Lennox Hearth Products MPD35ST-NM-B User manual

Other Lennox Hearth Products Indoor Fireplace manuals

Lennox Hearth Products

Lennox Hearth Products Signature Montebello Series User manual

Lennox Hearth Products

Lennox Hearth Products EBVSTNM-B User manual

Lennox Hearth Products

Lennox Hearth Products MLDVTCD-35NM User manual

Lennox Hearth Products

Lennox Hearth Products VISION Elite Series User manual

Lennox Hearth Products

Lennox Hearth Products Montecito User manual

Lennox Hearth Products

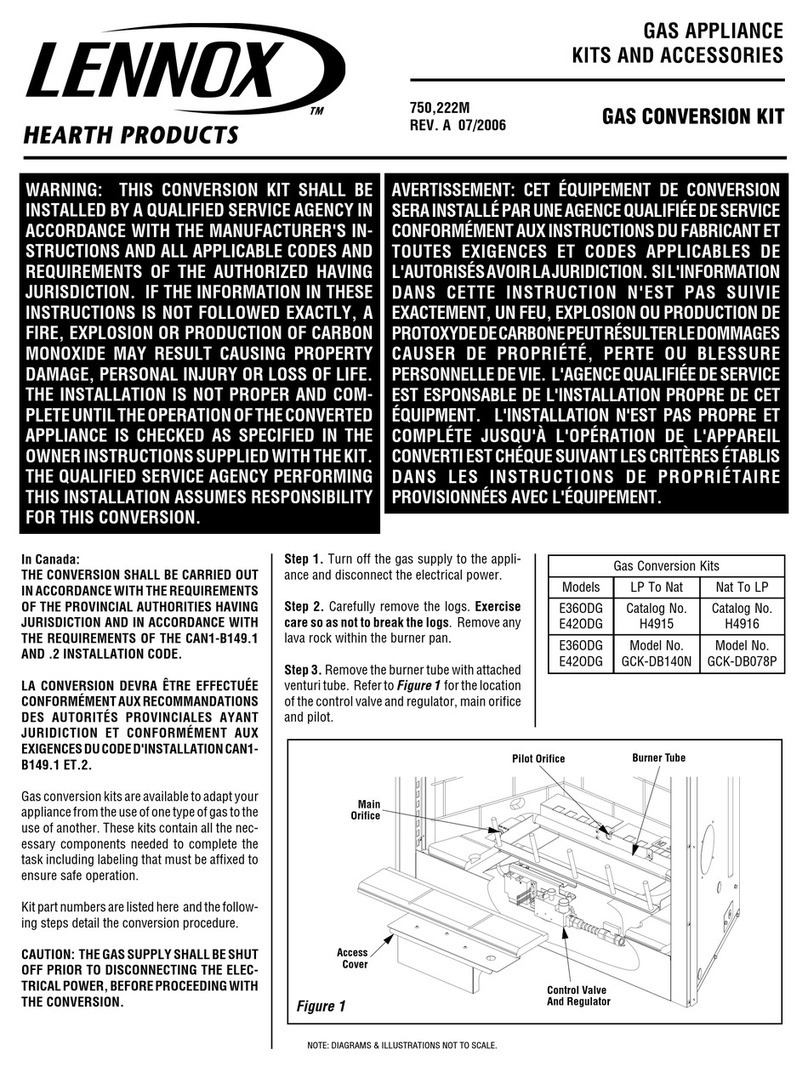

Lennox Hearth Products E36ODG User manual

Lennox Hearth Products

Lennox Hearth Products LMDTV-3328CNM User manual

Lennox Hearth Products

Lennox Hearth Products MPE-36R Assembly instructions

Lennox Hearth Products

Lennox Hearth Products Merit LMBV-42REN User manual

Lennox Hearth Products

Lennox Hearth Products Performer C210 User manual

Lennox Hearth Products

Lennox Hearth Products LDV42 User manual

Lennox Hearth Products

Lennox Hearth Products MPDT-3328CNM-B User manual

Lennox Hearth Products

Lennox Hearth Products LENNOX MPE-33R User manual

Lennox Hearth Products

Lennox Hearth Products LMBV-36RMN User manual

Lennox Hearth Products

Lennox Hearth Products L30 DVF-2 Owner's manual

Lennox Hearth Products

Lennox Hearth Products ELITE ELITE CVF User manual

Lennox Hearth Products

Lennox Hearth Products MERIT Direct-Vent MEDINA User manual

Lennox Hearth Products

Lennox Hearth Products 055M User manual

Lennox Hearth Products

Lennox Hearth Products BRENTWOOD LV User manual

Lennox Hearth Products

Lennox Hearth Products Merit Series HCI-36-H User manual

Popular Indoor Fireplace manuals by other brands

Brigantia

Brigantia 35-DVRS31N-2 User's installation, operation and maintenance manual

Nordpeis

Nordpeis Bergen Installation and user manual

Superior

Superior BCT2536TMN Installation and operation instructions

Quadra-Fire

Quadra-Fire 5100I-GD-B owner's manual

Renaissance

Renaissance RUMFORD 1000 user manual

Lacunza

Lacunza IV-800 Instruction book

Baxi

Baxi 940 Installer and owner guide

Dru

Dru Maestro 60/2 Tall RCH installation manual

Diamond Fireglass

Diamond Fireglass SS-O22 General assembly, installation, and operation instructions

HearthStone

HearthStone Windsor Bay 8830 Owner's manual and installation guide

Napoleon

Napoleon ASCENT B42 quick start guide

Enviro

Enviro E33GI owner's manual

Smeg

Smeg L30 FABE Installation & user's instructions

KEDDY

KEDDY K700 Installation instructions care and firing instructions

Godin

Godin 3451 manual

Jøtul

Jøtul Jotul GI 535 DV IPI New Harbor Installation and operation instructions

Desa

Desa CCFPDFT Owner's operating & installation manual

Miles Industries

Miles Industries Vogue 1300IRN Installation & operating instructions