2

Shipping and Packing List..............................................................................2

Indoor Transformer Requirements ................................................................2

Overview...........................................................................................................2

Equipment Interface Module Control Layout................................................3

Jumpers Pins, DIP Switch, Connections and LEDs.....................................4

Unit Type Jumper Pin Settings ................................................................................... 4

Heat Stages Jumper Pin Settings .............................................................................. 4

Heat Pump Capacity Jumper Pin Settings ................................................................. 5

Others / Vent DIP Switch Settings.............................................................................. 5

Sensor Connections ................................................................................................... 5

Dual-Fuel Terminal Connections ................................................................................ 6

Conventional Terminal Connections and Wiring Requirement ................................... 6

LED Indicators............................................................................................................ 7

Soft Disable ................................................................................................................ 7

Lennox Communicating Thermostat Commissioning (Conventional Outdoor Unit) ... 8

Operating Environment Specications .........................................................8

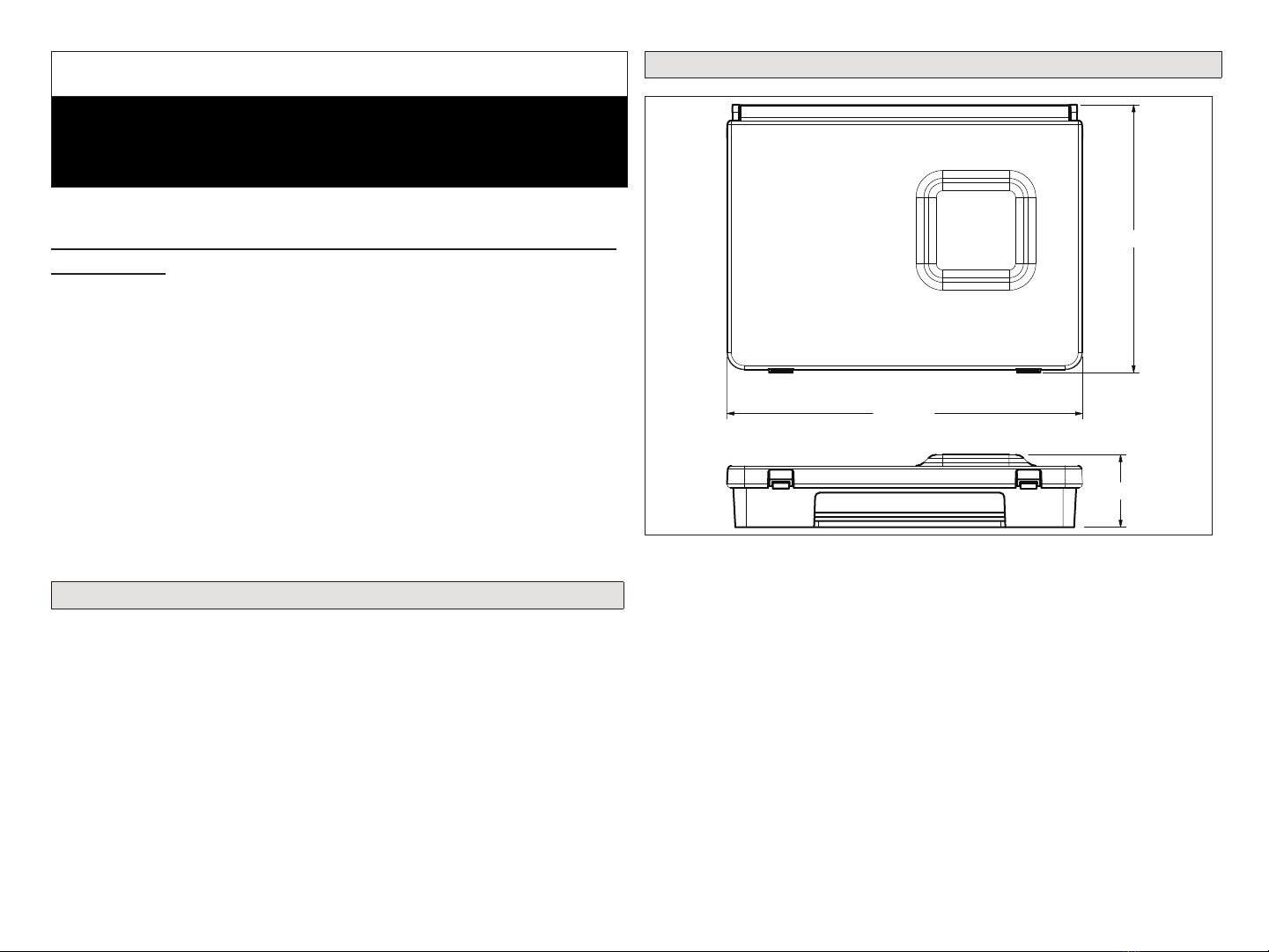

Unit Dimensions ..............................................................................................8

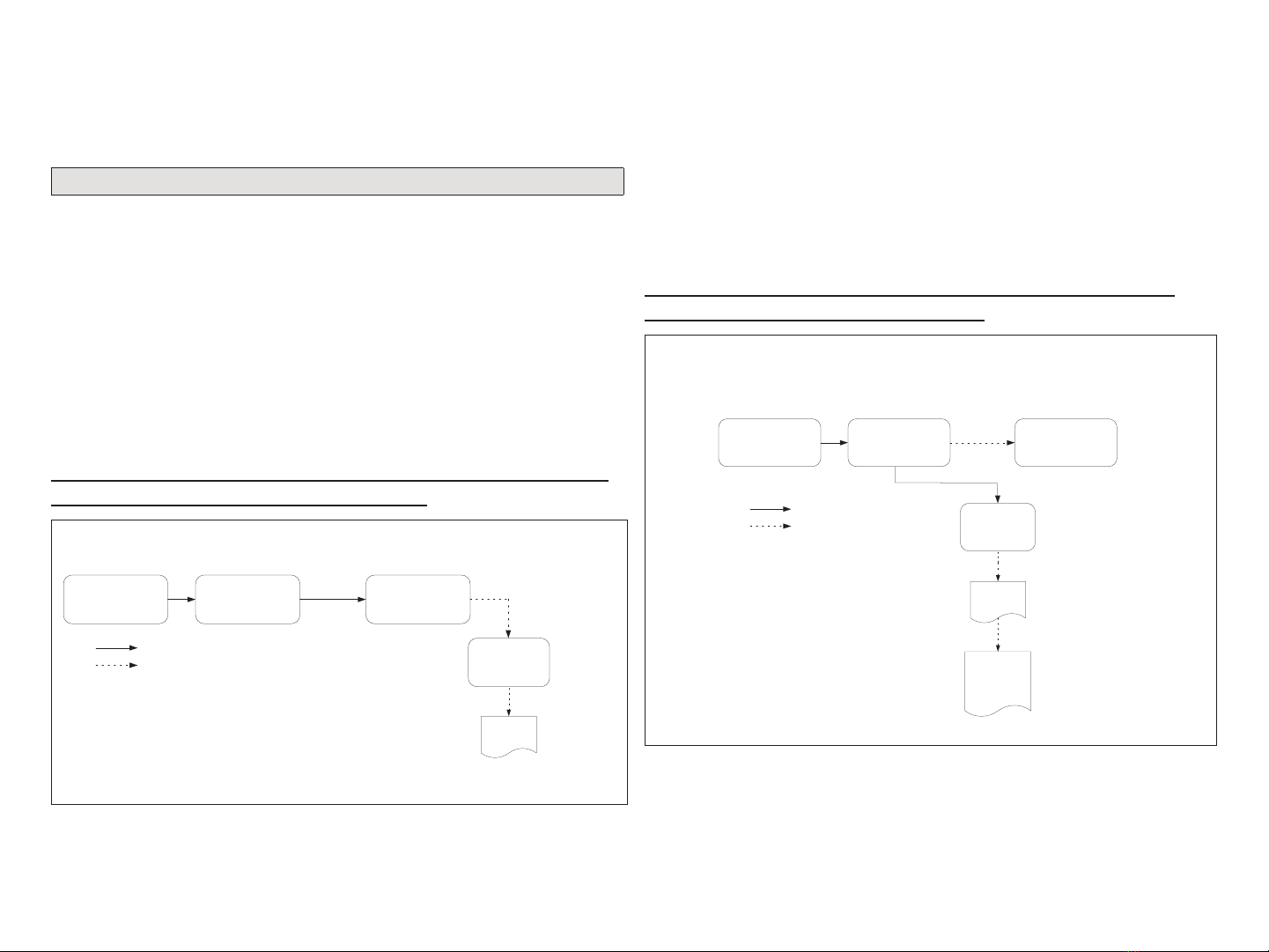

Most Common Congurations.......................................................................9

Lennox Communicating Thermostat, EIM, Non-communicating Furnace,

Non-communicating Air Conditioner or Heat Pump.................................................... 9

Lennox Communicating Thermostat, EIM, Non-communicating Air Handler,

Non-communicating Air Conditioner or Heat Pump.................................................... 9

Lennox S40 Smart Thermostat Only, EIM and Ventilation Only................................. 9

Duel-Fuel Congurations..............................................................................10

Lennox Communicating Thermostat, EIM, Lennox Communicating Furnace and

Non-communicating Heat Pump .............................................................................. 10

Lennox Communicating Thermostat, EIM, Non-Communicating Furnace and

Communicating Heat Pump ..................................................................................... 10

Lennox S40 Smart Thermostat Only, EIM (2), Lennox Communicating

Furnace, 24VAC Heat Pump and Ventilation (ERV/HRV) .........................................11

Thermostat Terminal Information ................................................................11

Field Wiring Diagrams...................................................................................12

Communicating Wiring Diagrams............................................................................. 13

Minimizing Electrical Noise....................................................................................... 14

Alert Codes and Troubleshooting................................................................22

Alert Code Types ...................................................................................................... 22

Alert Codes............................................................................................................... 23

Applications (Ventilation and Zoning) ........................................................31

ERV/HRV Applications ............................................................................................. 31

Fresh Air Damper Application................................................................................... 31

Ventilation Zoning Application .................................................................................. 31

Ventilation Control Modes ........................................................................................ 32

Thermostat Ventilation Parameters .......................................................................... 33

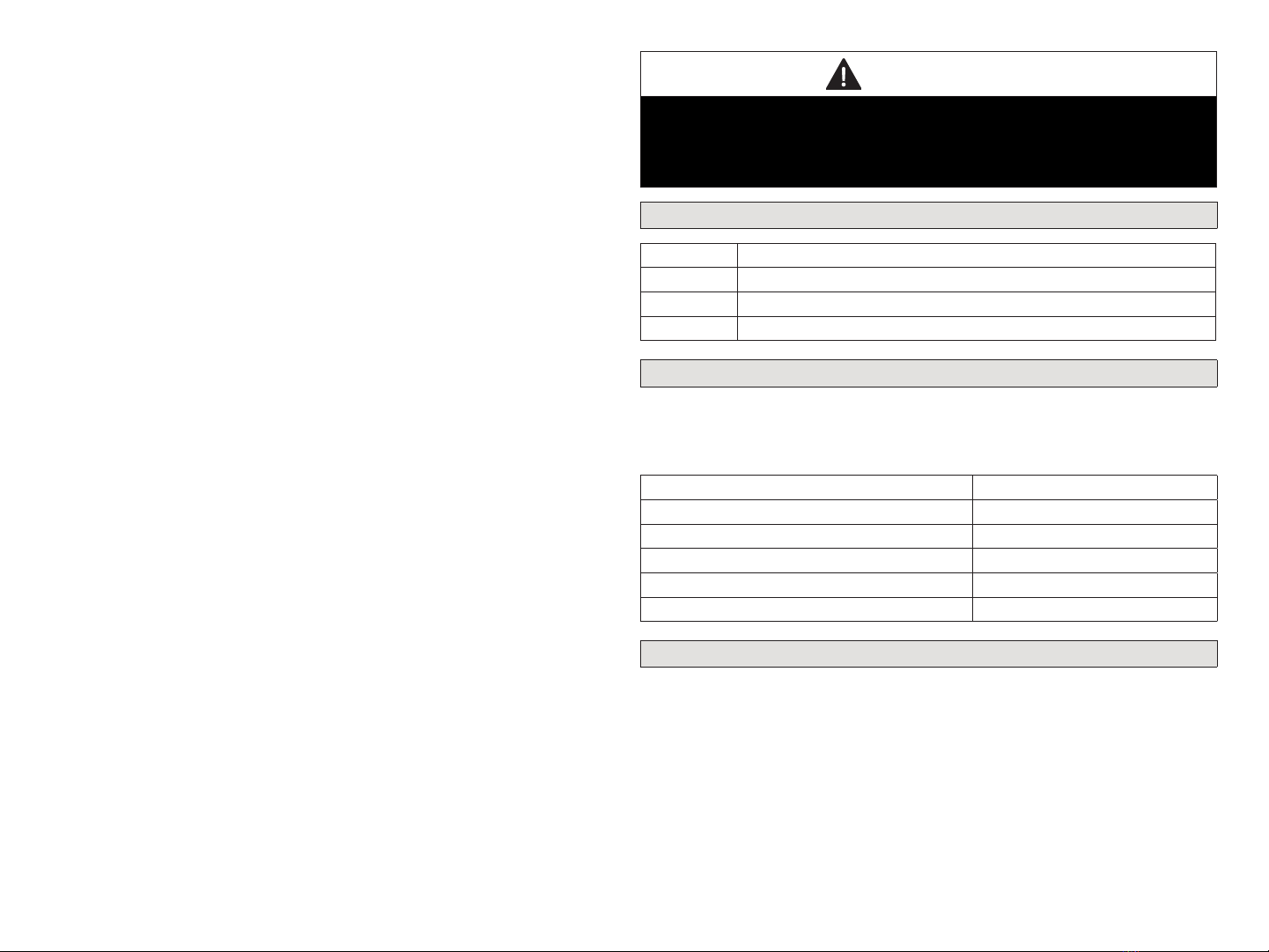

TABLE OF CONTENTS WARNING

Improper installation, adjustment, alteration, service or maintenance can

cause property damage, personal injury or loss of life.

Installation and service must be performed by a licensed professional

HVAC installer (or equivalent) or a service agency.

Shipping and Packing List

Quantity Description

1 Equipment Interface Module.

1 Installation and setup guide

1Warranty certicate

Indoor Transformer Requirements

The following lists the required indoor unit transformer rating (VA) for spe-

cic congurations.

Table 1. System VA Loading Chart

Conguration Minimum Transformer Rating (VA)

2-Stage HP, 3-Stage Electric heat and Fresh Air 70

2-Stage HP, 2-Stage Furnace (with tempering) 70

2-Stage HP, 2-Stage Furnace (without tempering) 50

2-Stage AC, 2-Stage Furnace 40

Single stage fresh air damper 6 to 12VA

Overview

The Equipment Interface Module (EIM) is used with an Lennox commu-

nicating thermostat using the R, i+, i-, and C terminals. The EIM is the

interface between non-communicating HVAC equipment and Lennox com-

municating HVAC equipment.

NOTE: EIM will support single-stage outdoor units with single-stage or

variable-stage indoor furnaces.

For ventilation or zoning applications, see “Applications (Ventilation and

Zoning)” on page 31.