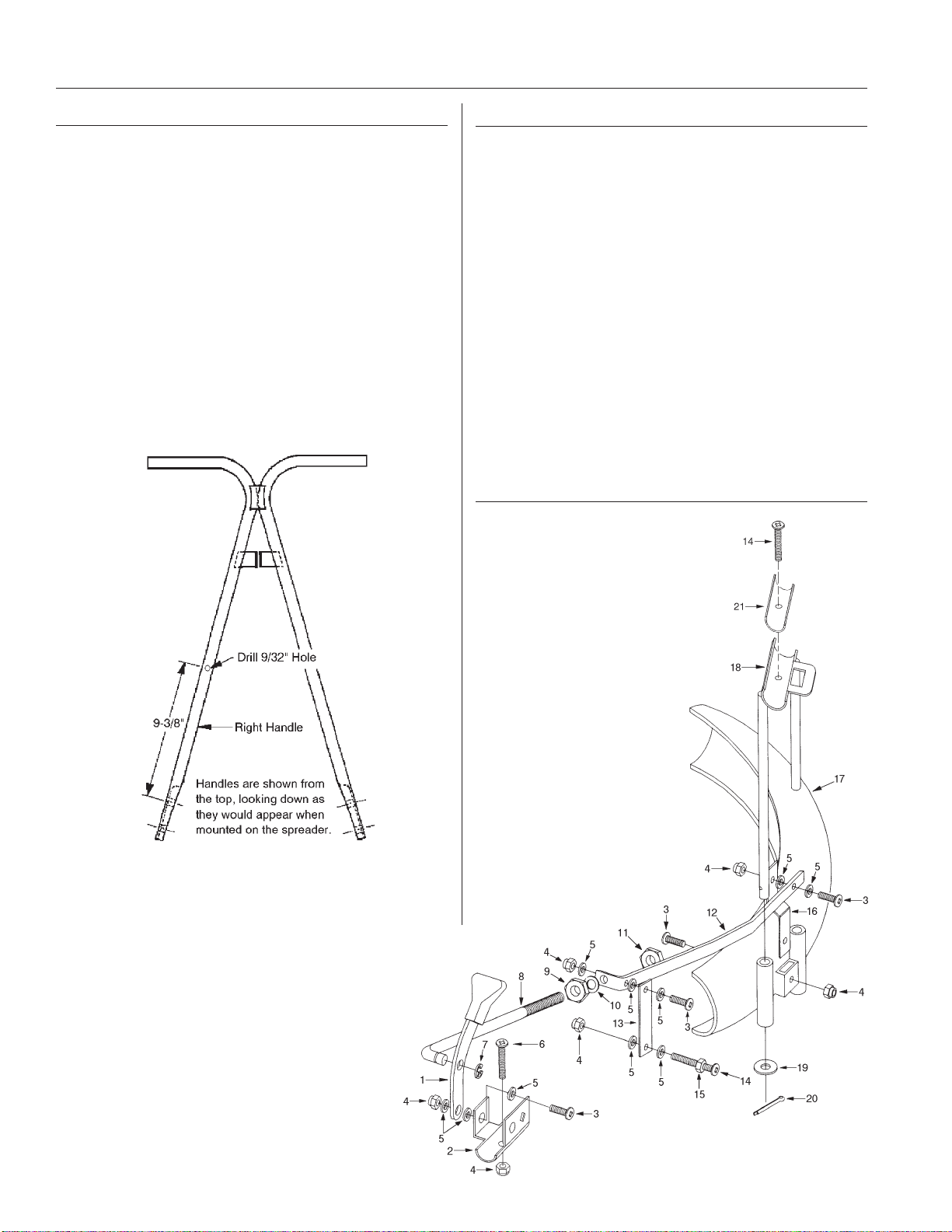

Note: To order replacement parts for your spreader, you need to

knowthe followinginformation:

A..Does your spreader have an epoxy-finish frame (white) or a

stainlesssteel frame(silver).

B.. Is it a standard wheel or a hi-wheel spreader. (The spreaders

can be identified by the numbers embossed on the side wall

of the tires. The standard wheel spreaders use a 4.10/3.50-4

tire while the hi-wheel spreaders use a 13x5.00-6 tire.)

C..If it is a standard wheel spreader, does it have an original

frame or a uni-frame. (Measure the vertical dimension

between the axle bearing mounts and the underside wheel

spreader, does it have an original frame or a uni-frame.

(Measure the vertical dimension between the axle bearing

mounts and the underside of the frame beneath the hopper. If

this dimension is 103/4" you have an original frame. If this

dimension is 123/4" you have a hi-wheel or uni-frame.)

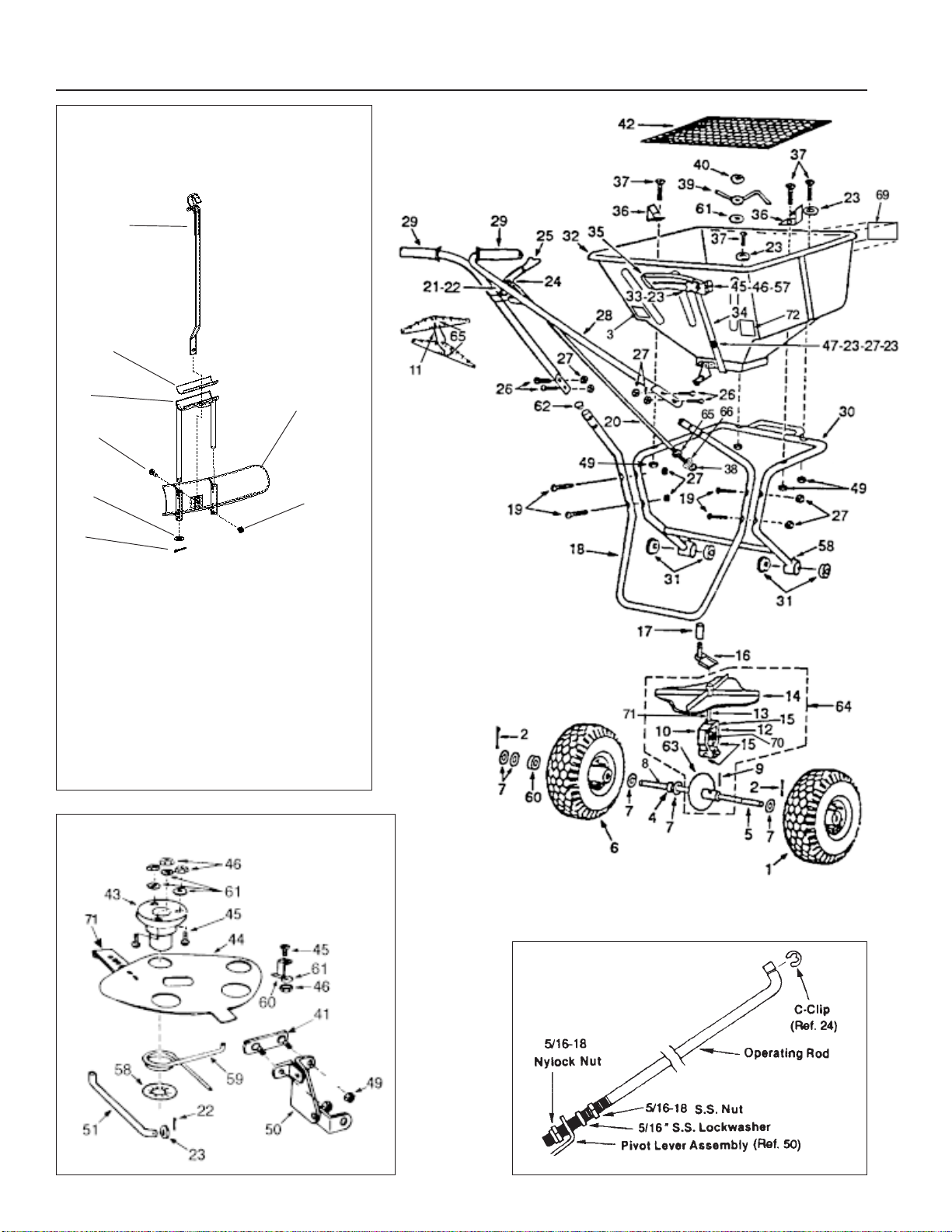

Rotary Spreaders — Parts List

2

Ref. Item No.

No. No. Description Used

1 060011 Drive Wheel, Steel - Standard ........................ 1

010048 Drive Wheel, Steel-Hi-Wheel.......................... 1

019789 Drive Wheel, Composite-Standard ................. 1

018901 Drive Wheel, Composite - Hi-Wheel............... 1

2 060012 Cotter Pin, 3/16 x 1-3/4, SS ............................ 2

3 011202 80 lb. Capacity Decal...................................... 1

4 020019 Axle Collar ...................................................... 1

5 020700 Axle ................................................................. 1

6 060016 Idler Wheel, Steel-Standard ........................... 1

010047 Idler Wheel, Steel - Hi-Wheel .........................1

018900 Idler Wheel, Composite - Standard ................ 1

019790 Idler Wheel, Composite-Hi Wheel .................. 1

7 060017 Spacer Washer, SS ........................................8

8 010985 Set Screw ....................................................... 1

9 060019 Roll Pin, 5/32 x 1-/14, SS ............................... 1

10 064000

Gear Support Assembly (Incl. 3 ea. Ref.15)w/

Fittings ............................................................

3

11 009941 Chain .............................................................. 1

12 060022 Roll Pin, 1/8 x 7/8, SS.....................................1

13 009004 Impeller Shaft (8-1/2" long)............................. 1

060023 Impeller Shaft (6-7/8" long) and Roll Pin

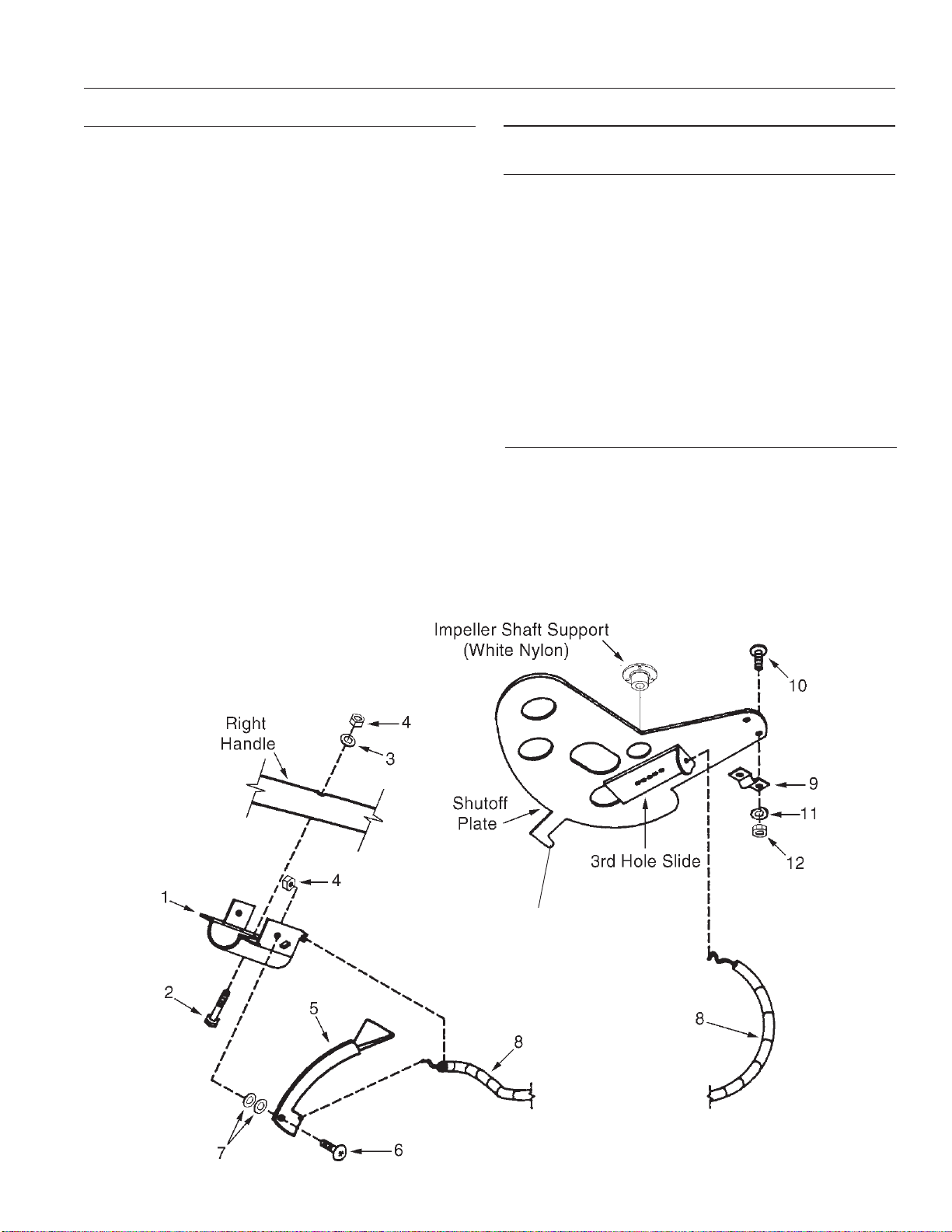

1/8 x 7/8, SS (Replacement for standard

wheel spreaders with original frames. See

Note C above.)................................................ 1

14 030317 Impeller ........................................................... 1

15 060095 Grease Fitting (Press-In Type) ....................... 3

16 030322 Agitator Arm and Shaft Assembly................... 1

17 060027 Bearing, Agitator Shaft ................................... 1

18 009188 Leg, Stainless Steel (Incl. 2 ea. Ref. 62) ........1

19 060029 Mach.Screw,1/4-20 x 2

Pan Phil. Hd., SS ............................................ 4

20 010087 Operating Lever Rod ...................................... 1

060030 Operating Lever Rod (29-1/2" long), Nut,

Locknut & Lock Washer Ass’y (Replace-

ment for standard wheel spreaders with

original frames. See Note C above.) .............. 1

21 060031 Clevis Pin, 1/4" x 1/2", SS .............................. 1

22 060032 Cotter Pin, 3/32 x 1/2, SS ...............................2

23 060033 Flat Washer1/4" SAE, SS ...............................5

24 010171 C-Clip .............................................................. 1

25 060034 Operating Lever and Rubber Handle ............. 1

26 060047 Cap Screw 1/4-20 x 1-1/2 Hex Hd., SS .......... 4

27 060036 Hex Nut 1/4-20 Nylock, SS............................. 9

28 060037 Handle, Epoxy Finish...................................... 1

020270 Handle, Stainless Steel .................................. 1

29 060038 Flanged Grip, Black, 3/4 x 4 ........................... 2

30 013206 Uni-Frame, Epoxy Finish (Incl. 4 ea.

Ref. Item No.

No. No. Description Used

Ref. 31 and 2 ea. Ref. 58.) .............................1

020556 Uni-Frame, Stainless Steel ............................1

077791 Frame, Epoxy Finish (Replacement Kit for

standard wheel spreaders with original

frames. See Note C above. (Incl. 4 ea. Ref.

31 & 2 ea. Ref. 58).......................................... 1

073947 Frame, Stainless Steel (Replacement Kit

for standard wheel spreaders with original

frames. See Note C above. Incl. 4 ea. Ref.

31 & 2 ea. Ref. 58).......................................... 1

31 060041 Axle Bearing ................................................... 1

018963 Axle Bushing, Composite ............................... 4

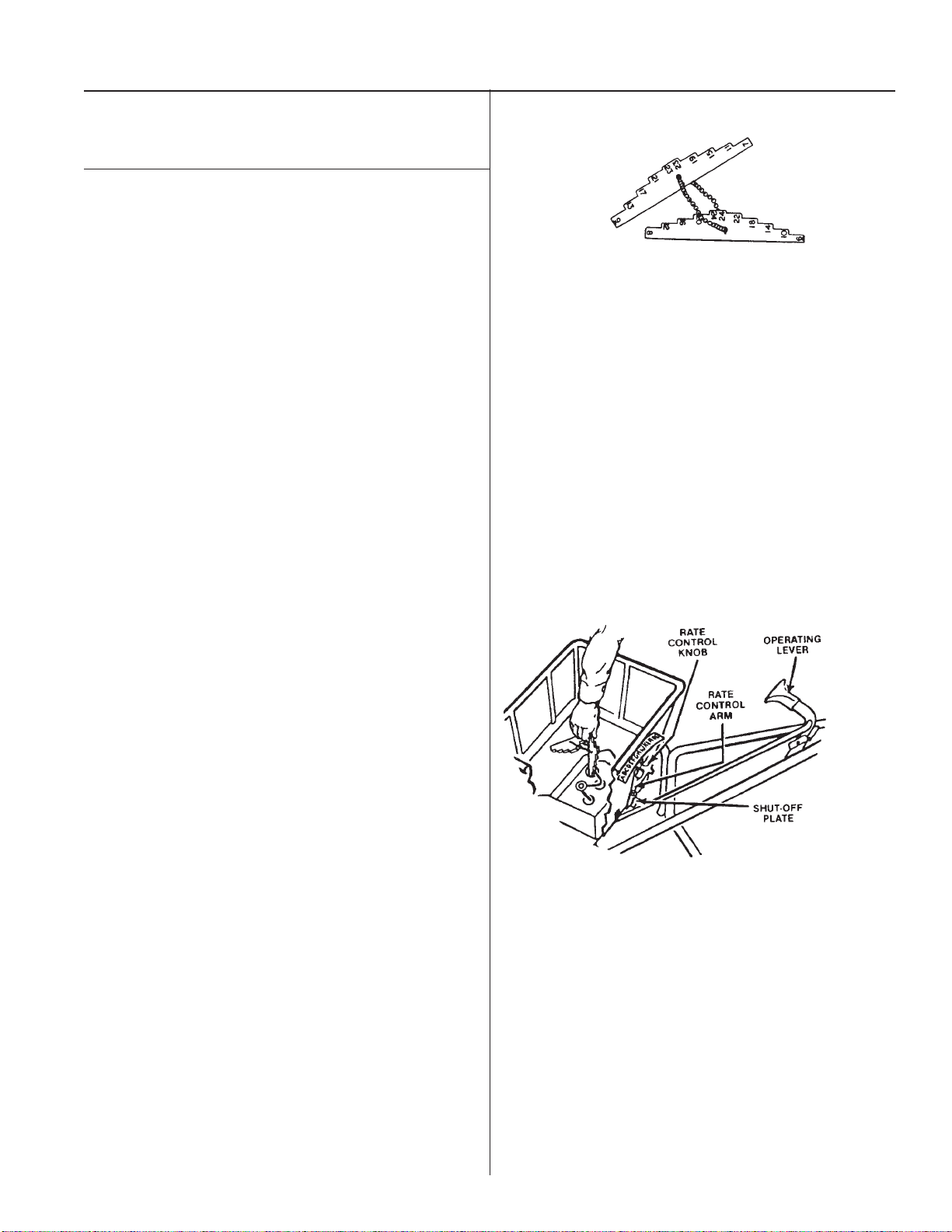

32 060042 Hopper ............................................................ 1

33 060043 Rate Control Knob ..........................................1

34 060044 Rate Control Arm ............................................ 1

35 060045 Rate Control Plate .......................................... 1

36 060046 Screen Clip, SS .............................................. 2

37 031167 Hex Cap Screw, 1/4-20 x 1-1/2

........................................................................ 4

38 060071 Hex Nut 5/16 x 18 ........................................... 1

39 060049 Agitator Arm .................................................... 1

40 060050 Agitator Clip .................................................... 1

41 704539 Plate, Two-Hole, Weldment ............................ 1

42 060052 Screen ............................................................ 1

43 060053 Shaft Support, Impeller ................................... 1

44 020491 Shutoff Plate Remote...................................... 1

45 031686 Mach. Screw, #8-32 x 1/2

Pan Phil. Hd., SS ............................................ 7

46 060056 Hex Nut, #8-32, SS......................................... 7

47 060057 Mach. Screw, 1/4-20 x 7/8

Pan Phil. Hd., SS ............................................ 1

48 – – –

49 060036 Hex Nut, 1/4-20, SS........................................ 6

50 060060 Pivot Lever Assembly ..................................... 1

51 060061 Pivot Lever Rod ..............................................1

52 060072 Nylock Nut ...................................................... 1

53 060073 Locking Washer .............................................. 1

54 060064 Spring Clip 3/4, SS ......................................... 1

55 060065 Rate Control Spring ........................................1

56 060066 Shutoff Plate Clip ............................................ 2

57 060083 Lock Washer #8 Star, SS ............................... 7

58 060064 Spring Clip 3/4, SS ......................................... 1

59 060065 Rate Control Spring ........................................1

60 078076 Spacer ............................................................ 1

61 005530 Flat Nylon Washer ..........................................1

62 020913 Plug, Plastic (Stainless Frame) ...................... 2

63 060013 Bevel Gear ...................................................... 1

64 020074 Impeller and Gear Assembly

(Incl. 1 ea. Ref. 10, 13, 14 & 63)..................... 1

020054 Impeller and Gear Assembly (Replace-

ment for standard wheel spreaders with

original frames. See Note C above. incl

1 ea. Ref. 10, 13, 14 & 63............................... 1

65 009742 Calibration Gauges-Odd ................................. 1

009746 Calibration Gauges-Even ............................... 1

66 700128 Nylon Washer ................................................. 2

67 016354 Carton (Box) ................................................... 1

68 020492 Slide Lever...................................................... 1

69 706895 “Lesco” Decal .................................................1

70 060021 Pinion Gear ....................................................1

71 060069 Roll Pin ...........................................................1

72 090006 “USA” Decal ................................................... 1

Optional Accessories for Rotary Spreaders

060087 Jet Action Deflector Ass'y. .............................. 1

060099 Hopper Cover (not shown) ............................. 1

009277 Spreader Gear Cover Ass’y. (not shown)....... 1

*Indicates this part can replace a similar part on a Scotts RX-7

spreader.