Contents

Contents . . . . . . . . . . . . . . . . . i

Safety . . . . . . . . . . . . . . . . . . iii

Chapter 1. Introduction . . . . . . . . . 1

Specifications . . . . . . . . . . . . . . . . 1

Management software . . . . . . . . . . . . . 3

Tech Tips . . . . . . . . . . . . . . . . . . 3

Security advisories . . . . . . . . . . . . . . 3

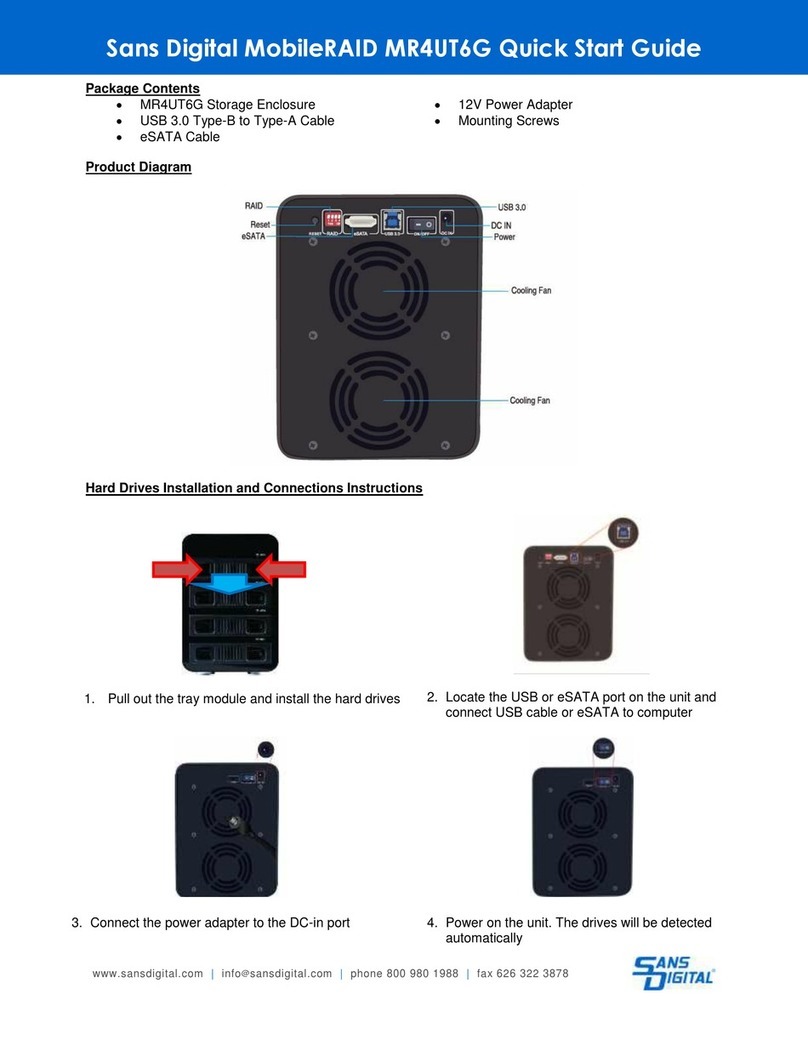

Chapter 2. System components. . . . . 5

Front view . . . . . . . . . . . . . . . . . . 5

Rear view . . . . . . . . . . . . . . . . . . 6

Rear view LEDs . . . . . . . . . . . . . . . . 7

Chapter 3. Rail kit installation

instructions . . . . . . . . . . . . . . 11

DM/DE Series 2U2 , 3U, U rail kit installation

instructions . . . . . . . . . . . . . . . . 11

DM/DE Series 2U12 rail kit installation

instructions . . . . . . . . . . . . . . . . 12

Chapter 4. System installation and

setup . . . . . . . . . . . . . . . . . . 17

Installation and setup high-level workflow . . . . 17

Preparing for installation . . . . . . . . . . . 17

Installing the hardware . . . . . . . . . . . . 18

Cabling a two-controller switchless cluster, unified

network configuration . . . . . . . . . . . . 19

Cabling a two-controller switchless cluster,

Ethernet network configuration . . . . . . . . . 20

Cabling a switched cluster, unified network

configuration . . . . . . . . . . . . . . . . 20

Cabling a switched cluster, Ethernet network

configuration . . . . . . . . . . . . . . . . 21

Cabling controllers to drive shelves . . . . . . . 22

Cabling storage on a two-controller switchless

cluster with no external storage . . . . . . . 22

Cabling storage on an HA pair with external

drive shelves . . . . . . . . . . . . . . 22

Completing system setup and configuration. . . . 23

Chapter 5. Hardware replacement

procedures . . . . . . . . . . . . . . . 27

Hot-swapping an internal disk drive . . . . . . . 27

Replacing the caching module . . . . . . . . . 28

Workflow diagram . . . . . . . . . . . . 28

Shutting down the degraded controller . . . . 29

Opening the system . . . . . . . . . . . 30

Replacing a caching module . . . . . . . . 32

Reinstalling the controller module . . . . . . 33

Running system-level diagnostics . . . . . . 3

Completing the replacement process . . . . 36

Replacing the NVMEM battery . . . . . . . . . 36

Workflow diagram . . . . . . . . . . . . 36

Shutting down the degraded controller . . . . 37

Opening the system . . . . . . . . . . . 38

Replacing the NVMEM battery . . . . . . . 0

Reinstalling the controller module . . . . . . 1

Running system-level diagnostics . . . . . . 2

Completing the replacement process . . . . 3

Swapping out a power supply . . . . . . . . .

Workflow diagram . . . . . . . . . . . . 5

Completing the replacement process . . . . 5

Replacing the controller module . . . . . . . . 5

Workflow diagram . . . . . . . . . . . . 6

Shutting down the degraded controller . . . . 7

Replacing the controller module hardware . . 8

Restoring and verifying the system

configuration . . . . . . . . . . . . . . 56

Completing system restoration . . . . . . . 60

Completing the replacement process . . . . 6

Important information after replacing the

controller module . . . . . . . . . . . . 6

Replacing a DIMM. . . . . . . . . . . . . . 6

Workflow diagram . . . . . . . . . . . . 6

Shutting down the degraded controller . . . . 65

Opening the system . . . . . . . . . . . 66

Replacing the DIMMs. . . . . . . . . . . 68

Reinstalling the controller module . . . . . . 70

Running system-level diagnostics . . . . . . 71

Completing the replacement process . . . . 73

Replacing the boot media . . . . . . . . . . . 73

Workflow diagram . . . . . . . . . . . . 73

Opening the system . . . . . . . . . . . 7

Replacing the boot media . . . . . . . . . 76

Transferring the boot image to the boot

media . . . . . . . . . . . . . . . . . 77

Completing the replacement process . . . . 79

Replacing the real-time clock battery . . . . . . 79

Workflow diagram . . . . . . . . . . . . 80

Shutting down the degraded controller . . . . 80

Opening the system . . . . . . . . . . . 81

Replacing the RTC battery . . . . . . . . . 83

Reinstalling the controller . . . . . . . . . 8

© Copyright Lenovo 2019, 2023 i