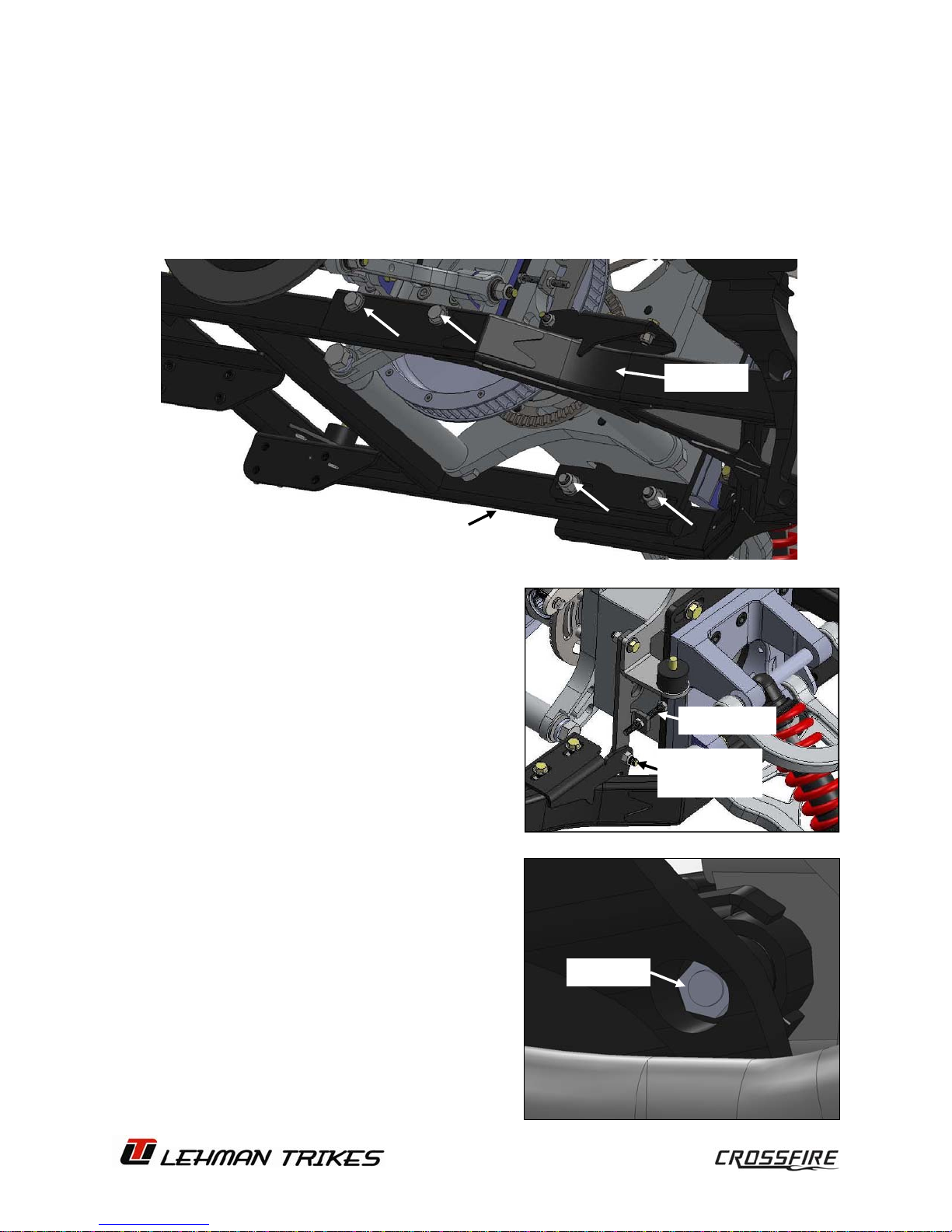

RearSuspensionDoubleA‐ArmIndependent

Storage5Cubicfeet

RearWheelSize15x7,4x4.5,+35mmOffset