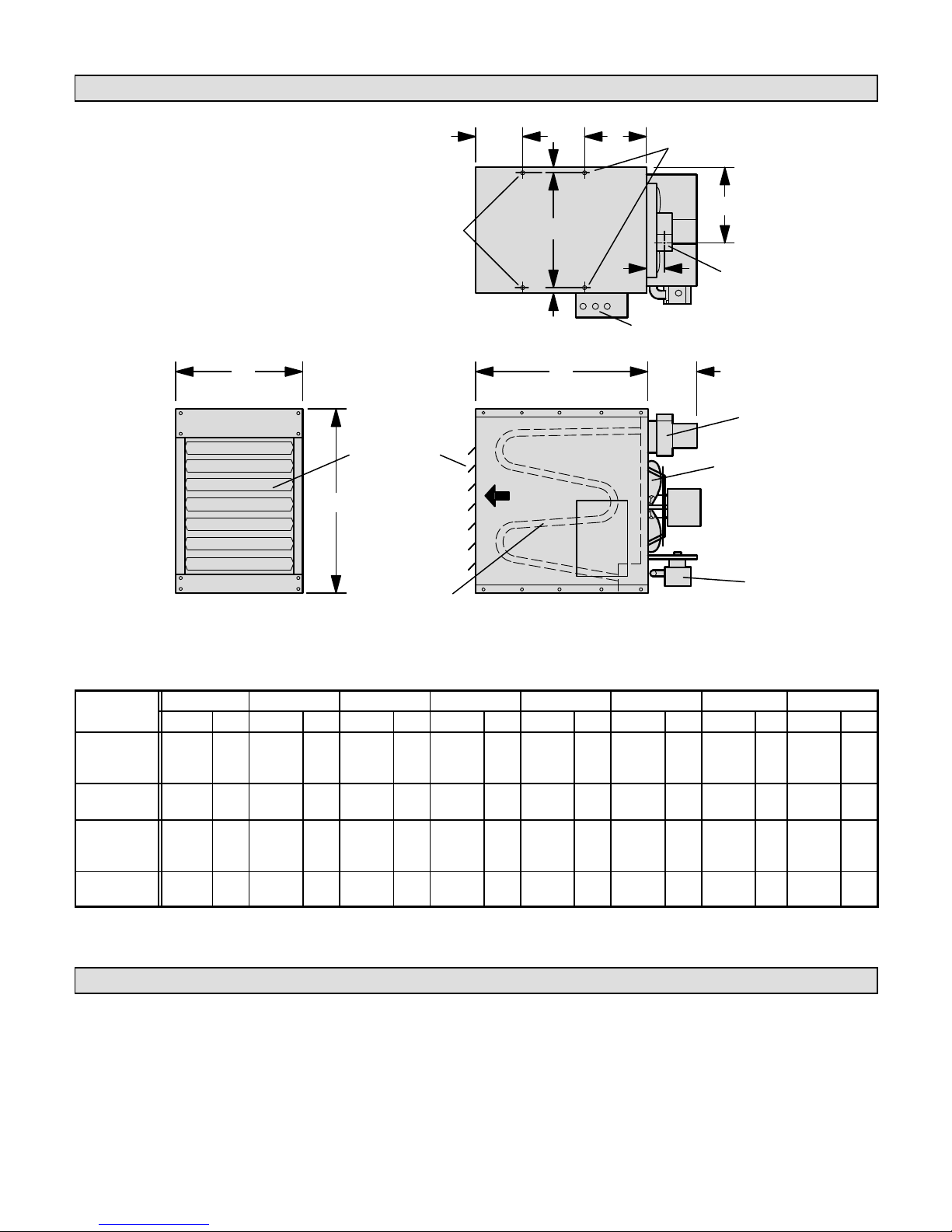

Page 7

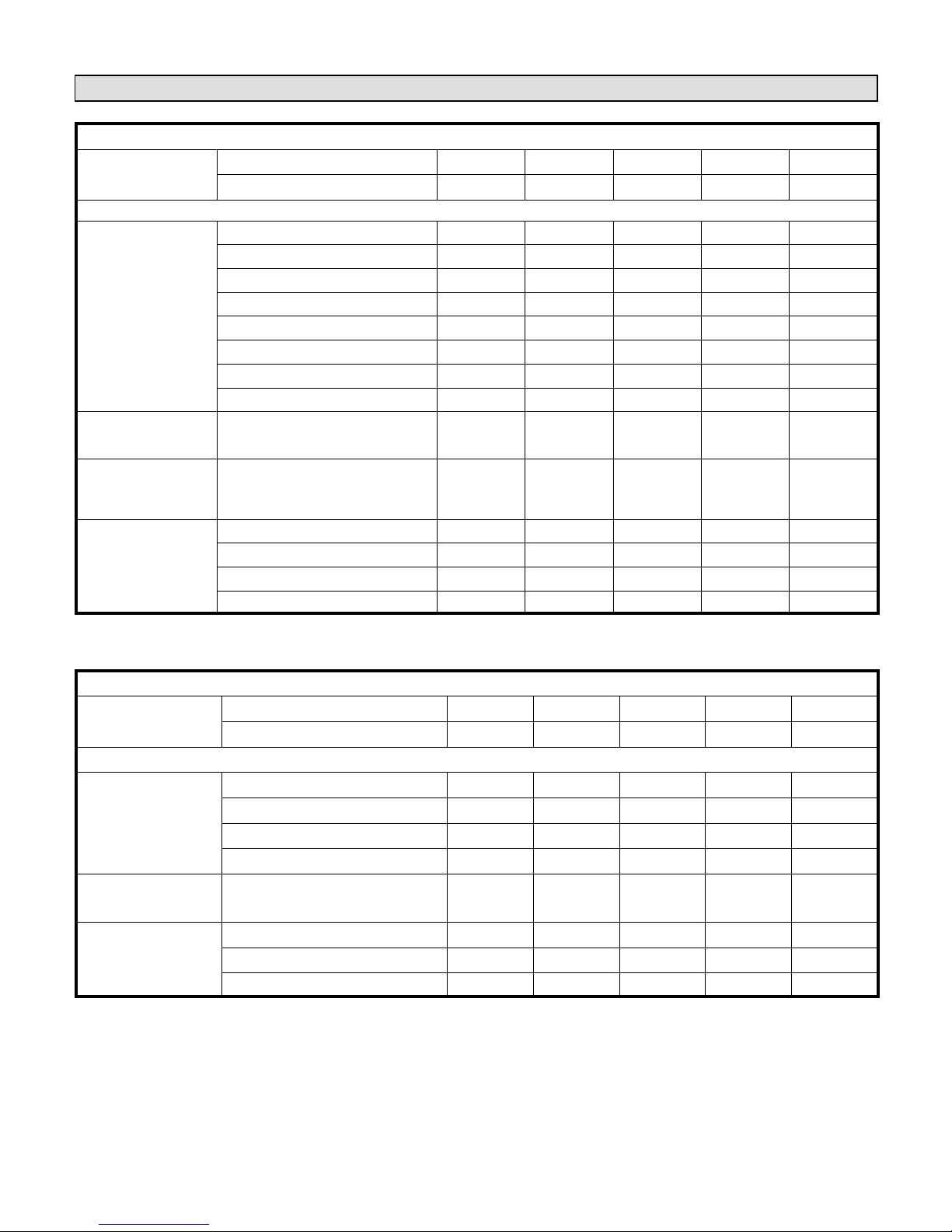

TABLE 6

MAXIMUM HORIZONTAL VENT CONNECTOR AND

HORIZONTAL VENT PIPE LENGTHS

No. of

Elbows

LF24−100, −115,

−145, −175, and

−200

LF24−230,

−250 and

−300

LF24−345 LF24−400

ft m ft m ft m ft m

1 25 7.6 35 10.7 31 9.4 21 6.4

2 20 6.1 30 9.1 22 6.7 12 3.6

3 15 4.6 25 7.6 13 4.0 3 0.9

4 10 3.0 20 6.1 4 1.2 −− −−

5 5 1.5 15 4.6 −− −− −− −−

6 −− −− 10 3.0 −− −− −− −−

7 −− −− 5 1.5 −− −− −− −−

HORIZONTAL VENTING

NOTE − Common venting is not allowed when horizontally

venting the unit heater.

If the LF24 unit heater is to be horizontally vented, a

positive pressure may be created in the vent. The unit

heater, when installed with horizontal venting, will

perform as a category III appliance.

1 − Special vent materials approved for use with

Category III appliances may be used with these

units. Refer to table 7 for venting components.

2 − If possible, do not terminate the horizontal vent

through a wall that is exposed to prevailing wind.

Exposure to excessive winds can affect unit

performance. If such a termination is necessary,

use a wind block to protect the vent termination from

direct winds.

3 − Vent termination must be free from obstructions and

at least 12" (30.5 cm) above grade level and

maximum snow height.

4 − Do not terminate vent directly below roof eaves or

above a public walkway, or any other area where

condensate dripping may be troublesome and may

cause some staining. Avoid windows where steam

may cause fogging or ice buildup.

5 − Minimum clearance for horizontal vent termination

from any door, window, gravity air inlet, gas or

electric meter, regulators, and relief equipment is 4

feet (1m) for United States installations.

In Canada, horizontal vent termination must have a

minimum 6−foot horizontal clearance from gas and

electric meters and relief devices.

Refer to latest editions of the ANSI Z223.1 or

CSA−B149 for installation compliance codes and

with local authorities with jurisdiction.

6 − Vent termination must be a minimum of 4 feet

(1.2m) horizontally from any soffit or under−eave

vent.

7 − Vent termination must be a minimum of 6 feet (1.83

m) from an inside corner formed by two exterior

walls. If possible, leave a 10−foot clearance.

8 − Vent termination must be a minimum of 10 feet (3m)

from any forced air inlet (includes fresh air inlet for

other appliances, such as a dryer).

9 − For upward sloped vent, a condensate tee and drain

must be installed within the first 5 feet (2m) from the

unit heater to protect the appliance. If a flexible

condensate drain line is used, the drain line must

include a loop filled with water to prevent

combustion products from entering the structure. If

the unit is shut down for an extended period of time

and will be exposed to sub−freezing temperatures,

the condensate may freeze.

10 − For upward sloped vent, see figure 3, condensate

tee and drain must be installed within the first 5 feet

(1.53 m) from the unit heater to protect the

appliance.

11 − Flexible loop trap in condensate line (if used) must

be filled with water to prevent combustion products

from entering structure.

12 − Select a wall termination point that will maintain 1/4"

rise per foot slope of horizontal run of vent pipe. In

areas where authorities having jurisdiction permit, a

downward slope of maximum 1/4" per foot is also

acceptable. Condensate drainage can be collected

in a tee pipe section (figure 4) with drain loop similar

to one used for upward slope vent, or allowed to drip

through the vent termination, if permitted by

authorities (figure 5).

13 −For horizontal venting, the vent pipe must be

supported with hangers no more than 3 feet (1m)

apart to prevent movement after installation.

14 − All horizontal vent applications which use Category

III vent pipe must terminate with an approved

Category III tee. Opening end must face downward.

15 − When termination is routed through an exterior

combustible wall, the vent must be supported using

a listed clearance thimble. Inside edge of vent

termination tee or elbow must be at least 12"

(305mm) from outside wall.