INTRODUCTION

Dear Customer,

We would like to thank you for choosing our product and we wish to provide you with some information about

this entirely unique and exclusive product, the FAST Box.

In over 50 years of operation, the Sito Group has achieved a series of goals and advances that have con-

tributed towards building a position of leadership in the aftermarket motorcycle exhaust system sector.

The most recent advance is called LeoVince Electronic Systems, a completely new department reporting to

LeoVince’s Research and Development Department. LeoVince Electronic Systems was created for the develop-

ment of electronic control units (ECUs) for engine management, to be used, initially, in conjunction with our own

LeoVince X3 (off-road) systems.

The goal of LeoVince electronic Systems is to create a unique and optimized “system”, i.e. producing an exhaust

system and an ECU, the latter being configured for use with both the exhaust and the motorcycle.

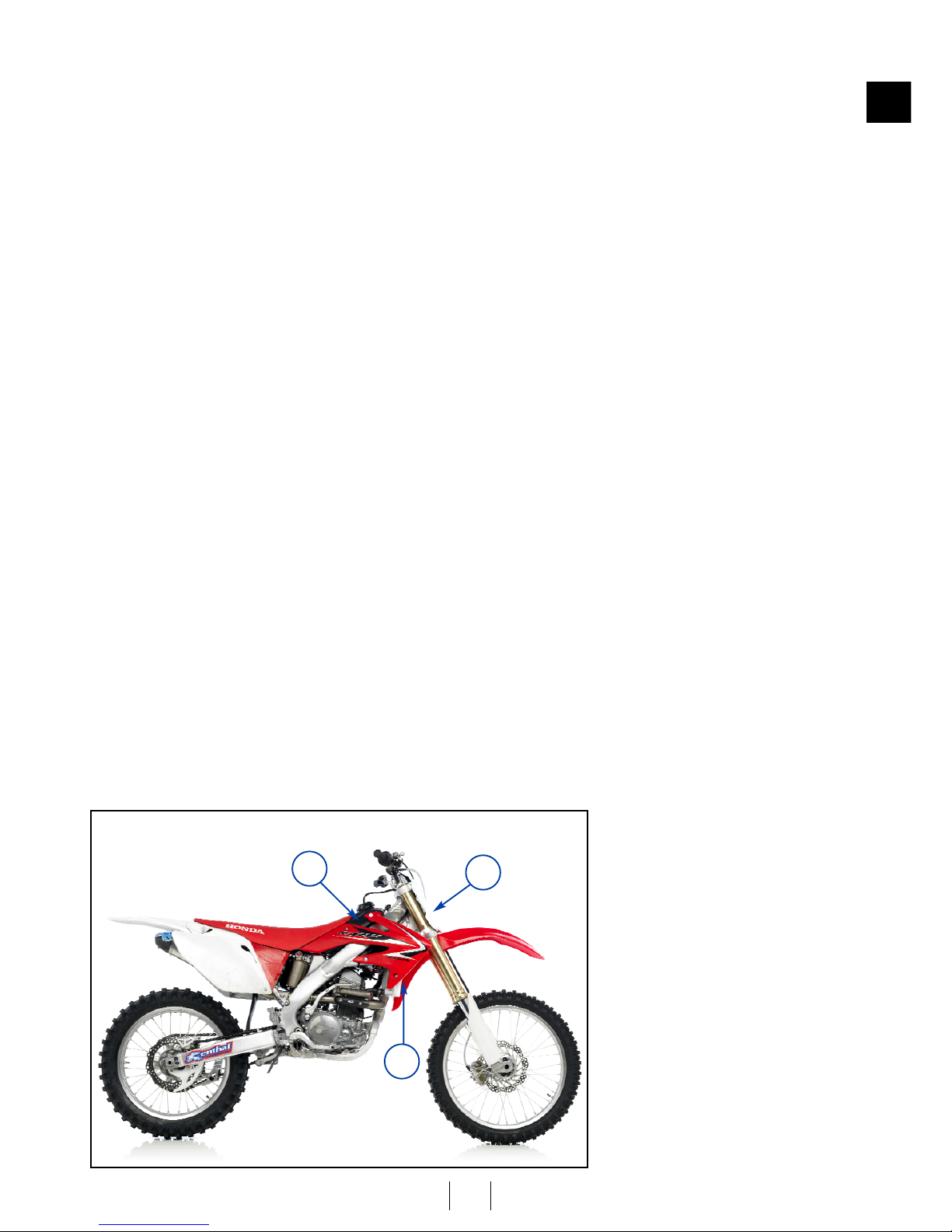

For the initial offering of the FAST Box, motorcycles designed for motocross, enduro and supermotard have been

chosen, ones specifically using a 4-stroke single cylinder engine with carburetor, so the FAST Box can be used

in conjunction with the LeoVince X3 line of exhaust systems.

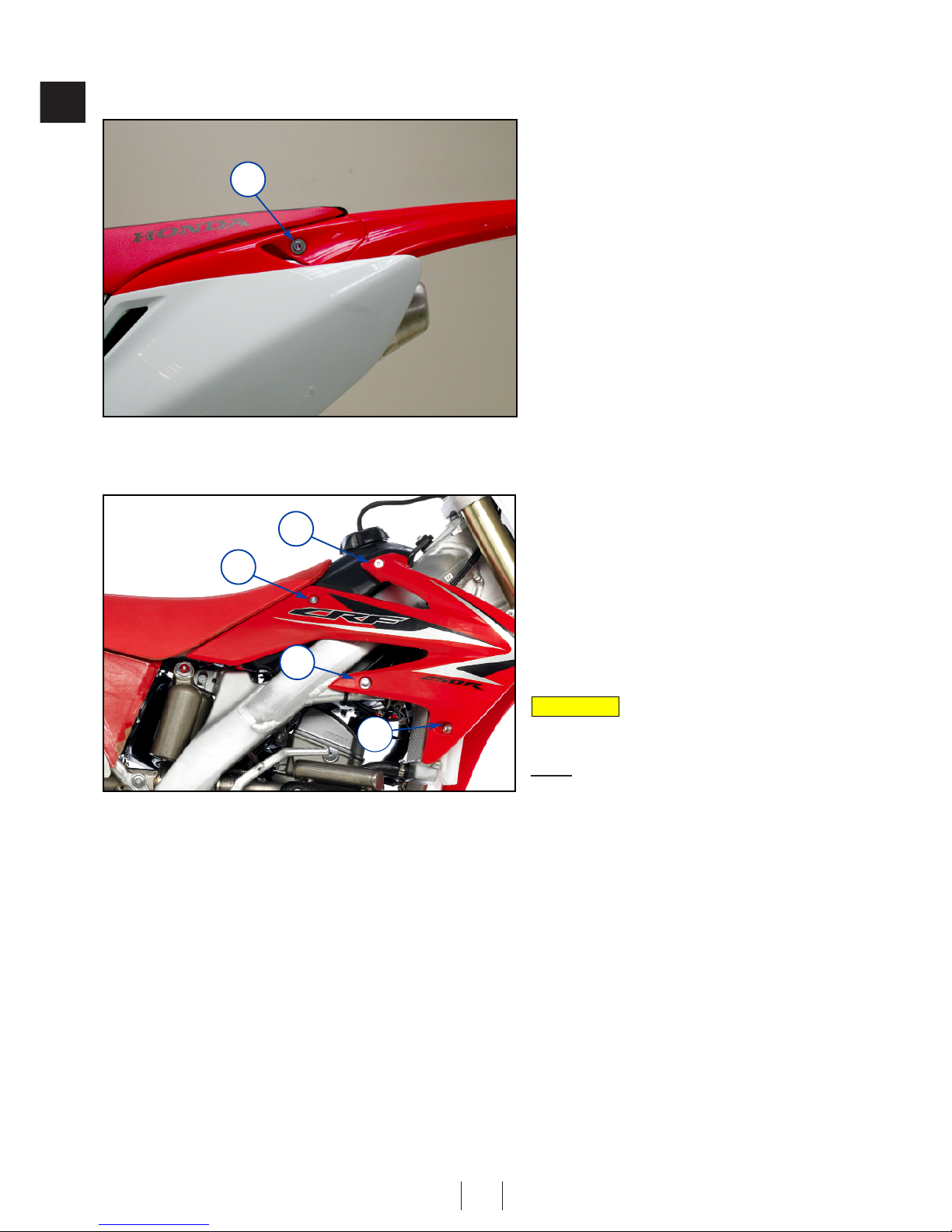

In this case, the ECU replaces the existing OEM ECU and is not used in tandem with the original, as it is pos-

sible to do on scooters and street bikes with fuel injection.

The LeoVince Electronic Systems engineers have designed and produced the FAST Box entirely within the com-

pany in close collaboration with the technicians who produce our exhaust systems, thereby obtaining a highly

focused and integrated product.

The ECU operates in extremely demanding mechanical, thermal and environmental conditions therefore TÜV

Italia has carried out all the inspection tests, guaranteeing its reliability.

After passing the bench tests, the definitive prototypes were handed over to users and professional riders to

carry out a series of tests “in the field”. Then, after some final adjustments, the commercial product was final-

ized and production begun.

This product represents the first steps in a diversified project, with the development program already looking

towards scooters, single and multi-cylinder fuel injected motorcycles.

Welcome to the FAST age!

FOR FURTHER INFORMATION:

3

GB