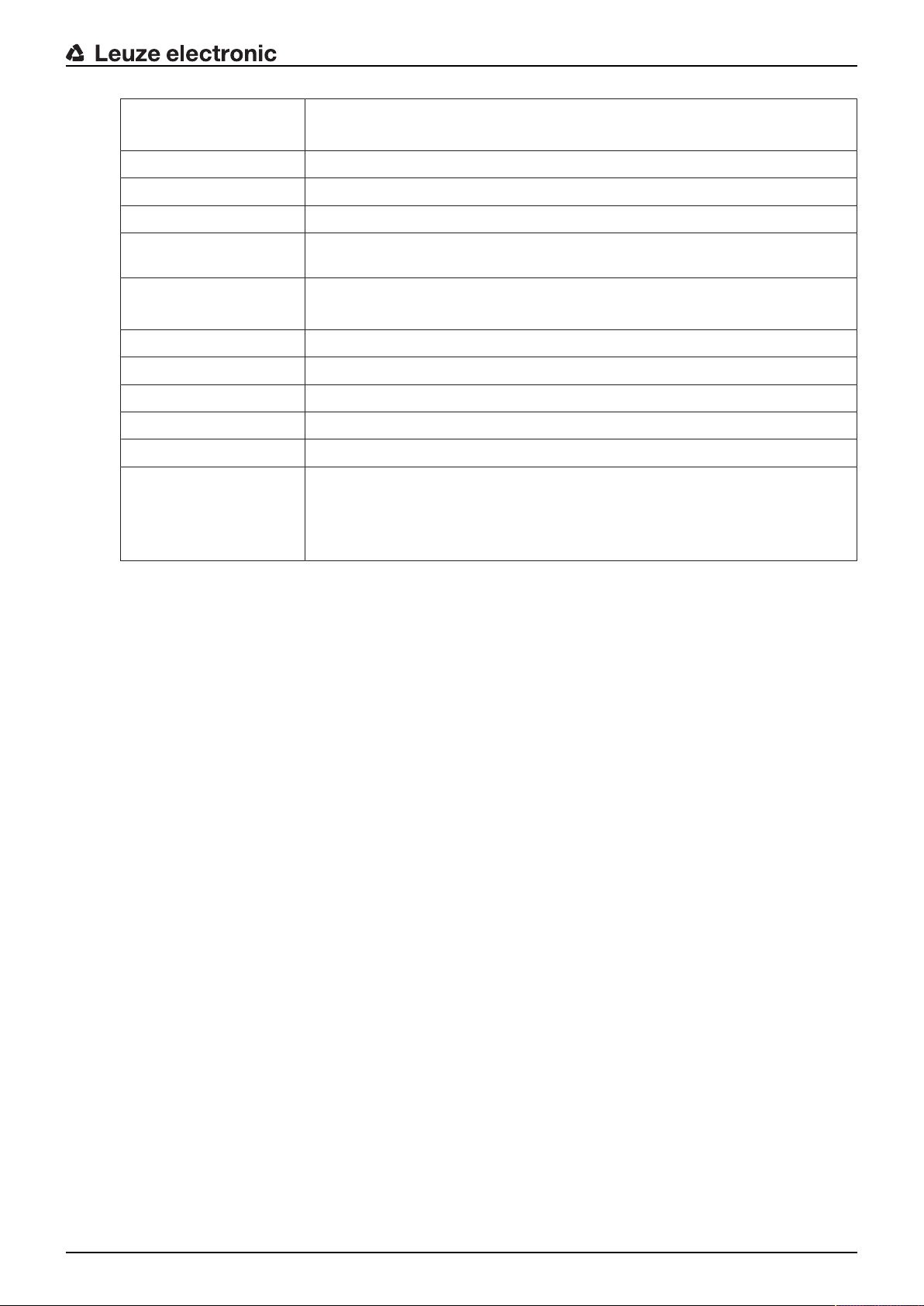

Table of contents

Leuze electronic MLC 530 SPG 3

Table of contents

1 About this document ............................................................................................5

1.1 Used symbols and signal words ............................................................................................. 5

1.2 Checklists................................................................................................................................ 6

2 Safety .....................................................................................................................7

2.1 Intended use and foreseeable misuse.................................................................................... 7

2.1.1 Intended use........................................................................................................................7

2.1.2 Foreseeable misuse ............................................................................................................8

2.2 Necessary competencies........................................................................................................ 8

2.3 Responsibility for safety.......................................................................................................... 9

2.4 Disclaimer ............................................................................................................................... 9

3 Device description ..............................................................................................10

3.1 Overview of Smart Process Gating (SPG)............................................................................ 10

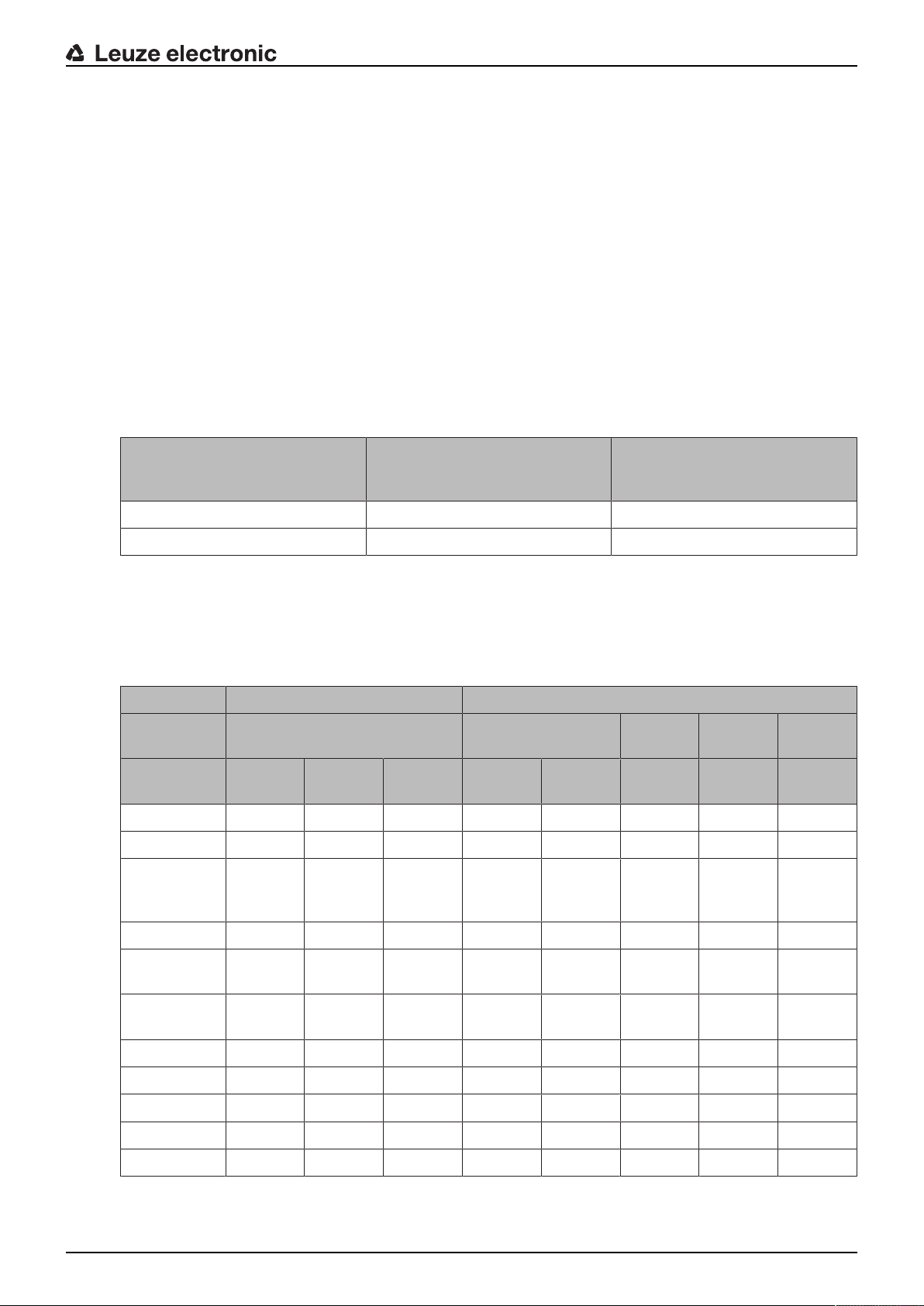

3.2 Device overview of the MLC family....................................................................................... 10

3.3 Connection technology ......................................................................................................... 12

3.4 Display elements .................................................................................................................. 12

3.4.1 Operating indicators on the MLC500 transmitter..............................................................12

3.4.2 Operating indicators on the MLC530SPG receiver .........................................................13

3.4.3 Alignment display ..............................................................................................................15

4 Functions.............................................................................................................16

4.1 Start/restart interlock RES .................................................................................................... 16

4.2 Transmission channel changeover ....................................................................................... 17

4.3 Operating range selection..................................................................................................... 17

4.4 Signal output......................................................................................................................... 17

4.5 Blanking ................................................................................................................................ 18

4.5.1 Fixed blanking ...................................................................................................................18

4.6 Smart Process Gating........................................................................................................... 20

4.6.1 SPG prerequisites .............................................................................................................22

4.6.2 Examples of signal generation for SPG mode ..................................................................24

4.6.3 Operating mode1 (qualified stop) ..................................................................................... 24

4.6.4 Operating mode5..............................................................................................................26

4.6.5 Operating mode 6 (partial gating)......................................................................................27

4.6.6 SPG termination by the control .........................................................................................29

4.6.7 SPG timeout extension......................................................................................................29

4.6.8 Gating sequence reset ......................................................................................................30

4.6.9 SPG restart........................................................................................................................31

4.6.10 Override.............................................................................................................................32

4.7 Error reset............................................................................................................................. 32

5 Applications ........................................................................................................33

5.1 Access guarding with SPG ................................................................................................... 33

5.1.1 Blanking.............................................................................................................................34

6 Mounting..............................................................................................................35

6.1 Arrangement of transmitter and receiver .............................................................................. 35

6.1.1 Calculation of safety distanceS ........................................................................................35

6.1.2 Calculation of safety distance if protective fields act orthogonally to the approach direction...36

6.1.3 Calculation of safety distanceS for parallel approach to the protective field ....................41

6.1.4 Minimum distance to reflective surfaces ...........................................................................42

6.1.5 Resolution and safety distance during fixed blanking .......................................................43

6.1.6 Preventing mutual interference between adjacent devices ............................................... 44