E-3

TABLE OF CONTENTS....................................................................................................page

PREFACE.......................................................................................................................5

WARRANTY CONDITIONS............................................................................................5

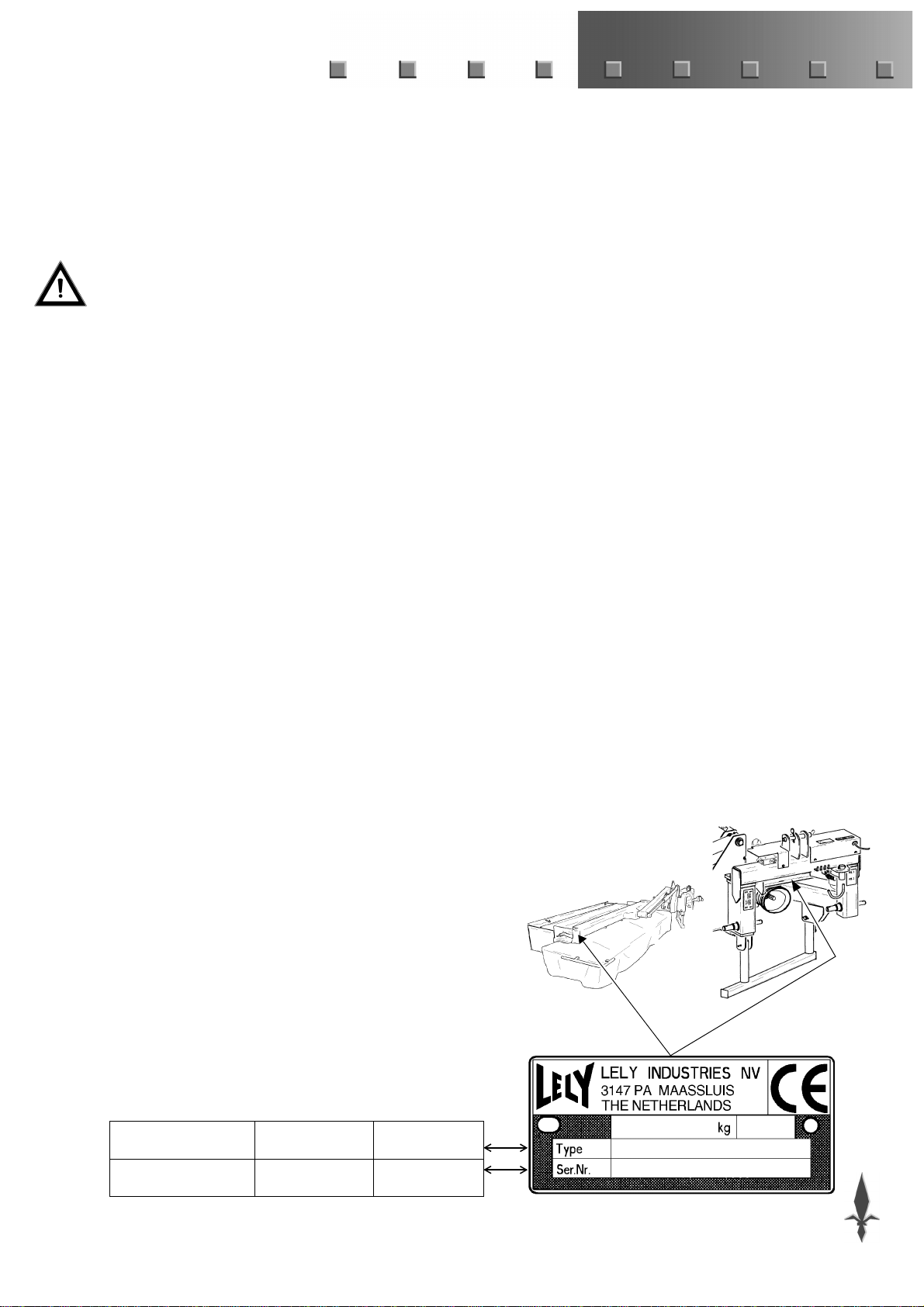

TYPE- AND SERIAL NUMBER OF YOUR MACHINE ...................................................5

SAFETY INSTRUCTIONS..............................................................................................6

EXPLANATION OF SAFETY DECALS ON THE MACHINE..........................................7

1 INTRODUCTION ............................................................................................................8

2 MOUNTING BEHIND THE TRACTOR ...........................................................................9

3 TRANSPORT.................................................................................................................10

4 MACHINE ADJUSTMENTS...........................................................................................11

4.1 Mowing height......................................................................................................11

4.2 Intensity of conditioning.......................................................................................11

4.3 Ground pressure..................................................................................................12

4.3.1 Mechanical ground pressure relief ............................................................12

4.3.2 Hydraulic ground pressure relief................................................................12

4.4 Swath width .........................................................................................................12

5 OPERATING THE SPLENDIMO® MC..........................................................................13

6 DISMOUNTING FROM THE TRACTOR.......................................................................14

7 MAINTENANCE.............................................................................................................15

7.1 Maintenance after operations ..............................................................................15

7.2 Lubrication...........................................................................................................15

7.3 Intermittent maintenance .....................................................................................16

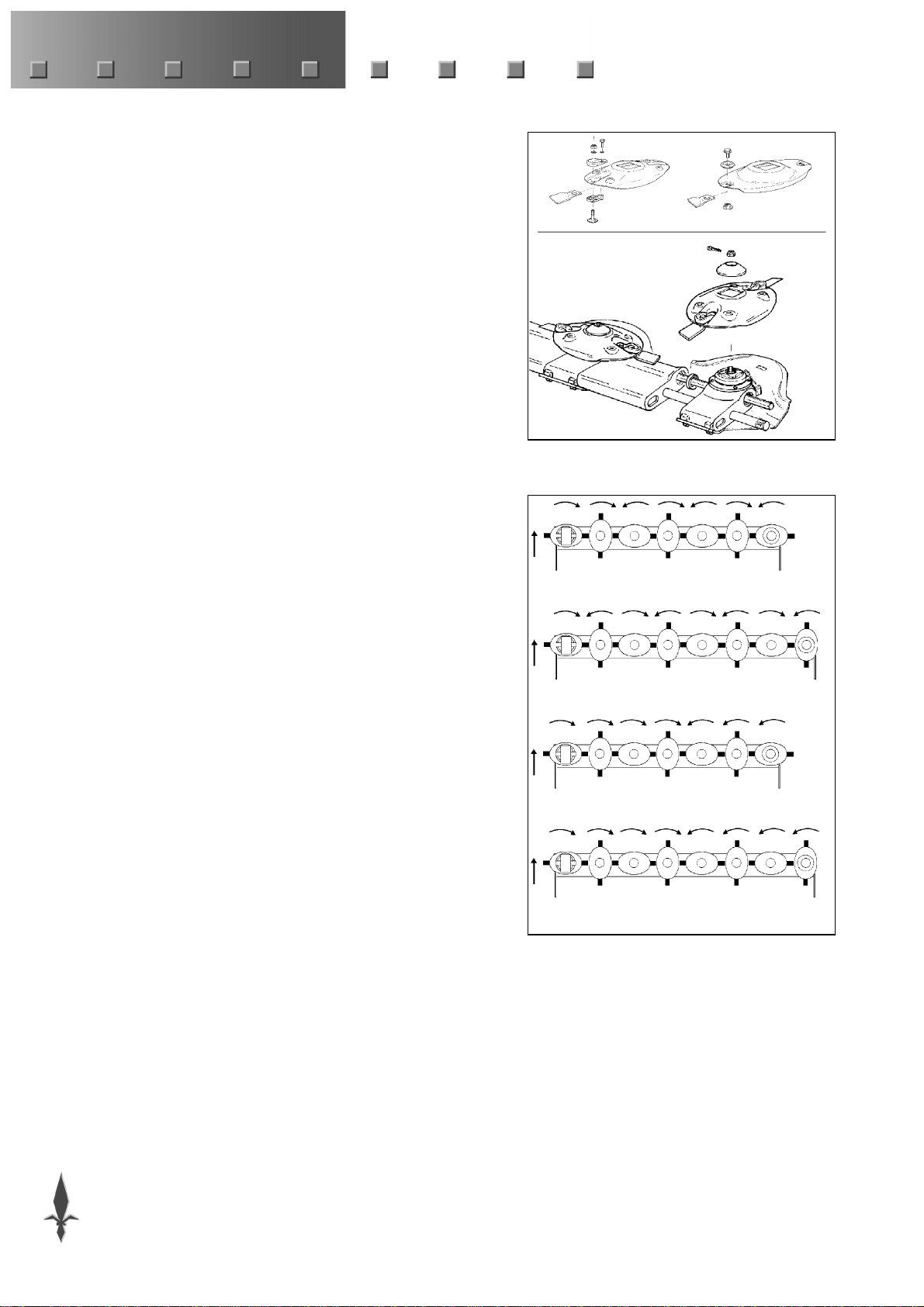

7.4 Replacement of knives ........................................................................................18

7.5 Change of oil in gearboxes..................................................................................18

7.6 Change of grease in mower elements.................................................................19

Supplements:

A REPAIRS TO THE CUTTER BAR.................................................................................20

A.1 Cutter bar assembly/disassembly........................................................................20

A.2 Replacement of the disc on the drive element.....................................................22

B CONDITIONER ADJUSTMENTS..................................................................................23

B.1 Position of top hood.............................................................................................23

B.2 Moving the conditioning rotor...............................................................................23

B.3 Rotor speed.........................................................................................................24

C HYDRAULIC GROUND PRESSURE RELIEF SYSTEM...............................................25

C.1 Scheme................................................................................................................25

C.2 Adjustment of minimum system pressure............................................................26

C.3 Trouble shouting..................................................................................................27

D OPTIONAL EXTRAS .....................................................................................................28

E TECHNICAL DETAILS...................................................................................................30