9

Unit Placement

In addition to clearances, the following items should be

considered:

WARNING

!

Use the provided and specied components when

installing equipment. Failure to do so may result in

unit falling, water leaking or electrical shocks, caus-

ing personal injury or equipment or property damage.

Check stability of wall, oor, or ceiling and unit

support. If support is not capable of carrying weight

of the unit, unit may fall causing personal injury or

equipment damage.

Consider the possibility of earthquakes in your

area when installing the equipment. If the unit is not

correctly secured, it may fall, causing personal injury

or equipment damage.

Safely dispose of packing materials, which include

nails, wood and other sharp objects, as well as plastic

wrapping. Children playing with plastic wrap or bags

risk the danger of suocation.

AVOID

Do not install the unit in the following locations:

• Areas exposed to petrochemicals or petrochemical

products

• Areas exposed to salt or other corrosive materials or

caustic gasses

• Areas exposed to extreme voltage variations (such as

factories

• Tightly enclosed areas that may impede service of the

unit

• Areas exposed to fossil fuels (such as oil or gas in

kitchens)

• Areas exposed to strong electromagnetic forces

• Areas exposed to acids or alkaline detergents (laundry

rooms)

DO:

• Locate the unit so that it is not exposed to direct sunlight

• Locate the indoor unit so that the room can be uniformly

cooled.

• Ensure the structural wall or oor can support the

weight of the unit.

• Select a location where condensate line will have the

shortest run to a suitable drain per local codes.

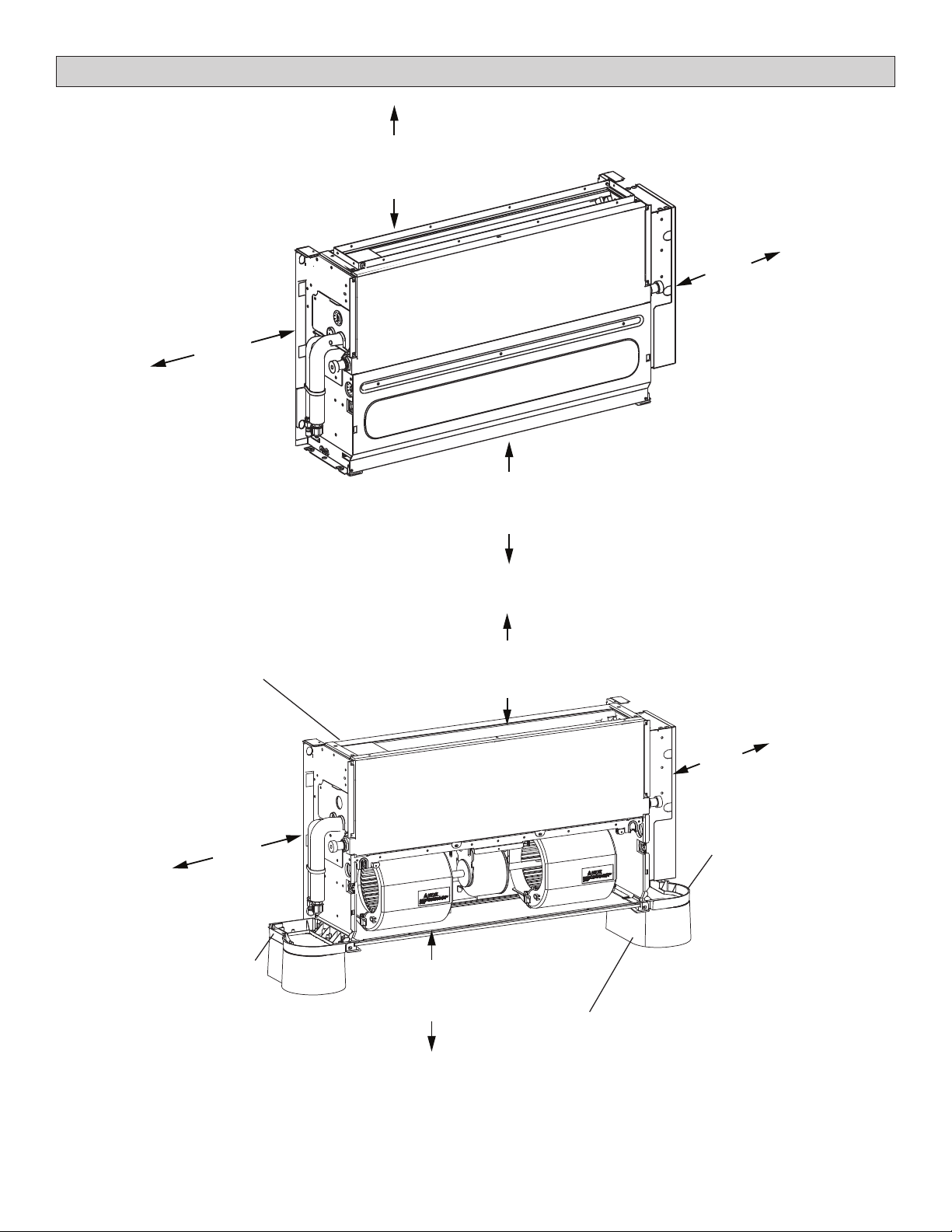

Installation

1. Locate a suitable position within the space where

maintenance access and supply air will not be restricted

or aected by obstacles. The minimum clearances are

given on Page 5.

CAUTION

!

Do not place items which may be damaged by water

under or around the indoor unit.

The unit should be installed at least 8 feet above the

oor (if possible) to ensure maximum performance

and comfort, when installed in the horizontal position

only.

• Allow sucient space around unit for proper operation

and maintenance (lter must able to be removed from

the front/bottom of the unit).

• Install unit a minimum of 3 feet away from any antenna,

power cord (line) radio, telephone, security system, or

intercom. Electrical interference and radio frequencies

from any of these sources may aect operation

• Be sure to instruct customers how to properly

operate the unit (especially maintenance of air lter,

and operation procedure) by having them carry out

operations themselves while looking at the manual

provided with the controller.

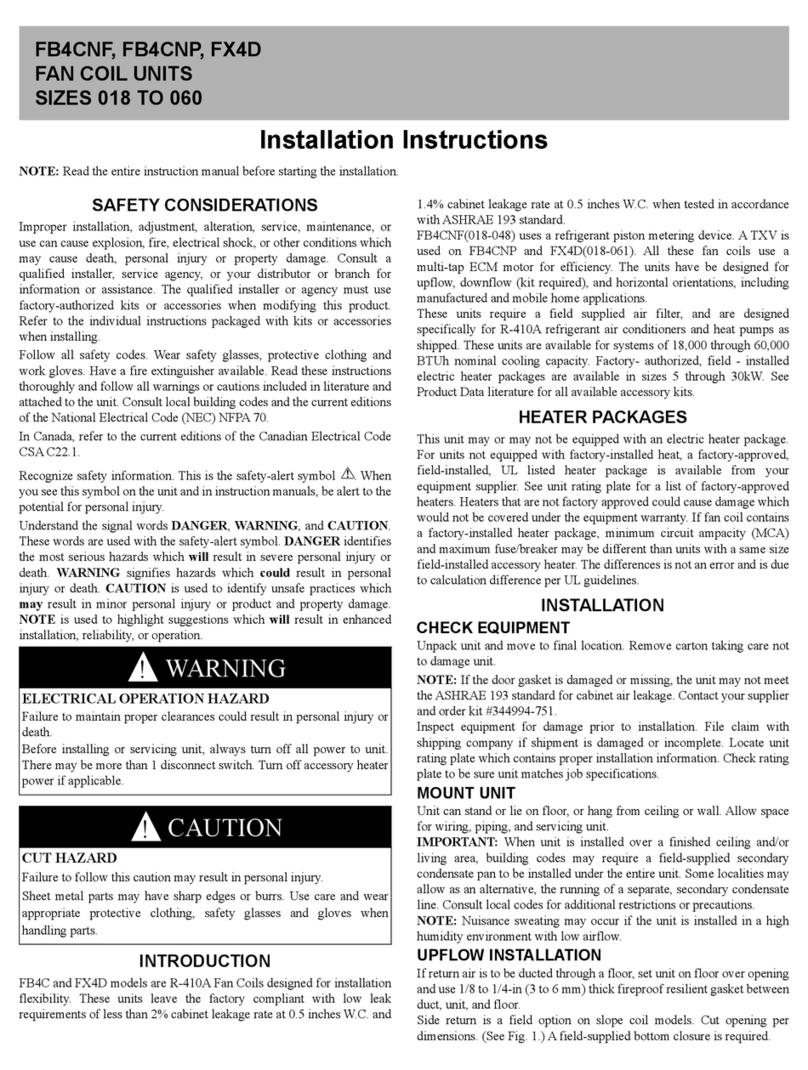

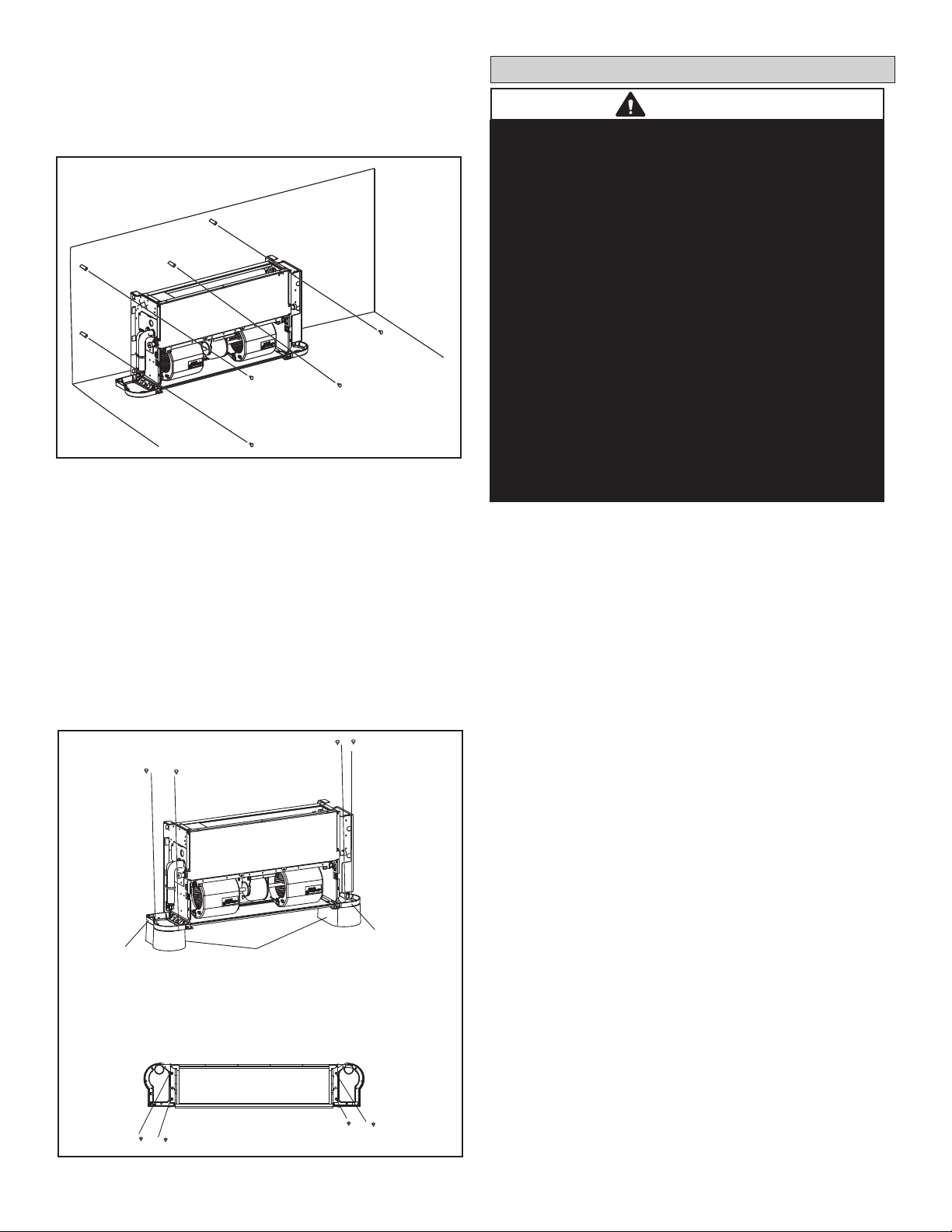

1. Remove the unit casing (VSC units only) by

removing the six screws shown in Figure 1.

After installation is complete, re-install the unit casing

by replacing the cover plate and side plate screws. It is

not necessary to replace the base screws.

2. The unit can be secured to a wall or mounted

on optional support feet V8VSA001-3P (19X68).

Figure 1. Remove Casing Assembly (VSC Only)

Casing

Assembly

Base

Screws

Cover Plate

Screws

Side Plate

Screws