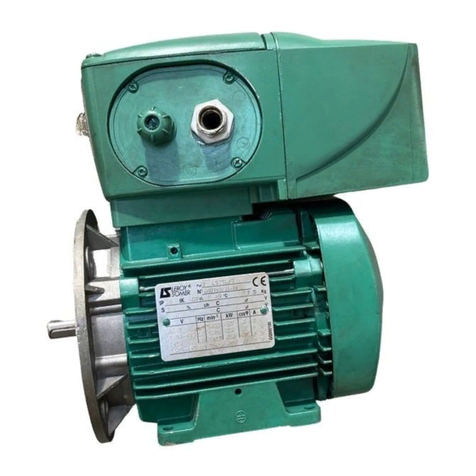

GEARED MOTOR Mb 3901

1 - STORAGE and INSTALLATION

1 - 1 Storage:

The geared motor must be stored under cover, protected against

inclement weather and possible pollutants. It should be kept in a humidity

lower than 98% and at a temperature between -10°C and +50°C.

If requested at the time of ordering (internal parts), geared motors

supplied without oil are protected against corrosion by pulverisation with

anti-corrosion oil, carried out in the factory. Protection lasts for a

maximum period of 6 months.

In the case of geared motors supplied with oil up to the level, it is

advisable to operate the motor for 10 minutes every 2 months. If this is

not possible, the machine should be completely filled with oil which

should be taken down to the level on installation.

1 - 2 Assembling transmission devices :

Motor coupling : put the V seal 103 . 10mm before the output shaft shoul-

der and perpendiculary to the axis. Insert Epexelf MO2 grease (or equiva-

lent) into the worm bore and the bearing 87. The quantity of grease must

be adequate to make a reserve in the bore back.

It is advisable to assemble the transmission devices before installing

the gearbox in its final environment.

Before assembling the transmission devices, remove the protections

on the shaft end(s) and flanges. If a solvent is used, ensure that it does not

come into contact with the seals.

For assembly, use the tapped hole in the shaft end. According to DIN

332, the transmission devices should preferably be heated to a

temperature of around 80°C. In no circumstances should a hammer be

used, as shocks and blows to the shaft end will damage the bearings.

Transmission devices should be assembled as near as possible to the

shoulder of the shaft. For chain transmissions, check that the shafts are

parallel and always follow the manufacturer's recommendations.

1 - 3 Installing - Fixing :

The gearbox itself (without the motor) must always be handled using

2 x 290 lifting rings.

The geared motor must be handled as follows :

- position B (horizontal motor) : lifting ring 290 situated at the front

of the gearbox (opposite the motor) + 2 motor shackles.

- position V (vertical motor) : 2 hooks in the 2 holes in the feet

behind the motor (motor side) + 2 motor shackles.

Installation of a Leroy-Somer geared motor or gearbox must be

carried out so that ventilation air can circulate freely. Equipment should

be installed on a flat, rigid baseplate capable of withstanding

mechanical vibrations and resistant to the effects of torsion or flexion.

The output shaft must be carefully aligned, and the foot mounting should

not cause any mechanical tension on the gearbox. The foot housing must

be flanged on its support by 4 x M24 screws (class 10-9 minimum) of

sufficient length. The tightening torque must ensure that the screws are

tightened to a tension of 70% to 75% of the elasticity of the screw

material. It is strongly recommended that the screws are locked using an

adhesive or appropriate mechanical solution. It is also advisable to fit

M24 NFE 25-513 plain washers under the screw heads.

1 - 4 Electrical connection of geared motor :

Check that the motor supply voltage conforms to the mains supply

voltage. Wiring diagrams can be found on the inside of the motor terminal

box cover.

Cross sections, conductor type and protective devices conform to

specifications and current standards.

Electrical connections must be carried out by qualified personnel

adhering to the current safety regulations.

1 - 5 Commissioning

Replace the 255 plug, situated on the top, with the 257 gauge

delivered with the gearbox. Check the conformity of the gauge depending

on the operating position of the gearbox. The marking under the gauge

head must be : position B = 155 to 165 mm, position V = 120 to 130 mm.

Check the oil level. Fill as required, (see lubrication).

2 - RUNNING-IN

2 - 1 First start-up

In order to increase the life of the gearbox, it is advisable to run it in

at 50% of the rated power for around 48 to 96 hrs, then to switch

gradually to the rated load for a few hundred hours. The oil, still hot,

should be drained after this period.

2 - 2 After 50 hours of operation

Check the state of the seals. Check the oil level, the tightness of the

gearbox fixing screws and the transmission rung according to the

manufacturer's recommendations.

2 - 3 Maintenance

The Leroy-Somer gearbox or geared motor only requires limited

maintenance. However, it is recommended that the oil level be regularly

checked.

3 - SECTIONAL VIEW and PARTS LIST

The parts list on page 4 corresponds to diagram 502638 on page 5.

4 - LUBRICATION

4 - 1 Type of lubricant:

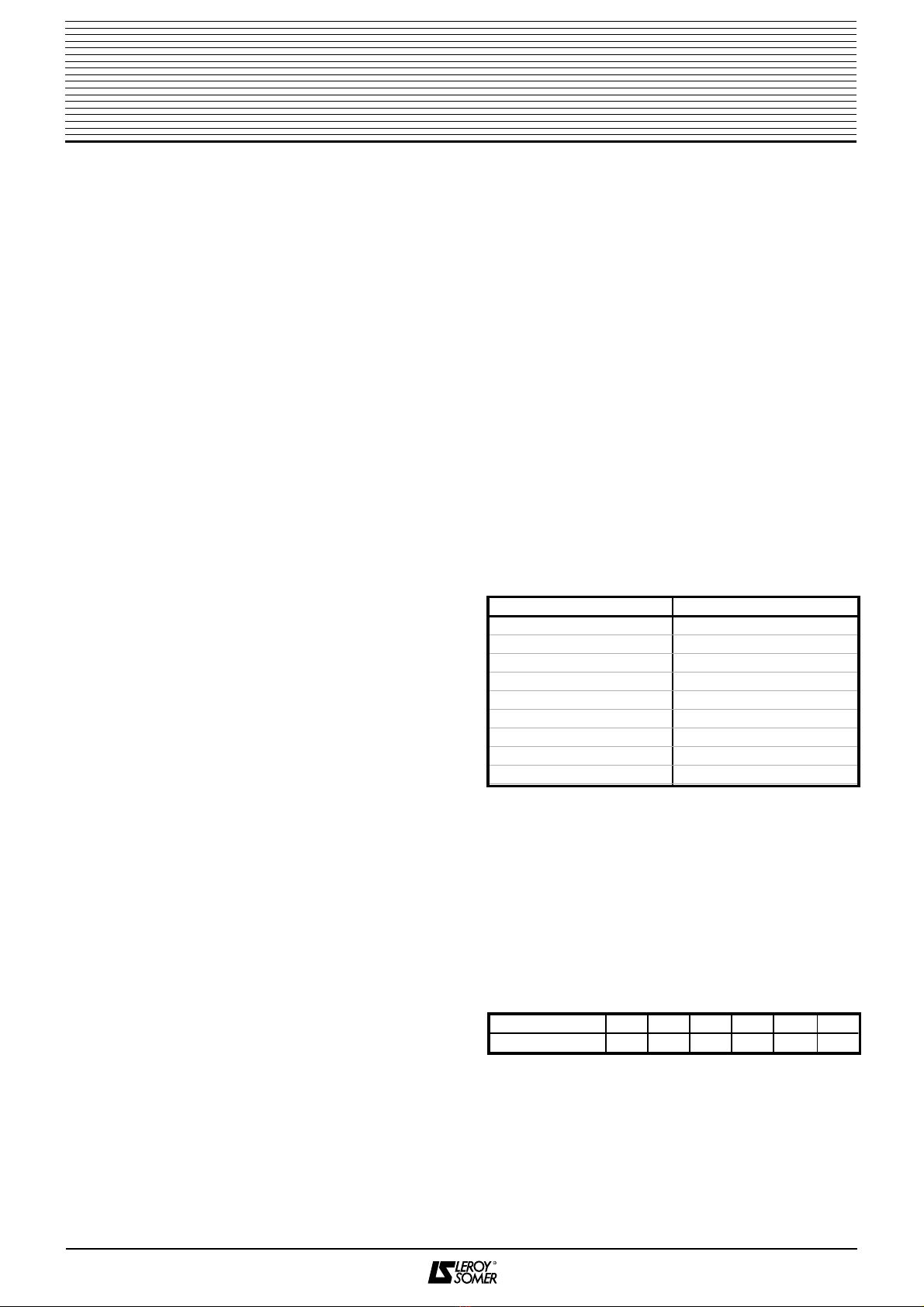

Leroy-Somer Motors recommends the use of Shell Tivela WB oil, a

polyalkylene glycol synthetic lubricant with ISO VG 220 viscosity, which

has been approved by its Technical Department. This lubricant can only

be substituted by the following lubricants with the same class of viscosity

(ISO VG 220) and of the same type (synthetic polyalkylene glycol).

These lubricants have not been approved by LSM, and the user or

recommending retailer is responsible for their use.

CAUTION:

These specifications, instructions and descriptions concern

standard operation. They do not take account of non-standard

versions or special adaptations. If these recommendations are not

adhered to, the gearbox or geared motor may suffer premature

deterioration and the guarantee may be invalidated.

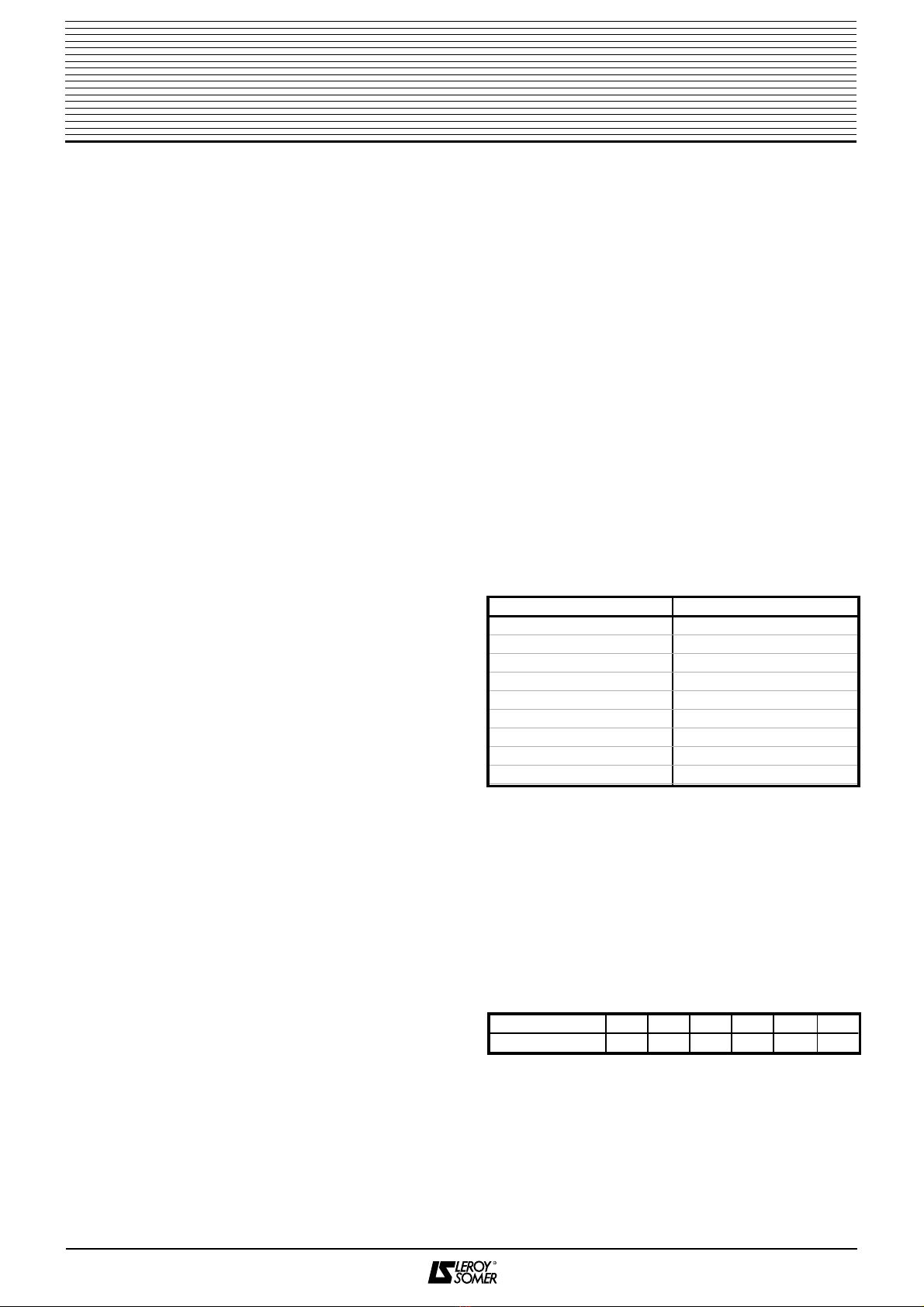

4 - 2 Draining:

In order to reduce pollution which might harm the bearings and seals,

it is important to first drain the oil after a maximum of 1000 hrs of

operation (see "comissioning and running-in"). The drainage interval

depends on the service conditions. If Shell Tivela WB oil is used, we

recommend the following intervals between oil changes :

Drainage can be carried out by use of gravity, removing the 255 plug

situated at the lowest point and/or by inserting a pump into the port on top

of the gearbox. The lubricant should still be warm (for better drainage of

particles in suspension).

Geared motor

Multibloc 3901 - TSA 50

2

SUPPLIER REFERENCE

BP ENERGOL SG-XP

CASTROL ALPHA PG

ICI TRIBOL TRIBOL 800

ICI TRIBOL TRIBOL 1310

KLUBER SYNTHESO HT

LUBRILOG LUBRILOG LY PG

MOBIL GLYGOYLE 30

TEXACO SYNLUBE CLP

TOTAL CORTUSA SY

Output power (kW) 22 18,5 15 11 9 7

Drainage interval (hrs) 7 300 7 300 8 000 9 000 10 000 10 000