Introduction PaveSmart 3D UM 3

Symbols The symbols used in this manual have the following meanings:

Trademarks • Windows is a registered trademark of Microsoft Corporation

• GOMACO is a registered trademark of Gomaco Corporation, Ida Grove, IA, USA

• Wirtgen is a registered trademark of Wirtgen Group, Windhagen, Germany

• MOBA is a registered trademark of MOBA Mobile Automation AG, Germany

• Vögele is a registered trademark of Wirtgen Group, Windhagen, Germany

• G&Z is a registered trademark of Guntert & Zimmerman Inc., Ripon, CA, USA

• PowerCurbers is a registered trademark of PowerCurbers Inc., Salisbury, NC, USA

• PowerPavers is a registered trademark of PowerPavers Inc., Cedar Falls, IA, USA

All other trademarks are the property of their respective owners.

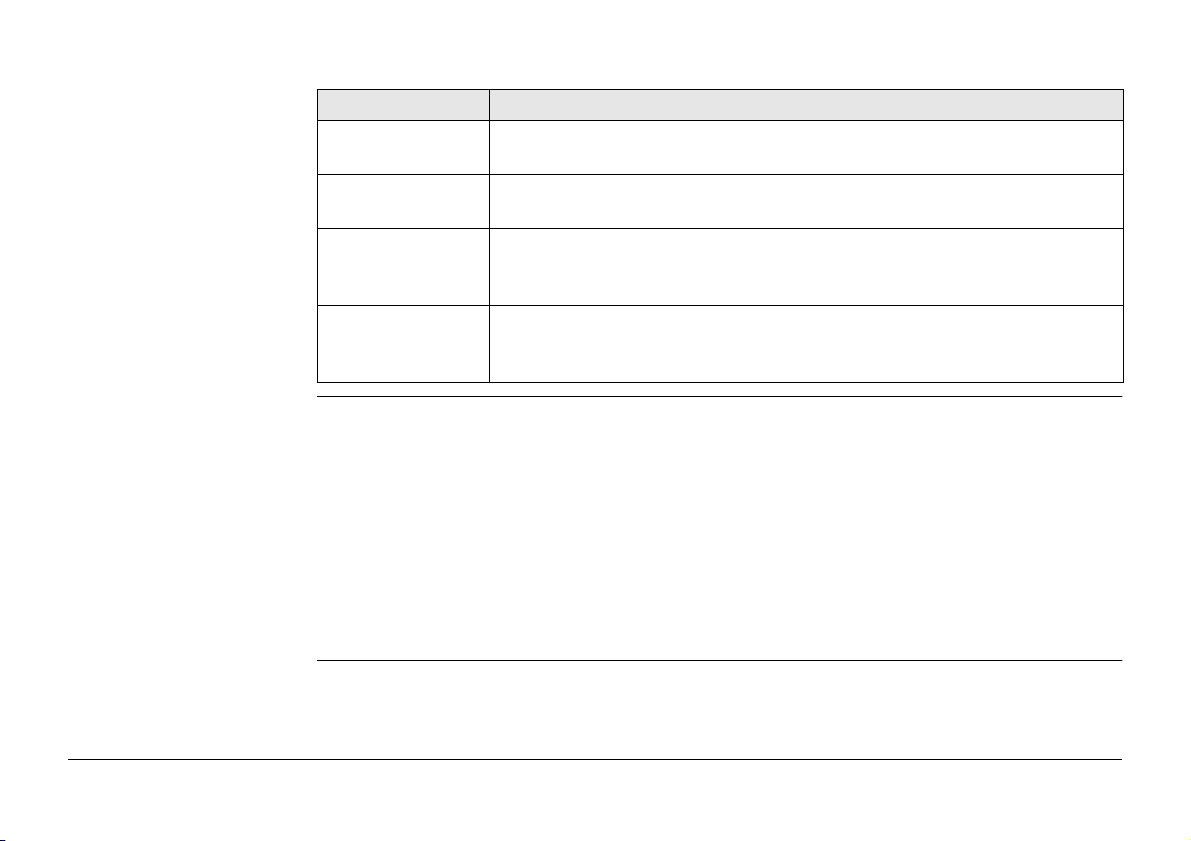

Type Description

Danger Indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Warning Indicates a potentially hazardous situation or an unintended use which,

if not avoided, could result in death or serious injury.

Caution Indicates a potentially hazardous situation or an unintended use which,

if not avoided, may result in minor or moderate injury and/or appreci-

able material, financial and environmental damage.

Important paragraphs which must be adhered to in practice as they

enable the product to be used in a technically correct and efficient

manner.