3

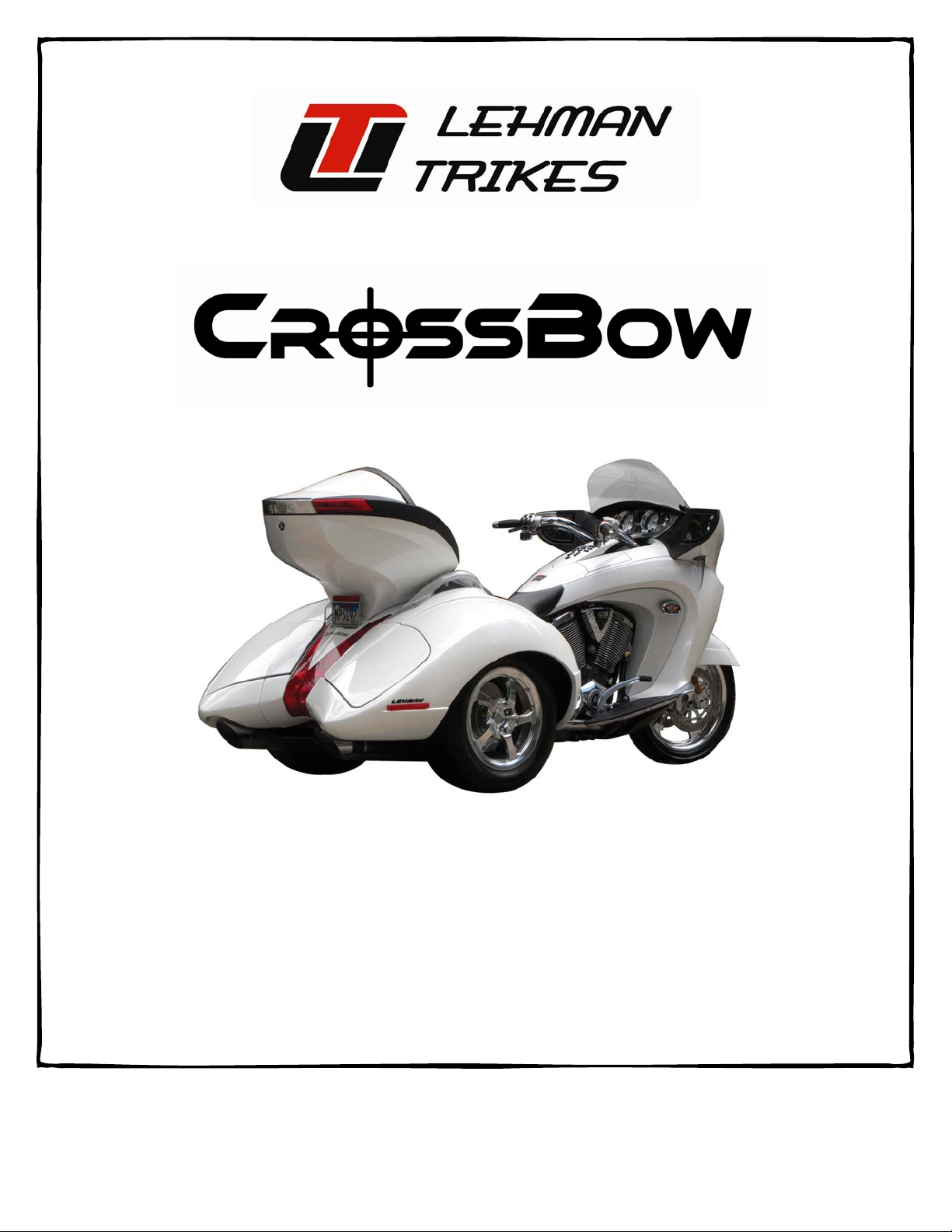

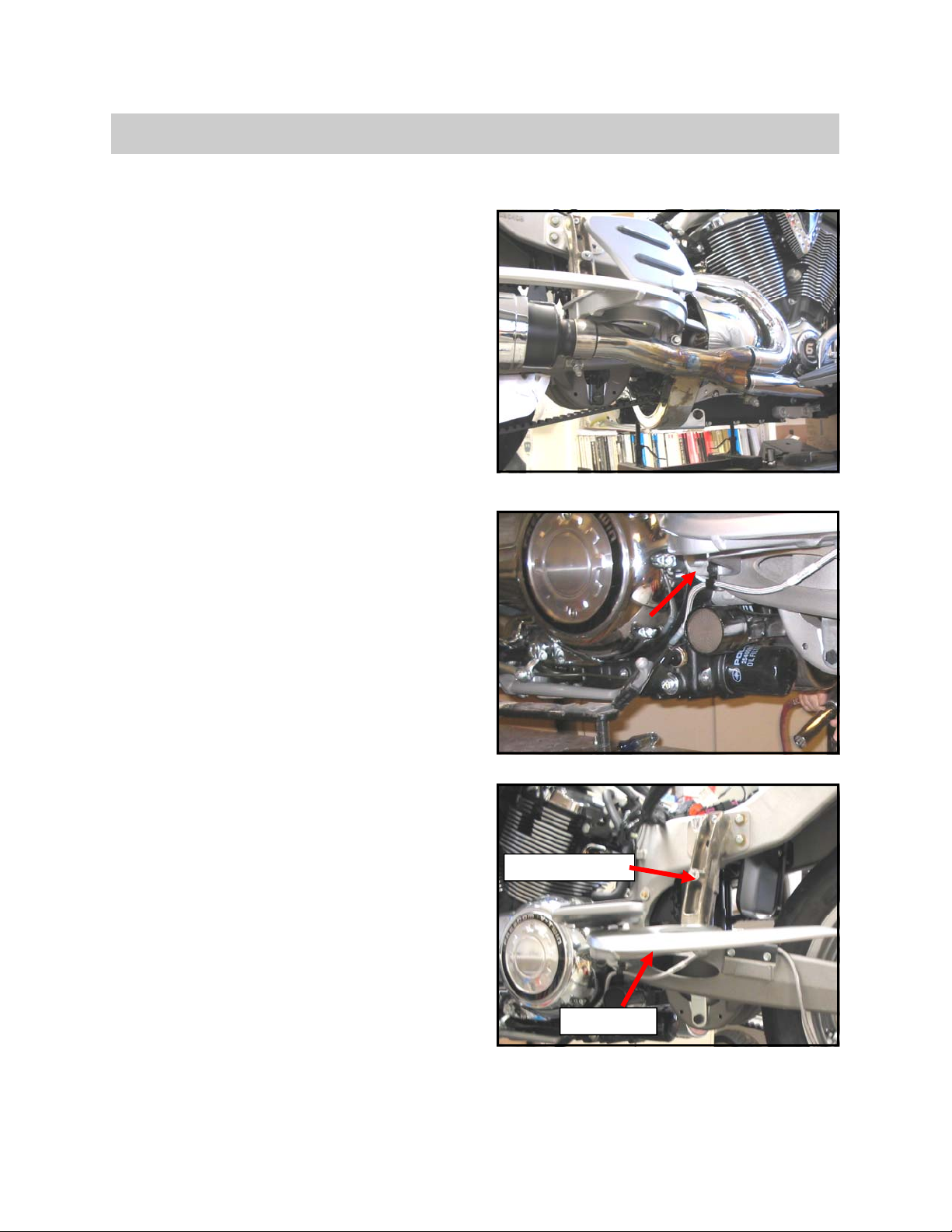

10. See Fig. 4. Using a silver sharpie, mark the loca-

tion of the cross-drilled holes on the assembled

banjo bolt as shown.

11. Remove OEM banjo bolt from clutch reservoir us-

ing 12mm wrench. Save banjo bolt in identified

container as these will go to the tech center for

modification.

• (1) OEM Banjo Bolt (save)

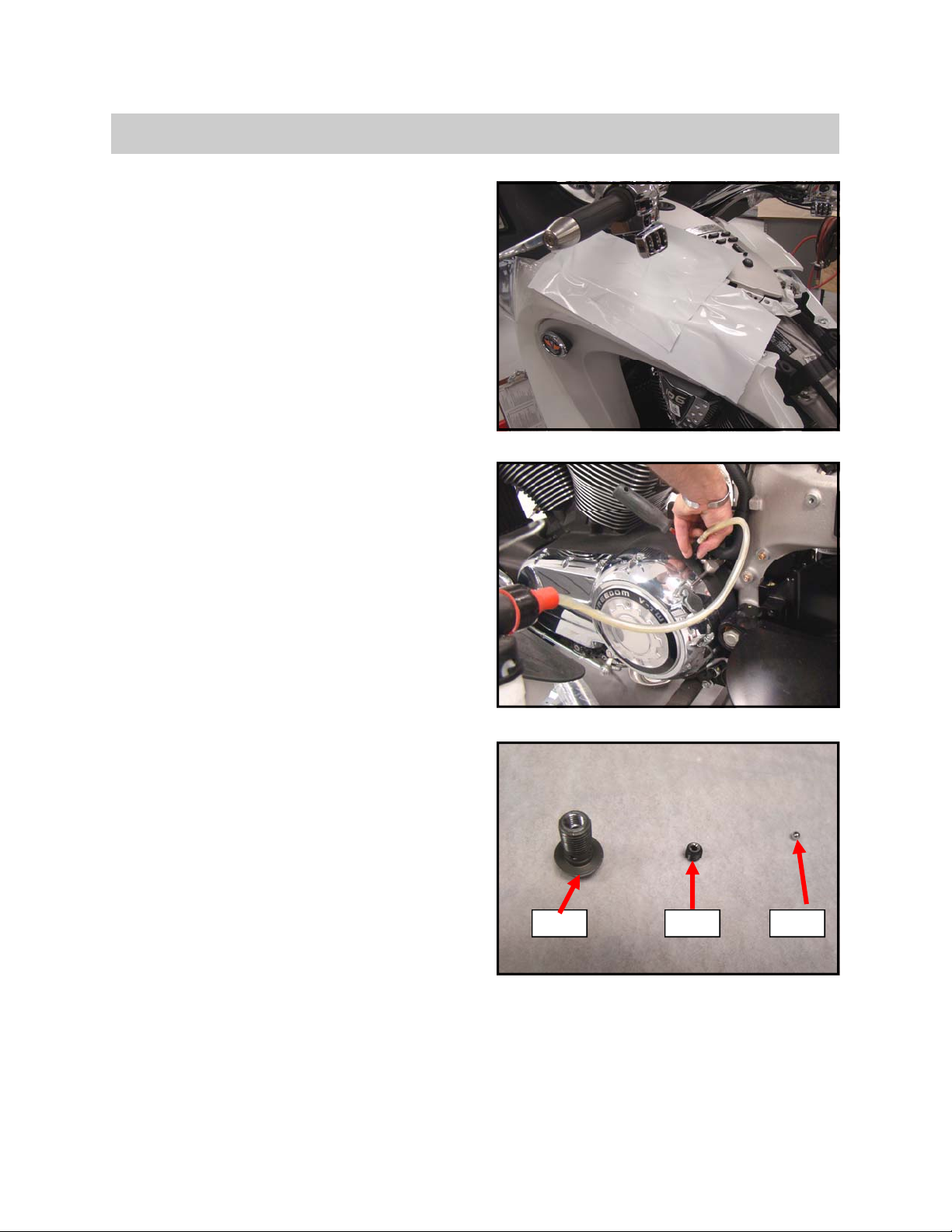

12. See Fig. 5. Install assembled banjo bolt to clutch

reservoir as shown using 12mm wrench.

13. Torque and mark banjo bolt to 16 ft. lbs using

12mm wrench.

NOTE: After torque is applied, make sure that the

cross-drilled holes are lined up with the banjo

adaptor as shown (Fig. 00-13). If the holes are not

lined up with the adaptor the clutch will not oper-

ate properly.

14. Fill clutch reservoir with DOT 5.1.

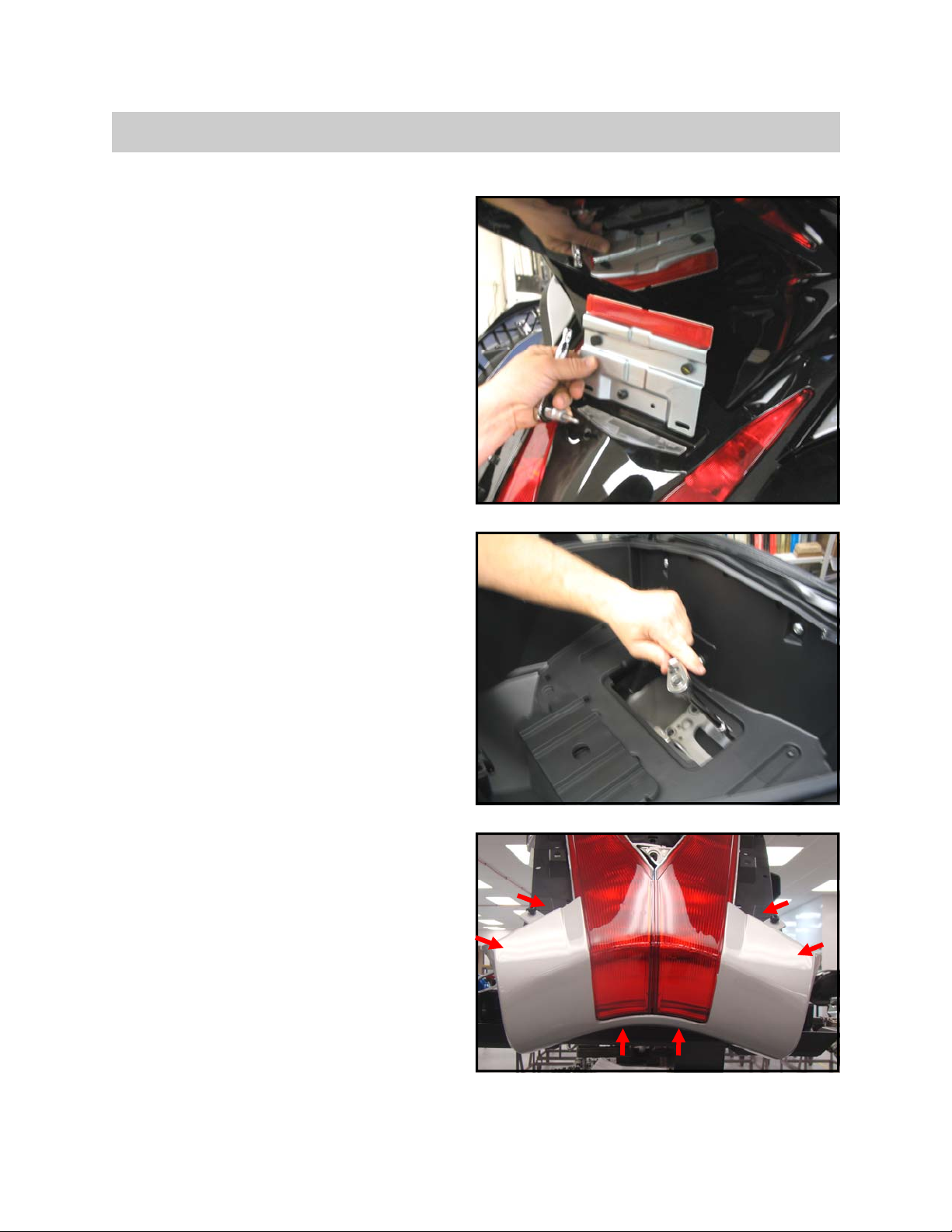

15. See Fig. 6. Bleed the clutch system as shown us-

ing brake bleeder.

16. Depress the clutch lever slowly and repeatedly

making sure all air bubbles are out of the system.

This can take some time. Make sure all the bub-

bles are out, even micro-bubbles.

17. Fill clutch reservoir to top of sight glass with DOT

5.1

18. Re-install reservoir cap using Phillips screw-

driver.

Fig. 5

Fig. 6

PART # PART DESCRIPTION TORQUE

S001502 BANJO BOLT 16 FT LBS

Fig. 4

CLUTCH VALVE