8

Bracket Installation

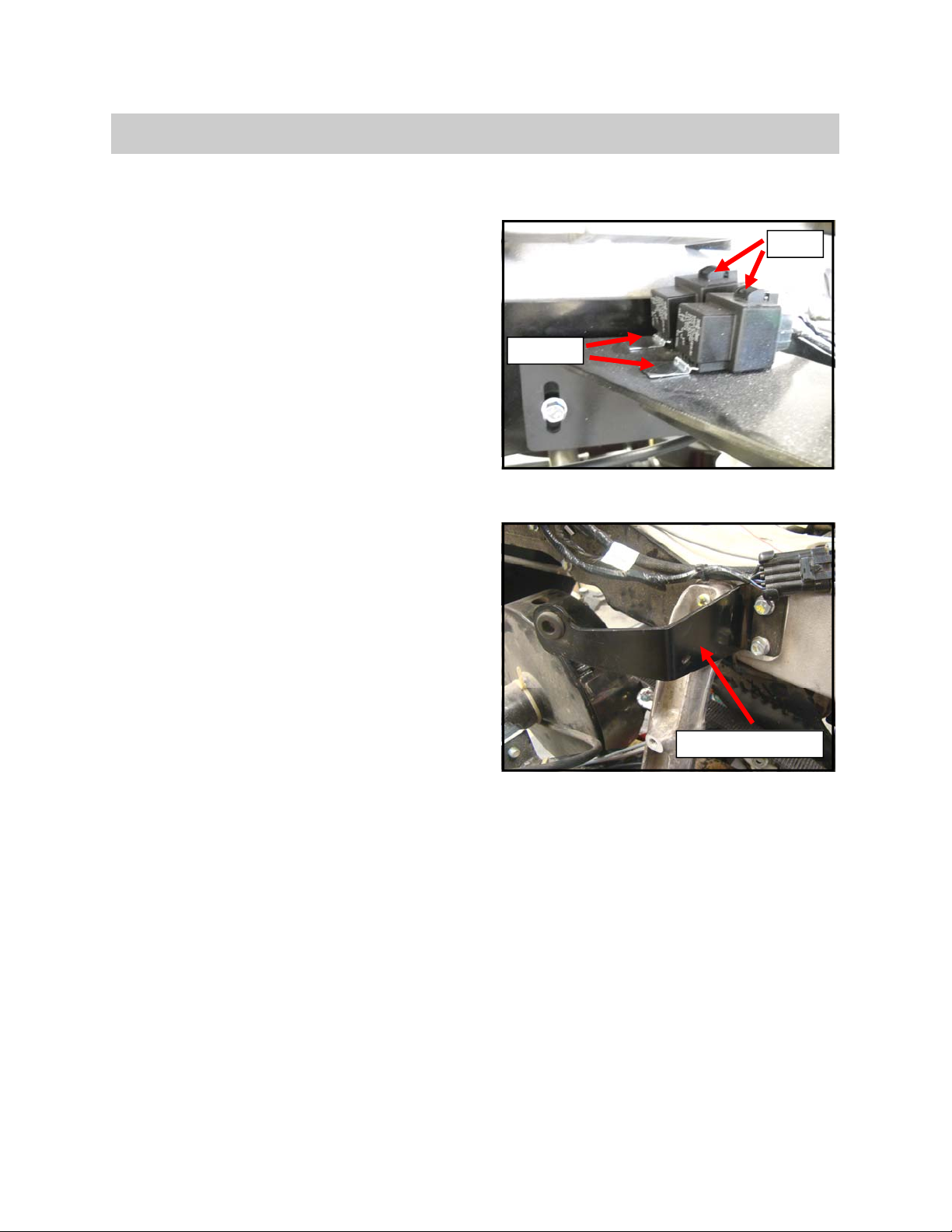

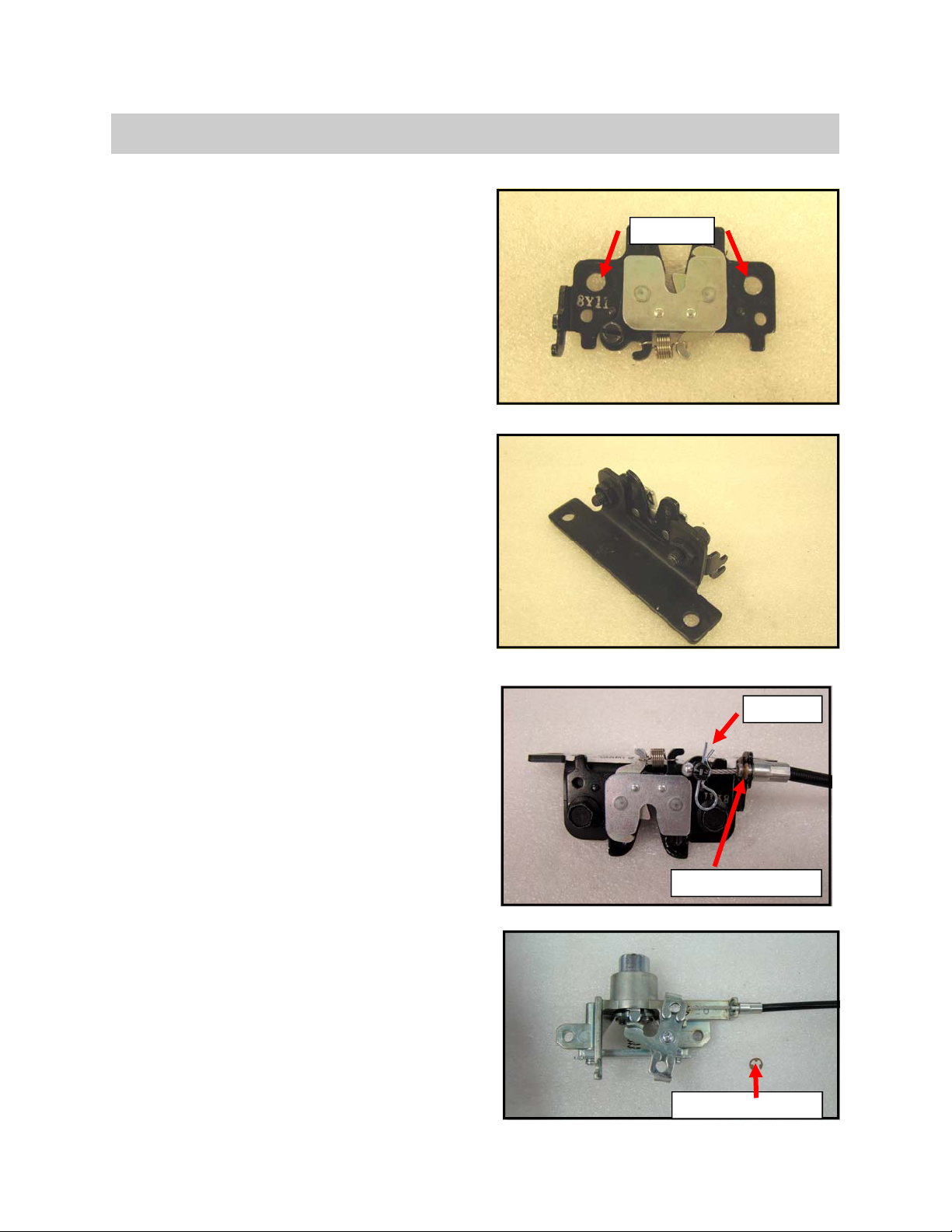

Operation 40 - Bracket Installation

EXHAUST INSTALLATION

1. See Fig. 1. Install (1) left side exhaust pipe as

shown using (1) exhaust clamp.

• (1) Left Side Exhaust Pipe (S001166)

• (1) Exhaust Clamp (Take-Off)

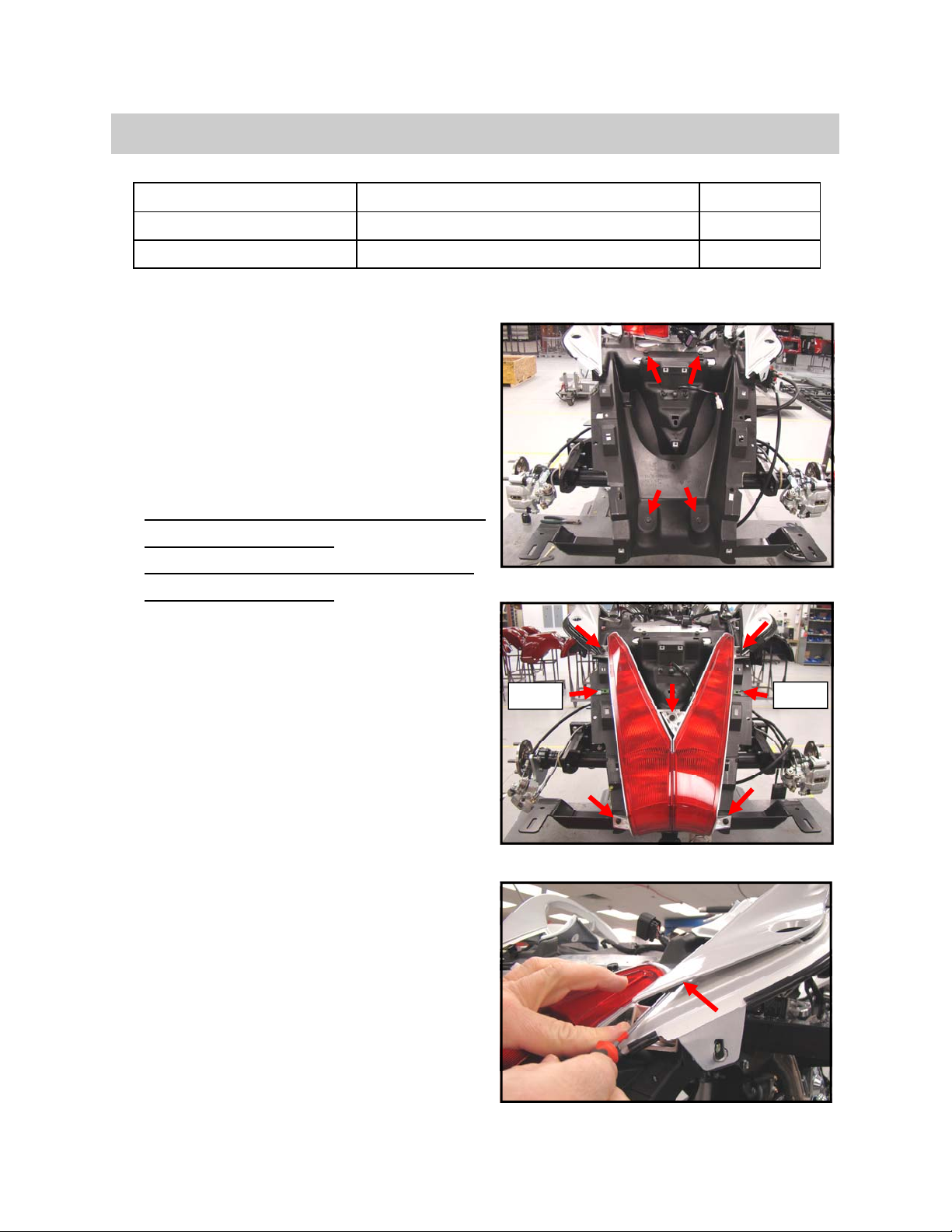

2. See Fig. 2. Install (1) polaris exhaust bracket to

transmission using (1) bolt (CB1906) in upper lo-

cation and (1) bolt (CB1928) with loctite 243.

Tighten using 4mm allen head socket and

15mm socket.

• (1) Polaris Exhaust Bracket (S001547)

• (1) Bolt (CB1906)

• (1) Bolt (CB1928)

3. Torque and mark upper exhaust bracket bolt

to 10 ft. lbs using 15mm socket.

4. Torque and mark lower exhaust bracket bolt to

35 ft. lbs using 15mm socket.

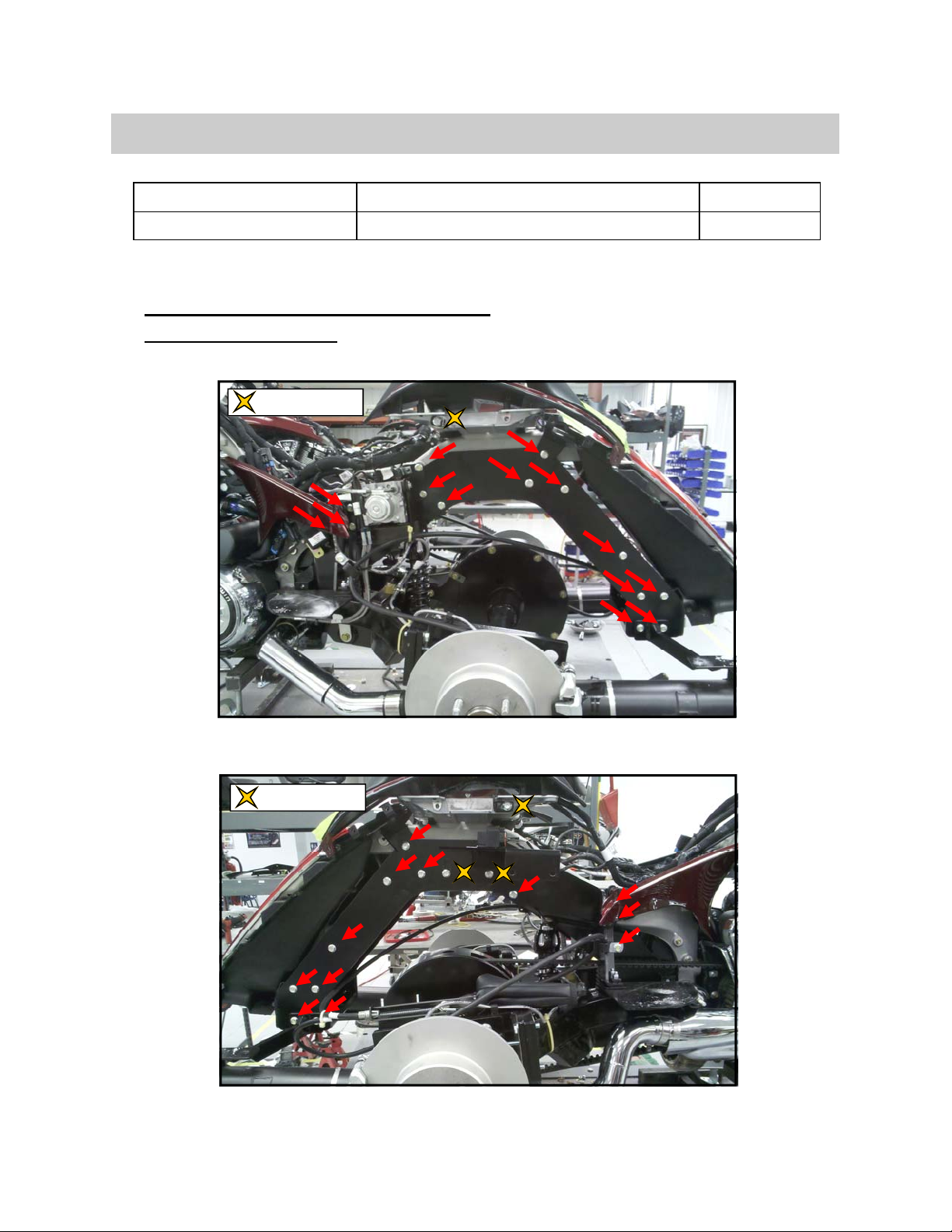

5. See Fig. 3. Install (1) right side exhaust pipe as

shown using (1) exhaust clamp.

• (1) Right Side Exhaust Pipe ( S001167)

• (1) Exhaust Clamp (S001412)

6. Re-install side covers with (1) push pin.

• (1) Push Pin (OEM take off)

• (1) Non Reverse Models Side Cover Set

(OEM)

OR

• (1) Reverse Models Side Cover Set

(Supplied with Reverse Kit) See modifica-

tion process on following page.

Fig. 1

Fig. 2

PART # PART DESCRIPTION TORQUE

CB1906 UPPER EXHAUST BRACKET BOLT (1) 10 FT LBS

CB1928 LOWER EXHAUST BRACKET BOLT (1) 35 FT LBS

Fig. 3

CB1906

CB1928