15

MAINTENANCE

(F)LS (ES, IA, MV, PX), FCR

3-phase asynchronous TEFV brake motors

5025 en - 2013.03 / a

LEROY-SOMER

en

4 - MAINTENANCE

Always disconnect the brake motor from its power supply

before working ont the brake.

4.1 - Dismantling for FCR brake motors

- Dismantle the brake motor using the correct tools (hub remover,

bearing remover, plastic or leather mallets, correctly sized keys and

screwdrivers, circlips pliers, etc.).

- Disconnect the brake motor from its power supply.

- Open the terminal box, locate the wires and mark their position

(power supply to the motor and the brake, probes, etc.).

- Disconnect the power supply wires from the motor terminal block and

the brake power supply unit (+ and - terminals).

- Unscrew the handle of the lever 53.1 when tted (following procedure

§4.2).

- Unscrew the cover screws 40, remove the steel cover 23.

- Remove the brake nut 24.

- Remove the sealing ring 50.

- Place an extractor with 2 arms pressing on the end of the shaft and

two arms on the armature pins 11.

- Remove the brake lining fan 15 and the armature 11.

- Mark the position of the springs 28 and remove them.

- Unscrew the assembly rods 5.

- Put aside the front shield 3.

- Pull out the stator housing 1 taking care not to damage the winding.

- Remove the internal circlip 6 to free the brake shield 8.

- Clean the parts:

• by blowing the electrical parts (do not use solvents or products

containing moisture);

• using a non slippery degreasing agent for the mechanical parts;

• using a scraper for the anges;

• if parts 11 and 15 are slippery: change part 15 and degrease part 11

with a non slippery degreasing agent.

- Change the seals and the bearings.

- Disconnect the bridge rectier and check the insulation of the stator

(>10 megOhms).

- Mark all faulty parts so that replacement parts can be ordered.

4.2 - Reassembly for FCR brake motors

- Lightly grease the shafts and bearing cages.

- Cover the seal lips with grease and put the seal back carefully (use

the protection sockets of the drive shaft keyway).

- Working in reverse order, assemble the motor.

- Replace the pressure springs 28, change the sealing ring 50.

- Position the housing 11, reposition the brake lining fan 15.

- Adjust the air gap (see above).

- Position the sealing ring 50.

- Fit on the lever 53 (following procedure bellow).

- Replace the steel cover 23 and x it using the cover screws 40.

- Reconnect the brake power supply unit, and any probes, and then the

motor - making sure that the wires are in the correct order - and close

the terminal box.

- Check that it works correctly (if this is not the case check that the

release lever is in the right position before coupling to the machine).

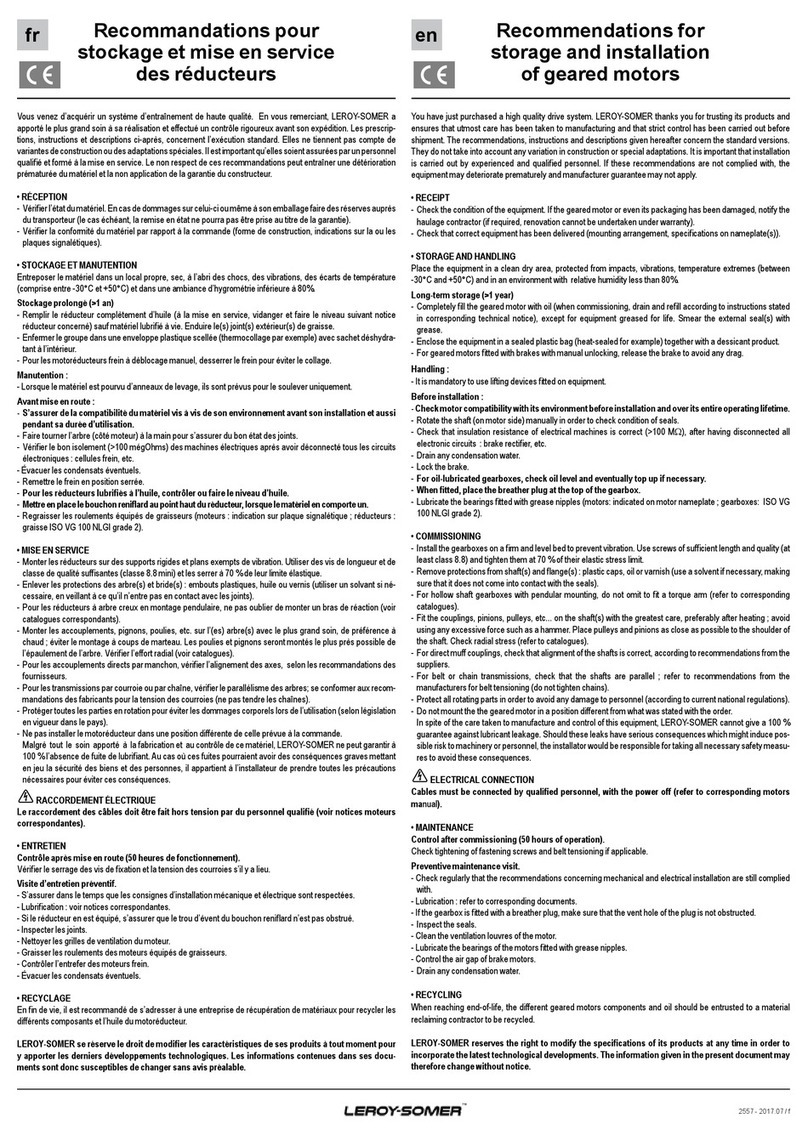

Desmantling, reassembling the brake lever (option: DLRA)

Desmantling the brake lever DLRA

- Unscrew the handle of the lever 53.1 (if tted on the hand release

lever).

- Unscrew the cover screws 40, which keep the cover 23 in place.

- Unscrew the two screws 53.3, release the spring 53.4.

- The hand release 53.2 may be removed.

Reassembling the brake lever DLRA

- Position the hand release 53.2 around the brake housing.

- Assemble the screw on the right 53.3 (when viewed from the output

shaft of the motor).

- Assemble the other screw 53.3 and get ready with the spring 53.4.

- Compress the spring 53.4 close to the maximum distance larger than

the section of brake lever 53.2 and smaller than the distance between

the screws on the brakes housing.

- Assemble the cover 23 and the screws 40.

- The handle 53.1, clipped to the stator, will be assembled, if needed to

release the brake.

4.3 - Adjustments

Adjusting the air gap

The air gap needs to be adjusted when the release mechanism no

longer functions normally.

- Unscrew the handle of the lever 53.1 when tted (following procedure

§4.2).

- Unscrew the cover screws 40 which keep the steel cover 23 in place.

- Remove the steel cover 23. Unscrew the brake nut 24, and remove

the sealing ring 50. Clean the parts: removal of lining’s friction dust.

Insert a 0.4 mm shim between the brake shield 8 and the armature 11.

Tighten the brake nut 24 so as to obtain working play of 4/10th between

armature 11 and brake shield 8 (the shim should slip slightly).

- The brake nut 24 should be changed after 3 adjustments.

- Replace the sealing ring 50. Replace the lever 53 (following proce-

dure §4.2).

- Replace the steel cover 23 and tighten the cover screws 40.

Adjusting the braking torque

- The braking torque depends on the number of springs and their

colour; use the values shown in the table on §4.4.

53.1

53.2

53.3

53.4

4.4 - Braking torque (N.m values given for indication only ; in case of Standards’ limitation, please consult us)

No. of

springs

LS 71 FCR (F)LS 80 FCR (F)LS 90 FCR (F)LS 100 FCR (F)LS 112 FCR LS 132S FCR (F)LS 132M1 FCR LS 1601 FCR

Colour N.m Colour N.m Colour N.m Colour N.m Colour N.m Colour N.m Colour N.m Colour N.m

3white 1.2 blue 2 green 4 green 4 orange 16 orange 16 yellow 40 yellow 40

4white 1.6 blue 3 green 6 green 6 orange 22 orange 22 yellow 50 yellow 50

5white 2 blue 3.5 green 8 green 8 - - - - - - - -

6white 2.4 blue 4.5 green 9 green 9 orange 32 orange 32 yellow 80 yellow 80

8- - - - - - - - orange 43 orange 43 yellow 105 yellow 105

9- - - - - - - - - - - - yellow 120 yellow 120

12 - - - - - - - - - - - - yellow 160 yellow 160

3blue 4 green 6 grey 15 grey 15 - - - - - - - -

4blue 5 green 8 grey 20 grey 20 - - - - - - - -

5blue 6 green 10 grey 25(32*) grey 25(32*) - - - - - - - -

6blue 7.5 green 12(15*) - - - - - - - -

1(F)LS 132M, LS 160 : braking torque to be chosen between 40 to 80 Nm or 105 to 120 Nm

(*) : with machined armature plate