INSTRUCTIONS

FOR

USE

HOTLINE®

WARMER

Table

of

Contents

ABOUT

THIS

MANUAL

K

K

tte

3

REFERENCES

eus

sucer

3

MESSAGES

...............

rr

итак

3

INDICATIONS

2...

K

erent

es

3

PRINCIPLES

OF

OPERATION

2.0...

cece

cee

eee

teen

ro

3

INFUSATE

DELIVERY

TEMPERATURES

,,,

aa

3

DESCRIPTION

.........

eee

4

HOTLINE

WARMER

............

K

arara

4

DISPLAY

PANEL

し

にし

に

に

に

に

に に

に

に に に

に に

に

に

レト

トレ

トト

ト

トト

トト

し

トト

て て

に

し

て し て て

ここ

て

て

て

て

し

て て

て

4

HOTLINE

WARMINGSET

..........

ee

eee

eee

eee

4

SAFETY

ee

K

4

CONTRAINDICAMONS

..............

1...

ear

4

WARNINGS

keen

eee

ere

skeerne

ssnne

5

CAUTIONS

..............

Ene

EEK

E

ee

5

ELECTRICALSAFETY

..............

ete

te

ee

raras

arara

arena

5

POWER

REQUIREMENT

に

に

に

に

rene

5

ELECTRICAL

SAFETY

TESTING

.................

RP

5

STORAGE

..........

e

6

PREPARATION

AND

SET-UP

..........

ete

etree

renee

eee

een

eal

6

INSTRUCTIONS

FOR

USE

........................

本

STEP

1:

HOTLINE

WARMER

SET-UP

νεο

νε

ων

ων

κενο

ον νε

χ

νε ων ον

εως

εν

7

STEP

2:

SET-UP

THE

HOTLINE

WARMING

SET

ων

ον

7

STEP

3:

CONNECT

THE

INTRAVENOUS

ADMINISTRATION

SET

.............

7

STEP

和

USE

ses

ere

resserre

7

STEP

5:

AFTER

USE

.....,.

чеки

0

κ

χε

εν

7

TROUBLESHOOTING

.............,....,..,

4444444

rr

rr

enon

eens

8

MAINTENANCE

K

K

enene

8

TESTING

K

renee

10

TEMPERATURE

VERIFICATION

..

0.0.0.0

erer

11

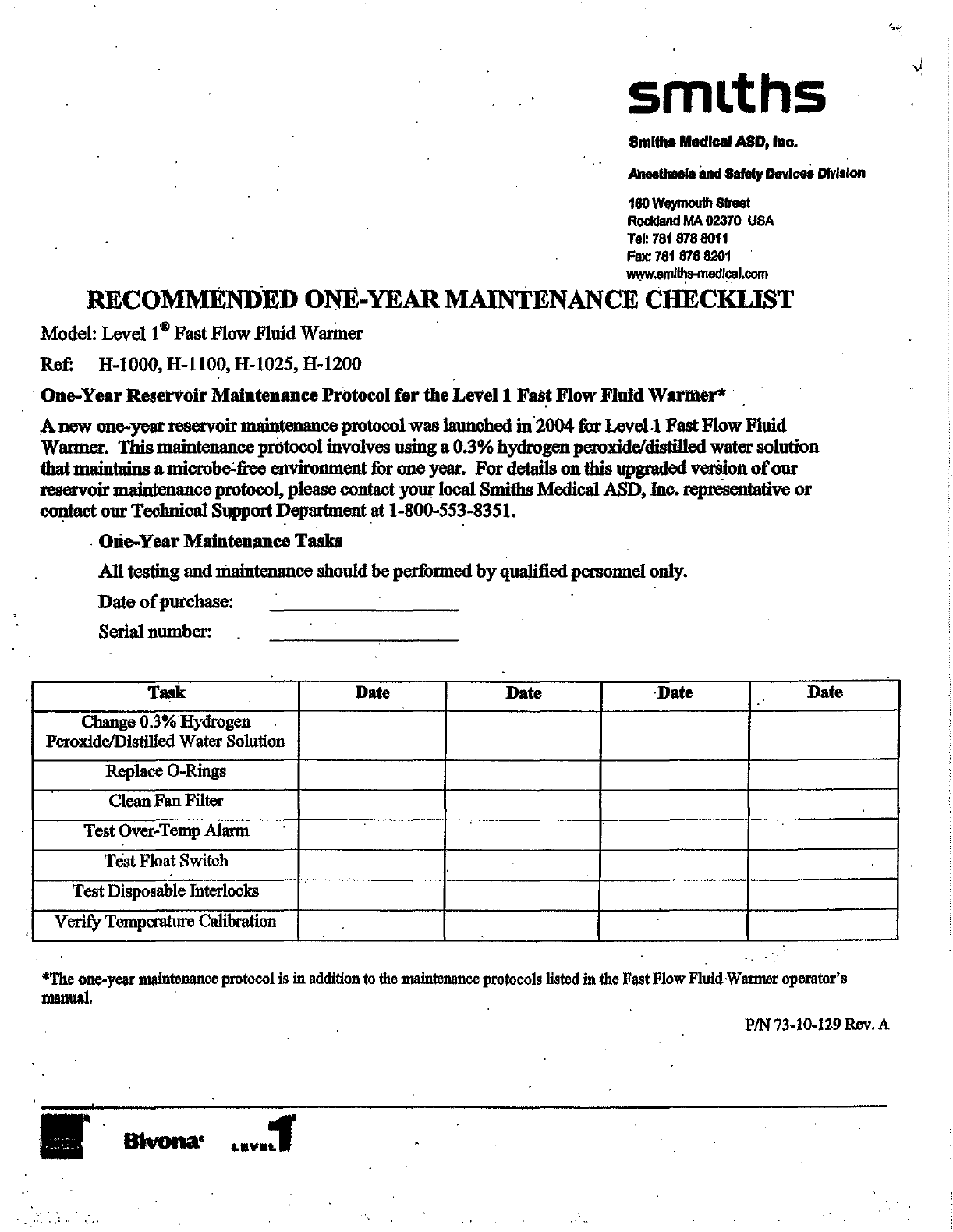

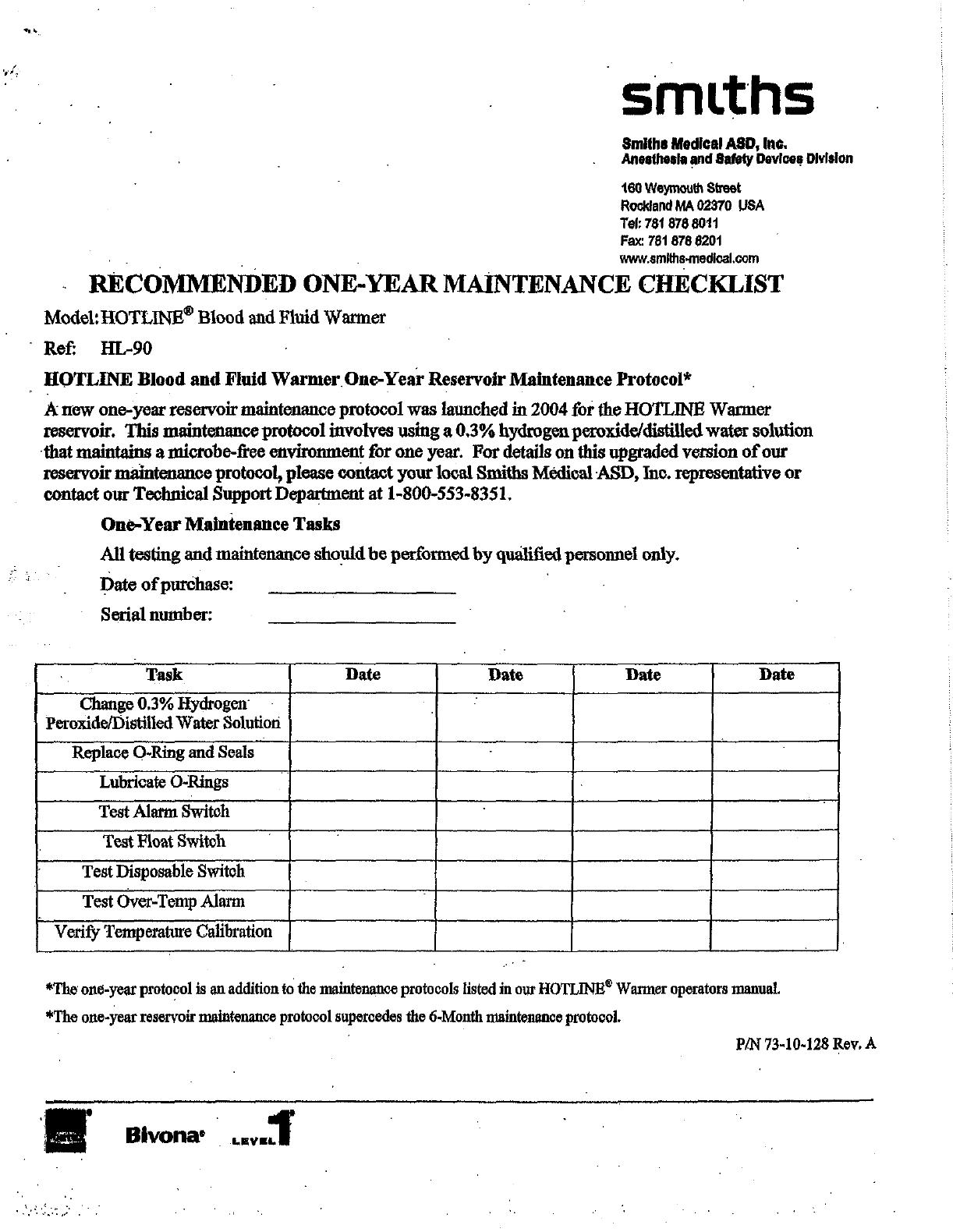

RECOMMENDED

MAİNTENANCE

CHECKLİST

...........

rro

12

LIMITED

WARRANTY

SECTION

..............

0mm

13

SERVİCE

...............

n

13

SPECIFICATIONS

............

L

K

nar

14

PHYSICAL

SPECİFİCATIONS

..........

0.

eee

ners

14

ELECTRICAL

SPECIFICATIONS

...........

ea

14

OPERATING

SPECIFICATIONS

.....0ooooocoocoroncor

rr

rr

14

ENVIRONMENTAL

SPECIFICATIONS

.

00...

ea

ee

14

ο

ο

αμ

rv

renee

14

ELECTRICAL

SCHEMATICS

AND

PARTS

LIST

...............,,...,.,....,,,,...,

15

SYMBOLS

...........

0...

learn

a

anana

нь

16