WWW.CONVERTED.CO.NZ

3. BIKE PREPARATION

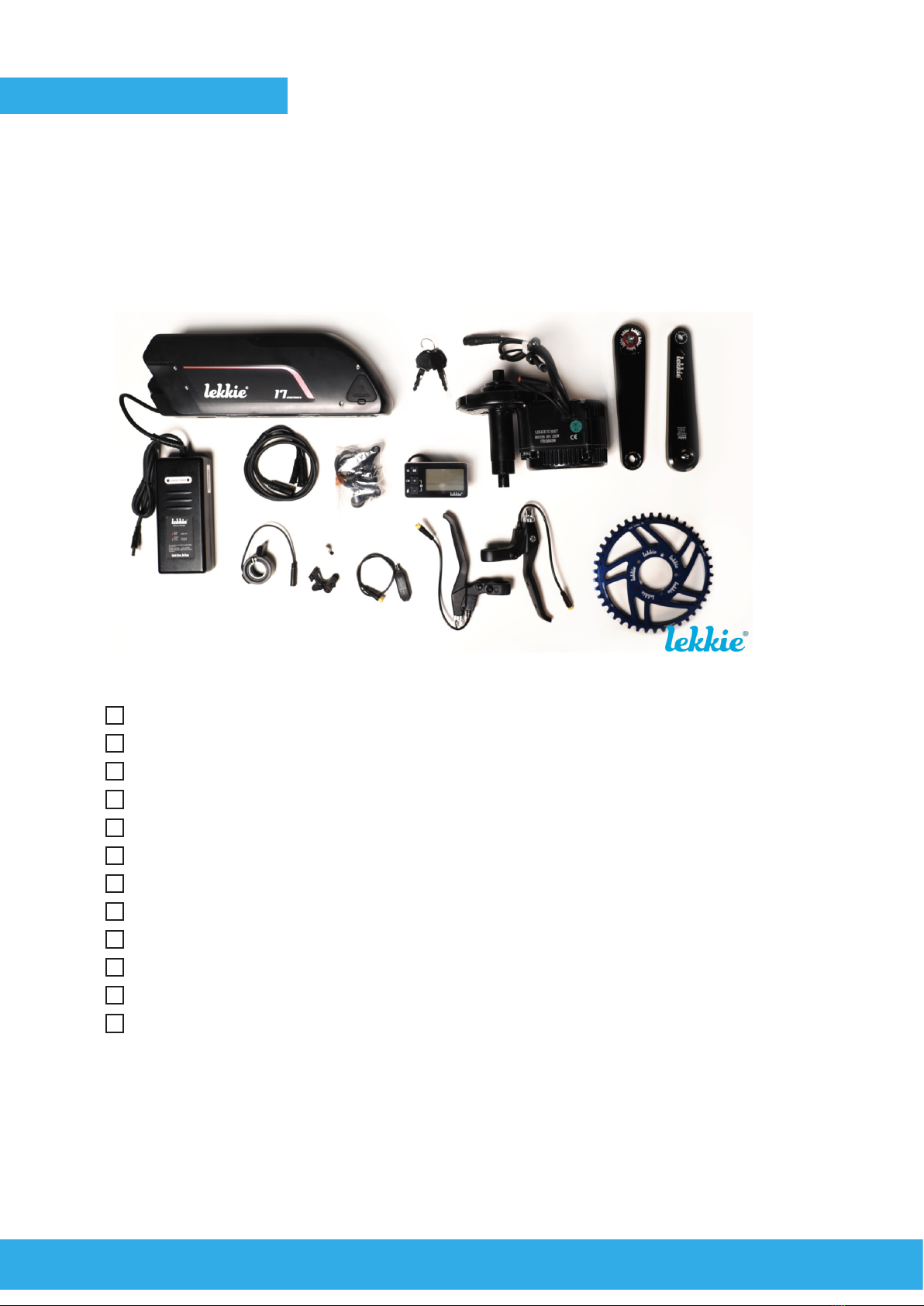

Installing your Converted System Summit kit is not hard, but you do need a certain

level of mechanical knowledge. There are plenty of online video tutorials on youtube

should you get stuck. Otherwise contact us and we can help you out.

3.1 Bike /Frame preparation

The Converted System Summit kit uses a Bafang mid-drive motor which replaces your existing

cranks/Chainring(s)/bottom bracket. The folowing instructions relate to frames with a standard

threaded bottom bracket, which is currently the most commonly found type. The internal diameter

is 34mm and the width between 68-73mm. For other styles of bottom bracket you may require an

additional tting adapters. Please contact Converted System for further info. as required.

3.2 Cranks/bottom bracket/front derailleur

Remove the pedals from the original cranks if you are planning to re-use (generally 15mm spanner

or allen key, Left pedal is reverse thread - turn clockwise to loosen)

Remove cranks,

• Remove the centre crank bolts (normally 8mm Allen Key)

• Using a crank extractor tool remove the cranks, (see manufacturer instructions).

If the bike is tted with a front derailleur, break the chain to allow removal.

Disconnect the front deraileur cable and remove the derailleur bracket (this normally clamps around

the seat tube).

Remove the bottom bracket with a Bottom bracket removal tool. Start on the left(non-drive) side of

the bike. removing the cup completely.

Repeat on the opposite(chainring) side, this will be reverse thread so turn clockwise to loosen.

The bottom bracket should pull out completely.

Remove the front derailleur cables.